lock Seat Toledo 2013 Workshop Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 151 of 258

149

Driving

The manual gearbox can be activated when the vehicle is either moving or

stationary.

When accelerating, the gearbox automatically shifts up shortly before the

maximum engine speed is reached.

On shifting up, the gear is only engaged when there is no risk of engine

damage.

When the accelerator pedal is pressed down to the kick-down zone, the

gearbox will shift down in line with the road speed and engine speed.

Note

The kick-down function is also available in manual shift mode.

Selector lever lock

Automatic selector lever lock

The selector lever is locked in the positions P and N when the ignition is on.

Press down on the brake to unlock it. Remember, if the selector lever is in

positions P and N then the ⇒ page 77 warning lamp will light up on the

general instrument panel.

When the selector lever merely moves through position N (e.g. when moved

from R to D), the lever lock is not applied. This makes it possible, for exam-

ple, to rock a stuck vehicle backwards and forwards. The lock is only applied

if the brake is not pressed and the selector lever is moved to position N for

more than 2 seconds.

The selector lever lock is only activated in vehicles that are stationary and at

speeds below 5 km/h (3 mph). It is automatically switched off in position N

at higher speeds. Interlock button

The interlock button on the selector lever knob prevents the driver from in-

advertently engaging a gear. Press the button to unlock the selector lever.

Safety interlock for ignition key

1)

After switching off the ignition, you can only remove the ignition key if the

selector lever is in position P. When the ignition key is removed, the selec-

tor lever is locked in position P.

Kick-down feature

The kick-down feature allows maximum acceleration to be reached.

In any gear programme, press down fully on the accelerator for the automat-

ic gearbox to activate the kick-down feature. This function takes priority over

the gear programmes without taking into account the position of the selec-

tor lever (D, S or Tiptronic) and is used to reach maximum acceleration, us-

ing full engine power. Depending on the road speed and engine speed, the

automatic gearbox shifts down and the vehicle accelerates. It only shifts up

after the maximum engine speed has been reached.

Driving programmes

Your vehicle is equipped with an electronically-controlled automatic gear-

box. Shifting up or down depends on the programme selected.

For a calm driving style, the gearbox uses the most economic programme.

The gearbox shifts up as quickly as possible and shifts down as late as pos-

sible, thus increasing driving economy.

1)

Valid only for certain countries.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 152 of 258

150Driving

With a sporty driving style , characterised by sudden acceleration, heavy ac-

celeration, speeds that often increase and decrease and maximum speed,

the gearbox adapts to this driving style when the accelerator is pressed fully

down (kick-down) by shifting down as quickly as possible and can even

shift down by several gears at once.

Selecting the best driving programmes is an endless job. Regardless of this,

the driver can also make the gearbox switch to a more dynamic gear shift

programme by pressing the accelerator quickly. This makes the automatic

gearbox shift down into a lower gear that would normally apply to the cur-

rent speed for more rapid acceleration (e.g. to overtake another vehicle)

without having to press the accelerator fully down into the kick-down posi-

tion. On shifting up in a corresponding driving style, the gearbox returns to

the original programme.

When driving along mountain roads, the gearbox adapts to the gradients.

This avoids having to frequently change gears when driving uphill. In Tip-

tronic mode, it is possible to shift down manually when driving downhill to

use the braking effect of the engine.

Back-up programme

A back-up programme exists in case of faults.

In the event of a fault in the gearbox electronics, this will continue to work

in one of the corresponding back-up programmes. All segments of the

screen are lit up or switched off.

The fault can be seen as follows:

● The gearbox only engages certain gears

● Reverse gear R cannot be engaged

● The manual gearbox switches off in the back-up programme

Note

If the gearbox switches to the back-up programme, visit an Authorised Serv-

ice as soon as possible to solve the problem.

