light Seat Toledo 2012 Owners Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Toledo, Model: Seat Toledo 2012Pages: 249, PDF Size: 3.6 MB

Page 186 of 249

185

Checking and refilling levels

Note

● The battery acid level is also regularly checked during servicing at au-

thorised SEAT dealers.

● The acid level on “AGM” vehicle batteries cannot be checked for techni-

cal reasons.

● Vehicles equipped with the “START-STOP” system include a battery con-

trol unit to control the battery level for repeat engine starting.

Winter service

At low temperatures the battery provides only a fraction of the starting pow-

er it has at normal temperatures.

A flat battery can also freeze at temperatures slightly below to 0 °C (32 °F).

We therefore recommend you have the battery checked and, if necessary,

charged at an official SEAT technical service before the start of winter.

Charging the battery

A fully-charged battery is essential for reliable starting.

– Switch off the ignition and all electrical equipment.

– For “fast-charging” only: disconnect both battery connection ca-

bles (first the “negative” terminal and then the “positive”).

– Connect the charger cables to the battery terminals (red = “pos-

itive”, black = “negative”).

– Plug in the battery charger and switch on. –

After charging the battery: Switch off the battery charger and

disconnect the cable.

– Remove the charger cables.

– If necessary, reconnect both battery cables to the battery (first

the “positive” cable, then the “negative” cable).

When charging with a low current (e.g. with a small battery charger), the

battery does not have to be disconnected. The instructions of the battery

charger manufacturer must be followed.

Use a current equivalent to or lower than 0.1 of the battery capacity to fully

charge the battery.

Before “fast-charging” the battery however, both battery cables must be

disconnected.

“Fast-charging” a battery is dangerous and requires a battery charger and

special knowledge. Fast charges should be performed by an official techni-

cal service.

The battery caps should not be opened while the battery is being charged.

CAUTION

In vehicles fitted with the “START-STOP” system, the charger cable cannot

be directly connected to the negative terminal of the vehicle battery but

must be attached to the engine earthing point ⇒ page 207.

Disconnecting and connecting the battery

The following functions will either be inoperative or will not work properly

after disconnecting and reconnecting the battery:

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 187 of 249

186Checking and refilling levels

FunctionInstallationSetting the clock⇒ page 58The multifunction display data is deleted⇒ page 59

Note

We recommend having the vehicle checked by an authorised SEAT dealer to

guarantee the correct working order of all electrical systems.

Changing the battery

A replacement battery must have the same capacity, voltage, current rating

and size as the original. The appropriate types of battery can be acquired

from authorised SEAT dealers.

We recommend having the battery changed by an authorised SEAT dealer,

where the new battery will be correctly installed and the original disposed

of in line with regulations.

Automatic disconnection of electrical equipment

When heavily-charging a battery, the programme selected by the electrical

system control unit prevents the battery from automatically discharging.

This may result in the following:

● Increase in idling speed so that the alternator can supply more current

to the electrical system.

● The performance of certain electrical components could be limited or

some may switch off temporarily, e.g. the heated seats, the heated rear win-

dow, the 12V power socket.

Note

Despite any measures taken by the control unit, the battery could drain. e.g.

with the engine is switched off, the key is turned in the ignition for a long

period or the side lights or parking lights are switched on. The switching off

of certain electrical components does not impair driving comfort and the

driver will often not even realise.

Page 193 of 249

192Wheels and tyres

Removing

–Insert the plastic clip into the cap until the inner retaining

notches on the clips touch the collar of the cap and then re-

move ⇒ Fig. 127.

Fitting

– Insert the caps as far as they will go over the wheel bolts.

The wheel bolt caps are stored in a box on the spare wheel or in the spare

wheel well.

Tyre pressure

Fig. 128 Tyre pressure

setting switch

The tyre pressure monitoring system uses ABS sensors to compare the revo-

lutions and the circumference of each wheel. Should the circumference of

any wheel change, the warning lamp in the general instrument panel

⇒ page 72 will light up and an audible warning will be heard.

