engine Seat Toledo 2017 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Toledo, Model: Seat Toledo 2017Pages: 248, PDF Size: 5.86 MB

Page 43 of 248

The essentials

Oil Fig. 50

Engine oil dipstick. Fig. 51

In the engine compartment: Engine

oil fi

ller cap. The level is measured using the dipstick loca-

t

ed in the en

gine c

ompartment

››› page 207.

The oil should leave a mark between zones A and

C . It should never exceed zone

A .

● Zone A : Do not add oil.

● Zone B : You can add oil but keep the level

in th at

zone. ●

Zone C : Add oil up to zone

B .

T op

pin

g up engine oil

● Unscrew cap from engine oil filler opening

›››

Fig. 51.

● Add oil slowly.

● At the same time, check the level to ensure

you do not a

dd too much. ●

When the oil l

evel reaches at least zone B ,

u n

s

crew the engine oil filler cap carefully.

Engine oil additives

No type of additive should be mixed with the

engine oil. The deterioration caused by these

additives is not covered by the warranty. » 41

Page 44 of 248

The essentials

Engine oil specificationsService intervalEngine typeSpecification

Petrol engines with Set Service Intervals (dependent on

time/distance travelled)1.0l / 1.4lVW 504 00

1.6lVW 502 00 a)

Petrol engines with Flexible Service Intervals (LongLife)1.0l / 1.4lVW 508 00

VW 504 00b)

Diesel engines with Set Service and Flexible Service In-

tervalsc)With particulate filter (DPF)VW 507 00

a)

If the quality of the fuel available in the country does not fulfil the EN 228 (for petrol) and EN 590 (for diesel) standards.

b) Use of engine oil compliant with the VW 504 00 specification instead of VW 508 00 may have a slight negative effect on the vehicle’s exhaust gas values.

c) Only use recommended oils, otherwise you may damage the engine.

››› page 207 Coolant

Fig. 52

Engine compartment: coolant expan-

s ion t

ank

cap. The coolant tank is located in the engine

c

omp

ar

tment ›››

page 207.

When the engine is cold, replace the coolant

when the level is below .

Coolant specifications

The engine cooling system is supplied from

the factory with a specially treated mixture of

water and at least 40 % of the additive G13

(TL-VW 774 J), purple. This mixture gives the

necessary frost protection down to -25°C

(-13°F) and protects the light alloy parts of

the engine cooling system against corrosion.

It also prevents scaling and considerably rai-

ses the boiling point of the coolant.

To protect the cooling system, the percentage

of additive must always be at least 40 %, even in warm climates where anti-freeze pro-

tection is

not required.

If for weather reasons further protection is

necessary, the proportion of additive may be

increased, but only up to 60 %; otherwise an-

tifreeze protection will diminish and this will

worsen cooling.

