towing Seat Toledo 2014 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Toledo, Model: Seat Toledo 2014Pages: 200, PDF Size: 4.37 MB

Page 119 of 200

Towing bracket device

Description Fig. 99

Towing bracket device support for

hitching/ball-headed bar. The ball-headed bar is detachable. It is loca-

ted in the spare wheel compartment or in the

spare wheel compartment in the boot

››› page 150, Vehicle tool kit*.

Key to ››› Fig. 99

13-pin socket

Safety flange

1 2 Clamping bush

Clamping bush cap

Ball head cover

Ball-headed bar

Locking balls

Centred

Red marking on the manual regulator

Manual regulator

Key

Key slot cover

Red marking on the manual regulator

White marking on the ball-headed bar

Note

Contact an Authorised Service Partner if you

lose your key. 3

4

5

6

7

8

9

10

11

12

13

14 Placing in service position

Fig. 100

Placing in service position.

» 117Technical specifications

Advice

Operation

Safety

Page 121 of 200

Towing bracket device

Fig. 103

Placing the key slot cover. –

Remove the cap from the clamping bush 4›››

Fig. 99 by pulling downwards.

– Plac

e the ball-headed bar in the service po-

sition ››› page 117.

– Hol

d the ball-headed bar from underneath

››› Fig. 102

and push it into the clamping

bush as far as possible until you hear it

click into place ››› .

The manual regulator A

automatically turns

in the op po

site direction, adjusting to the

ball-headed bar ››› .

– Switch off the manual regulator lock with

key B by turning the key fully to the right

in the direction of arrow 1 – the arrow in

the key displays the “locked” symbol.

– Remove the key in the direction of arrow

2 .

– Place cover C over the manual regulator

lock in the direction of arrow 3

››› Fig. 103 .–

Verif

y the correct placement of the ball-

headed bar ››› page 119. WARNING

● Do not hold the manual regulator with your

hand when fitting the ball-headed bar since

you could sustain injuries to your fingers.

● When mounting the ball-headed bar, al-

ways lock it with a key and remove the key

from the slot.

● The ball-headed bar must not be in the

service position with the key in the key slot.

● If the ball-headed bar is not placed in the

service position you will not be able to place

it in the clamping bush. CAUTION

When removing the key, always place the

cover over the key slot of the manual regula-

tor to prevent dirt from entering. Note

Once removed, place the clamping bush cap

in an appropriate location in the boot. Verification of correct placement

Fig. 104

Correct placement of the ball-head-

ed bar. Before using the ball-headed bar, ensure it is

correctly fitted.

Ensure that:

● The ball-headed bar does not come out of

the clamping bush in a “jerky” manner.

● The red mark A

››› Fig. 104 on the manual

r e

gulator signals toward the white mark on

the ball-headed bar.

● The manual regulator is adjusted to the

ball-headed bar, leaving no space between

them.

● The regulator is locked and the key has

been removed.

● Cover B has been placed over the manual

regulator lock. »

