lock Seat Toledo 2013 Repair Manual

[x] Cancel search | Manufacturer: SEAT, Model Year: 2013, Model line: Toledo, Model: Seat Toledo 2013Pages: 258, PDF Size: 3.94 MB

Page 178 of 258

176Care of the vehicle and cleaning

Note

● Make sure, when washing the vehicle, that the least amount of water

possible enters the lock cylinders.

● We recommend the use of products from the selection of SEAT Original

Accessories to care for the door lock cylinder.

Wheels

Wheel trims

If you wash the vehicle regularly, you must also thoroughly wash the wheel

trims. Regularly remove any brake abrasion residue and road salt from the

wheels, otherwise the wheel material could be damaged. Repair any dam-

age to the wheel paintwork immediately.

Alloy wheels

After thorough washing, treat the wheels with a protective product for alloy

wheels. Do not use abrasive products to care for the wheels.

WARNING

Moisture, ice and road salt may affect braking efficiency. Risk of acci-

dent!

CAUTION

Heavy dirt on the wheels could lead to their misalignment. This could result

in vibrations being transmitted to the steering wheel that under certain con-

ditions may cause premature steering wear. This dirt must be removed.

Note

We recommend you leave paint damage repairs to a SEAT Authorised Serv-

ice. Underbody sealant

The underside of the vehicle is coated to permanently protect it from chemi-

cal and mechanical agents.

Given that damage to the

protective coating during driving cannot be com-

pletely ruled out, we recommend you check the condition of the protective

coating on the underbody and suspension at regular intervals, preferably

before the start and end of the coldest season of the year.

Authorised SEAT dealers have suitable special products and the necessary

facilities and are aware of the techniques required for their application. We

therefore recommend all touch-up work or additional anti-corrosion meas-

ures be performed by an authorised SEAT dealer.

WARNING

Do not apply underseal or anti-corrosion coatings to the exhaust pipes,

catalytic converter, particulate filter or heat shields on the exhaust sys-

tem. Once the engine has reached operating temperature, these substan-

ces could catch fire. Risk of fire!

Cavity waxing

All cavities on the vehicle exposed to corrosion are permanently factory-pro-

tected by a wax solution .

This wax solution does not need to be checked or touched up. Should wax

run out of the cavities at high ambient temperatures, remove it using a plas-

tic scraper and clean away any stains using lighter fluid.

Page 180 of 258

178Care of the vehicle and cleaning

CAUTION

● Avoid exposing leather to direct sunlight for long periods so that it does

not lose its colour. If the car is left for a prolonged period outdoors, cover

the leather so that it does not lose its colour.

● Sharp-edged objects on clothing, such as zips, rivets or belts can leave

permanent scratches and rough marks on the surface of the leather.

● Use of the mechanical steering wheel lock can damage the leather sur-

face of the steering wheel.

Note

● Use a suitable impregnating cream with ultra-violet protection at regular

intervals and after cleaning. The cream will nourish and moisturise the

leather, keep it supple and able to breathe. In addition, it will also help to

protect the surface of the leather.

● Clean the leather every 2 to 3 months and remove fresh dirt as necessa-

ry.

● Preserve the colour of the leather. A special coloured cream for leather

will renew the colour of more heavily worn areas as required.

● Leather is a natural material with specific properties. During vehicle use,

parts of the leather covers may change in appearance, such as folds or wrin-

kles, as a result of their use.

Seat belts

Keep the seat belts clean!

Wash soiled seat belts with mild, soapy water, removing any heavier dirt

with a soft brush.

Check the condition of all seat belts at regular intervals.

Very soiled belts may not retract properly.

WARNING

● The seat belts should never be removed from the vehicle for cleaning.

● Never clean using chemical products, as chemical detergents destroy

the fabric. Ensure that the seat belts do not come into contact with corro-

sive fluids such as acids, etc.

● If you find any damage to the belt webbing, belt fittings, the belt re-

tractor or the buckle, the belt in question must be replaced by an Official

Service.

● Make sure that the inertia reel seat belts are completely dry before

allowing them to retract.

