lights Seat Toledo 2012 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2012, Model line: Toledo, Model: Seat Toledo 2012Pages: 249, PDF Size: 3.6 MB

Page 193 of 249

192Wheels and tyres

Removing

–Insert the plastic clip into the cap until the inner retaining

notches on the clips touch the collar of the cap and then re-

move ⇒ Fig. 127.

Fitting

– Insert the caps as far as they will go over the wheel bolts.

The wheel bolt caps are stored in a box on the spare wheel or in the spare

wheel well.

Tyre pressure

Fig. 128 Tyre pressure

setting switch

The tyre pressure monitoring system uses ABS sensors to compare the revo-

lutions and the circumference of each wheel. Should the circumference of

any wheel change, the warning lamp in the general instrument panel

⇒ page 72 will light up and an audible warning will be heard.

Tyre circumference may change if:

● Tyre pressure is too low

● Tyre structure is damaged ●

Vehicle load not evenly distributed

● Wheels on one axle are subjected to greater load, (e.g. driving with trail-

er, uphill, downhill)

● Snow chains are fitted

● The temporary spare wheel is fitted

● One wheel on the axle has been changed

Basic system settings

Should the tyre pressure change or if one or more wheels are changed or

the position of the wheel on the vehicle is changed, e.g. changing round the

front and rear wheels, or where a warning lamp lights up when driving, the

system must be adjusted as follows:

● Inflate all tyres to the prescribed pressures ⇒ page 188.

● Switch the ignition on.

● Hold the

⇒ Fig. 128 button down for at least 2 seconds. The warn-

ing lamp will light up when the button is pressed. The system memory is

also deleted and a new calibration system will begin, which is indicated by

an audible warning before the warning lamp switches off .

● If the warning lamp remains lit and does not switch off, not even once

the basic setting process is complete, this indicates a fault in the system.

Contact an Official Service.

The warning lamp lights up

If the pressure on at least one tyre is significantly lower than the pressure

set by the driver, the warning lamp ⇒

will light up.

The warning lamp flashes

If the warning lamp flashes, there is a fault in the system. Contact a special-

ised service to have it fixed.

Page 194 of 249

193

Wheels and tyres

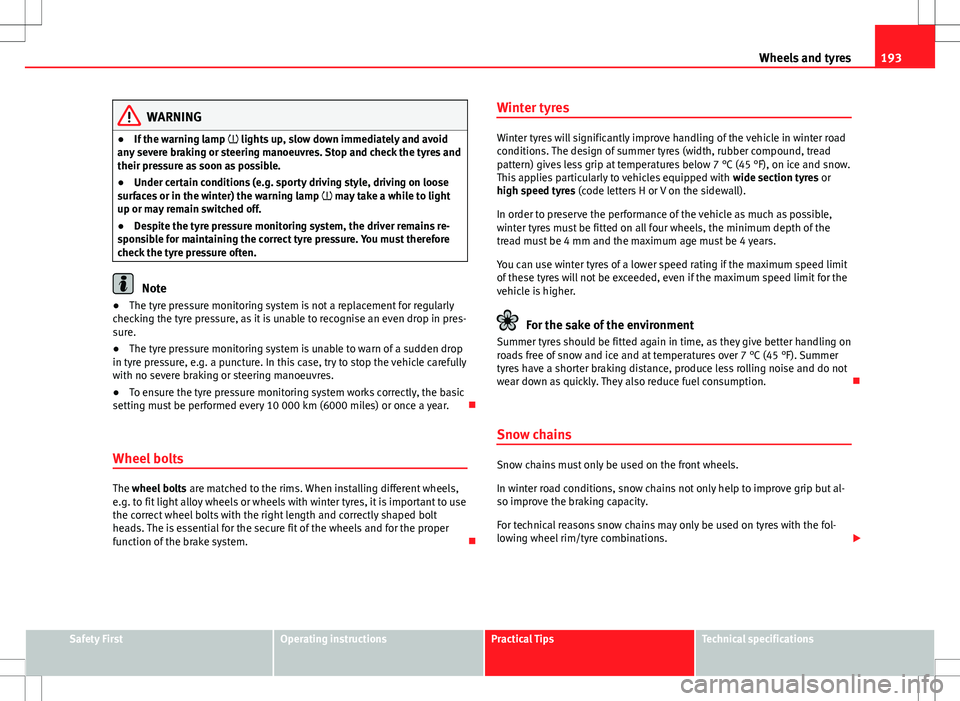

WARNING

● If the warning lamp lights up, slow down immediately and avoid

any severe braking or steering manoeuvres. Stop and check the tyres and

their pressure as soon as possible.