When the coolant is topped up, use a mixture

of distilled water and at least 40 % of the

G13 or G12 plus-plus (TL-VW 774 G) additive

(both are purple) to obtain optimal anti-corro-

sion protection. The mixture of G13 with G12

plus (TL-VW 774 F), G12 (red) or G11 (green-

blue) engine coolants will significantly re-

duce anti-corrosion protection and should

therefore be avoided. 42

Page 45 of 248

The essentials

››› in Topping up the coolant level on

page 211

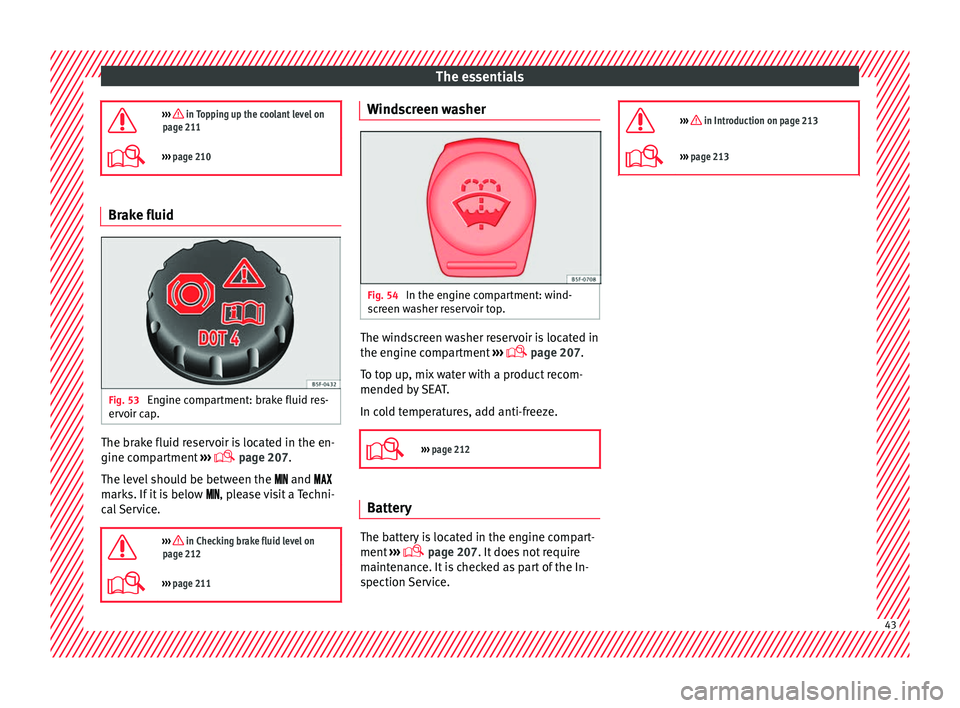

››› page 210 Brake fluid

Fig. 53

Engine compartment: brake fluid res-

er v

oir c

ap. The brake fluid reservoir is located in the en-

gine c

omp

ar

tment ›››

page 207

.

The level should be between the and

marks. If it is below , please visit a Techni-

cal Service.

››› in Checking brake fluid level on

page 212

››› page 211 Windscreen washer

Fig. 54

In the engine compartment: wind-

s c

r

een washer reservoir top. The windscreen washer reservoir is located in

the en

gine c

omp

artment ›››

page 207.

To top up, mix water with a product recom-

mended by SEAT.

In cold temperatures, add anti-freeze.

››› page 212 Battery

The battery is located in the engine compart-

ment

›

›

› page 207. It does not require

maintenance. It is checked as part of the In-

spection Service.

››› in Introduction on page 213

›››

page 213 43

Page 46 of 248

The essentials

Emergencies F u

se

s

Fuse location Fig. 55

On the driver-side dash panel: fuse

bo x

c

over. Fig. 56

In the engine compartment: fuse box

c o

v

er. Underneath the instrument panel

● Carefully tilt the cover in the direction indi-

c at ed b

y the arrow and remove it ››› Fig. 55.

● After changing the fuse, replace the cover

on the dash p

anel in the direction opposite

that is indicated by the arrow so that the cov-

er tabs fit into the slots on the dash panel.

Subsequently, press down on the cover to

close.

In the engine compartment

Press the locking tabs to release the fuse box

cover ››› Fig. 56.