119

Technical specifications

Advice

Operation

Safety

Page 122 of 200

Operation

WARNING

Only use the towing bracket device when the

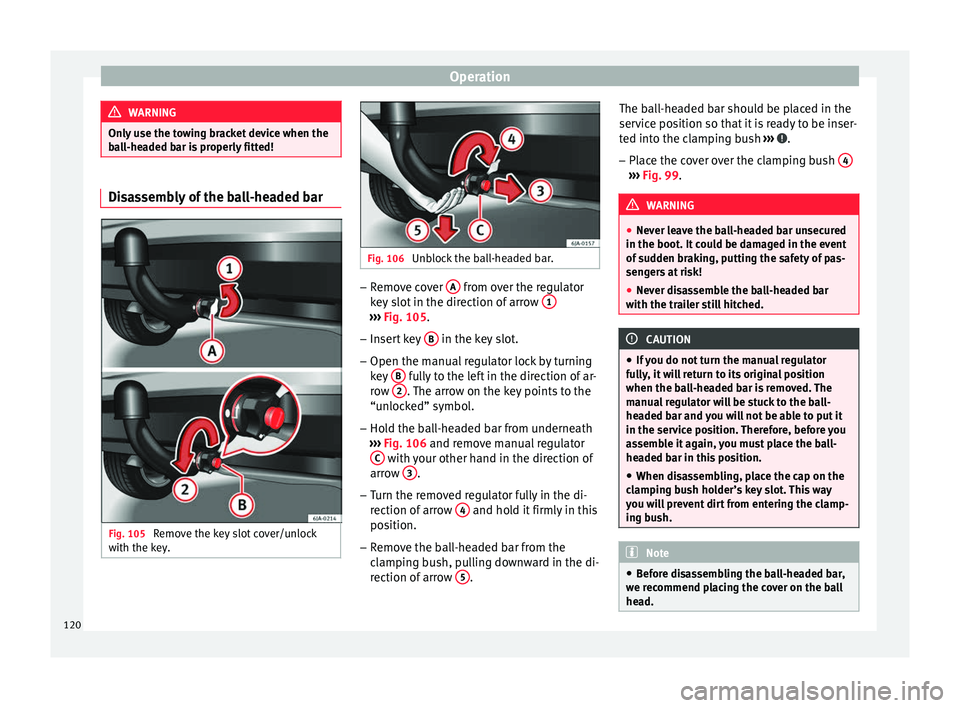

ball-headed bar is properly fitted! Disassembly of the ball-headed bar

Fig. 105

Remove the key slot cover/unlock

with the key. Fig. 106

Unblock the ball-headed bar. –

Remove cover A from over the regulator

key slot in the direction of arrow 1 ›››

Fig. 105 .

– Inser

t key B in the key slot.

– Open the manual regulator lock by turning

key B fully to the left in the direction of ar-

row 2 . The arrow on the key points to the

“unlocked” symbol.

– Hold the ball-headed bar from underneath

››› Fig. 106 and remove manual regulator

C with your other hand in the direction of

arrow 3 .

– Turn the removed regulator fully in the di-

rection of arrow 4 and hold it firmly in this

position.

– Remove the ball-headed bar from the

clamping bush, pulling downward in the di-

rection of arrow 5 .The ball-headed bar should be placed in the

service position so that it is ready to be inser-

ted into the clamping bush

››› .

– Place the cover over the clamping bush 4 ›››

Fig. 99 . WARNING

● Never leave the ball-headed bar unsecured

in the boot. It could be damaged in the event

of sudden braking, putting the safety of pas-

sengers at risk!

● Never disassemble the ball-headed bar

with the trailer still hitched. CAUTION

● If you do not turn the manual regulator

fully, it will return to its original position

when the ball-headed bar is removed. The

manual regulator will be stuck to the ball-

headed bar and you will not be able to put it

in the service position. Therefore, before you

assemble it again, you must place the ball-

headed bar in this position.

● When disassembling, place the cap on the

clamping bush holder’s key slot. This way

you will prevent dirt from entering the clamp-

ing bush. Note

● Before disassembling the ball-headed bar,

we recommend placing the cover on the ball

head. 120

Page 123 of 200

Towing bracket device

●

Clean the ball-headed bar thoroughly be-

fore returning it to the on-board toolbox. Use and maintenance

Cover the clamping bush with the cap to pre-

vent dirt from entering.

Before hooking on the trailer, check the ball

head and, if necessary, lubricate it with ade-

quate lubricant.

Place the protective cover over the ball head

when storing the bar. This way, you will avoid

getting the boot dirty.

If it gets dirty, clean and dry the clamping

bush thoroughly with an appropriate prod-

uct.

CAUTION

The top part of the clamping bush opening is

lubricated. Be careful not to remove this lu-

brication. 121Technical specifications

Advice

Operation

Safety

Page 138 of 200

Advice

● Avoid mixing this oil with other engine oils.

● Only in exceptional circumstances, if the

engine oil level is too low ››› page 136 and

you cannot obtain the oil specified for your

vehicle, you can use a small quantity of oil

(once) conforming to the VW 506 00,

VW 506 01, VW 505 00, VW 505 01 or

ACEA B3/ACEA B4 specification. (up to 0.5 l).

Oil propertiesEngine typeSpecification

Petrol without flexible

service intervalVW 502 00/VW 504 00

Petrol with flexible serv-

ice interval (LongLife)VW 504 00

Diesel. Engines without

Particulate filter (DPF)VW 505 01/VW 506 01/VW

507 00

Diesel. Particulate Filter

Engines (DPF).

With or without flexible

service interval (with

and without LongLife) a)VW 507 00

a)

Only use recommended oils, otherwise you may damage the

engine.

