boot Seat Toledo 2014 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Toledo, Model: Seat Toledo 2014Pages: 200, PDF Size: 4.37 MB

Page 85 of 200

Transport and practical equipment

During an accident, even small and light ob-

jects can have so much kinetic energy that

they can cause very severe injuries. The

amount of kinetic energy depends on the

speed of the vehicle and the weight of the

object. However, the speed of the vehicle is

the most important factor.

Example: An unsecured object weighing 4.5

kg produces energy corresponding to 20

times its weight in a frontal collision at 50

km/h (31 mph). This means that its weight

reaches around 90 kg. You can imagine the

severity of the injuries that might be sus-

tained if this “projectile” strikes an occupant

as it flies through the vehicle interior. WARNING

● Store objects in the luggage compartment

and secure to the fastening points.

● In an accident or sudden manoeuvre, loose

objects in the interior can be flung forward

and possibly injure vehicle occupants or oth-

ers. This risk is even greater if the flying ob-

jects hit a triggering airbag. In this case, any

rebounding objects could injure vehicle occu-

pants. Risk of fatal injuries!

● Take into account that transporting heavy

objects changes the centre of gravity that

could also cause changes in vehicle handling.

Risk of accident! Therefore, always adjust

your speed and driving style to suit these cir-

cumstances. ●

Securing the load to the rings using unsuit-

able or damaged straps could lead to injuries

in the event of an accident or sudden braking

manoeuvre. Secure suitable straps safely to

the rings to ensure this does not happen.

● Position the load so it cannot move forward

during a sudden braking manoeuvre. Risk of

injuries!

● If transporting sharp or dangerous objects

in the space provided when the rear seats are

folded, ensure the safety of the occupant of

the remaining rear seat ››› page 8.

● If the r

ear seat located alongside a folded

seat is occupied, ensure safety, for example,

by placing the load so that it stops the seat

from folding backward in the event of being

hit from behind.

● Never drive with the rear lid open or half-

closed, exhaust gases may penetrate into the

interior of the vehicle. Danger of poisoning!

● Never exceed the allowed axle loads or al-

lowed maximum weight. Risk of accident!

● Never transport passengers in the luggage

compartment! CAUTION

Make sure sharp objects stored in the boot

cannot not damage the rear window heating

filaments. Note

Tyre pressure must be adapted to suit the

load ››› page 144, Life cycle of tyres . Category N1 vehicles

Category N1 vehicles with no protection grille

must use a retaining set compliant with

Standard EN 12195 (1 – 4) to secure the

load.

