technical specifications Seat Toledo 2014 Manual PDF

[x] Cancel search | Manufacturer: SEAT, Model Year: 2014, Model line: Toledo, Model: Seat Toledo 2014Pages: 200, PDF Size: 4.37 MB

Page 143 of 200

Checking and refilling levels

●

Neutralize any acid splashes on the skin or

clothing with soap solution as quickly as pos-

sible and rinse off with plenty of water. If acid

is swallowed by mistake, consult a doctor im-

mediately.

● Keep children away from the battery.

● Hydrogen is released and a highly explo-

sive mixture of gases is generated when the

battery is under charge. Sparks when discon-

necting or releasing cable terminals with the

ignition switched on could also cause an ex-

plosion.

● A short circuit is produced if the battery ter-

minals are bridged, e.g. using metal objects,

cables, etc. Possible consequences of a short

circuit: melting of lead plates, battery explo-

sion and fire, splashing acid.

● The following is forbidden while working on

the battery: fire and open flames, smoking

and activities that could produce sparks.

Avoid causing sparks when handling cables

or electrical apparatus. Risk of injury in the

event of large sparks.

● Before working on the electrical system,

you must switch off the engine, the ignition

and all electrical components and disconnect

the cable from the negative terminal (-) of the

battery. To change a bulb, simply switch off

the corresponding light.

● Never charge a frozen or thawed out bat-

tery. Risk of explosion and acid burns! Re-

place a frozen battery.

● Never use the jump leads on batteries in

which the electrolyte level is too low. Risk of

explosion and acid burns! ●

Never use a damaged battery. Risk of ex-

plosion! Replace a damaged battery immedi-

ately. CAUTION

● Never disconnect the battery when the igni-

tion is switched on, as the electrical system

(electronic components) of the vehicle could

be damaged. When disconnecting the battery

from the vehicle electrical system, disconnect

its negative terminal (-) first. Only then may

the positive terminal (+) be disconnected.

● When connecting the battery, first connect

the positive terminal (+) and then the nega-

tive terminal (-). The battery cables must nev-

er be connected to the wrong battery termi-

nals. Risk of burning the electrical installa-

tion!

● Make sure the battery acid does not come

into contact with the bodywork. Risk of paint-

work damage.

● Do not expose the battery to direct sunlight

to protect it from ultraviolet radiation.

● If the vehicle is not used for 3 or 4 weeks,

the battery could run flat. This is because

some components use electricity even in

standby mode (e.g. control units). Prevent the

battery from running flat by disconnecting its

negative terminal or leave it charging at a low

current.

● If you frequently use the vehicle for short

trips, the battery may not fully charge and

could run flat. For the sake of the environment

A flat battery is particularly harmful waste for

the environment. It must therefore be dis-

posed of according to current local law. Note

Replace a battery once it is older than 5

years. Open the battery cover.

Fig. 115

Battery: Opening the cover. The battery is located beneath a plastic cover

in the engine compartment.

–

Open the battery cover in the direction indi-

cated by the arrow ›››

Fig. 115 .

– The po s

itive terminal (+) of the battery is

connected in reverse order.

141

Technical specifications

Advice

Operation

Safety

Page 145 of 200

Checking and refilling levels

CAUTION

In vehicles fitted with the “Start-Stop” sys-

tem, the charger cable cannot be directly con-

nected to the negative terminal of the vehicle

battery but must be attached to the engine

ground point ››› page 158. Disconnecting and connecting the

battery

The following functions will either be inoper-

ative or will not work properly after discon-

necting and reconnecting the battery:FunctionInstallation

Setting the clock›››

page 32

The multifunction display data

is deleted››› page 39 Note

We recommend having the vehicle checked by

an authorised SEAT dealer to guarantee the

correct working order of all electrical sys-

tems. Changing the battery

A replacement battery must have the same

capacity, voltage, current rating and size as

the original. The appropriate types of battery can be acquired from authorised SEAT deal-

ers.

We recommend having the battery changed

by an authorised SEAT dealer, where the new

battery will be correctly installed and the

original disposed of in line with regulations.