● Under certain conditions (e.g. sporty driving style, driving on loose

surfaces or in the winter) the warning lamp may take a while to light

up or may remain switched off.

● Despite the tyre pressure monitoring system, the driver remains re-

sponsible for maintaining the correct tyre pressure. You must therefore

check the tyre pressure often.

Note

● The tyre pressure monitoring system is not a replacement for regularly

checking the tyre pressure, as it is unable to recognise an even drop in pres-

sure.

● The tyre pressure monitoring system is unable to warn of a sudden drop

in tyre pressure, e.g. a puncture. In this case, try to stop the vehicle carefully

with no severe braking or steering manoeuvres.

● To ensure the tyre pressure monitoring system works correctly, the basic

setting must be performed every 10 000 km (6000 miles) or once a year.

Wheel bolts

The wheel bolts are matched to the rims. When installing different wheels,

e.g. to fit light alloy wheels or wheels with winter tyres, it is important to use

the correct wheel bolts with the right length and correctly shaped bolt

heads. The is essential for the secure fit of the wheels and for the proper

function of the brake system. Winter tyres

Winter tyres will significantly improve handling of the vehicle in winter road

conditions. The design of summer tyres (width, rubber compound, tread

pattern) gives less grip at temperatures below 7 °C (45 °F), on ice and snow.

This applies particularly to vehicles equipped with

wide section tyres or

high speed tyres (code letters H or V on the sidewall).

In order to preserve the performance of the vehicle as much as possible,

winter tyres must be fitted on all four wheels, the minimum depth of the

tread must be 4 mm and the maximum age must be 4 years.

You can use winter tyres of a lower speed rating if the maximum speed limit

of these tyres will not be exceeded, even if the maximum speed limit for the

vehicle is higher.

For the sake of the environment

Summer tyres should be fitted again in time, as they give better handling on

roads free of snow and ice and at temperatures over 7 °C (45 °F). Summer

tyres have a shorter braking distance, produce less rolling noise and do not

wear down as quickly. They also reduce fuel consumption.

Snow chains

Snow chains must only be used on the front wheels.

In winter road conditions, snow chains not only help to improve grip but al-

so improve the braking capacity.

For technical reasons snow chains may only be used on tyres with the fol-

lowing wheel rim/tyre combinations.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 199 of 249

