brakes Seat Toledo 2006 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2006, Model line: Toledo, Model: Seat Toledo 2006Pages: 298, PDF Size: 9.04 MB

Page 199 of 298

Cleaning and caring for your vehicle197

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

WARNING

•

Never wash tyres with a cylindrical jet. Even at large spraying distances

and short cleaning times, visible and invisible damage can occur to the

tyres. This may cause an accident.

•

Moisture, ice and salt on the brakes may affect braking efficiency. Risk

of accident. If possible, avoid sudden braking immediately after washing

the vehicle. You must “dry” the brakes by applying the brakes carefully

several times ⇒ page 183, “Braking effect and braking distance”.

Cleaning alloy wheelsEvery two weeks

– Wash salt and brake dust from alloy wheels.

– Use an acid free detergent to clean the wheels.

Every three months

– Apply a hard wax compound to the wheels.Alloy wheels require regular attention to preserve their appearance. It is

important to remove road salt and brake dust by washing the wheels at

regular intervals, otherwise the finish will be impaired.

Always use an acid-free detergent for alloy wheels.

Car polish or other abrasive agents should not be used. If the protective

coating is damaged, e.g. by stone impact, the damaged area should be

repaired immediately.

WARNING

•

Never wash tyres with a cylindrical jet. Even at large spraying distances

and short cleaning times, visible and invisible damage can occur to the

tyres. This may cause an accident.

•

Moisture, ice and salt on the brakes may affect braking efficiency. Risk

of accident. If possible, avoid sudden braking immediately after washing

the vehicle. You must “dry” the brakes by applying the brakes carefully

several times ⇒ page 183, “Braking effect and braking distance”.

Underbody sealant

The underside of the vehicle is coated to protect it from corro-

sion and damage.The protective coating could be damage d when driving. We recommend that

the protective coating under the body and on the running gear should be

checked, and reinstated if necessary, before and after the winter season.

We recommend that repair work and addi tional anti-corrosion work is carried

out by your Authorised Service Centre.

WARNING

Do not apply underseal or anti-corros ion coatings to the exhaust pipes,

catalytic converter or the heat shield s on the exhaust system. The heat of

the exhaust system or the engine could cause them to ignite! This is a fire

hazard.

toledo_angles_0706 Seite 197 Dienstag, 5. September 2006 10:32 10

Page 200 of 298

Cleaning and caring for your vehicle

198Cleaning the engine compartment

Take special care when cleaning the engine compartment.Anti-corrosion treatment

The engine compartment and the surface of the power unit are given anti-

corrosion treatment at the factory.

Good corrosion protection is particularl y important in winter when the car is

frequently driven on salted roads. To prevent the salt corroding the vehicle,

the entire engine compartment should be thoroughly cleaned before and

after the salting period.

Your Authorised Service Centre is able to provide the correct cleaning and

preserving products and has the necessary equipment. For this reason, we

recommend having this work performed by them.

The anti-corrosion protection is usually removed if the engine compartment

is cleaned with grease removing solutions, or if you have the engine cleaned.

If this job is carried out, you should ensure that all surfaces, seams, joints and

components in the engine compartmen t are given anti-corrosion treatment

afterwards.

WARNING

•

When working in the engine compartment, always observe the safety

warnings ⇒ page 208.

•

Switch off the engine, apply the parking brake firmly and always

remove the key from the ignitio n before you open the bonnet.

•

Allow the engine to cool before you clean the engine compartment.

•

Do not clean the underside of vehicle, wheel arches without protecting

your hands and arms. You may cut your self on sharp-edged metal parts.

Failure to comply could result in injury.

•

Moisture, ice and salt on the brakes may affect braking efficiency. Risk

of accident. If possible, avoid sudden braking immediately after washing

the vehicle.

•

Never touch the radiator fan. It is temperature-controlled and could

start automatically, even when the key is removed from the ignition!For the sake of the environment

Fuel, grease and oil deposits could be removed when the engine is washed.

The polluted water must be cleaned in an oil separator. For this reason,

engine washing should be carried out only by a qualified workshop or a suit-

able filling station.Care of the vehicle interiorCleaning plastic parts and the dash panel– Use a clean, damp cloth to clean plastic parts and the dash panel.