Automatic disconnection of electrical

equipment When heavily-charging a battery, the pro-

gramme selected by the electrical system

control unit prevents the battery from auto-

matically discharging. This may result in the

following:

● Increase in idling speed so that the alterna-

tor can supply more current to the electrical

system.

● The performance of certain electrical com-

ponents could be limited or some may switch

off temporarily, e.g. the heated seats, the

heated rear window, the 12 V power socket. Note

Despite any measures taken by the control

unit, the battery could drain. e.g. with the en-

gine is switched off, the key is turned in the

ignition for a long period or the side lights or

parking lights are switched on. The switching

off of certain electrical components does not

impair driving comfort and often the driver

will not even notice. 143

Technical specifications

Advice

Operation

Safety

Page 147 of 200

Wheels and tyres

indicators is given on the tyre sidewalls by

the letters “TWI”, triangular symbols or other

symbols.

The useful life of the tyres depends primarily

on the following factors:

Tyre pressure values

Under-inflation or over-inflation will consider-

ably reduce the useful life of the tyres and

impair the vehicle's handling. Therefore,

check the tyre pressure, including the spare

wheel, at least once a month and before any

long journey.

Inflation pressures for summer tyres are lis-

ted on a sticker inside the fuel tank flap. The

pressures for winter tyres are 0.2 bar (2.9

psi/20 kPa) above the summer values.

Always check the pressure when the tyre is

cold. Do not reduce over-pressure in warm

tyres. The tyre pressures must be altered to

suit notable changes in the load being car-

ried.

Driving style

Fast cornering, heavy acceleration and hard

braking all increase tyre wear.

Wheel balancing

The wheels on new vehicles are balanced.

Various factors encountered when driving

can cause them to become unbalanced, which results in vibration of the steering

wheel.

The wheel must be rebalanced if a new tyre is

fitted or if a tyre is repaired.

Incorrect wheel alignment

Incorrect front or rear wheel alignment cau-

ses excessive tyre wear, frequently on one

side, and also impairs vehicle safety. If tyre

wear is very irregular, contact an Official

Service.

Tyre damage

To avoid damage to tyres and wheels, only

drive over kerbs or similar obstacles slowly

and at a right angle if possible.

Check tyres and wheels regularly for damage

(punctures, cracks, blisters, deformities,

etc.). Remove any foreign objects embedded

in outside of the treads.

Unusual vibration or the car pulling to one

side may indicate that one of the tyres is

damaged.

Reduce speed immediately and

s t

op if you suspect that damage may have

occurred! Check the tyres for damage (blis-

ter

s, cracks, etc.). If no external damage is

visible, drive slowly and carefully to the near-

est Official Service and have the vehicle in-

spected. Interchanging tyres

Fig. 118

Interchanging tyres. Changing wheels around

If the wear is visibly greater on the front tyres,

they should be exchanged for the rear tyres

as shown in the diagram

››› Fig. 118 . All the

ty r

es will then last for about the same time.

To ensure that the wear is equal on all tyres

and maintain their optimum useful life, they

should be changed around every 10 000 km.

Storing tyres

When you remove the tyres, mark them in or-

der to maintain the same direction of rotation

when they are installed again.

When removed, the wheels and/or tyres

should be stored in a cool, dry and preferably

dark location. Store tyres in a vertical posi-

tion, if they are not fitted on wheel rims.

145

Technical specifications

Advice

Operation

Safety

Page 149 of 200

Wheels and tyres

The tyre pressure of the spare wheel must be

checked (preferably whenever the tyre pres-

sure is checked – see sticker on fuel tank flap

››› page 144 ) to ensure the spare wheel re-

m ain

s ready for use.

If the spare wheel is not the same size or de-

sign as the tyres that are mounted on the car

(for example if the car has winter tyres or

tyres with direction tread), only use the spare

tyre for a short period of time in the event of

breakdown and drive with the corresponding

care ››› .

It must be replaced as soon as possible for a

wheel with a normal size and finish.

Temporary spare wheel

If the vehicle is equipped with a temporary

spare wheel, there will be a warning sign on

the rim of the wheel.