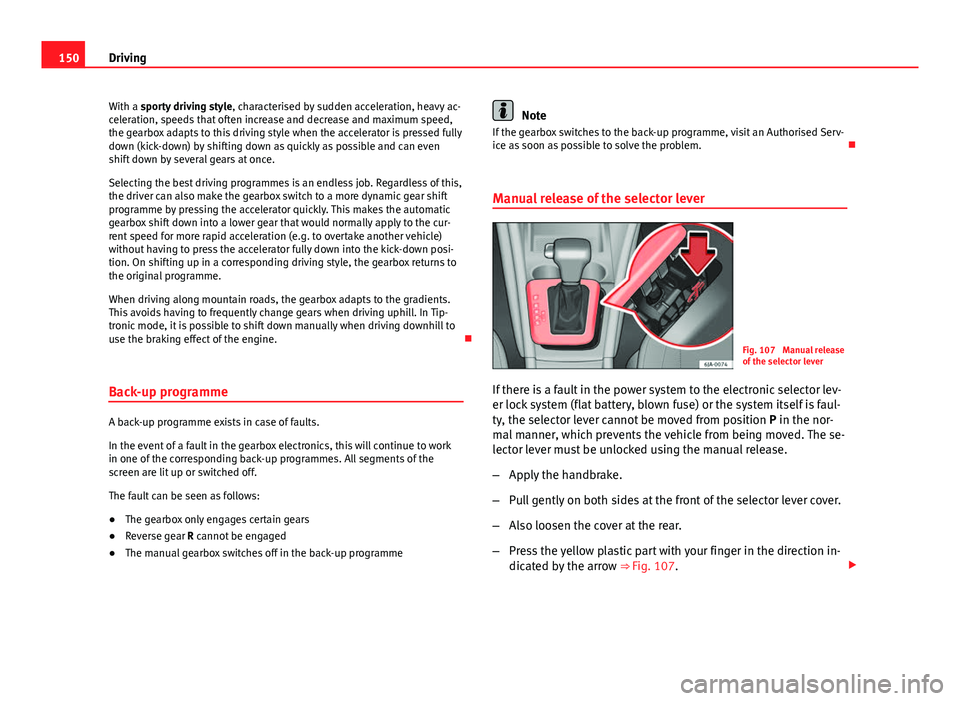

Manual release of the selector lever

Fig. 107 Manual release

of the selector lever

If there is a fault in the power system to the electronic selector lev-

er lock system (flat battery, blown fuse) or the system itself is faul-

ty, the selector lever cannot be moved from position P in the nor-

mal manner, which prevents the vehicle from being moved. The se-

lector lever must be unlocked using the manual release.

– Apply the handbrake.

– Pull gently on both sides at the front of the selector lever cover.

– Also loosen the cover at the rear.

– Press the yellow plastic part with your finger in the direction in-

dicated by the arrow ⇒

Fig. 107.

Page 153 of 258

151

Driving

– Press the interlock button on the selector lever knob at the

same time and move the selector lever to position N (if the se-

lector lever were to be moved back to position P then it would

lock again).

Foot pedals

Under no circumstances must correct use of the pedals be impaired!

Only a floor mat secured to the two corresponding fastening points may be

used in the driver footwell.

Only use floor mats from the catalogue of SEAT Original Accessories that

fasten at two points.

WARNING

No object must be left in the driver footwell. Risk of preventing or limit-

ing use of the foot pedals!