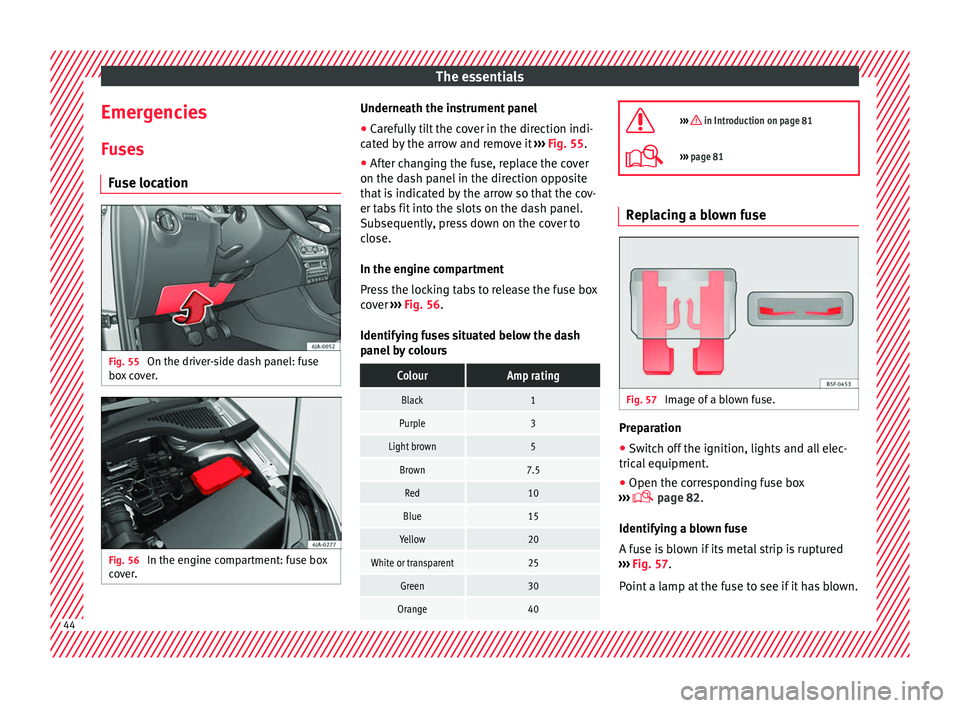

Identifying fuses situated below the dash

panel by colours

ColourAmp rating

Black1

Purple3

Light brown5

Brown7.5

Red10

Blue15

Yellow20

White or transparent25

Green30

Orange40

››› in Introduction on page 81

›››

page 81 Replacing a blown fuse

Fig. 57

Image of a blown fuse. Preparation

●

Switch off the ignition, lights and all elec-

tric al

equipment

.

● Open the corresponding fuse box

›››

page 82.

Identifying a blown fuse

A fuse is blown if its metal strip is ruptured

››› Fig. 57.

Point a lamp at the fuse to see if it has blown. 44

Page 48 of 248

The essentials

Repairing a tyre with the anti-punc-

t ur

e k

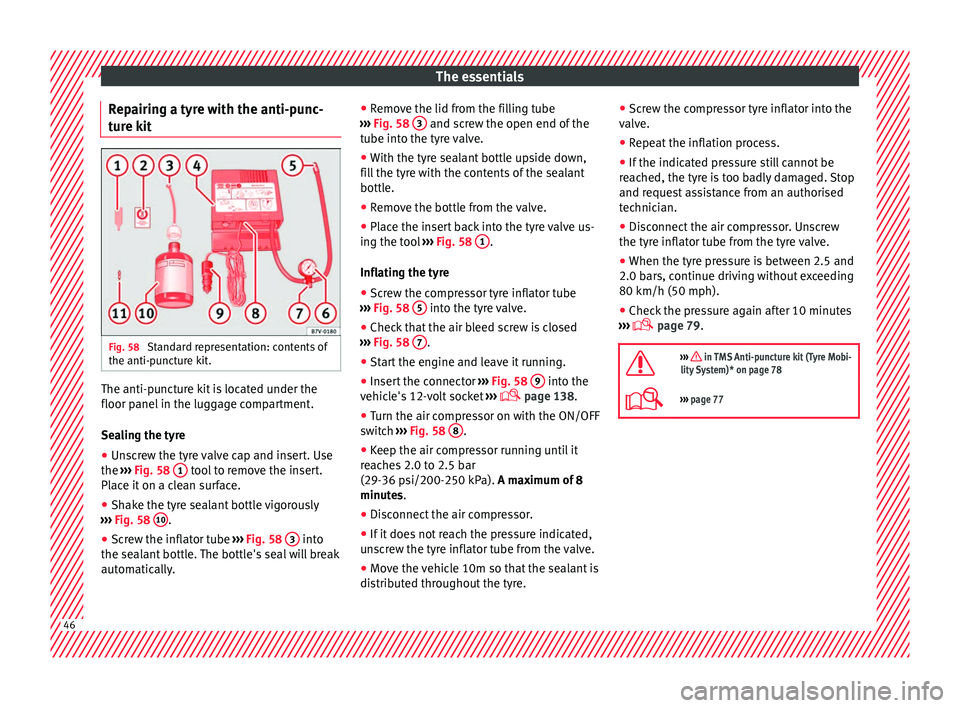

it Fig. 58

Standard representation: contents of

the anti-p u

nct

ure kit. The anti-puncture kit is located under the

floor p

anel

in the lug

gage compartment.

Sealing the tyre

● Unscrew the tyre valve cap and insert. Use

the ›››

Fig. 58 1 tool to remove the insert.