Follow the instructions below when driving

with this wheel fitted.

● After fitting the wheel, the warning sign

must not be covered.

● Do not drive faster than 80 km/h (50 mph)

with the spare wheel and take great care

while driving. Avoid heavy acceleration, hard

braking and fast cornering.

● The tyre pressure is the same as that of the

standard tyres. ●

Only use this spare wheel to reach the

nearest Official Service, as it is not designed

for permanent use. WARNING

● Under no circumstances must damaged

spare wheels be used.

● If the spare wheel is different in size or de-

sign to the tyres currently fitted, never drive

faster than 80 km/h (50 mph). Avoid heavy

acceleration, hard braking and fast cornering. CAUTION

Follow the instructions given on the tempora-

ry spare wheel label. Note

The tyre pressure of the spare wheel must al-

ways correspond to the highest pressure pre-

scribed for the model of vehicle in question. Tyre control systems

Tyre pressure* Fig. 120

Tyre pressure adjustment switch. The tyre pressure monitoring system uses

ABS sensors to compare the revolutions and

the circumference of each wheel. Should the

circumference of any wheel change, the

warning lamp on the general dash panel

››› page 38 will light up and an audible warn-

in g w

ill be heard.

Tyre circumference may change if:

● Tyre pressure is too low

● Tyre structure is damaged

● Vehicle load not evenly distributed

● wheels on one axle are subjected to greater

load, (e.g. driving with trailer, uphill, down-

hill);

● Snow chains are fitted »

147

Technical specifications

Advice

Operation

Safety

Page 151 of 200

Emergencies

Snow chains Snow chains must only be used on the front

wheels.

In winter road conditions, snow chains not

only help to improve grip but also improve

the braking capacity.

For technical reasons snow chains may only

be used on tyres with the following wheel

rim/tyre combinations.Rim sizeRim offsetTyre size

5J x 14

a)35 mm175/70

6J x 15b)38 mm185/60

6J x 15b)38 mm195/55

a)

Only use snow chains with fine-pitch links and lock no greater

than 9 mm.

b) Only use snow chains with fine-pitch links and lock no greater

than 13 mm.

Remove the wheel trims before fitting snow

chains. CAUTION

Chains must be removed when roads are free

of snow. Otherwise they will impair handling,

damage the tyres and wear out very quickly. Emergencies

Emergency equipment First-aid kit and warning triangle* Fig. 121

Location of the warning triangle. The warning triangle, measuring max.

436 x 45 x 32 mm, can be secured to the lin-

ing on the rear of the luggage compartment

with rubber straps

››› Fig. 121. WARNING

The first-aid kit and fire extinguisher must be

properly secured so that they are not catapul-

ted through the vehicle during driving and

braking manoeuvres or in the event of an ac-

cident. Risk of injury. Note

● Observe the expiry date of the contents of

the first aid kit.

● We recommend you use the first-aid kit and

the warning triangle from the SEAT Original

Accessories programme available in author-

ised SEAT dealers. Fire extinguisher*

Read the instructions given on the fire extin-

guisher carefully.

The fire extinguisher must be checked once a

year by an authorised person (take the appli-

cable legal regulations into account).

WARNING

The fire extinguisher must be properly se-

cured so that it is not catapulted through the

vehicle, causing injuries, during driving and

braking manoeuvres or in the event of an ac-

cident. Note

● The fire extinguisher must comply with lo-

cal legal requirements.

● Observe the expiry date of the fire extin-

guisher. The fire extinguisher may not work

properly if used after the expiry date. 149

Technical specifications

Advice

Operation

Safety

Page 153 of 200

Emergencies

●

If the anti-theft wheel bolt is overly tight-

ened, this could damage the bolt and the

adapter. Note

● The set of anti-theft wheel bolts or the

adapter are available from authorised SEAT

dealers.

● Please observe the relevant local legal reg-

ulations when changing the wheel. Preparation work

Some preparation is required before chang-

ing a wheel:

– If you have a flat tyre, stop the vehicle as

far away as possible from moving traffic.

The surface must be horizontal.