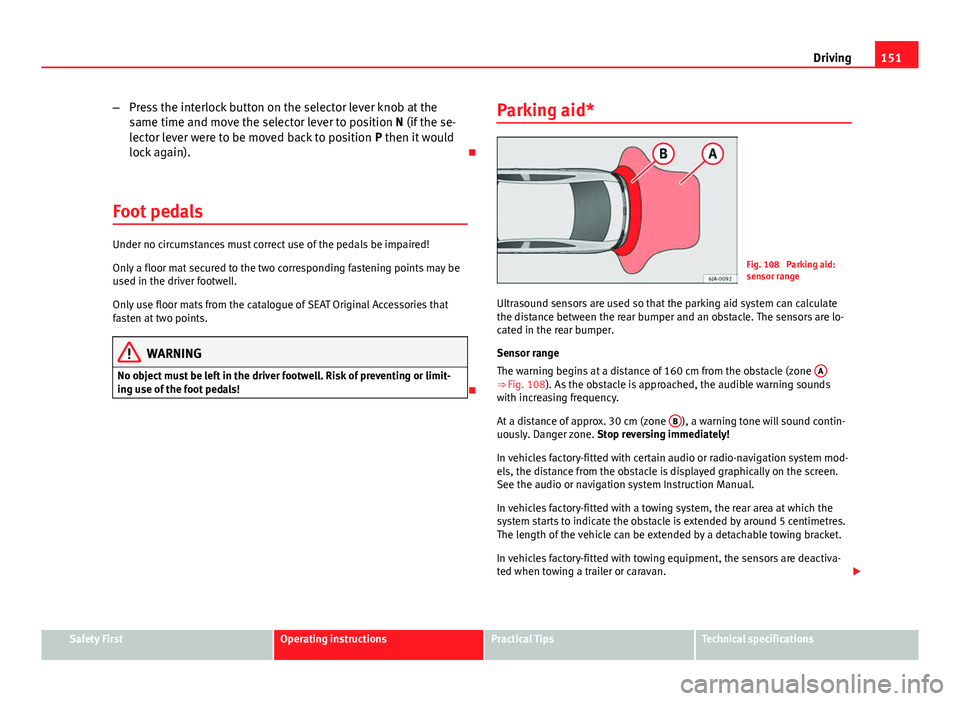

Parking aid*

Fig. 108 Parking aid:

sensor range

Ultrasound sensors are used so that the parking aid system can calculate

the distance between the rear bumper and an obstacle. The sensors are lo-

cated in the rear bumper.

Sensor range

The warning begins at a distance of 160 cm from the obstacle (zone A

⇒ Fig. 108). As the obstacle is approached, the audible warning sounds

with increasing frequency.

At a distance of approx. 30 cm (zone B

), a warning tone will sound contin-

uously. Danger zone. Stop reversing immediately!

In vehicles factory-fitted with certain audio or radio-navigation system mod-

els, the distance from the obstacle is displayed graphically on the screen.

See the audio or navigation system Instruction Manual.

In vehicles factory-fitted with a towing system, the rear area at which the

system starts to indicate the obstacle is extended by around 5 centimetres.

The length of the vehicle can be extended by a detachable towing bracket.

In vehicles factory-fitted with towing equipment, the sensors are deactiva-

ted when towing a trailer or caravan.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 167 of 258

165

Driving the vehicle with a trailer

WARNING

● Exceeding the maximum established load per axle and the maximum

towing bracket load in addition to the maximum permitted load or the

load of the vehicle + trailer assembly can cause accidents and serious in-

juries.

● A sliding load could considerably affect the stability and safety of the

vehicle + trailer assembly, resulting in accidents and serious injuries.

Towing a trailer

Exterior mirrors

Check whether you can see enough of the road behind the trailer with the

standard rear vision mirrors. If this is not the case, you should have addi-

tional exterior mirrors fitted. Observe the relevant statutory requirements of

the country you are in.

Headlights

Before starting a journey, also check the headlight beam settings with the

trailer hitched up. Adjust the headlight range settings if necessary

⇒ page 99, Range control of main lights .

Driving speed

For your own safety do not drive faster than the maximum permitted speed

indicated on the trailer.

At all times, immediately reduce speed if you detect the slightest swaying

movement of the trailer. Never try to “return the trailer to a straight posi-

tion” by accelerating.

Brakes

Brake in due course! If the trailer has an overrun brake, apply the brakes

gently at first and then, firmly. This will prevent the jerking that can be caused by locking of trailer wheels. Change to a lower gear in good time be-

fore descending a slope in order to take advantage of the engine brake.

The trailer is incorporated into the vehicle anti-theft alarm system.