Pl ac

e it

on a clean surface.

● Shake the tyre sealant bottle vigorously

›››

Fig. 58 10 .

● Screw the inflator tube ››

›

Fig. 58 3 into

the se al

ant

bottle. The bottle's seal will break

automatically. ●

Remov

e the lid from the filling tube

››› Fig. 58 3 and screw the open end of the

t ube int

o the ty

re valve.

● With the tyre sealant bottle upside down,

fill

the tyre with the contents of the sealant

bottle.

● Remove the bottle from the valve.

● Place the insert back into the tyre valve us-

ing the too

l ››› Fig. 58 1 .

Infl atin

g the ty

re

● Screw the compressor tyre inflator tube

›››

Fig. 58 5 into the tyre valve.

● Check that the air bleed screw is closed

› ›

›

Fig. 58 7 .

● Start the engine and leave it running.

● Insert the connector ››

›

Fig. 58 9 into the

v ehic

l

e's 12-volt socket ›››

page 138.

● Turn the air compressor on with the ON/OFF

switc

h ››› Fig. 58 8 .

● Keep the air compressor running until it

r e

ac

hes 2.0 to 2.5 bar

(29-36 psi/200-250 kPa). A maximum of 8

minutes.

● Disconnect the air compressor.

● If it does not reach the pressure indicated,

uns

crew the tyre inflator tube from the valve.

● Move the vehicle 10m so that the sealant is

dis trib

uted throughout the tyre. ●

Scr ew the c

ompressor tyre inflator into the

valve.

● Repeat the inflation process.

● If the indicated pressure still cannot be

reac

hed, the tyre is too badly damaged. Stop

and request assistance from an authorised

technician.

● Disconnect the air compressor. Unscrew

the tyre infl

ator tube from the tyre valve.

● When the tyre pressure is between 2.5 and

2.0 bars, c

ontinue driving without exceeding

80 km/h (50 mph).

● Check the pressure again after 10 minutes

›››

page 79.

››› in TMS Anti-puncture kit (Tyre Mobi-

lity System)* on page 78

››› page 77 46

Page 54 of 248

The essentials

Notes for the driver of the towing vehicle

● The tow rope must be taut before you drive

off .

● Rel

ease the clutch very carefully when start-

ing the v

ehicle (manual gearbox), or acceler-

ate gently (automatic gearbox).

Driving style

Towing requires some experience, especially

when using a tow rope. Both drivers should

realise how difficult it is to tow a vehicle. In-

experienced drivers should not attempt to

tow.

Do not pull too hard with the towing vehicle

and take care to avoid jerking the tow rope.

When towing on an unpaved road, there is al-

ways a risk of overloading and damaging the

anchorage points.

The towline anchorages are located under

the floor panel in the luggage compartment.

Switch on the ignition so that the turn sig-

nals, windscreen wipers and windscreen

washer can work. Ensure that the steering

wheel is unlocked and moves freely.

Place the gear lever in neutral on vehicles

with a manual gearbox. With an automatic

gearbox, place the lever in N.

To brake, press the brake pedal firmly. The

brake servo does not work when the engine

is switched off. The power steering only works when the igni-

tion is sw

itched on and the vehicle is moving,

provided that the battery is sufficiently charg-

ed. Otherwise, it will need more force.

Ensure that the tow rope remains taut at all

times.

››› page 79 Tow-starting

If the engine will not start, first try starting it

u

s

in

g the battery of another vehicle

››› page 52. You should only attempt to tow-

start a vehicle if charging the battery does

not work. This is done by leveraging wheel

movement.

When tow-starting a vehicle with a petrol en-

gine, do not tow it more than a short dis-

tance, otherwise unburned fuel can enter the

catalytic converter.

● Engage 2nd or 3rd gear before moving off.

● Press the clutch and hold the pedal down.

● Switch the ignition on.

● Once both vehicles are moving, release the

clutc

h.

● As soon as the engine has started, press

the clutc

h and move the gear lever to neutral. How to jump start

Jump lea

ds The jump lead must have a sufficient wire

cr

o

ss section.

If the engine fails to start because of a dis-

charged battery, the battery can be connec-

ted to the battery of another vehicle to start

the engine.