Engine oil additives

No type of additive should be mixed with the

engine oil. The deterioration caused by these

additives is not covered by the warranty. Note

Before a long trip, we recommend finding an

engine oil that conforms to the correspond-

ing VW specifications and recommend keep-

ing it in the vehicle. This way, the correct en-

gine oil will always be available for a top-up if

needed. Checking the engine oil level

Fig. 111

Engine oil dipsticks. The dipstick shows the engine oil level.

››› Fig. 111 .

Chec k

ing oil level

– Park the vehicle on a level surface and en-

sure the engine is at operating tempera-

ture.

– Switch the ignition off.

– Open the bonnet. –

Wait a few minutes for the engine oil to

flow back to the sump and remove the dip-

stick.

– Wipe the dipstick with a clean cloth and in-

sert it again as far as it will go.

– Then pull the dipstick out again and check

the oil level.

Oil level in area A –

Do not

t

op up oil.

Oi

l level in area B –

Oil can be topped up. After topping up the

oi l

level could be in area A .

Oil level in area C –

Oil must be topped up. After topping up,

the oil level should be in area B .

It is normal for the engine to consume a cer-

tain amount of oil. Depending on how you

drive and the conditions in which the vehicle

is used, oil consumption can be up to 0.5 li-

tres per 1,000 km. Oil consumption can also

be higher for the first 5,000 km (3000 miles).

You should therefore check the oil level at

regular intervals, ideally every time you fill

the tank or before setting off on a long trip.

When the engine is working hard, for in-

stance during sustained motorway cruising in

summer, when towing a trailer or caravan or

136

Page 152 of 200

Advice

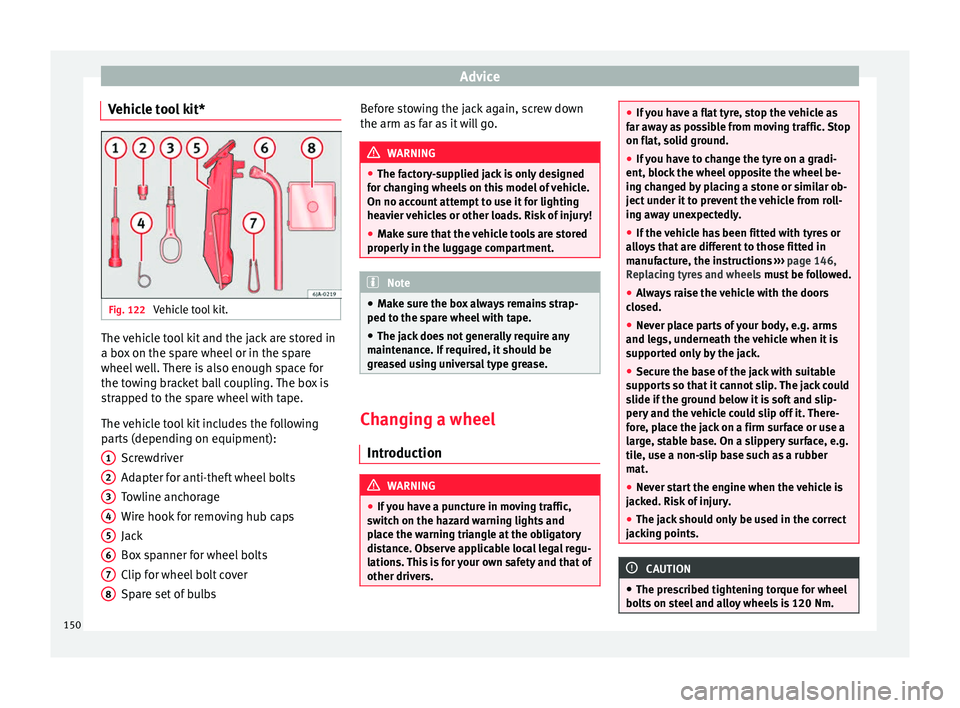

Vehicle tool kit* Fig. 122

Vehicle tool kit. The vehicle tool kit and the jack are stored in

a box on the spare wheel or in the spare

wheel well. There is also enough space for

the towing bracket ball coupling. The box is

strapped to the spare wheel with tape.

The vehicle tool kit includes the following

parts (depending on equipment):

Screwdriver

Adapter for anti-theft wheel bolts

Towline anchorage

Wire hook for removing hub caps

Jack

Box spanner for wheel bolts

Clip for wheel bolt cover

Spare set of bulbs

1 2

3

4

5

6

7

8 Before stowing the jack again, screw down

the arm as far as it will go.