●

When the vehicle has a factory-fitted anti-theft alarm and a towing

bracket

● When the trailer is electrically connected to the vehicle via the towing

bracket socket

● When the vehicle electrical device and the towing bracket are operation-

al

● When the vehicle is locked and the vehicle anti-theft alarm device is ac-

tivated

Once the electrical connection is interrupted with the vehicle trailer locked,

the alarm sounds.

Always switch off the vehicle anti-theft alarm device before connecting or

disconnecting a trailer. The vehicle anti-theft alarm device could cause the

alarm to sound ⇒ page 91, Anti-theft alarm system*.

Engine overheating

In the event that the coolant temperature gauge needle moves to the right

section of the scale or to the red area, immediately reduce speed. If the con-

trol lamp flashes on the general instrument panel, stop the vehicle and

switch off the engine. Wait several minutes and check the coolant level in

the tank ⇒ page 188.

Please observe the following indications ⇒ page 72, Coolant level and tem-

perature .

The coolant temperature can be reduced by switching on the heating.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 169 of 258

167

Driving the vehicle with a trailer

Towing bracket device Introduction

If the vehicle is equipped with a towing bracket device from the factory or

consisting of genuine SEAT accessories, it meets all the national technical

and legal requirements for towing.

Your vehicle is fitted with a 13-pin power socket for the electrical connection

between the trailer and the vehicle. If the towing bracket is equipped with a

7-pin connector, the corresponding available adaptor may be used as a

genuine SEAT accessory.

The towing device has a maximum vertical load of 50 kg.

WARNING

● Before driving with the ball-headed bar fitted, verify its correct as-

sembly and placement in the clamping bush.

● Do not use the ball-headed bar if it is not correctly placed and fixed in

the clamping bush.

● Do not use the towing device for towing if it is damaged or missing

parts.

● Do not modify or adapt the towing device for towing.

● Never disengage the ball-headed bar with the trailer still hitched.

CAUTION

Be careful not to damage the paint on the bumper when handling the ball-

headed bar. Description

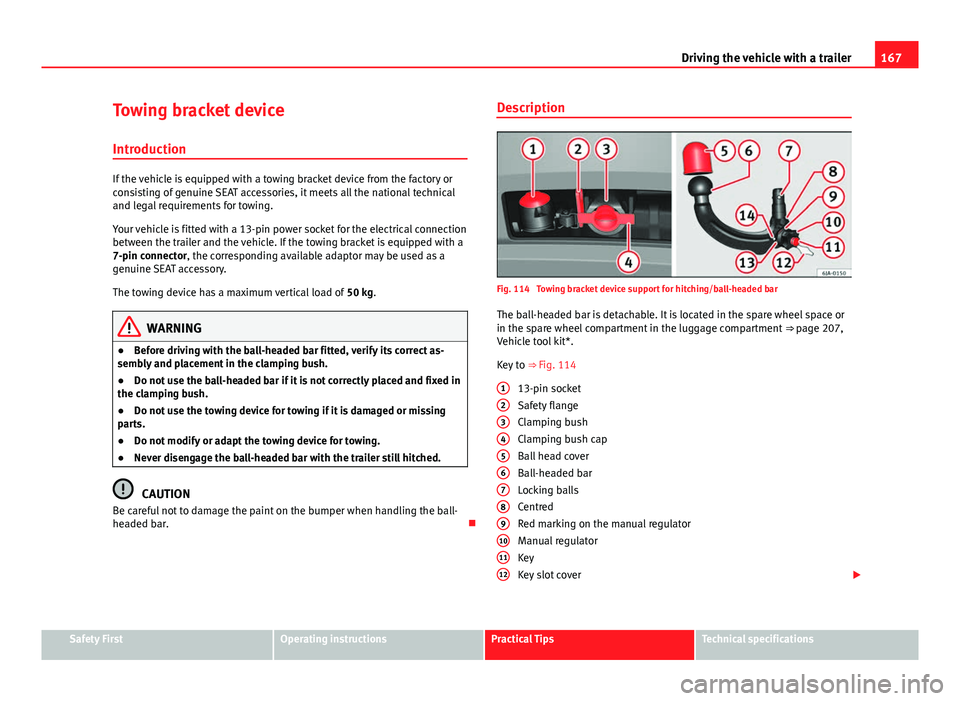

Fig. 114 Towing bracket device support for hitching/ball-headed bar

The ball-headed bar is detachable. It is located in the spare wheel space or

in the spare wheel compartment in the luggage compartment ⇒ page 207,

Vehicle tool kit*.