Both batteries need to have nominal voltage

of 12 V. The capacity (Ah) of the back-up bat-

tery should not be notably less than the

drained battery.

Jump leads must comply with standard DIN

72553 (see cable manufacturer's instruc-

tions). The wire cross section must be at least

25 mm 2

for petrol engines and at least

35 mm 2

for diesel engines.

Jump leads

Positive cable – usually red

Negative cable – usually black WARNING

● A flat b

attery can also freeze at tempera-

tures slightly below 0°C (+32°F). Do not at-

tempt to start the vehicle with a frozen bat-

tery. Risk of explosion! 52

Page 55 of 248

The essentials

●

Ple a

se note the safety warnings referring to

working in the engine compartment

››› page 204.

● The non-insulated parts of the battery

clamp

s must not be allowed to touch. Addi-

tionally, the jump lead attached to the posi-

tive battery terminal must not touch metal

parts of the vehicle. Risk of short circuit!

● Do not connect the negative lead to the

negativ

e terminal of the discharged battery.

In the event of sparks when starting the en-

gine, the explosive gas given off by the bat-

tery could catch fire.

● Position the jump leads in such a way that

they cannot

come into contact with any mov-

ing parts in the engine compartment.

● Do not bend over the battery. Risk of acid

burns!

● The s

crew plugs on the battery cells must

be scr

ewed in firmly.

● Keep sources of fire (flames, lit cigarettes,

etc.) a

way from the battery. - Risk of explo-

sion!

● Never use the jump leads on batteries in

which the electr

olyte level is too low. Risk of

explosion and acid burns. Note

● The v ehic

les must not touch each other, as

electricity could flow as soon as the positive

terminals are connected. ●

The dis c

harged battery must be properly

connected to the vehicle electrical system.