WARNING

● The factory-supplied jack is only designed

for changing wheels on this model of vehicle.

On no account attempt to use it for lighting

heavier vehicles or other loads. Risk of injury!

● Make sure that the vehicle tools are stored

properly in the luggage compartment. Note

● Make sure the box always remains strap-

ped to the spare wheel with tape.

● The jack does not generally require any

maintenance. If required, it should be

greased using universal type grease. Changing a wheel

Introduction WARNING

● If you have a puncture in moving traffic,

switch on the hazard warning lights and

place the warning triangle at the obligatory

distance. Observe applicable local legal regu-

lations. This is for your own safety and that of

other drivers. ●

If you have a flat tyre, stop the vehicle as

far away as possible from moving traffic. Stop

on flat, solid ground.

● If you have to change the tyre on a gradi-

ent, block the wheel opposite the wheel be-

ing changed by placing a stone or similar ob-

ject under it to prevent the vehicle from roll-

ing away unexpectedly.

● If the vehicle has been fitted with tyres or

alloys that are different to those fitted in

manufacture, the instructions ››› page 146,

Replacing tyres and wheels must be followed.

● Always raise the vehicle with the doors

closed.

● Never place parts of your body, e.g. arms

and legs, underneath the vehicle when it is

supported only by the jack.

● Secure the base of the jack with suitable

supports so that it cannot slip. The jack could

slide if the ground below it is soft and slip-

pery and the vehicle could slip off it. There-

fore, place the jack on a firm surface or use a

large, stable base. On a slippery surface, e.g.

tile, use a non-slip base such as a rubber

mat.

● Never start the engine when the vehicle is

jacked. Risk of injury.

● The jack should only be used in the correct

jacking points. CAUTION

● The prescribed tightening torque for wheel

bolts on steel and alloy wheels is 120 Nm. 150

Page 157 of 200

Emergencies

●

Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fast cornering.

● Check the tyre pressure after 10 minutes of

driving!

● The sealant is harmful to health and must

be immediately rinsed from affected skin. For the sake of the environment

Used or out-of-date sealant must be disposed

of in line with environmental protection regu-

lations. Note

● Observe the usage instructions provided by

the snow chain manufacturer.

● A new can of sealant can be acquired from

the selection of SEAT Original Accessories.

● Change the tyre repaired using the Tyre

Mobility System as soon as possible or ask

an official service about the possibility of re-

pairing it for you. Components of the Tyre Mobility

System*

Fig. 128

Contents of the Tyre Mobility System. The Tyre Mobility System contains the follow-

ing components:

An adapter to fit and remove the valve

Sticker indicating the speed: “max. 80

km/h” or “max. 50 mph”

Flexible filling hose with cap

Compressor

Flexible tyre inflating hose

Tyre pressure gauge

Air release screw

ON/OFF button

12 V cable connector ››› page 79

Can of sealant

1 2

3

4

5

6

7

8

9

10 Spare valve

The valve extractor 1

››› Fig. 128 has a slot

in its lo

wer end that fits onto the valve insert.

This is used to remove the valve insert from

the tyre and to replace it. This is also valid for

the spare valve insert 11 .

Work prior to using the Tyre Mobility

System The following jobs must be performed before

using the Tyre Mobility System:

– If you have a flat tyre, stop the vehicle well

away from moving traffic. Stop on flat, solid

ground.

– All vehicle occupants should leave the ve-

hicle . Vehicle occupants should wait in a

s af

e place (e.g. behind the roadside crash

barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral

or move the selector lever on the automatic

g

earbox to position P.

– Apply the handbrake firmly.

– Check

whether the tyre can be repaired us-

ing the Tyre Mobility System ›››

page 154.

– If towing a trailer, unhitch it.

– Remove the Tyre Mobility System from the

boot

. »

11

155

Technical specifications

Advice

Operation

Safety

Page 161 of 200

Emergencies

on battery). Failure to comply could result in

an explosion.

●

Never use jump leads when one of the bat-

teries is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing the vehicle

Introduction Vehicles with manual gearbox can be towed

using a towbar or towrope. They can also be

towed with either the front or rear wheels lif-

ted off the road.