Tyre circumference may change if:

● Tyre pressure is too low

● Tyre structure is damaged ●

Vehicle load not evenly distributed

● Wheels on one axle are subjected to greater load, (e.g. driving with trail-

er, uphill, downhill)

● Snow chains are fitted

● The temporary spare wheel is fitted

● One wheel on the axle has been changed

Basic system settings

Should the tyre pressure change or if one or more wheels are changed or

the position of the wheel on the vehicle is changed, e.g. changing round the

front and rear wheels, or where a warning lamp lights up when driving, the

system must be adjusted as follows:

● Inflate all tyres to the prescribed pressures ⇒ page 188.

● Switch the ignition on.

● Hold the

⇒ Fig. 128 button down for at least 2 seconds. The warn-

ing lamp will light up when the button is pressed. The system memory is

also deleted and a new calibration system will begin, which is indicated by

an audible warning before the warning lamp switches off .

● If the warning lamp remains lit and does not switch off, not even once

the basic setting process is complete, this indicates a fault in the system.

Contact an Official Service.

The warning lamp lights up

If the pressure on at least one tyre is significantly lower than the pressure

set by the driver, the warning lamp ⇒

will light up.

The warning lamp flashes

If the warning lamp flashes, there is a fault in the system. Contact a special-

ised service to have it fixed.

Page 194 of 249

193

Wheels and tyres

WARNING

● If the warning lamp lights up, slow down immediately and avoid

any severe braking or steering manoeuvres. Stop and check the tyres and

their pressure as soon as possible.

● Under certain conditions (e.g. sporty driving style, driving on loose

surfaces or in the winter) the warning lamp may take a while to light

up or may remain switched off.

● Despite the tyre pressure monitoring system, the driver remains re-

sponsible for maintaining the correct tyre pressure. You must therefore

check the tyre pressure often.

Note

● The tyre pressure monitoring system is not a replacement for regularly

checking the tyre pressure, as it is unable to recognise an even drop in pres-

sure.

● The tyre pressure monitoring system is unable to warn of a sudden drop

in tyre pressure, e.g. a puncture. In this case, try to stop the vehicle carefully

with no severe braking or steering manoeuvres.

● To ensure the tyre pressure monitoring system works correctly, the basic

setting must be performed every 10 000 km (6000 miles) or once a year.

Wheel bolts

The wheel bolts are matched to the rims. When installing different wheels,

e.g. to fit light alloy wheels or wheels with winter tyres, it is important to use

the correct wheel bolts with the right length and correctly shaped bolt

heads. The is essential for the secure fit of the wheels and for the proper

function of the brake system. Winter tyres

Winter tyres will significantly improve handling of the vehicle in winter road

conditions. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip at temperatures below 7 °C (45 °F), on ice and snow.

This applies particularly to vehicles equipped with

wide section tyres or

high speed tyres (code letters H or V on the sidewall).

In order to preserve the performance of the vehicle as much as possible,

winter tyres must be fitted on all four wheels, the minimum depth of the

tread must be 4 mm and the maximum age must be 4 years.

You can use winter tyres of a lower speed rating if the maximum speed limit

of these tyres will not be exceeded, even if the maximum speed limit for the

vehicle is higher.

For the sake of the environment

Summer tyres should be fitted again in time, as they give better handling on

roads free of snow and ice and at temperatures over 7 °C (45 °F). Summer

tyres have a shorter braking distance, produce less rolling noise and do not

wear down as quickly. They also reduce fuel consumption.

Snow chains

Snow chains must only be used on the front wheels.

In winter road conditions, snow chains not only help to improve grip but al-

so improve the braking capacity.