Key to ⇒ Fig. 114

13-pin socket

Safety flange

Clamping bush

Clamping bush cap

Ball head cover

Ball-headed bar

Locking balls

Centred

Red marking on the manual regulator

Manual regulator

Key

Key slot cover

1

23456789101112

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 170 of 258

168Driving the vehicle with a trailer

Red marking on the manual regulator

White marking on the ball-headed bar

Note

Contact an Authorised Service Partner if you lose your key.

Placing in service position

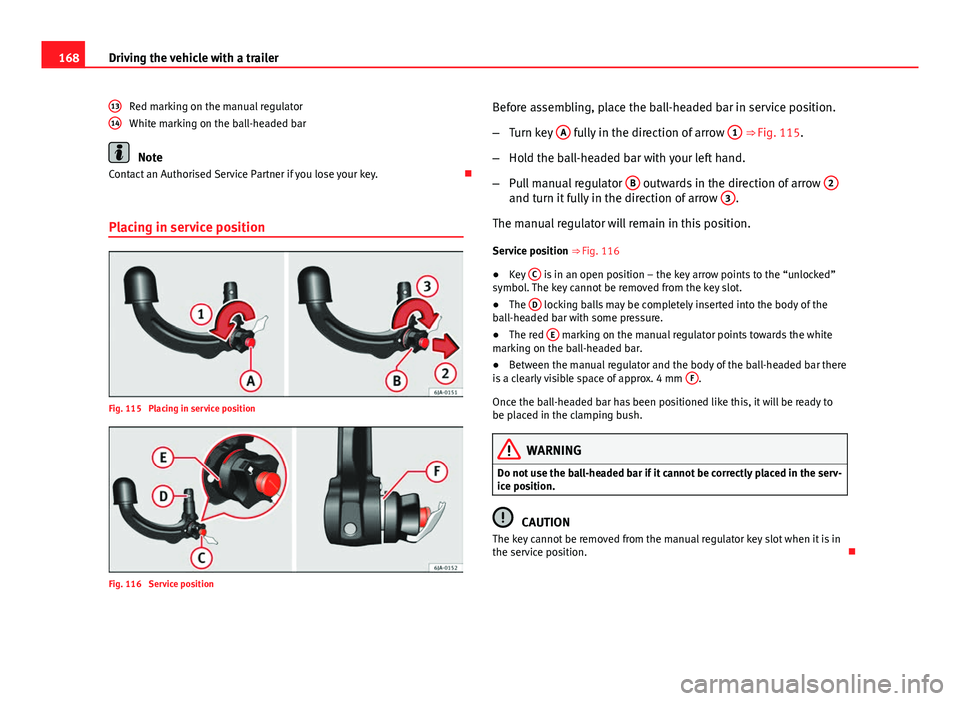

Fig. 115 Placing in service position

Fig. 116 Service position 13

14Before assembling, place the ball-headed bar in service position.

–

Turn key A

fully in the direction of arrow 1 ⇒ Fig. 115.

– Hold the ball-headed bar with your left hand.

– Pull manual regulator B

outwards in the direction of arrow 2and turn it fully in the direction of arrow 3.

The manual regulator will remain in this position.

Service position ⇒ Fig. 116

● Key C

is in an open position – the key arrow points to the “unlocked”

symbol. The key cannot be removed from the key slot.

● The D

locking balls may be completely inserted into the body of the

ball-headed bar with some pressure.

● The red E

marking on the manual regulator points towards the white

marking on the ball-headed bar.

● Between the manual regulator and the body of the ball-headed bar there

is a clearly visible space of approx. 4 mm F

.