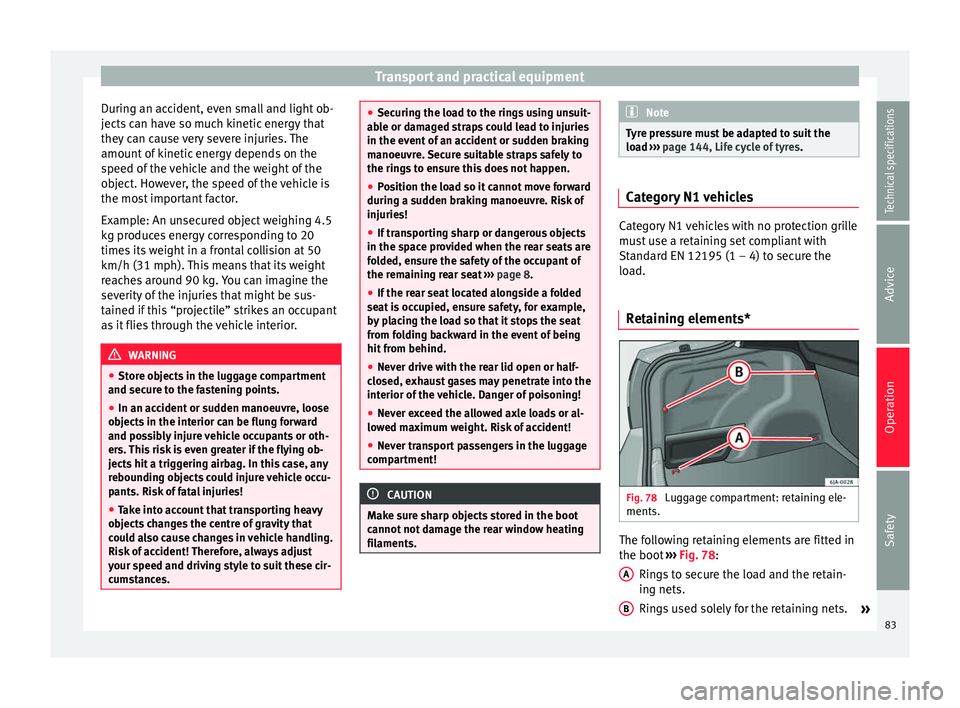

Retaining elements* Fig. 78

Luggage compartment: retaining ele-

ments. The following retaining elements are fitted in

the boot

›››

Fig. 78 :

Rin g

s to secure the load and the retain-

ing nets.

Rings used solely for the retaining nets. »

A B

83

Technical specifications

Advice

Operation

Safety

Page 86 of 200

Operation

CAUTION

The rings support a maximum load of 3.5 kN

(350 kg). Note

The front ring B is below the folding back-

rest of the rear seats ››› Fig. 78. Hook*

Fig. 79

Luggage compartment: hook. There are hooks on both sides of the boot to

secure light items of luggage such as bags,

etc.

›››

Fig. 79 . CAUTION

The side hooks support a maximum load of

7.5 kg. Retaining nets*

Fig. 80

Retaining nets. Fig. 81

Retaining nets. Example of securing retaining nets

››› Fig. 80

and ››› Fig. 81 .

Sidew a

ys bag

Ground net

Lengthways bag

A B

C WARNING

Do not exceed the maximum load that the

nets can support. Heavy objects cannot be

safely secured. Risk of injury! CAUTION

● The retaining nets support a maximum load

of 1.5 kg.

● Do not place any item with sharp edges in

the net. Risk of damaging the net! 84

Page 119 of 200

Towing bracket device

Description Fig. 99

Towing bracket device support for

hitching/ball-headed bar. The ball-headed bar is detachable. It is loca-

ted in the spare wheel compartment or in the

spare wheel compartment in the boot

››› page 150, Vehicle tool kit*.

Key to ››› Fig. 99

13-pin socket

Safety flange

1 2 Clamping bush

Clamping bush cap

Ball head cover

Ball-headed bar

Locking balls

Centred

Red marking on the manual regulator

Manual regulator

Key

Key slot cover

Red marking on the manual regulator

White marking on the ball-headed bar

Note

Contact an Authorised Service Partner if you

lose your key. 3

4

5

6

7

8

9

10

11

12

13

14 Placing in service position

Fig. 100

Placing in service position.

» 117Technical specifications

Advice

Operation

Safety

Page 121 of 200

Towing bracket device

Fig. 103

Placing the key slot cover. –

Remove the cap from the clamping bush 4›››

Fig. 99 by pulling downwards.

– Plac

e the ball-headed bar in the service po-

sition ››› page 117.

– Hol

d the ball-headed bar from underneath

››› Fig. 102

and push it into the clamping

bush as far as possible until you hear it

click into place ››› .

The manual regulator A

automatically turns

in the op po

site direction, adjusting to the

ball-headed bar ››› .

– Switch off the manual regulator lock with

key B by turning the key fully to the right

in the direction of arrow 1 – the arrow in

the key displays the “locked” symbol.

– Remove the key in the direction of arrow

2 .

– Place cover C over the manual regulator

lock in the direction of arrow 3

››› Fig. 103 .–

Verif

y the correct placement of the ball-

headed bar ››› page 119. WARNING

● Do not hold the manual regulator with your

hand when fitting the ball-headed bar since

you could sustain injuries to your fingers.

● When mounting the ball-headed bar, al-

ways lock it with a key and remove the key

from the slot.

● The ball-headed bar must not be in the

service position with the key in the key slot.