198Self-help

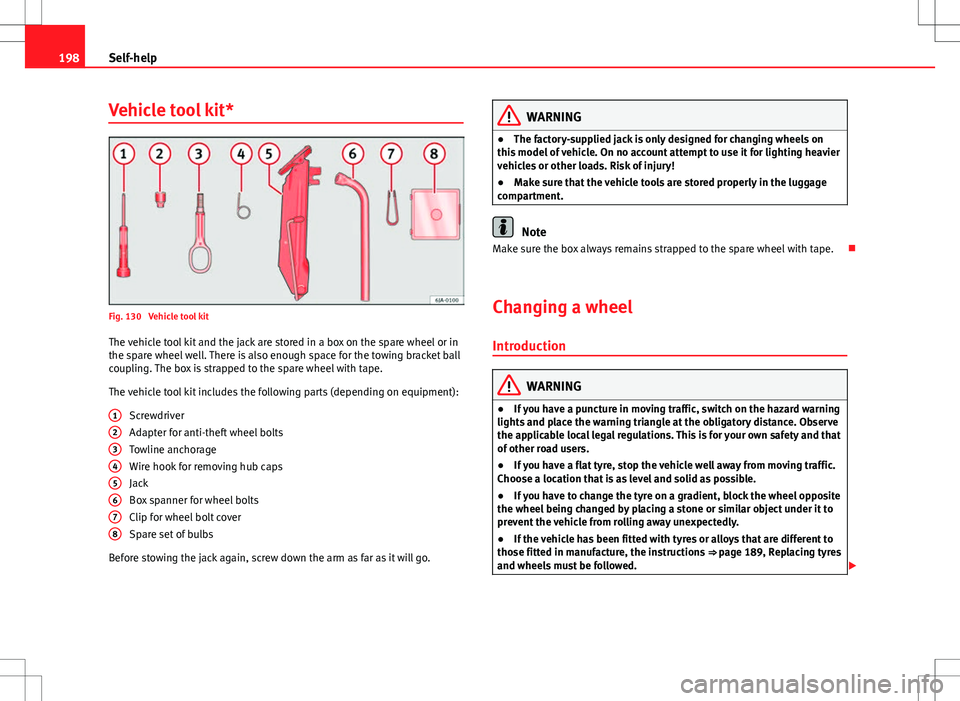

Vehicle tool kit*

Fig. 130 Vehicle tool kit

The vehicle tool kit and the jack are stored in a box on the spare wheel or in

the spare wheel well. There is also enough space for the towing bracket ball

coupling. The box is strapped to the spare wheel with tape.

The vehicle tool kit includes the following parts (depending on equipment):

Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

Before stowing the jack again, screw down the arm as far as it will go. 1

2345678

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model of vehicle. On no account attempt to use it for lighting heavier

vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored properly in the luggage

compartment.

Note

Make sure the box always remains strapped to the spare wheel with tape.

Changing a wheel Introduction

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● If you have to change the tyre on a gradient, block the wheel opposite

the wheel being changed by placing a stone or similar object under it to

prevent the vehicle from rolling away unexpectedly.

● If the vehicle has been fitted with tyres or alloys that are different to

those fitted in manufacture, the instructions ⇒ page 189, Replacing tyres

and wheels must be followed.

Page 204 of 249

203

Self-help

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● A tyre filled with sealant does not have the same performance proper-

ties as a conventional tyre.

● Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and fast cornering.

● Check the tyre pressure after 10 minutes of driving!

● The sealant is harmful to health and must be immediately rinsed from

affected skin.

For the sake of the environment

Used or out-of-date sealant must be disposed of in line with environmental

protection regulations.

Note

● Observe the instructions for use provided by the tyre repair kit manufac-

turer.

● A new can of sealant can be acquired from the selection of SEAT Original

Accessories.

● Change the tyre repaired using the tyre repair kit as soon as possible or

ask an Official Service about the possibility of repair. Tyre repair kit components

Fig. 135 Tyre repair kit

components

The tyre repair kit includes the following parts:

An adapter to fit and remove the valve

Sticker indicating the speed: “max. 80 km/h” or “max. 50 mph”

Flexible filling hose with cap

Compressor

Flexible tyre inflating hose

Tyre pressure gauge

Air release screw

ON/OFF button

12 Volt cable connector ⇒ page 119

Can of sealant

Spare valve

The valve extractor 1

⇒ Fig. 135 has a slot in its lower end that fits onto

the valve insert. This is used to remove the valve insert from the tyre and to

replace it. This is also valid for the spare valve insert 11

.