Page 181 of 258

179

Checking and refilling levels

Checking and refilling levels Fuel

Introduction

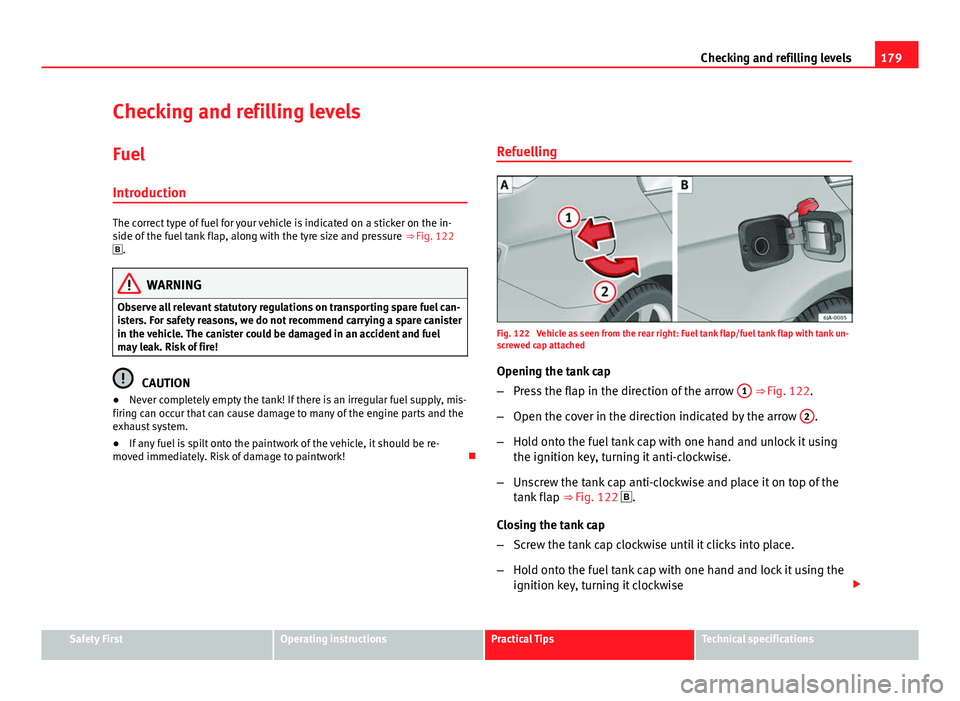

The correct type of fuel for your vehicle is indicated on a sticker on the in-

side of the fuel tank flap, along with the tyre size and pressure ⇒ Fig. 122

.

WARNING

Observe all relevant statutory regulations on transporting spare fuel can-

isters. For safety reasons, we do not recommend carrying a spare canister

in the vehicle. The canister could be damaged in an accident and fuel

may leak. Risk of fire!

CAUTION

● Never completely empty the tank! If there is an irregular fuel supply, mis-

firing can occur that can cause damage to many of the engine parts and the

exhaust system.

● If any fuel is spilt onto the paintwork of the vehicle, it should be re-

moved immediately. Risk of damage to paintwork! Refuelling

Fig. 122 Vehicle as seen from the rear right: Fuel tank flap/fuel tank flap with tank un-

screwed cap attached

Opening the tank cap

– Press the flap in the direction of the arrow 1

⇒ Fig. 122.

– Open the cover in the direction indicated by the arrow 2

.

– Hold onto the fuel tank cap with one hand and unlock it using

the ignition key, turning it anti-clockwise.

– Unscrew the tank cap anti-clockwise and place it on top of the

tank flap ⇒ Fig. 122 .

Closing the tank cap

– Screw the tank cap clockwise until it clicks into place.

– Hold onto the fuel tank cap with one hand and lock it using the

ignition key, turning it clockwise

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 192 of 258

190Checking and refilling levels

WARNING

If the fluid level has dropped below the MIN mark, do not drive on.

Risk of accident! Seek professional help.

Changing the brake fluid

Brake fluid absorbs moisture. Therefore, it gradually absorbs moisture from

the atmosphere. If the water content in the brake fluid is too high, the brake

system could corrode. The water content also reduces the boiling point of

the brake fluid.

The brake fluid must comply with one of the following standards or specifi-

cations:

● VW 50114

● FMVSS 116 DOT4

WARNING

Heavy use of the brakes may cause a vapour lock if the brake fluid is left

in the brake system for too long. This would seriously affect the efficien-

cy of the brakes and the safety of the vehicle.