● The jump leads should be checked in a spe-

cia

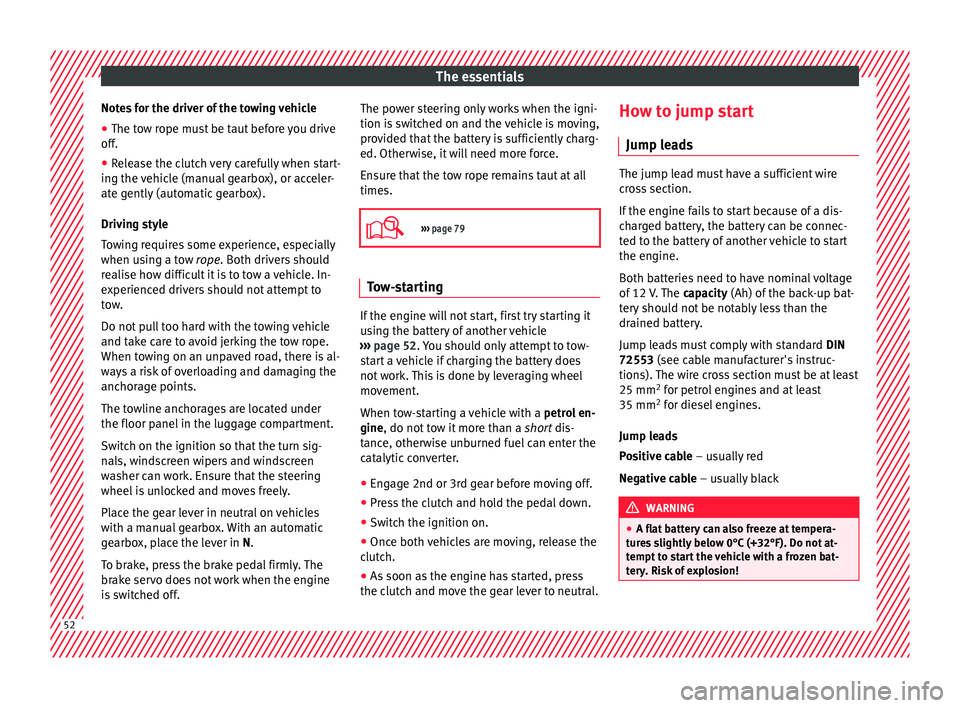

list vehicle battery shop. How to jump start: description

Fig. 68

Diagram of connections for vehicles

w ithout

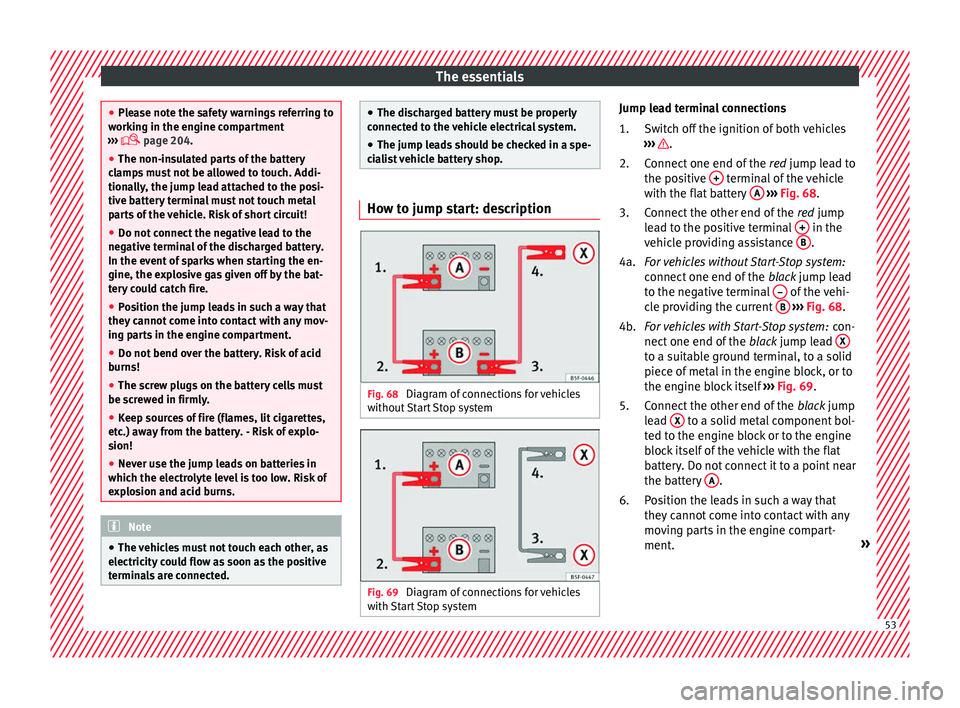

Start Stop system Fig. 69

Diagram of connections for vehicles

w ith

St

art Stop system Jump lead terminal connections

Switc

h off the ignition of both vehicles

››› .

C onnect

one end of

the red jump lead to

the positive + terminal of the vehicle

w ith the fl

at

battery A

› ››

Fig. 68

.

C

onnect the other end of the red jump

lead to the positive terminal + in the

v ehic

l

e providing assistance B .

F or

vehicles without Start-Stop system:

connect one end of the black jump lead

to the negative terminal – of the vehi-

c l

e pr

oviding the current B

› ›

› Fig. 68 .

For vehicles with Start-Stop system: con-

nect one end of the black jump lead X to a suitable ground terminal, to a solid

piec

e of

met

al in the engine block, or to

the engine block itself ››› Fig. 69.

Connect the other end of the black jump

lead X to a solid metal component bol-

t ed t

o the en

gine block or to the engine

block itself of the vehicle with the flat

battery. Do not connect it to a point near

the battery A .

P o

s

ition the leads in such a way that

they cannot come into contact with any

moving parts in the engine compart-

ment. »

1.

2.

3.

4a.

4b.

5.

6.

53

Page 56 of 248

The essentials

Starting Star

t

the engine of the vehicle with the

boosting battery and let it run at idling

speed.

Start the engine of the vehicle with the

flat battery and wait for 2 or 3 minutes

until the engine is running.

Removing the jump leads Before you remove the jump leads,

switch off the dipped beam headlights if

they are switched on.

Turn on the heater blower and heated

rear window in the vehicle with the flat

battery. This helps minimise voltage

peaks which are generated when the

leads are disconnected.

When the engine is running, disconnect

the leads in reverse order to the details

given above.

Make sure the battery clamps have sufficient

metal-to-metal contact with the battery termi-

nals.

If the engine fails to start after about 10 sec-

onds, switch off the starter and try again after

about 1 minute. WARNING

● Ple a

se note the safety warnings referring to

working in the engine compartment

››› page 204. 7.