1

234567891011

Safety FirstOperating instructionsPractical TipsTechnical specifications

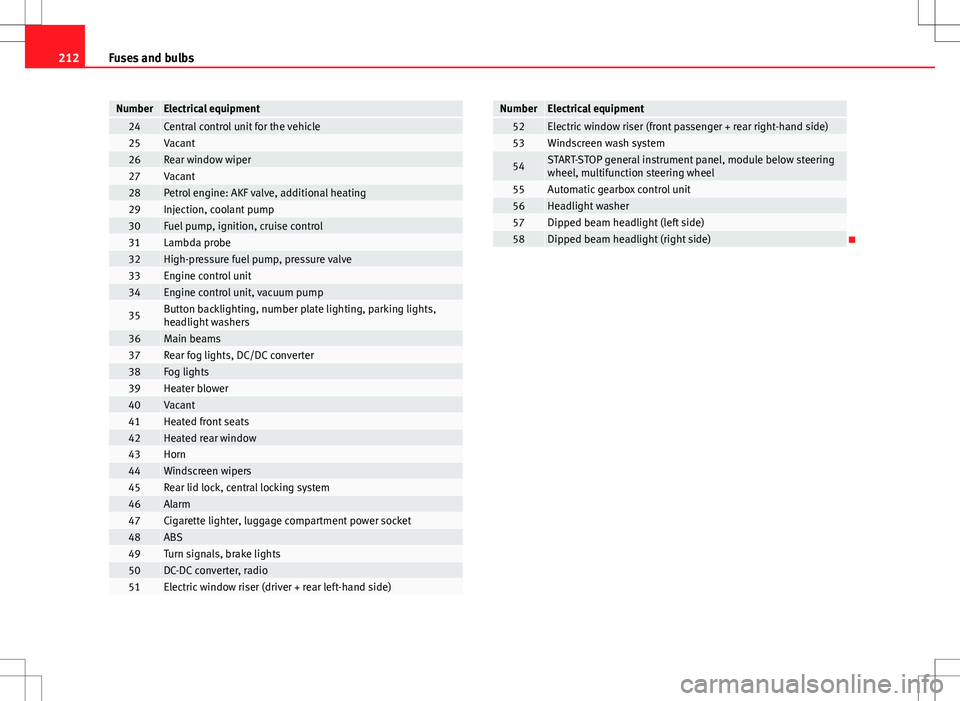

Page 212 of 249

211

Fuses and bulbs

Fuses in the dash panel

Fig. 140 Bottom of the

dash panel. Fuse cover

Fig. 141 Diagram of the

fuse box to the left/right

of the steering wheel

The fuses are located behind a cover below the steering wheel.

● Carefully tilt the cover in the direction indicated by the arrow and remove

it ⇒ Fig. 140.

● After changing the fuse, replace the cover on the dash panel in the di-

rection opposite that is indicated by the arrow so that the cover tabs fit into

the slots on the dash panel. Subsequently, press down on the cover to

close. List of fuses in the dash panel

NumberElectrical equipment1S - ignition2START-STOP

3Instrument panel, headlight range control, telephone, oil level

sensor

4ABS/ESC control unit5Petrol engine: cruise control6Reverse light (manual gearbox)7Switch, engine control unit, automatic gearbox8Brake switch, clutch switch, cooling fan

9Heating control panel, air conditioning control unit, parking

aid, electric window riser, radiator fan, windscreen wiper jets

10DC-DC converter11Exterior mirror control12Towing bracket control unit13Automatic gearbox control unit, automatic gear selector14Headlight range control15Vacant16Power steering, speed sensor, engine control unit17Radio (START-STOP ) daytime driving light18Heated mirrors19Ignition inlet20Engine control unit, fuel pump control unit, fuel pump

21Reverse light (automatic gearbox), fog lights with CORNER func-

tion

22Heating control panel, control unit of the climate control, tele-

phone, general instrument panel, steering wheel angle sensor,

multifunction steering wheel, automatic gearbox key lock

23Interior lighting, glove compartment and luggage compartment

lighting, side lights

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 213 of 249

212Fuses and bulbs

NumberElectrical equipment24Central control unit for the vehicle25Vacant26Rear window wiper27Vacant28Petrol engine: AKF valve, additional heating29Injection, coolant pump30Fuel pump, ignition, cruise control31Lambda probe32High-pressure fuel pump, pressure valve33Engine control unit34Engine control unit, vacuum pump

35Button backlighting, number plate lighting, parking lights,

headlight washers

36Main beams37Rear fog lights, DC/DC converter38Fog lights39Heater blower40Vacant41Heated front seats42Heated rear window43Horn44Windscreen wipers45Rear lid lock, central locking system46Alarm47Cigarette lighter, luggage compartment power socket48ABS49Turn signals, brake lights50DC-DC converter, radio51Electric window riser (driver + rear left-hand side)