CAUTION

Brake fluid damages the vehicle paintwork. Windscreen washer

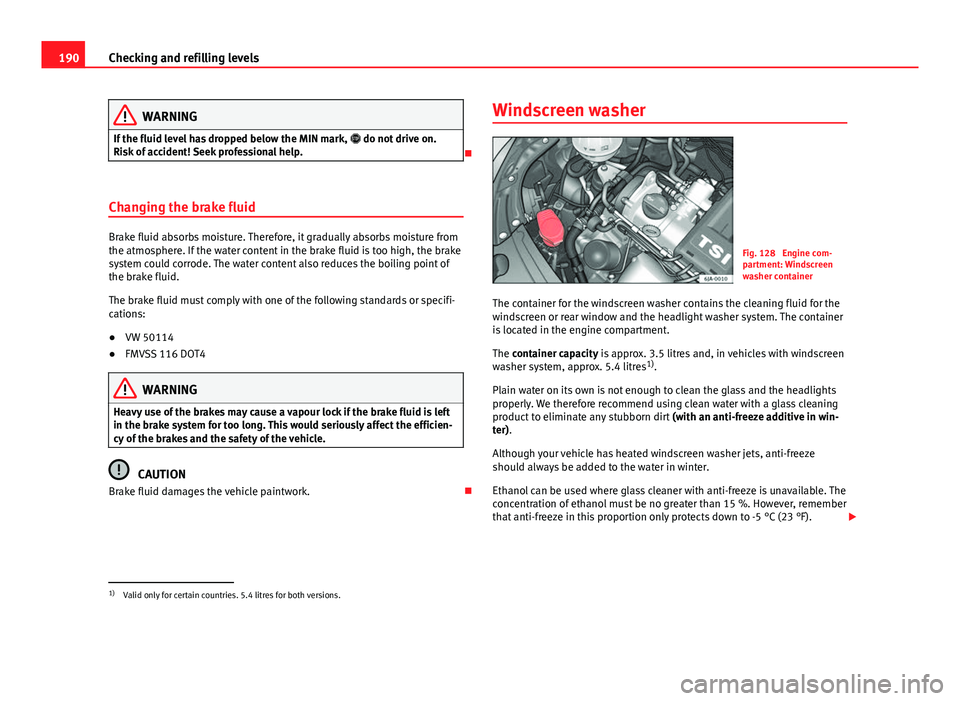

Fig. 128 Engine com-

partment: Windscreen

washer container

The container for the windscreen washer contains the cleaning fluid for the

windscreen or rear window and the headlight washer system. The container

is located in the engine compartment.

The container capacity is approx. 3.5 litres and, in vehicles with windscreen

washer system, approx. 5.4 litres 1)

.

Plain water on its own is not enough to clean the glass and the headlights

properly. We therefore recommend using clean water with a glass cleaning

product to eliminate any stubborn dirt (with an anti-freeze additive in win-

ter).

Although your vehicle has heated windscreen washer jets, anti-freeze

should always be added to the water in winter.

Ethanol can be used where glass cleaner with anti-freeze is unavailable. The

concentration of ethanol must be no greater than 15 %. However, remember

that anti-freeze in this proportion only protects down to -5 °C (23 °F).

1)

Valid only for certain countries. 5.4 litres for both versions.

Page 196 of 258

194Checking and refilling levels

–After charging the battery: Switch off the battery charger and

disconnect the cable.

– Remove the charger cables.

– If necessary, reconnect both battery cables to the battery (first

the “positive” cable, then the “negative” cable).

When charging with a low current (e.g. with a small battery charger), the

battery does not have to be disconnected. The instructions of the battery

charger manufacturer must be followed.

Use a current equivalent to or lower than 10% of the battery capacity to fully

charge the battery.

Before “fast-charging” the battery however, both battery cables must be

disconnected.

“Fast-charging” a battery is dangerous and requires a battery charger and

special knowledge. Fast charges should be performed by an official techni-

cal service.

The battery caps should not be opened while the battery is being charged.

CAUTION

In vehicles fitted with the “START-STOP” system, the charger cable cannot

be directly connected to the negative terminal of the vehicle battery but

must be attached to the engine earthing point ⇒ page 216.

Disconnecting and connecting the battery

The following functions will either be inoperative or will not work properly

after disconnecting and reconnecting the battery:

effectInstallationSetting the clock⇒ page 60The multifunction display data is deleted⇒ page 61

Note

We recommend having the vehicle checked by an authorised SEAT dealer to

guarantee the correct working order of all electrical systems.

Changing the battery

A replacement battery must have the same capacity, voltage, current rating

and size as the original. The appropriate types of battery can be acquired

from authorised SEAT dealers.

We recommend having the battery changed by an authorised SEAT dealer,

where the new battery will be correctly installed and the original disposed

of in line with regulations.