– All vehicle occupants should leave the ve-

hicle . Vehicle occupants should wait in a

s af

e place, e.g. behind the roadside crash

barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral

or move the selector lever on the automatic

g

earbox to position P.

– Apply the handbrake firmly.

– If t

owing a trailer, unhitch it. –

Take the vehicle tool kit ››

› page 150 and

the spare wheel ››› page 150 out of the lug-

gage compartment.

Wheel trim Removing

– Place the hook from the vehicle tool kit on

the reinforced edge of the wheel trim.

– Insert the box spanner through the hook,

supporting it on the tyre and remove the

wheel trim.

Fitting – First press the wheel trim onto the wheel at

the cut out designed for the valve. Then

press the wheel trim on both sides in the

direction of the valve so that it fits correctly

in place around all the perimeter. CAUTION

● Press down by hand, do not hit the wheel

trim! Knocking it sharply, particularly at

points where the wheel trim has not yet been

inserted, could result in damage to the wheel

trim guiding and centring elements.

● Before fitting the trim on a steel wheel at-

tached with an anti-theft wheel bolt, make

sure the bolt is in the hole in the valve area

››› page 154, Anti-theft wheel bolts*. ●

Where trim is fitted at a later date, ensure

enough air inflow is guaranteed in order to

cool the brake system. Wheel bolt caps

Fig. 123

Pull off the wheel bolt cap. Removing

– Insert the plastic clip into the cap until the

inner retaining notches on the clips touch

the collar of the cap and then remove it

››› Fig. 123 .

Fittin g

– In

sert the caps as far as they will go over

the wheel bolts.

The wheel bolt caps are stored in a box on

the spare wheel or in the spare wheel well.

151

Technical specifications

Advice

Operation

Safety

Page 155 of 200

Emergencies

Loosening wheel bolts – Fit the box spanner as far as it will go over

the wheel bolt 1)

.

– Grip the end of the box spanner and turn

the wheel bolt about one turn anti-clock-

w i

se ››› Fig. 124.

Tightening wheel bolts – Fit the box spanner as far as it will go over

the wheel bolt 1)

.