● If the ball-headed bar is not placed in the

service position you will not be able to place

it in the clamping bush. CAUTION

When removing the key, always place the

cover over the key slot of the manual regula-

tor to prevent dirt from entering. Note

Once removed, place the clamping bush cap

in an appropriate location in the boot. Verification of correct placement

Fig. 104

Correct placement of the ball-head-

ed bar. Before using the ball-headed bar, ensure it is

correctly fitted.

Ensure that:

● The ball-headed bar does not come out of

the clamping bush in a “jerky” manner.

● The red mark A

››› Fig. 104 on the manual

r e

gulator signals toward the white mark on

the ball-headed bar.

● The manual regulator is adjusted to the

ball-headed bar, leaving no space between

them.

● The regulator is locked and the key has

been removed.

● Cover B has been placed over the manual

regulator lock. »

119

Technical specifications

Advice

Operation

Safety

Page 122 of 200

Operation

WARNING

Only use the towing bracket device when the

ball-headed bar is properly fitted! Disassembly of the ball-headed bar

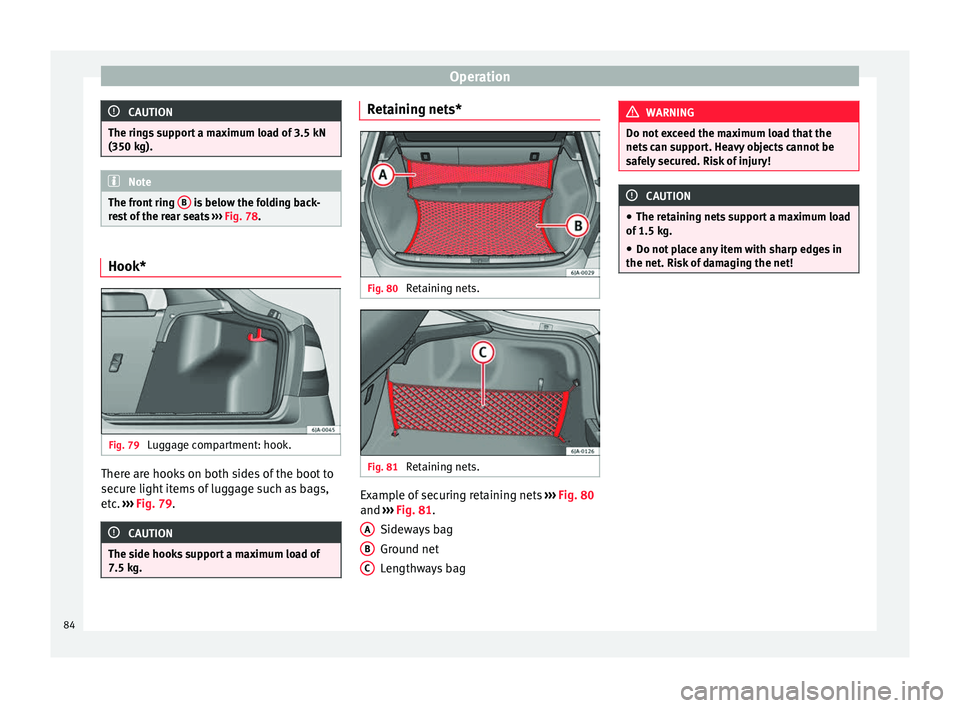

Fig. 105

Remove the key slot cover/unlock

with the key. Fig. 106

Unblock the ball-headed bar. –

Remove cover A from over the regulator

key slot in the direction of arrow 1 ›››

Fig. 105 .

– Inser

t key B in the key slot.

– Open the manual regulator lock by turning

key B fully to the left in the direction of ar-

row 2 . The arrow on the key points to the

“unlocked” symbol.

– Hold the ball-headed bar from underneath

››› Fig. 106 and remove manual regulator

C with your other hand in the direction of

arrow 3 .

– Turn the removed regulator fully in the di-

rection of arrow 4 and hold it firmly in this

position.