– If this does not provide satisfactory results, use a special solvent-free plastic cleaning product.

WARNING

Never clean the dash panel and surface of the airbag module with cleaners

containing solvents. Solvents cause the surface to become porous. If the

airbag inflates, disintegrating plastic parts can cause substantial injuries.

WARNING (continued)

toledo_angles_0706 Seite 198 Dienstag, 5. September 2006 10:32 10

Page 224 of 298

Checking and refilling levels

222However, if the level goes down noticeably in a short time, or drops below the

“MIN” mark, there may be a leak in the brake system. A display on the instru-

ment panel will warn you if the brake fluid level is too low ⇒page 72.

WARNING

Before opening the bonnet to check the brake fluid level, read and observe

the warnings ⇒page 208.Changing the brake fluid

The brake fluid must be renewed every two years.We recommend that you have the brake fluid changed by an Authorised

Service Centre.

Before opening the bonnet, please read and follow the warnings ⇒ in

“Safety instructions on working in the engine compartment” on page 208 in

“Working in the engine compartment”.

Brake fluid absorbs moisture. In the cour se of time, it will absorb water from

the ambient air. If the water content in the brake fluid is too high, the brake

system could corrode. This also considerably reduces the boiling point of the

brake fluid. Heavy use of the brakes may then cause a vapour lock which

could impair the braking effect.

For this reason the brake fluid must be renewed every two years.

It is important that you use only use brake fluid compliant with the US

standard FMVSS 116 DOT 4. We recommend the use of Genuine SEAT brake

fluid.

WARNING

Brake fluid is poisonous. Old brake fluid impairs the braking effect.

•

Before opening the bonnet to check the brake fluid level, read and

observe the warnings ⇒page 208.

•

Brake fluid should be stored in the closed original container in a safe

place out of reach of children. There is a toxic risk.

•

Have the brake fluid changed every two years at the latest. Heavy use

of the brakes may cause a vapour lock if the brake fluid is left in the system

for too long. This would seriously affect the efficiency of the brakes and the

safety of the vehicle. This may cause an accident.Caution

Brake fluid could damage the paintwork. Wipe off any brake fluid from the

paintwork immediately.

For the sake of the environment

Brake fluid must be drained and disposed of in the proper manner observing

environmental regulations.

WARNING (continued)

toledo_angles_0706 Seite 222 Dienstag, 5. September 2006 10:32 10

Page 231 of 298

Checking and refilling levels229

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

easier to choose the correct tyres. Radial tyres have the tyre designations

marked on the sidewall, for example:

195/65 R15 91T

This contains the following information:

195 Tyre width in mm

65 Height/width ratio in %

R Tyre construction: Radial

15 Rim diameter in inches

91 Load rating code

T Speed rating

The tyres could also have the following information:

•

A direction of rotation symbol

•

“Reinforced” denotes heavy-duty tyres.

The manufacturing date is also indicated on the tyre sidewall (possibly only

on the inner side of the wheel).

“DOT ... 1103 ...” means, for example, th at the tyre was produced in the 11th

week of 2003.

We recommend that work on tyres and wheels is carried out by an Authorised

Service Centre. They are familiar with the procedure and have the necessary

special tools and spare parts as well as the proper facilities for disposing of

the old tyres.

Any Authorised Service Centre has full information on the technical require-

ments when installing or changing tyres, wheels or wheel trims.

WARNING

•

We recommend that you use only wheels and tyres that have been

approved by SEAT for your model. Fa ilure to do so could impair vehicle

handling. Risk of accident.

•

Avoid running the vehicle on tyres th at are more than six years old. If

you have no alternative, you should dr ive slowly and with extra care at all

times.

•

Never use old tyres or those with an unknown “history of use”.

•

If wheel trims are retrofitted, you must ensure that the flow of air to the

brakes is not restricted. This could cause them to overheat.

•

All four wheels must be fitted with radial tyres of the same type, size

(rolling circumference) and the same tread pattern.For the sake of the environment

Old tyres must be disposed of accordi ng to the laws in the country concerned.

Note

•

For technical reasons, it is not generally possible to use the wheels from

other vehicles. This can also apply to wheels of the same model. The use of

wheels or tyres which have not been approved by SEAT for use with your

model may invalidate the vehicle's type approval for use on public roads.