Once the ball-headed bar has been positioned like this, it will be ready to

be placed in the clamping bush.

WARNING

Do not use the ball-headed bar if it cannot be correctly placed in the serv-

ice position.

CAUTION

The key cannot be removed from the manual regulator key slot when it is in

the service position.

Page 171 of 258

169

Driving the vehicle with a trailer

Assembling the ball-headed bar

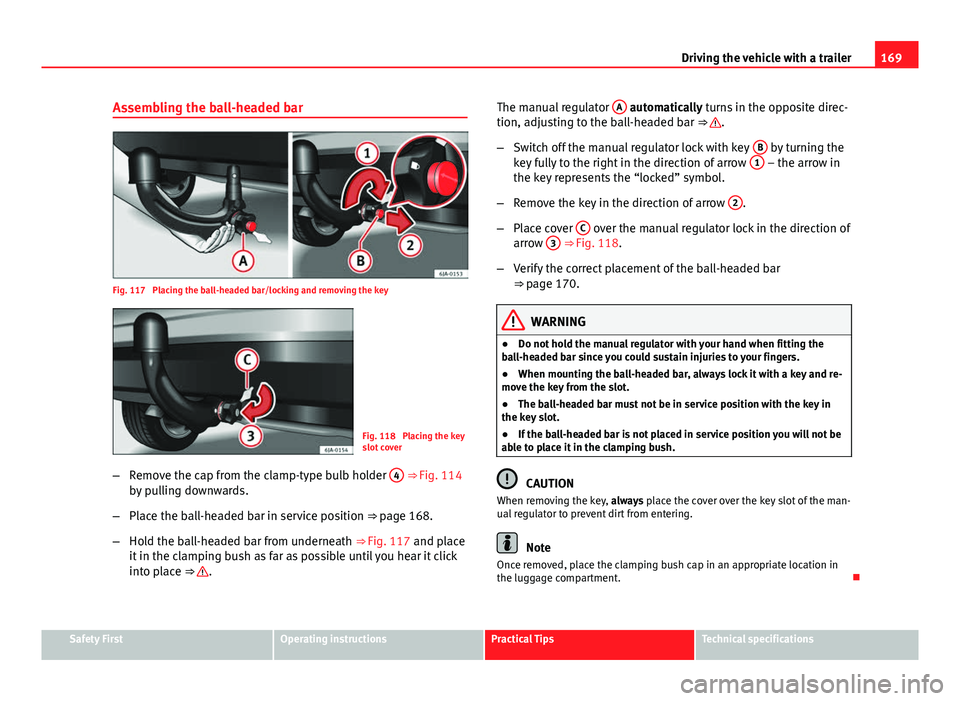

Fig. 117 Placing the ball-headed bar/locking and removing the key

Fig. 118 Placing the key

slot cover

– Remove the cap from the clamp-type bulb holder 4

⇒ Fig. 114

by pulling downwards.

– Place the ball-headed bar in service position ⇒ page 168.

– Hold the ball-headed bar from underneath ⇒ Fig. 117 and place

it in the clamping bush as far as possible until you hear it click

into place ⇒

. The manual regulator

A

automatically turns in the opposite direc-

tion, adjusting to the ball-headed bar ⇒ .

– Switch off the manual regulator lock with key B

by turning the

key fully to the right in the direction of arrow 1 – the arrow in

the key represents the “locked” symbol.

– Remove the key in the direction of arrow 2

.

– Place cover C

over the manual regulator lock in the direction of

arrow 3 ⇒ Fig. 118.

– Verify the correct placement of the ball-headed bar

⇒ page 170.

WARNING

● Do not hold the manual regulator with your hand when fitting the

ball-headed bar since you could sustain injuries to your fingers.

● When mounting the ball-headed bar, always lock it with a key and re-

move the key from the slot.

● The ball-headed bar must not be in service position with the key in

the key slot.

● If the ball-headed bar is not placed in service position you will not be

able to place it in the clamping bush.