– Remove the ball-headed bar from the

clamping bush, pulling downward in the di-

rection of arrow 5 .The ball-headed bar should be placed in the

service position so that it is ready to be inser-

ted into the clamping bush

››› .

– Place the cover over the clamping bush 4 ›››

Fig. 99 . WARNING

● Never leave the ball-headed bar unsecured

in the boot. It could be damaged in the event

of sudden braking, putting the safety of pas-

sengers at risk!

● Never disassemble the ball-headed bar

with the trailer still hitched. CAUTION

● If you do not turn the manual regulator

fully, it will return to its original position

when the ball-headed bar is removed. The

manual regulator will be stuck to the ball-

headed bar and you will not be able to put it

in the service position. Therefore, before you

assemble it again, you must place the ball-

headed bar in this position.

● When disassembling, place the cap on the

clamping bush holder’s key slot. This way

you will prevent dirt from entering the clamp-

ing bush. Note

● Before disassembling the ball-headed bar,

we recommend placing the cover on the ball

head. 120

Page 123 of 200

Towing bracket device

●

Clean the ball-headed bar thoroughly be-

fore returning it to the on-board toolbox. Use and maintenance

Cover the clamping bush with the cap to pre-

vent dirt from entering.

Before hooking on the trailer, check the ball

head and, if necessary, lubricate it with ade-

quate lubricant.

Place the protective cover over the ball head

when storing the bar. This way, you will avoid

getting the boot dirty.

If it gets dirty, clean and dry the clamping

bush thoroughly with an appropriate prod-

uct.

CAUTION

The top part of the clamping bush opening is

lubricated. Be careful not to remove this lu-

brication. 121Technical specifications

Advice

Operation

Safety

Page 129 of 200

Care and maintenance

Underbody sealant The underside of the vehicle is coated to per-

manently protect it from chemical and me-

chanical agents.

Given that damage to the

protective coating

during driving cannot be completely ruled

out, we recommend you check the condition

of the protective coating on the underbody

and suspension at regular intervals, prefera-

bly before the start and end of the coldest

season of the year.

Authorised SEAT dealers have suitable spe-

cial products and the necessary facilities and

are aware of the techniques required for their

application. We therefore recommend all

touch-up work or additional anti-corrosion

measures be performed by an authorised

SEAT dealer. WARNING

Do not apply underseal or anti-corrosion

coatings to the exhaust pipes, catalytic con-

verter, particulate filter or heat shields on the

exhaust system. Once the engine has

reached operating temperature, these sub-

stances could catch fire. Risk of fire! Cavity waxing

All cavities on the vehicle exposed to corro-

sion are permanently factory-protected by a

wax solution

.

This wax solution does not need to be

checked or touched up. Should wax run out

of the cavities at high ambient temperatures,

remove it using a plastic scraper and clean

away any stains using lighter fluid. WARNING

Note the regulations concerning safety and

environmental protection if you use lighter

fluid to remove the wax. Risk of fire! Leatherette and upholstery

Leatherette can be cleaned with a damp

cloth. If this is not sufficient, these parts

should only be cleaned with

solvent-free

plastic care and cleaning products .

Textile covers and trim parts on doors, boot

lid, etc. can be cleaned with special deter-

gents, e.g. dry foam. A soft sponge or brush

or a micro-fibre cloth for normal cleaning can

be used. Use special products to clean the

headliner.

The dye used in many garments, for example

dark jeans, is not always sufficiently colour-

fast. Seat upholstery (fabric and leather), es- pecially when light-coloured, may visibly dis-

colour if the dye comes out of clothing, even

in normal conditions. This is not an uphols-

tery defect but indicates that the dye in the

item of clothing is not solid enough.

Heated seat upholstery Do not clean the seat upholstery with

damp

products, as this could damage the seat

he atin

g system.

Clean the upholstery with special products,

e.g. dry foam, etc.

Natural leather Leather should be looked after from time to

time, depending on its use.

Normal cleaning

Moisten a cotton or woollen cloth with water

and wipe over the leather surfaces.

More stubborn dirt

Do not let water soak through the leather or

penetrate the seams.