NumberElectrical equipment52Electric window riser (front passenger + rear right-hand side)53Windscreen wash system

54START-STOP general instrument panel, module below steering

wheel, multifunction steering wheel

55Automatic gearbox control unit56Headlight washer57Dipped beam headlight (left side)58Dipped beam headlight (right side)

Page 215 of 249

214Fuses and bulbs

Changing fuses in the engine compartment

Fig. 144 Battery: fuse cover (version 1)

Fig. 145 Battery: fuse cover (version 2)

●Press the flexible tabs on the fuse box cover in the direction indicated by

the arrows 1

⇒ Fig. 144.

● Remove the cover by sliding it in the direction indicated by arrow 2.

● Use a flat-headed screwdriver to unlock the holes 3.

● Open the cover in the direction indicated by the arrow 4.Changing bulbs

Introduction

Changing bulbs requires a certain degree of practical skill. If in doubt, we

recommend you have defective bulbs changed by a specialised service or,

in case of an emergency, seek professional assistance.

● Switch off the ignition and all of the lights before changing a bulb.

● Do not touch the glass part of the bulb with your bare hands. The finger-

prints left on the glass will vaporise as a result of the heat generated by the

bulb, causing a reduction in bulb life and condensation on the mirror sur-

face, thus reducing efficiency.

● A bulb must only be replaced by one of the same type. The type is indi-

cated on the bulb, either on the glass part or on the base.

● There is a storage area for the bulb box in the spare wheel well or below

the carpet in the luggage compartment.

The light source used for each function is listed below:

Double headlights

H7 Long Life

H7

W5W Long Life PY21W NA P21W Super Long Life

Dipped beam:

Main beam:

Side lights:

Turn signals:

Daytime driving lights:

Page 216 of 249

215

Fuses and bulbs

WARNING

● Take particular care when working on components in the engine com-

partment if the engine is warm. Risk of burns.

● Bulbs are highly sensitive to pressure. The glass can break when you

touch the bulb, causing injury.

● The high voltage element of gas discharge bulbs* (xenon light) must

be handled correctly. Otherwise, there is a risk of death.

● When changing bulbs, please take care not to injure yourself on sharp

parts in the headlight housing.

CAUTION

● Remove the ignition key before working on the electric system. Other-

wise, a short circuit could occur.

● Switch off the lights and the parking light before changing a bulb.

For the sake of the environment

Please ask your specialist retailer how to dispose of used bulbs in the prop-

er manner.

Note

● Depending on weather conditions (cold or wet), the front lights, the fog

lights, the rear lights and the turn signals may be temporarily misted. This

has no influence on the useful life of the lighting system. By switching on

the lights, the area through which the beam of light is projected will quickly

be demisted. However, the edges may remain misted.

● Please check at regular intervals that all lighting (especially the exterior

lighting) on your vehicle is functioning properly. This is not only in the inter-

est of your own safety, but also in that of all other road users. ●

Before changing a bulb, make sure you have the correct new bulb.

● Do not touch the glass part of the bulb with your bare hands, use a cloth

or paper towel instead. Otherwise, the fingerprints left on the glass will va-

porise as a result of the heat generated by the bulb, they will be deposited

on the reflector and will impair its surface.

Double headlight bulbs

Fig. 146 Main headlight

bulbs

Installation position of double headlight bulbs side light

main beam headlight

dipped beam headlight

turn signal light

daytime driving light

A

BCDE

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 221 of 249

220Fuses and bulbs

–Remove the bulb by pressing on the bulb holder and turning it

anti-clockwise at the same time.

– Installation involves all of the above steps in reverse sequence.

– Check that the bulb works properly.