CAUTION

When removing the key, always place the cover over the key slot of the man-

ual regulator to prevent dirt from entering.

Note

Once removed, place the clamping bush cap in an appropriate location in

the luggage compartment.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 172 of 258

170Driving the vehicle with a trailer

Verification of correct placement

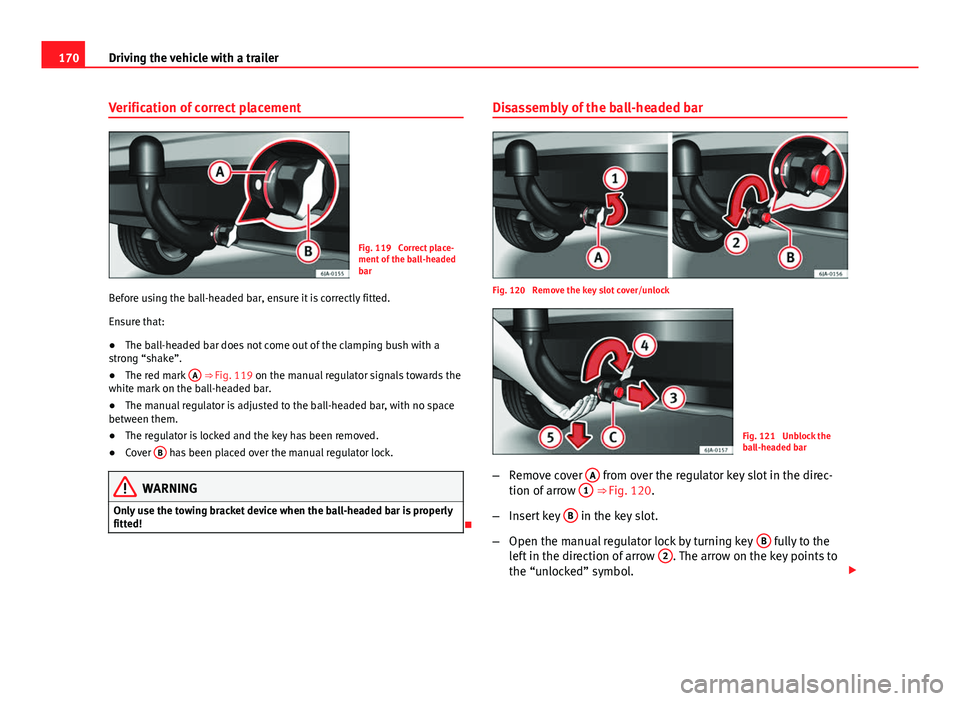

Fig. 119 Correct place-

ment of the ball-headed

bar

Before using the ball-headed bar, ensure it is correctly fitted.

Ensure that:

● The ball-headed bar does not come out of the clamping bush with a

strong “shake”.

● The red mark A

⇒ Fig. 119 on the manual regulator signals towards the

white mark on the ball-headed bar.

● The manual regulator is adjusted to the ball-headed bar, with no space

between them.

● The regulator is locked and the key has been removed.

● Cover B

has been placed over the manual regulator lock.

WARNING

Only use the towing bracket device when the ball-headed bar is properly

fitted!

Disassembly of the ball-headed bar

Fig. 120 Remove the key slot cover/unlock

Fig. 121 Unblock the

ball-headed bar

– Remove cover A

from over the regulator key slot in the direc-

tion of arrow 1 ⇒ Fig. 120.

– Insert key B

in the key slot.

– Open the manual regulator lock by turning key B

fully to the

left in the direction of arrow 2. The arrow on the key points to

the “unlocked” symbol.

Page 174 of 258

172Care of the vehicle and cleaning

Care of the vehicle and cleaning

Care of the vehicle

Introduction

Regular and suitable care helps to maintain the useful life of your vehicle.

This may also be one of the requirements for upholding any warranty claims

in the event of corrosion or paint defects.

We recommend you use cleaning products from the SEAT Original Accesso-

ries programme available in SEAT dealers. Please follow the instructions for

use on the packaging.