•

If the spare tyre is not the same as the tyres that are mounted on the

vehicle - for example with winter tyres - you should only use the spare tyre for

a short period of time and drive with extra care. Refit the normal road wheel

as soon as possible.

Wheel bolts

Wheel bolts must be tightened to the correct torque.The design of wheel bolts is matched to the rims. If different wheel rims are

fitted, the correct wheel bolts with the right length and correctly shaped bolt

WARNING (continued)

toledo_angles_0706 Seite 229 Dienstag, 5. September 2006 10:32 10

Page 247 of 298

If and when245

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

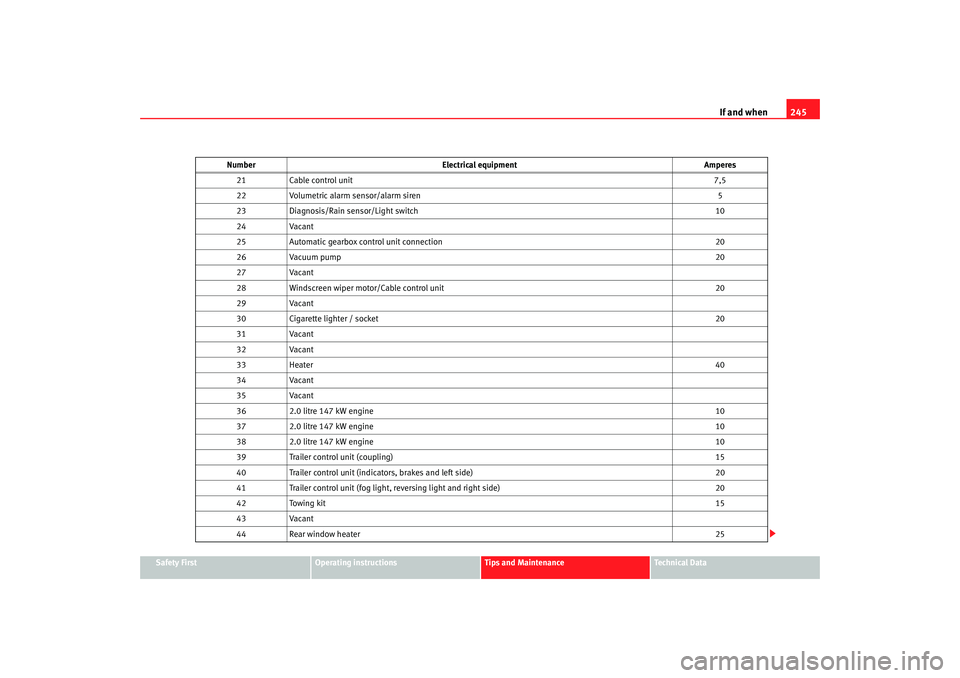

21

Cable control unit 7,5

22 Volumetric alarm sensor/alarm siren 5

23 Diagnosis/Rain sensor/Light switch 10

24 Vacant

25 Automatic gearbox control unit connection 20

26 Vacuum pump 20

27 Vacant

28 Windscreen wiper motor/Cable control unit 20

29 Vacant

30 Cigarette lighter / socket 20

31 Vacant

32 Vacant

33 Heater 40

34 Vacant

35 Vacant

36 2.0 litre 147 kW engine 10

37 2.0 litre 147 kW engine 10

38 2.0 litre 147 kW engine 10

39 Trailer control unit (coupling) 15

40 Trailer control unit (indicators, brakes and left side) 20

41 Trailer control unit (fog light, reversing light and right side) 20

42 Towing kit 15

43 Vacant

44 Rear window heater 25

Number

Electrical equipment Amperes

toledo_angles_0706 Seite 245 Dienstag, 5. September 2006 10:32 10

Page 273 of 298

Technical Data271

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Petrol engine 1.4 litre 63 kW (86 bhp)General engine data