Dry it with a soft, dry cloth.

»

127

Technical specifications

Advice

Operation

Safety

Page 156 of 200

Advice

– Adjust the jack so that its claw surrounds

the jacking point on the door sill ››› Fig. 126

- B underneath the stamp on the door sill.

– Make sure that the base of the jack is en-

tirely supported on a flat surface and that it

is vertical ››› Fig. 126 to the point where the

c l

aw surrounds the jacking point on the

door sill.

– Continue to wind up the jack using the

crank handle until the defective wheel is

clear off the ground.

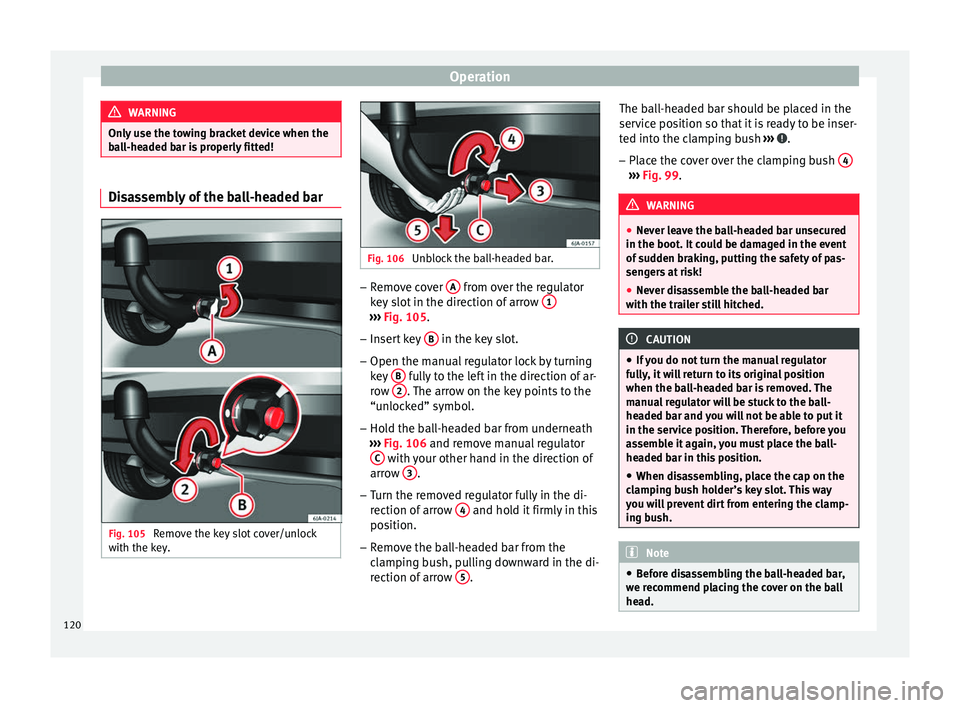

Anti-theft wheel bolts* Fig. 127

Anti-theft wheel bolt with adapter. On vehicles fitted with anti-theft wheel bolts

(one bolt per wheel) these bolts can only be

loosened or tightened using a factory-sup-

plied adapter.

– Pull off the hub cap or bolt cover. –

Insert the adapter B

››› Fig. 127 with its

t oothed s

ide as far as it will go on the inte-

rior toothing of the anti-theft wheel bolt A so that only the outer hexagonal is protrud-

ing.

– Fit the box spanner as far as it will go over

adapter B .

– Loosen or firmly tighten the wheel bolt

››› page 152 .

– Af t

er removing the adapter, replace the hub

cap or the anti-theft wheel bolt cover.

– Have the tightening torque of the wheel

bo

lts checked as soon as possible with a

tor

que wrench.

Note down the code number stamped on the

front of the adapter or on the front of the anti-

theft wheel bolt. You will need this number to

obtain a spare adapter from the SEAT original

accessories programme.

We recommend you always carry the wheel

bolt adapter in the vehicle. It should be stor-

ed in the vehicle tool kit.