Vehicles with automatic gearbox can be tow-

ed using a towbar or towrope. They can also

be towed with the front wheels lifted off the

road. If the vehicle is towed with the rear

wheels lifted off the road the automatic gear-

box will be damaged!

It is safer to tow a vehicle with a

towbar. A

towrope should only be used if you do not

h av

e a towbar.

Follow the instructions below when towing a

vehicle:

Notes for the driver of the towing vehicle

– Engage the clutch very gently when starting

to move or on vehicles with automatic gear-

box press the accelerator carefully. –

On vehicles with a manual gearbox, the

towrope must be taut before driving off.

Maximum towing speed is 50 km/h (31

mph).

Note

s for the driver of the towed vehicle

– The ignition should be switched on so that

the steering wheel lock is not engaged and

the turn signals, horn and windscreen wip-

ers and washers can be used.

– Put the gear lever in neutral or move the se-

lector lever to position N (automatic gear-

bo

x).

The brake servo and power steering only

work when the engine is running. Considera-

bly more effort is required on the brake pedal

and steering wheel when the engine is

switched off.

Ensure the towrope remains taut at all times

when towing. CAUTION

● Do not tow-start the engine. Risk of engine

damage! In vehicles with a catalytic convert-

er, fuel that has not been burned could reach

the catalytic converter and catch fire in it.

This could damage and destroy the catalytic

converter. You may use the battery from an-

other vehicle to help you start your engine

››› page 158.

» 159

Technical specifications

Advice

Operation

Safety

Page 162 of 200

Advice

●

If, due to a fault, there is no oil in the gear-

box, the car may only be towed with the

driven wheels lifted clear of the road and

transported on a special vehicle transporter

or trailer.

● If normal towing is not possible or if the ve-

hicle is to be towed for further than 50 km,

the vehicle must be transported on a special

vehicle transporter or trailer.

● The towrope should be slightly elastic to

reduce the load on both vehicles during tow-

ing. It is advisable to use a towrope made of

synthetic fibre or similar material only.

● Do not pull too hard with the towing vehicle

and always take care to avoid jerking the tow-

rope. When towing on a loose surface there is

always a risk of overloading and damaging

the anchorage points.

● Attach the towrope or towbar only to the

towline anchorages or to the removable tow-

ing bracket ››› page 114, or ››› page 161. Note

● We recommend you use the towrope or tow-

bar available in the SEAT Original Accessories

programme from authorised SEAT dealers.

● Towing a vehicle requires a certain degree

of practical skill. Both drivers should be fa-

miliar with the technique required for towing.

Inexperienced drivers should not attempt to

tow away another vehicle or to have their ve-

hicle towed. ●

Note the legal regulations concerning tow-

ing, particularly those regarding the signal-

ling of the towed and towing vehicle.