Performance figures

Weights

Trailer weightsPower output in kW (bhp)

rpm 63 (86)/ 5000

Maximum torque in Nm at rpm 132/ 3800

No. of cylinders, capacity in cm

3

4/ 1390

Compression 10,5 ± 0,3

Fuel 95 Octane petrol

Maximum speed in km/h 169

Acceleration from 0-80 km/h in sec. 9,9

Acceleration from 0-100 km/h in sec. 15

Gross vehicle weight in kg 1915

Weight in working order (with driver) in kg 1390

Gross axle weight, front in kg 940

Gross axle weight, rear in kg 1020

Permitted roof load in kg 75

With no brakes, gradients up to 12% 690

With brakes, gradients up to 12% 1200

toledo_angles_0706 Seite 271 Dienstag, 5. September 2006 10:32 10

Page 275 of 298

Technical Data273

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

Trailer weights

Engine oil capacity

Petrol engine 2.0 litre 110 kW (150 bhp)General engine data

Performance figures

With no brakes, gradients up to 12%

700

With brakes, gradients up to 12% 1200

Approximate engine oil capacity with oil filter change 4.8 litres

Power output in kW (bhp) rpm 110 (150)/ 6000

Maximum torque in Nm at rpm 200/ 3500

No. of cylinders, capacity in cm

3

4/ 1984

Compression 11,5-0,5

Fuel Super Plus unleaded 98 RON or Premium unleaded 95 RON

a)

a)With a slight power lossMaximum speedin km/h 206

Acceleration from 0-80 km/h in sec. 6,6

Acceleration from 0-100 km/h in sec. 9,7

toledo_angles_0706 Seite 273 Dienstag, 5. September 2006 10:32 10

Page 276 of 298

Technical Data

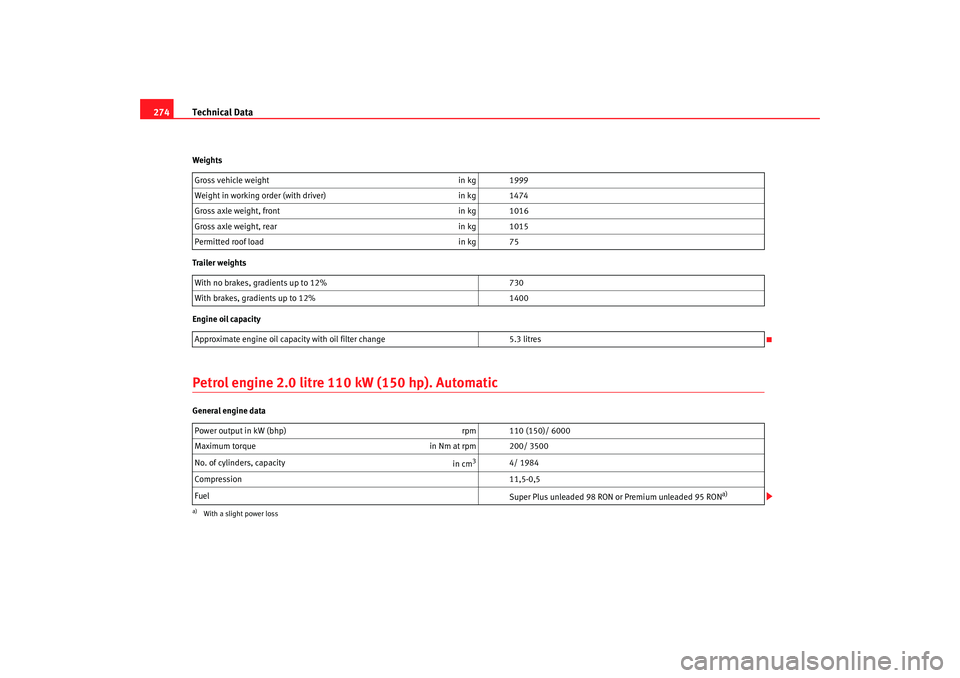

274Weights

Trailer weights

Engine oil capacityPetrol engine 2.0 litre 110 kW (150 hp). AutomaticGeneral engine data Gross vehicle weight

in kg 1999

Weight in working order (with driver) in kg 1474

Gross axle weight, front in kg 1016

Gross axle weight, rear in kg 1015

Permitted roof load in kg 75

With no brakes, gradients up to 12% 730

With brakes, gradients up to 12% 1400

Approximate engine oil capacity with oil filter change 5.3 litres

Power output in kW (bhp) rpm 110 (150)/ 6000

Maximum torque in Nm at rpm 200/ 3500

No. of cylinders, capacity in cm

3

4/ 1984

Compression 11,5-0,5

Fuel Super Plus unleaded 98 RON or Premium unleaded 95 RON

a)