8.

9.

10.

11. ●

The batt er

y providing assistance must have

the same voltage as the flat battery (12V) and

approximately the same capacity (see imprint

on battery). Failure to comply could result in

an explosion.

● Never use jump leads when one of the bat-

teries

is frozen. Danger of explosion! Even af-

ter the battery has thawed, battery acid could

leak and cause chemical burns. If a battery

freezes, it should be replaced.

● Keep sparks, flames and lighted cigarettes

awa

y from batteries, danger of explosion.

Failure to comply could result in an explo-

sion.

● Observe the instructions provided by the

manufact

urer of the jump leads.

● Do not connect the negative cable from the

other vehic

le directly to the negative terminal

of the flat battery. The gas emitted from the

battery could be ignited by sparks. Danger of

explosion.

● Never attach the negative cable to fuel sys-

tem component

s or the brake lines in the oth-

er vehicle.

● The non-insulated parts of the battery

clamp

s must not be allowed to touch. The

jump lead attached to the positive battery

terminal must not touch metal parts of the ve-

hicle, this can cause a short circuit.

● Position the leads in such a way that they

cannot c

ome into contact with any moving

parts in the engine compartment.

● Do not lean on the batteries. This could re-

sult

in chemical burns. Note

The vehicles must not touch each other, oth-

erw i

se electricity could flow as soon as the

positive terminals are connected. Changing the windscreen wiper

bl

a

des

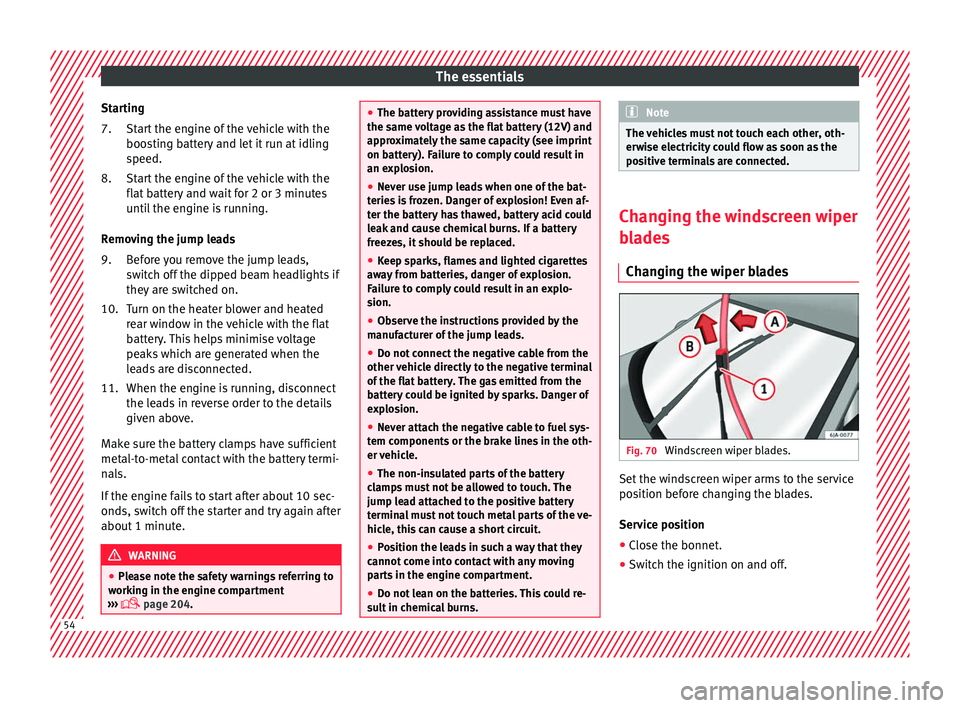

Changing the wiper blades Fig. 70

Windscreen wiper blades. Set the windscreen wiper arms to the service

po

s

ition bef

ore changing the blades.

Service position

● Close the bonnet.

● Switch the ignition on and off. 54

Page 71 of 248

Airbag system

frontal collision the system might not trigger

corr

ectly

or may fail to trigger at all. Airbag activation

The airbags deploy extremely rapidly, within

thous

andths

of a second, to provide addi-

tional protection in the event of an accident.