Automatic disconnection of electrical equipment

When heavily-charging a battery, the programme selected by the electrical

system control unit prevents the battery from automatically discharging.

This may result in the following:

● Increase in idling speed so that the alternator can supply more current

to the electrical system.

● The performance of certain electrical components could be limited or

some may switch off temporarily, e.g. the heated seats, the heated rear win-

dow, the 12V power socket.

Page 205 of 258

203

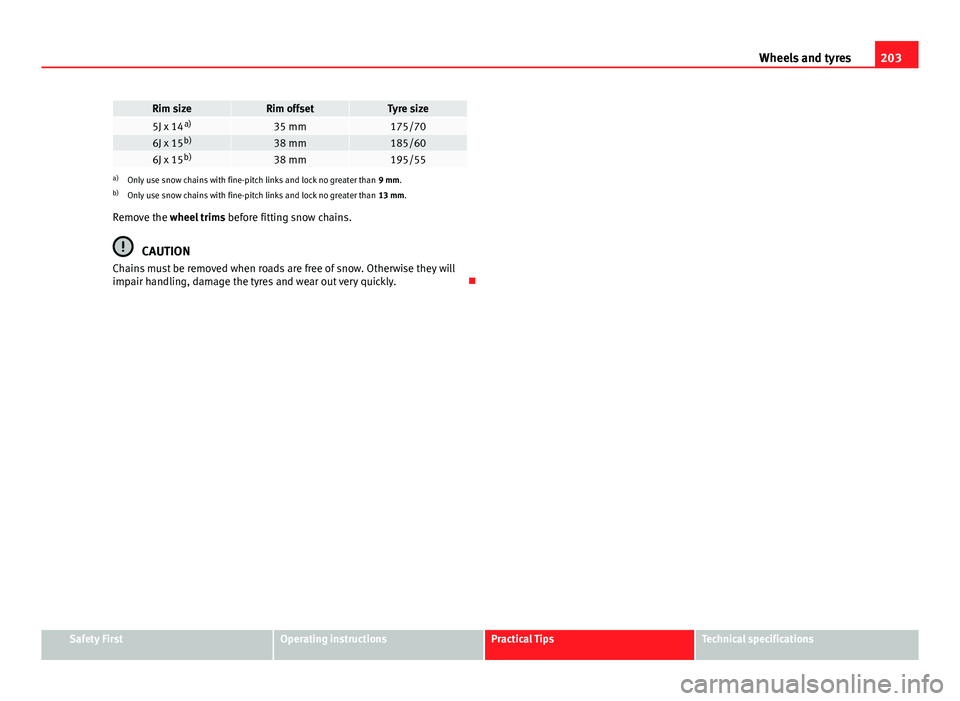

Wheels and tyres

Rim sizeRim offsetTyre size5J x 14 a)35 mm175/706J x 15b)38 mm185/606J x 15b)38 mm195/55a)

Only use snow chains with fine-pitch links and lock no greater than 9 mm.

b) Only use snow chains with fine-pitch links and lock no greater than 13 mm.

Remove the wheel trims before fitting snow chains.

CAUTION

Chains must be removed when roads are free of snow. Otherwise they will

impair handling, damage the tyres and wear out very quickly.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 209 of 258