For technical reasons snow chains may only be used on tyres with the fol-

lowing wheel rim/tyre combinations.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 199 of 249

198Self-help

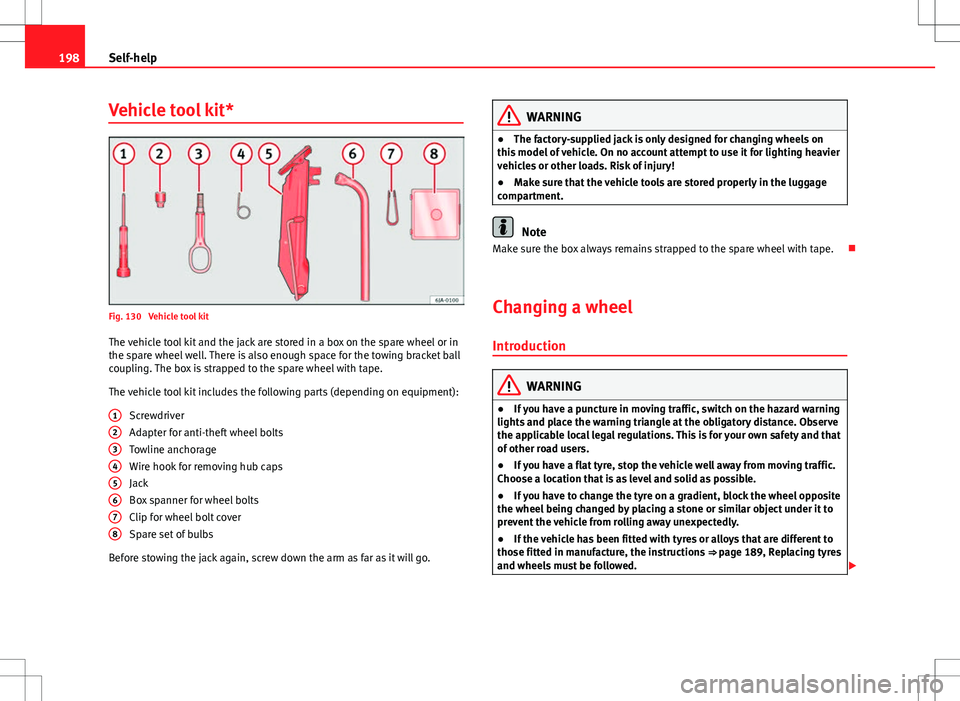

Vehicle tool kit*

Fig. 130 Vehicle tool kit

The vehicle tool kit and the jack are stored in a box on the spare wheel or in

the spare wheel well. There is also enough space for the towing bracket ball

coupling. The box is strapped to the spare wheel with tape.

The vehicle tool kit includes the following parts (depending on equipment):

Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

Before stowing the jack again, screw down the arm as far as it will go. 1

2345678

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model of vehicle. On no account attempt to use it for lighting heavier

vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored properly in the luggage

compartment.

Note

Make sure the box always remains strapped to the spare wheel with tape.

Changing a wheel Introduction

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● If you have to change the tyre on a gradient, block the wheel opposite

the wheel being changed by placing a stone or similar object under it to

prevent the vehicle from rolling away unexpectedly.

● If the vehicle has been fitted with tyres or alloys that are different to

those fitted in manufacture, the instructions ⇒ page 189, Replacing tyres

and wheels must be followed.

Page 200 of 249

199

Self-help

WARNING (Continued)

● Always raise the vehicle with the doors closed.

● Never place parts of your body, e.g. arms and legs, underneath the

vehicle when supported only by the jack.

● Secure the base of the jack with suitable supports so that it cannot

slip. The jack could slide if the ground below it is soft and slippery and

the vehicle could slip off it. Therefore, place the jack on a firm surface or

use a large, stable base. On a slippery surface, e.g. tiles, use a non-slip

base such as a rubber mat.

● Never start the engine when the vehicle is raised. Risk of injury.

● The jack should only be used in the correct jacking points.