WARNING

● Cleaning products and other materials used for car care can damage

the health if misused.

● Always keep car care materials in a safe place out of the reach of chil-

dren. Risk of poisoning!

● When washing the car during the winter season: Moisture and ice on

the brakes may affect braking efficiency. Risk of accident!

● The ignition must always be switched off when the car is washed.

Risk of accident!

● Do not clean the underside of the car or inside the wheel arches with-

out protecting your hands and arms. You may cut yourself on sharp metal

parts!

● Perfumes and air fresheners inside the vehicle may be harmful to

health at high temperatures in the interior.

CAUTION

● Check the colour stability of your clothing to avoid damaging or visibly

staining the fabric (leather), upholstery and fabric trim.

● Cleaning products containing solvents may damage the material being

cleaned.

● Do not wash the vehicle in direct sunlight. Risk of damage to paintwork.

● If washing the vehicle with a hose in winter, do not direct the jet of water

directly at the locks or at the door seals or bonnet. Risk of freezing.

● Do not use insect sponges or abrasive household sponges, etc. on pain-

ted surfaces. Risk of damage to the painted surface.

● Do not put stickers on the inner side of the window in areas where heat-

ing elements or the aerial is located. This could cause damage and, in the

case of the aerial, radio and navigation system reception faults.

● Do not clean the inner side of the window with sharp objects or corro-

sive or acidic cleaning products. Risk of damaging the heating elements or

the aerial.

● Do not attach any fragrance or air freshener to the dash panel. Risk of

damage to the dash panel.

● To avoid damaging the parking aid system sensors, spray them only

briefly at a minimum distance of 10 cm when cleaning the vehicle with a

high-pressure or steam cleaner.

● Do not clean the roof panel with a brush. Risk of damage to the panel

surface!

For the sake of the environment

● The packaging of the product used to care for your vehicle is hazardous

waste. It must be disposed of according to current local law.

● Only wash the car in special wash bays.

Page 177 of 258

175

Care of the vehicle and cleaning

Plastic parts

Exterior plastic parts will come clean using a damp cloth. If this is not suffi-

cient, plastic parts can also be treated with special solvent-free plastic

cleaning detergents.

Do not use paint cleaners, polishes or wax on plastic parts.

Windows and exterior mirrors

Remove snow and ice from windows and rear vision mirrors with a plastic

scraper only. To avoid damaging the surface of the glass, the scraper should

only be pushed in one direction and not moved to and fro.

The windows should also be cleaned on the inside at regular intervals.

Use a separate cloth or chamois to dry the windows and rear vision mirrors.

Do not use the chamois used to polish the bodywork to dry the windows.

Waxing and polishing residues could cause smears on the glass and hinder

visibility.

CAUTION

● Never use warm or hot water to remove snow and ice from the windows

and mirrors. Risk of cracking glass!

● Make sure you do not damage the paintwork on the vehicle on removing

snow and ice from the windows and rear vision mirrors.

● Do not remove the snow or ice from windows and mirrors that are dirty

with thick particles, e.g. gravel, sand or road salt. Risk of damage to surface

of glass and windows. Radio reception and aerial

In vehicles factory-fitted with an audio and navigation system, the aerial

may be installed in different places:

●

Inside the rear window next to the heating elements

● on the roof of the vehicle.

Headlights

Use soap and clean, hot water to clean the front headlights.

CAUTION

● Never rub the headlights dry and do not use sharp objects to clean the

plastic glass material. These could damage the protective paint and cause

the headlights to crack.

● Do not use aggressive cleaning products or chemical solvents to clean

the glass. This could damage the headlights.

Care of rubber seals

The weatherstrips on doors and windows will remain pliable and last longer

if they are occasionally treated with a suitable rubber care product. This will

prevent premature ageing and leaks. If they are correctly cared for, the seals

will be less likely to freeze up in the winter.

Door lock cylinder

Special products must be used to defrost lock cylinders.

Safety FirstOperating instructionsPractical TipsTechnical specifications