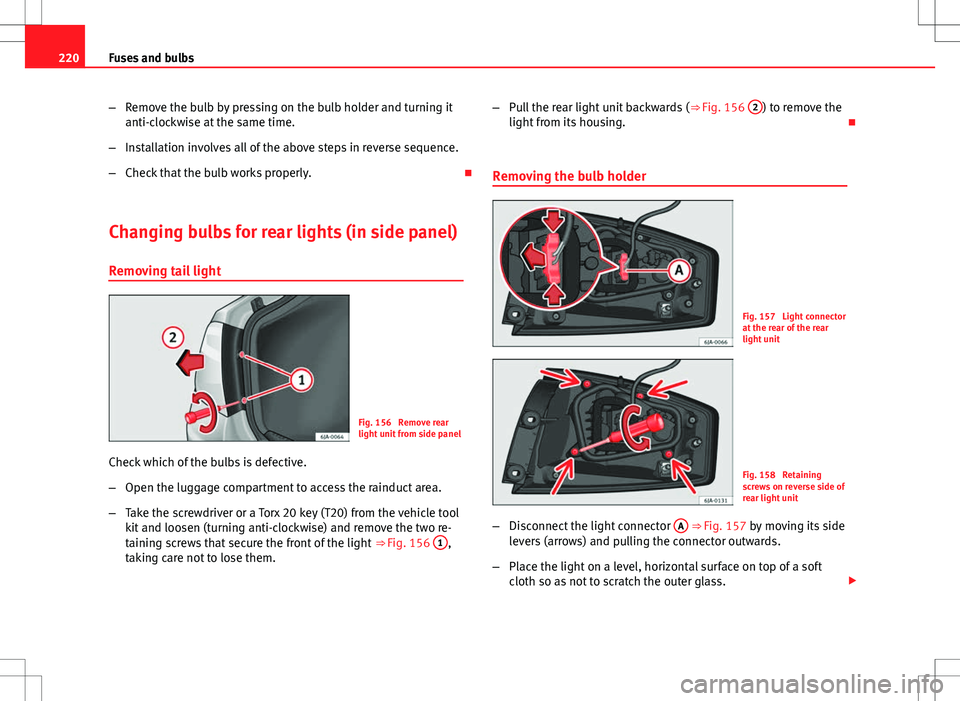

Changing bulbs for rear lights (in side panel) Removing tail light

Fig. 156 Remove rear

light unit from side panel

Check which of the bulbs is defective.

– Open the luggage compartment to access the rainduct area.

– Take the screwdriver or a Torx 20 key (T20) from the vehicle tool

kit and loosen (turning anti-clockwise) and remove the two re-

taining screws that secure the front of the light ⇒ Fig. 156 1

,

taking care not to lose them. –

Pull the rear light unit backwards ( ⇒ Fig. 156 2

) to remove the

light from its housing.

Removing the bulb holder

Fig. 157 Light connector

at the rear of the rear

light unit

Fig. 158 Retaining

screws on reverse side of

rear light unit

– Disconnect the light connector A

⇒ Fig. 157 by moving its side

levers (arrows) and pulling the connector outwards.

– Place the light on a level, horizontal surface on top of a soft

cloth so as not to scratch the outer glass.

Page 222 of 249

221

Fuses and bulbs

– Unscrew the four retaining screws from the bulb holder anti-

clockwise using a screwdriver or a Torx 20 key (T20) from the ve-

hicle tool kit ⇒ Fig. 158. Take care not to lose the bulb holder

retaining screws.

Changing bulbs

All bulbs can be changed easily in the bulb holder.

Fig. 159 Position of the

bulbs in the bulb holder

The bulbs are secured with a bayonet fastener. The table below

gives an overview of the bulbs.

– Lightly press the defective bulb into the bulb holder, then turn it

anti-clockwise and remove it.

– Fit the new bulb, pressing it into the bulb holder and turn it

clockwise as far as it will go.

– Use a cloth to remove any fingerprints from the glass part of the

bulb. –

Check that the new bulb works properly.

– Replace the bulb holder.

– Screw in the bulb holder using the four screws, turning them

clockwise.

List of bulbs

Position: ⇒ Fig. 159Bulb functionATurn signals: PY21W NA LLBSide lights-brake lights: P21/5WCSide lights: P21/5W

Note

Check the condition of the seal. If damaged, a replacement can be acquired

from an Official Service.

Safety FirstOperating instructionsPractical TipsTechnical specifications