CAUTION

● The prescribed tightening torque for wheel bolts on steel and alloy

wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tightened, this could damage the

bolt and the adapter

Note

● The set of anti-theft wheel bolts or the adapter are available from au-

thorised SEAT dealers.

● Please observe the relevant local legal regulations when changing the

wheel.

Preparation work

Some preparation is required before changing a wheel:

– If you have a flat tyre, stop the vehicle as far away as possible

from moving traffic. The surface must be horizontal.–

All vehicle occupants should leave the vehicle . Vehicle occu-

pants should waiting in a safe place, e.g. behind the roadside

crash barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral or move the selector

lever on the automatic gearbox to position P.

– Apply the handbrake firmly.

– If towing a trailer, unhitch it.

– Take the vehicle tool kit ⇒ page 198 and the spare wheel

⇒ page 198 out of the luggage compartment.

Changing a wheel

If possible, change the wheel on a level surface.

– Pull off the hub cap ⇒ page 191 or the wheel bolt covers

⇒ page 191.

– First loosen the anti-theft wheel bolts and then the other wheel

bolts ⇒ page 200.

– Raise the vehicle until the wheel to be changed is no longer

touching the ground ⇒ page 201.

– Remove the wheel bolts and place them on a clean surface

(cloth, paper, etc.).

– Take off the wheel.

– Lift the spare wheel into position and tighten the wheel bolts

lightly.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 202 of 249

201

Self-help

– Grip the box spanner as close to the end as possible and tight-

en the bolt firmly by turning clockwise.

WARNING

The wheel bolts should only be loosened slightly (about one turn) before

raising the vehicle with the jack. Risk of accident!

Note

If the wheel bolt is very tight, it may be possible to loosen it by pushing

down the end of the box spanner carefully with your foot. Hold on to the ve-

hicle for support and take care not to slip.

Raising the vehicle

Fig. 132 Changing a

wheel: Jacking points

Fig. 133 Fitting the jack

To place the jack, locate the jacking point under the door sill clos-

est to the wheel to be changed ⇒ Fig. 132. The jacking point is di-

rectly underneath the stamp on the door sill.

– Turn the crank handle on the jack to wind it up under the jack-

ing point until its claw is directly below the jacking point of the

door sill.

– Adjust the jack so that its claw surrounds the jacking point on

the door sill ⇒ Fig. 133 - B underneath the stamp on the door

sill.

– Make sure that the base of the jack is entirely supported on a

flat surface and that it is vertical ⇒ Fig. 133 to the point where

the claw surrounds the jacking point on the door sill.

– Continue to wind up the jack using the crank handle until the

defective wheel is clear off the ground.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 204 of 249

203

Self-help

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● A tyre filled with sealant does not have the same performance proper-

ties as a conventional tyre.

● Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and fast cornering.

● Check the tyre pressure after 10 minutes of driving!

● The sealant is harmful to health and must be immediately rinsed from

affected skin.

For the sake of the environment

Used or out-of-date sealant must be disposed of in line with environmental

protection regulations.

Note

● Observe the instructions for use provided by the tyre repair kit manufac-

turer.

● A new can of sealant can be acquired from the selection of SEAT Original

Accessories.

● Change the tyre repaired using the tyre repair kit as soon as possible or

ask an Official Service about the possibility of repair. Tyre repair kit components

Fig. 135 Tyre repair kit

components

The tyre repair kit includes the following parts:

An adapter to fit and remove the valve

Sticker indicating the speed: “max. 80 km/h” or “max. 50 mph”

Flexible filling hose with cap

Compressor

Flexible tyre inflating hose

Tyre pressure gauge

Air release screw

ON/OFF button

12 Volt cable connector ⇒ page 119

Can of sealant

Spare valve

The valve extractor 1

⇒ Fig. 135 has a slot in its lower end that fits onto

the valve insert. This is used to remove the valve insert from the tyre and to

replace it. This is also valid for the spare valve insert 11

.