Tyre repairs TMS (Tyre Mobility System)* The Tyre Mobility System is stored in a box

under the carpet in the boot.Using the Tyre Mobility System you can relia-

bly seal tyres damaged by foreign bodies,

provided that cuts or punctures are no larger

than approx. 4 mm in diameter. Do not re-

move the foreign bodies, e.g. bolts or nails,

from the tyre!

The tyre must be repaired immediately.

The repair made using the Tyre Mobility Sys-

tem

under no circumstances replaces

perm

a-

nent

tyre repair and should only be used to

drive to the nearest official service.

The Tyre Mobility System kit shall not be

used:

● If the wheel rim has been damaged,

● when the outside temperature is below

-20 °C (-4 °F),

● on slashes or punctures larger than 4 mm,

● if the sidewall of the wheel has been dam-

aged,

● If you have been driving with very low tyre

pressure or a completely flat tyre

● If the best-before date on the air can has

expired WARNING

Read and observe the safety warnings ››› in

Introduction on page 150.

● A ty r

e filled with sealant does not have the

same performance properties as a conven-

tional tyre. 154

Page 157 of 200

Emergencies

●

Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fast cornering.

● Check the tyre pressure after 10 minutes of

driving!

● The sealant is harmful to health and must

be immediately rinsed from affected skin. For the sake of the environment

Used or out-of-date sealant must be disposed

of in line with environmental protection regu-

lations. Note

● Observe the usage instructions provided by

the snow chain manufacturer.

● A new can of sealant can be acquired from

the selection of SEAT Original Accessories.

● Change the tyre repaired using the Tyre

Mobility System as soon as possible or ask

an official service about the possibility of re-

pairing it for you. Components of the Tyre Mobility

System*

Fig. 128

Contents of the Tyre Mobility System. The Tyre Mobility System contains the follow-

ing components:

An adapter to fit and remove the valve

Sticker indicating the speed: “max. 80

km/h” or “max. 50 mph”

Flexible filling hose with cap

Compressor

Flexible tyre inflating hose

Tyre pressure gauge

Air release screw

ON/OFF button

12 V cable connector ››› page 79

Can of sealant

1 2

3

4

5

6

7

8

9

10 Spare valve

The valve extractor 1

››› Fig. 128 has a slot

in its lo

wer end that fits onto the valve insert.

This is used to remove the valve insert from

the tyre and to replace it. This is also valid for

the spare valve insert 11 .

Work prior to using the Tyre Mobility

System The following jobs must be performed before

using the Tyre Mobility System:

– If you have a flat tyre, stop the vehicle well

away from moving traffic. Stop on flat, solid

ground.

– All vehicle occupants should leave the ve-

hicle . Vehicle occupants should wait in a

s af

e place (e.g. behind the roadside crash

barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral

or move the selector lever on the automatic

g

earbox to position P.

– Apply the handbrake firmly.

– Check

whether the tyre can be repaired us-

ing the Tyre Mobility System ›››

page 154.

– If towing a trailer, unhitch it.

– Remove the Tyre Mobility System from the

boot

. »

11

155

Technical specifications

Advice

Operation

Safety

Page 173 of 200

Fuses and bulbs

Position of the bulbs››› Fig. 156Bulb function

ATurn signals: PY21W NA LL

BSide lights-brake lights: P21/5W

CSide lights: P21/5W Note

Check the condition of the seal. If damaged, a

replacement can be acquired from an Official

Service. Fitting rear light

Fig. 157

Fit the tail light unit. Fig. 158

Fit the tail light unit. –

Make sure the connector is correctly in

place.

– Press the rear light unit backwards (driving

direction) by fitting the fastenings into the

rubber mountings ››› Fig. 157 A .

– Take the screwdriver or a Torx 20 key (T20)

from the vehicle tool kit and tighten (turn-

ing clockwise ››› Fig. 158 ) the two retaining

s c

rews that secure the front of the light. Changing rear lights (in rear

lid)

Remove the bulb holder Fig. 159

Remove the cover from the boot lid.

» 171

Technical specifications

Advice

Operation

Safety