207

Self-help

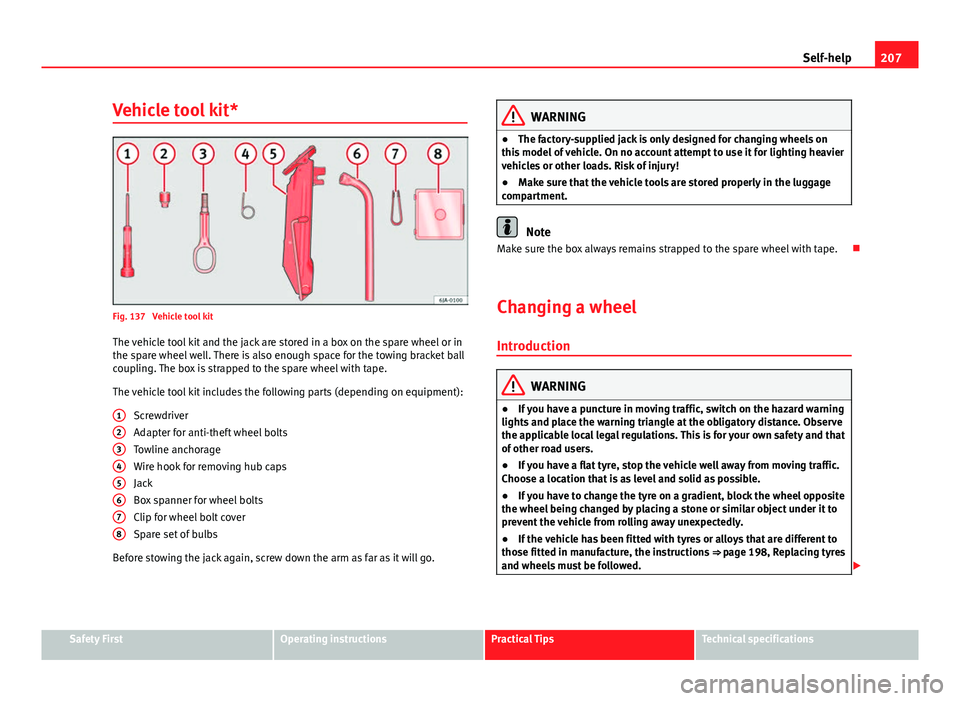

Vehicle tool kit*

Fig. 137 Vehicle tool kit

The vehicle tool kit and the jack are stored in a box on the spare wheel or in

the spare wheel well. There is also enough space for the towing bracket ball

coupling. The box is strapped to the spare wheel with tape.

The vehicle tool kit includes the following parts (depending on equipment): Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

Before stowing the jack again, screw down the arm as far as it will go. 1

2345678

WARNING

● The factory-supplied jack is only designed for changing wheels on

this model of vehicle. On no account attempt to use it for lighting heavier

vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored properly in the luggage

compartment.

Note

Make sure the box always remains strapped to the spare wheel with tape.

Changing a wheel Introduction

WARNING

● If you have a puncture in moving traffic, switch on the hazard warning

lights and place the warning triangle at the obligatory distance. Observe

the applicable local legal regulations. This is for your own safety and that

of other road users.

● If you have a flat tyre, stop the vehicle well away from moving traffic.

Choose a location that is as level and solid as possible.

● If you have to change the tyre on a gradient, block the wheel opposite

the wheel being changed by placing a stone or similar object under it to

prevent the vehicle from rolling away unexpectedly.

● If the vehicle has been fitted with tyres or alloys that are different to

those fitted in manufacture, the instructions ⇒ page 198, Replacing tyres

and wheels must be followed.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 211 of 258

209

Self-help

– Lower the vehicle.

– Tighten the wheel bolts firmly in diagonal sequence with the

box spanner and then the anti-theft wheel bolt ⇒ page 209.

– Replace the hub cap and/or the bolt covers.

Note

● All bolts must be clean and turn easily.

● Never grease or oil the wheel bolts!

● Note the direction of rotation when putting on a tyre with directional

tread pattern ⇒ page 196.

After changing a wheel

Tasks that must be carried out after changing a wheel.

– Place the wheel with the defective tyre in the spare wheel well

and secure it using a special bolt ⇒ page 199.

– Put the vehicle tools back in their storage location.

– Check the tyre pressure of the newly fitted spare wheel as soon

as possible.

– Have the tightening torque of the wheel bolts checked as soon

as possible with a torque wrench.

– Have the flat tyre replaced or ask an Official Service about the

possibility of repair.

Note

● If you notice that the wheel bolts are rusty and difficult to turn when

changing a wheel, they must be replaced before having the tightening tor-

que checked.

● Drive carefully and at moderate speeds until the tightening torque of the

wheel bolts has been checked.