1

234567891011

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 209 of 249

208Self-help

road. If the vehicle is towed with the rear wheels lifted off the road

the automatic gearbox will be damaged!

It is easier and safer to tow a vehicle with a towbar. A towrope

should only be used if you do not have a towbar.

Follow the instructions below when towing a vehicle:

Notes for the driver of the towing vehicle

– Engage the clutch very gently when starting to move or on vehi-

cles with automatic gearbox press the accelerator carefully.

– On vehicles with manual gearbox, the towrope must be taut be-

fore driving off.

The maximum towing speed is 50 km/h (31 mph).

Notes for the driver of the towed vehicle

– The ignition should be switched on so that the steering wheel

lock is not engaged and the turn signals, horn and windscreen

wipers and washers can be used.

– Put the gear lever in neutral or move the selector lever to posi-

tion N (automatic gearbox).

The brake servo and power steering only work when the engine is

running. Considerably more effort is required on the brake pedal

and steering wheel when the engine is switched off.

Ensure the towrope remains taut at all times when towing.

CAUTION

● Do not tow-start the engine. Risk of engine damage! In vehicles with a

catalytic converter, unburnt fuel could reach the catalytic converter and

catch fire in it. This could damage and destroy the catalytic converter. Use

the battery from another vehicle for help in starting the engine ⇒ page 206,

Starting the engine.

● If, due to a fault, there is no oil in the gearbox, the car may only be tow-

ed with the driven wheels lifted clear of the road and transported on a spe-

cial vehicle transporter or trailer.

● If normal towing is not possible or if the vehicle is to be towed for further

than 50 km (31 miles), the vehicle must be transported on a special vehicle

transporter or trailer.

● The towrope should be slightly elastic to reduce the loading on both ve-

hicles during towing. It is advisable to use a towrope made of synthetic fibre

or similar material only.

● Do not pull too hard with the towing vehicle and always take care to

avoid jerking the towrope. When towing on a loose surface there is always a

risk of overloading and damaging the anchorage points.

● Attach the towrope or towbar only to the towline anchorages or to the

removable towing bracket ⇒ page 161, or ⇒ page 209.

Note

● We recommend you use the towrope or towbar available in the SEAT

Original Accessories programme from authorised SEAT dealers.

● Towing a vehicle requires some experience. Both drivers should be fa-

miliar with the technique required for towing. Inexperienced drivers should

not attempt to tow away another vehicle or to have their vehicle towed.

● Note the legal regulations concerning towing, particularly those regard-

ing the signalling of the towed and towing vehicle.

● The towrope must not be twisted, as under certain circumstances this

could unscrew the front towline anchorage.

Page 211 of 249

210Fuses and bulbs

Fuses and bulbs

Fuses

Introduction

All the electrical circuits are protected by fuses.

● Switch off the ignition and the electrical component concerned before

changing a fuse.

● Identify the fuse corresponding to the failed electrical component

⇒ page 211, Fuses in the dash panel, or ⇒ page 214, Changing fuses in

the engine compartment.

● Take the plastic clip from inside the fuse cover, fit it onto the blown fuse

and pull the fuse out.

● Replace the blown fuse (which will have a melted metal strip) with a new

fuse of the same amp rating.

Fuse colour code

ColourMaximum amp rating

light brown5dark brown7,5red10blue15yellow20white25green30

WARNING

Read and follow the warnings ⇒ page 173, Engine compartment before

starting work in the engine compartment.

CAUTION

● Never “repair” a fuse or replace it by fitting a fuse with a higher amp rat-

ing. Risk of fire! This could also cause damage to other parts of the electri-

cal system.

● If a newly replaced fuse blow again when the electrical component con-

cerned is switched on, the electrical system must be checked by an Official

Service as soon as possible.

Note

● It is advisable to always keep spare fuses in the vehicle. The spare fuse

box is available in the range of original SEAT parts.

● One single electrical component could have more than one fuse.

● Several electrical components may be protected by the same fuse.