– Grip the box spanner as close to the end as

possible and tighten the bolt firmly by turn-

ing clockwise. WARNING

The wheel bolts should only be loosened

slightly (about one turn) before raising the

vehicle with the jack. Risk of accident! Note

If the wheel bolt is very tight, it may be pos-

sible to loosen it by pushing down the end of

the box spanner carefully with your foot. Hold

on to the vehicle for support and take care

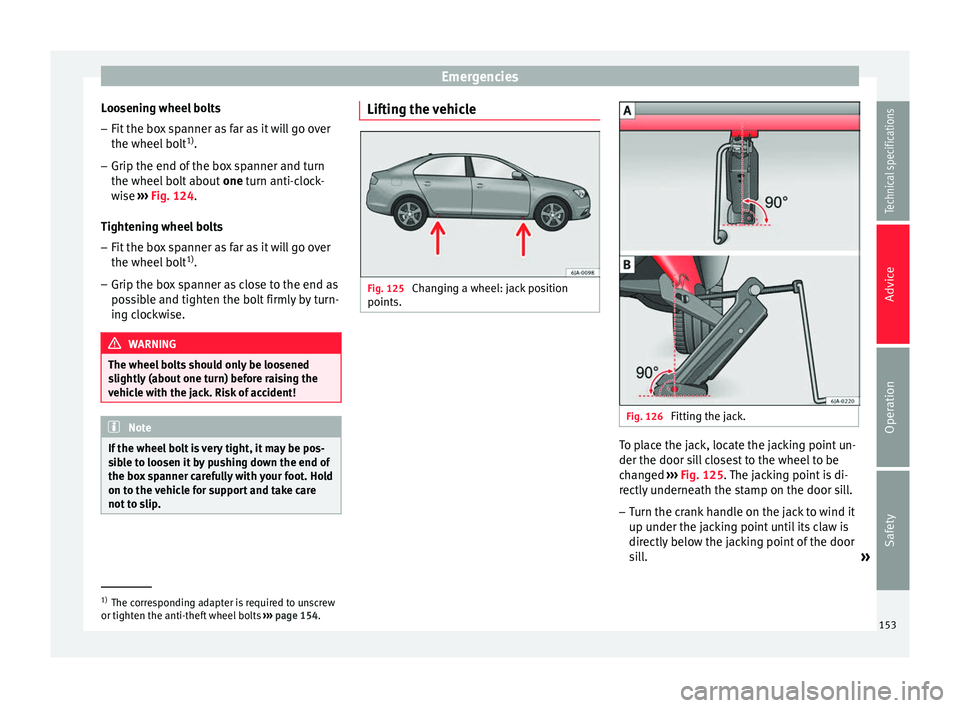

not to slip. Lifting the vehicle

Fig. 125

Changing a wheel: jack position

points. Fig. 126

Fitting the jack. To place the jack, locate the jacking point un-

der the door sill closest to the wheel to be

changed

››› Fig. 125 . The jacking point is di-

r ectly

underneath the stamp on the door sill.

– Turn the crank handle on the jack to wind it

up under the jacking point until its claw is

directly below the jacking point of the door

sill.

»1)

The corresponding adapter is required to unscrew

or tighten the anti-theft wheel bolts ››› page 154.

153

Technical specifications

Advice

Operation

Safety

Page 157 of 200

Emergencies

●

Do not drive faster than 80 km/h (50 mph).

● Avoid heavy acceleration, hard braking and

fast cornering.

● Check the tyre pressure after 10 minutes of

driving!

● The sealant is harmful to health and must

be immediately rinsed from affected skin. For the sake of the environment

Used or out-of-date sealant must be disposed

of in line with environmental protection regu-

lations. Note

● Observe the usage instructions provided by

the snow chain manufacturer.

● A new can of sealant can be acquired from

the selection of SEAT Original Accessories.

● Change the tyre repaired using the Tyre

Mobility System as soon as possible or ask

an official service about the possibility of re-

pairing it for you. Components of the Tyre Mobility

System*

Fig. 128

Contents of the Tyre Mobility System. The Tyre Mobility System contains the follow-

ing components:

An adapter to fit and remove the valve

Sticker indicating the speed: “max. 80

km/h” or “max. 50 mph”

Flexible filling hose with cap

Compressor

Flexible tyre inflating hose

Tyre pressure gauge

Air release screw

ON/OFF button

12 V cable connector ››› page 79

Can of sealant

1 2

3

4

5

6

7

8

9

10 Spare valve

The valve extractor 1

››› Fig. 128 has a slot

in its lo

wer end that fits onto the valve insert.

This is used to remove the valve insert from

the tyre and to replace it. This is also valid for

the spare valve insert 11 .

Work prior to using the Tyre Mobility

System The following jobs must be performed before

using the Tyre Mobility System:

– If you have a flat tyre, stop the vehicle well

away from moving traffic. Stop on flat, solid

ground.

– All vehicle occupants should leave the ve-

hicle . Vehicle occupants should wait in a

s af

e place (e.g. behind the roadside crash

barrier) while the wheel is being changed.

– Switch off the ignition and engage neutral

or move the selector lever on the automatic

g

earbox to position P.

– Apply the handbrake firmly.

– Check

whether the tyre can be repaired us-

ing the Tyre Mobility System ›››

page 154.

– If towing a trailer, unhitch it.

– Remove the Tyre Mobility System from the

boot

. »

11

155

Technical specifications

Advice

Operation

Safety

Page 159 of 200

Emergencies

Check after 10 minutes of driving Check the tyre pressure after 10 minutes of

driving!

If the tyre pressure is less than 1.3 bar

(18.8 psi/130 kPa):

– Do not drive on! The tyr e cannot be suffi-

ciently filled using the tyre repair kit.

– See professional assistance.

If the tyre pressure is greater than 1.3 bar

(18.8 psi/130 kPa): – Correct the tyre pressure again to the cor-

rect value (see inside of the fuel tank flap).