a)With a slight power loss

toledo_angles_0706 Seite 274 Dienstag, 5. September 2006 10:32 10

Page 277 of 298

Technical Data275

Safety First

Operating instructions

Tips and Maintenance

Te c h n i c a l D a t a

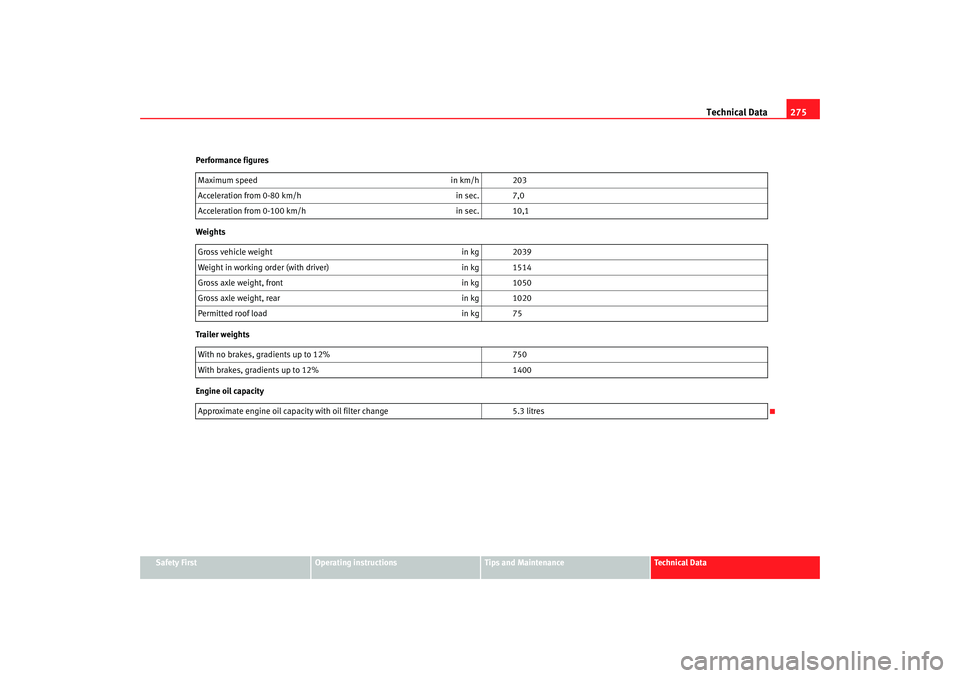

Performance figures

Weights

Trailer weights

Engine oil capacity

Maximum speed

in km/h 203

Acceleration from 0-80 km/h in sec. 7,0

Acceleration from 0-100 km/h in sec. 10,1

Gross vehicle weight in kg 2039

Weight in working order (with driver) in kg 1514

Gross axle weight, front in kg 1050

Gross axle weight, rear in kg 1020

Permitted roof load in kg 75

With no brakes, gradients up to 12% 750

With brakes, gradients up to 12% 1400

Approximate engine oil capacity with oil filter change 5.3 litres

toledo_angles_0706 Seite 275 Dienstag, 5. September 2006 10:32 10

Page 278 of 298

Technical Data

276Petrol engine 2.0 litre 147 kW (200 hp). ManualGeneral engine data

Performance figures

Weights

Trailer weights Power output in kW (bhp)

rpm 147 (200)/5100- 6000

Maximum torque in Nm at rpm 280/ 1800-5000

No. of cylinders, capacity in cm

3

4/ 1984

Compression 10,3-0,5

Fuel 98 octane or 95 octane

a)

a)With a slight power lossMaximum speedin km/h 220

Acceleration from 0-80 km/h in sec. 5,4

Acceleration from 0-100 km/h in sec. 7,7

Gross vehicle weight in kg 1960

Weight in working order (with driver) in kg 1492

Gross axle weight, front in kg 1079

Gross axle weight, rear in kg 1001

Permitted roof load in kg 75

With no brakes, gradients up to 12% 740

With brakes, gradients up to 12% 1400

toledo_angles_0706 Seite 276 Dienstag, 5. September 2006 10:32 10