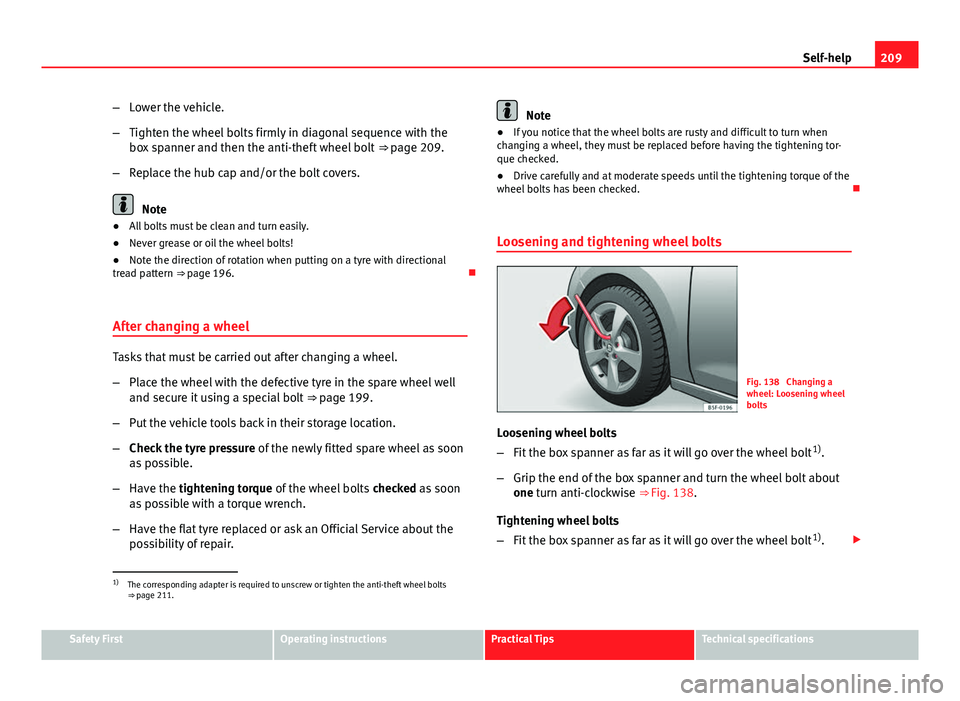

Loosening and tightening wheel bolts

Fig. 138 Changing a

wheel: Loosening wheel

bolts

Loosening wheel bolts

– Fit the box spanner as far as it will go over the wheel bolt 1)

.

– Grip the end of the box spanner and turn the wheel bolt about

one turn anti-clockwise ⇒ Fig. 138.

Tightening wheel bolts

– Fit the box spanner as far as it will go over the wheel bolt 1)

.

1)

The corresponding adapter is required to unscrew or tighten the anti-theft wheel bolts

⇒ page 211.

Safety FirstOperating instructionsPractical TipsTechnical specifications

Page 212 of 258

210Self-help

–Grip the box spanner as close to the end as possible and tight-

en the bolt firmly by turning clockwise.

WARNING

The wheel bolts should only be loosened slightly (about one turn) before

raising the vehicle with the jack. Risk of accident!

Note

If the wheel bolt is very tight, it may be possible to loosen it by pushing

down the end of the box spanner carefully with your foot. Hold on to the ve-

hicle for support and take care not to slip.

Raising the vehicle

Fig. 139 Changing a

wheel: Jacking points

Fig. 140 Fitting the jack

To place the jack, locate the jacking point under the door sill clos-

est to the wheel to be changed ⇒ Fig. 139. The jacking point is di-

rectly underneath the stamp on the door sill.

– Turn the crank handle on the jack to wind it up under the jack-

ing point until its claw is directly below the jacking point of the

door sill.

– Adjust the jack so that its claw surrounds the jacking point on

the door sill ⇒ Fig. 140 - B underneath the stamp on the door

sill.

– Make sure that the base of the jack is entirely supported on a

flat surface and that it is vertical ⇒ Fig. 140 to the point where

the claw surrounds the jacking point on the door sill.

– Continue to wind up the jack using the crank handle until the

defective wheel is clear off the ground.

Page 218 of 258

216Self-help

Connecting negative terminals with the engine block

–Connect one end 3

⇒ Fig. 143 to the negative terminal of the

boosting battery B.

– Attach the other end 4

to a solid metal part firmly attached to

the engine block or to the engine block itself.

Starting the engine

– Start the engine of the vehicle and let it run at idling speed.

– Now start the engine of the vehicle with the discharged battery.

– If the engine fails to start, do not operate the start for longer

than 10 seconds. Wait for about 30 seconds and try again.

– Remove the jump leads from the engine in exactly the opposite

sequence to that described above. Jump-starting vehicles with the START-STOP system

Fig. 144 Jump-starting

vehicles with the START-

STOP system

In vehicles fitted with the START-STOP system, the booster cable cannot be

directly connected to the negative terminal of the vehicle battery but must

be attached to the engine earthing point.

Towing the vehicle

Introduction

Vehicles with manual gearbox can be towed using a towbar or tow-

rope. They can also be towed with either the front or rear wheels

lifted off the road.

Vehicles with automatic gearbox can be towed using a towbar or

towrope. They can also be towed with the front wheels lifted off the