– Carefully drive to the nearest specialised

workshop at a maximum speed of 80 km/h

(50 mph).

Jump-starting Introduction If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine. Suitable jump leads are required.

Both batteries need to have nominal voltage

of 12 V. The

capacity (Ah) of the back-up bat- t

er

y should not be notably less than the

drained battery.

Jump leads

The jump leads must be heavy enough to car-

ry the starter current and must be fitted with

insulated battery clamps. Refer to the instruc-

tions given by the manufacturer.

Positive cable – usually red

Neg

ative cable

– usually black WARNING

● A flat battery can also freeze at tempera-

tures slightly below to 0 °C (32 °F). Do not at-

tempt to start the vehicle with a frozen bat-

tery. Risk of explosion!

● Please note the safety warnings referring to

working in the engine compartment

››› page 132.

● The non-in s

ulated parts of the battery

clamps must not be allowed to touch. Addi-

tionally, the jump lead attached to the posi-

tive battery terminal must not touch metal

parts of the vehicle. Risk of short circuit!

● Do not connect the negative lead to the

negative terminal of the discharged battery.

In the event of sparks when starting the en-

gine, the explosive gas given off by the bat-

tery could catch fire.

● Position the jump leads in such a way that

they cannot come into contact with any mov-

ing parts in the engine compartment. ●

Do not bend over the battery. Risk of acid

burns!

● The screw plugs on the battery cells must

be screwed in firmly.

● Keep sources of fire (flames, lit cigarettes,

etc.) away from the battery. - Risk of explo-

sion!

● Never use the jump leads on batteries in

which the electrolyte level is too low. Risk of

explosion and acid burns. Note

● The vehicles must not touch each other, as

electricity could flow as soon as the positive

terminals are connected.

● The discharged battery must be properly

connected to the vehicle electrical system.

● The jump leads should be checked in a spe-

cialist vehicle battery shop. 157

Technical specifications

Advice

Operation

Safety

Page 161 of 200

Emergencies

on battery). Failure to comply could result in

an explosion.

●

Never use jump leads when one of the bat-

teries is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

away from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufacturer of the jump leads.

● Do not connect the negative cable from the

other vehicle directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Do not attach the negative cable from the

other vehicle to parts of the fuel system or to

the brake line.

● The non-insulated parts of the battery

clamps must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot come into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult in chemical burns. Note

The vehicles must not touch each other, oth-

erwise electricity could flow as soon as the

positive terminals are connected. Towing the vehicle

Introduction Vehicles with manual gearbox can be towed

using a towbar or towrope. They can also be

towed with either the front or rear wheels lif-

ted off the road.

Vehicles with automatic gearbox can be tow-

ed using a towbar or towrope. They can also

be towed with the front wheels lifted off the

road. If the vehicle is towed with the rear

wheels lifted off the road the automatic gear-

box will be damaged!

It is safer to tow a vehicle with a

towbar. A

towrope should only be used if you do not

h av

e a towbar.

Follow the instructions below when towing a

vehicle:

Notes for the driver of the towing vehicle

– Engage the clutch very gently when starting

to move or on vehicles with automatic gear-

box press the accelerator carefully. –

On vehicles with a manual gearbox, the

towrope must be taut before driving off.

Maximum towing speed is 50 km/h (31

mph).

Note

s for the driver of the towed vehicle

– The ignition should be switched on so that

the steering wheel lock is not engaged and

the turn signals, horn and windscreen wip-

ers and washers can be used.

– Put the gear lever in neutral or move the se-

lector lever to position N (automatic gear-

bo

x).

The brake servo and power steering only

work when the engine is running. Considera-

bly more effort is required on the brake pedal

and steering wheel when the engine is

switched off.

Ensure the towrope remains taut at all times

when towing. CAUTION

● Do not tow-start the engine. Risk of engine

damage! In vehicles with a catalytic convert-

er, fuel that has not been burned could reach

the catalytic converter and catch fire in it.

This could damage and destroy the catalytic

converter. You may use the battery from an-

other vehicle to help you start your engine

››› page 158.

» 159

Technical specifications

Advice

Operation

Safety