● The towrope must not be twisted, as under

certain circumstances this could unscrew the

front towline anchorage. Towline anchorage

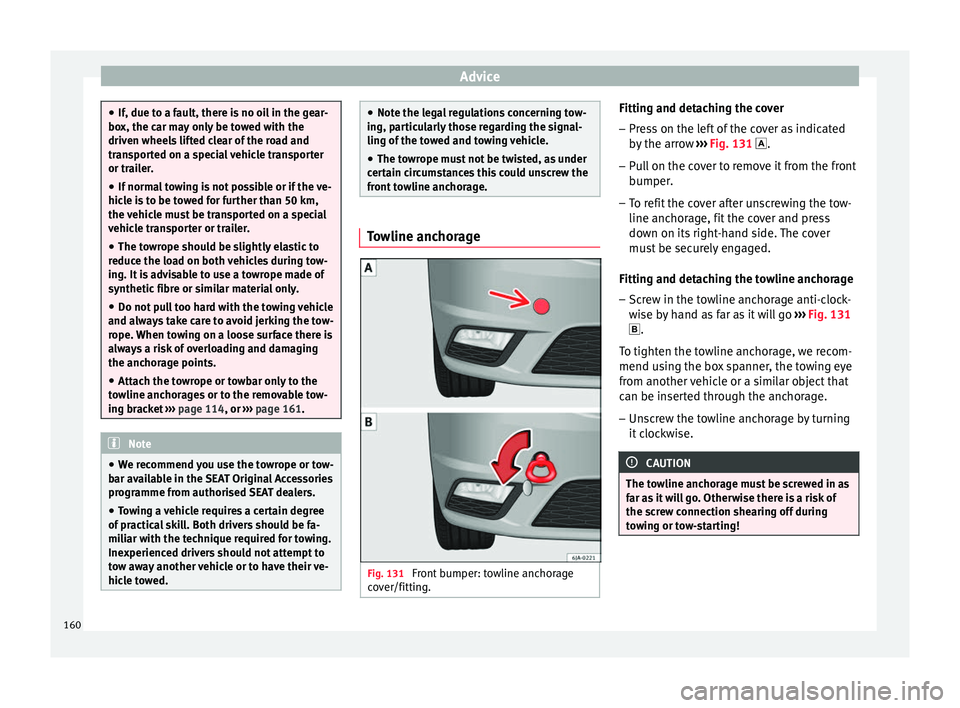

Fig. 131

Front bumper: towline anchorage

cover/fitting. Fitting and detaching the cover

– Press on the left of the cover as indicated

by the arrow ››› Fig. 131 .

– Pull on the cover to remove it from the front

bumper.

– To refit the cover after unscrewing the tow-

line anchorage, fit the cover and press

down on its right-hand side. The cover

must be securely engaged.

Fitting and detaching the towline anchorage

– Screw in the towline anchorage anti-clock-

wise by hand as far as it will go ››› Fig. 131

.

To tighten the towline anchorage, we recom-

mend using the box spanner, the towing eye

from another vehicle or a similar object that

can be inserted through the anchorage.

– Unscrew the towline anchorage by turning

it clockwise. CAUTION

The towline anchorage must be screwed in as

far as it will go. Otherwise there is a risk of

the screw connection shearing off during

towing or tow-starting! 160

Page 177 of 200

Technical specifications

Type plate

The type plate ››› Fig. 165 is located at the

bott om of

the front driver side door pillar be-

tween the front and rear doors.

The type plate indicates the following

weights:

Total permitted weight of the vehicle

when loaded

Maximum authorised weight of the vehi-

cle with a trailer, when the vehicle oper-

ates as a tractor

Maximum permitted load of the front axle

Maximum permitted load of the rear axle

Weight in running order

The weight in running order only has one ap-

proximate value. This value corresponds to

the minimum operative weight of the vehicle

without additional equipment that increases

its weight, i.e. air conditioning, spare wheel,

towing bracket.

The running order weight also includes 75 kg

of the weight of the driver and service fluids,

in addition to a fuel tank at 90% capacity.

From the difference between the total permit-

ted weight in running order the approximate

carrying capacity can be calculated ››› .

The carrying capacity must include:

● occupants,

8 9

10

11 ●

all pieces of equipment and other weights,

● roof loads including the roof rack,

● equipment that is not included in the run-

ning order weight,

● when using the towing bracket, the draw-

bar load (max. 50 kg)

Calculating fuel consumption and CO 2

emissions according to the ECE regulations

and the EU specifications

Calculation of fuel consumption for urban

driving begins when cold-starting the engine.

Then, normal city driving is simulated.

In calculating extra-urban driving fuel con-

sumption, braking and acceleration is done

in all gears, as in daily use of the vehicle.

Driving speed varies within a range of 0 and

120 km/h (75 mph).

The consumption value in combined driving

is composed of 37% of the value of urban

driving and 63% of the value of extra-urban

driving. WARNING

The maximum permitted weight values must

not be exceeded – Risk of an accident and

damage to the vehicle! Note

● If you wish to calculate the exact weight of

your vehicle please contact a SEAT dealer. ●

Depending on the volume of equipment,

driving style, road conditions, weather condi-

tions and the condition of the vehicle, con-

sumption values can differ from the theoreti-

cal values stated here. Information on fuel

consumption

Fuel consumption The consumption and emission details

shown on the vehicle data sticker differ from

one vehicle to another.

Vehicle fuel consumption and CO

2 emissions

appear on the vehicle data sticker in the

spare wheel well, inside the boot and on the

rear cover of the Maintenance Programme.

The fuel consumption and CO 2 emission val-

ues refer to the weight category assigned to

your vehicle according to the engine and

gearbox combination, as well as the specific

equipment fitted, and is only used to com-

pare between the different models.

The fuel consumption and CO 2 emissions do

not depend only on the performance of the

vehicle, they can also differ from the estab-

lished values depending on other factors

such as driving style, road conditions, traffic

conditions, environmental conditions, load

and number of passengers. »

175

Technical specifications

Advice

Operation

Safety