A fine dust may develop when the airbag de-

ploys. This is normal and it is not an indica-

tion of fire in the vehicle.

The airbag system is only ready to function

when the ignition is on.

In special accidents instances, several air-

bags may activate at the same time.

In the event of minor head-on and side colli-

sions, rear-end collisions, overturning or roll-

over of the vehicle, airbags do not activate.

Activation factors

The conditions that lead to the airbag system

activating in each situation cannot be gener-

alised. Some factors play an important role,

such as the properties of the object the vehi-

cle hits (hard/soft), angle of impact, vehicle

speed, etc.

Deceleration trajectory is key for airbag acti-

vation. The control unit analyses the collision trajec-

tor

y

and activates the respective restraint

system.

If the deceleration rate is below the prede-

fined reference value in the control unit the

airbags will not be triggered, even though

the accident may cause extensive damage to

the car.

The following airbags are triggered in seri-

ous head-on collisions:

● Driver airbag.

● Front passenger front airbag

The fol

lowing airbags are triggered in seri-

ous side-on collisions:

● Front side airbag on the side of the acci-

dent.

● Re

ar side airbag on the side of the acci-

dent.

● Cur

tain (head) airbag on the side of the ac-

cident.

In an ac

cident with airbag activation:

● the interior lights switch on (if the interior

light swit

ch is in the courtesy light position);

● the hazard warning lights switch on;

● all doors are unlocked;

● the fuel supply to the engine is cut. Airbag and seat belt tensioner control

lamp The control lamp monitors all airbags and

seat

belt

tensioners in the vehicle, including

control units and wiring connections.

Monitoring of airbag and belt tensioner sys-

tem

Both the airbag and belt tensioner systems

operation is constantly monitored electroni-

cally. Each time the ignition is switched on,

the control lamp illuminates for several

seconds (self-diagnosis) and the instrument

panel display* shows AIRBAG/TENSIONER.

The system must be checked when the con-

trol lamp :

● does not light up when the ignition is

swit c

hed on,

● turns off after 4 seconds after the ignition

is sw

itched on,

● turns off and then lights up again after the

ignition is sw

itched on,

● illuminates or flashes while the vehicle is

movin

g.

In the event of a malfunction, the warning

lamp stays on continuously. In addition, de-

pending on the malfunction, a fault message

appears on the instrument panel display for

approximately 10 seconds and a short audi-

ble warning is given. In this event, you »

69

Technical data

Advice

Operation

Emergencies

Safety

Page 79 of 248

Self-help

distance. Observe applicable local legal regu-

lation

s.

This is for your own safety and that of

other drivers.

● If you have a flat tyre, stop the vehicle as

far aw

ay as possible from moving traffic. Stop

on flat, solid ground.

● If you have to change the tyre on a gradi-

ent, block

the wheel opposite the wheel be-

ing changed by placing a stone or similar ob-

ject under it to prevent the vehicle from roll-

ing away unexpectedly.

● If the vehicle has been fitted with tyres or

allo

ys that are different to those fitted in

manufacture, the instructions ››› page 219,

New tyres or wheels must be followed.

● Always raise the vehicle with the doors

closed.

● Nev

er place parts of your body, e.g. arms

and leg

s, underneath the vehicle when it is

supported only by the jack.

● Secure the base of the jack with suitable

suppor

ts so that it cannot slip. The jack could

slide if the ground below it is soft and slip-

pery and the vehicle could slip off it. There-

fore, place the jack on a firm surface or use a

large, stable base. On a slippery surface, e.g.

tile, use a non-slip base such as a rubber

mat.

● Never start the engine when the vehicle is

jack

ed. Risk of injury.

● The jack should only be used in the correct

jack

ing points. CAUTION

● The pre s

cribed tightening torque for wheel

bolts on steel and alloy wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tight-

ened, this c

ould damage the bolt and the

adapter. Note

● The set of anti-thef

t wheel bolts or the

adapter are available from authorised SEAT

dealers.

● Please observe the relevant local legal reg-

ulation

s when changing the wheel. Wheel bolts

The wheel

bolts

ar

e m

atched to the rims.

When installing different wheels, e.g. to fit

light alloy wheels or wheels with winter tyres,

it is important to use the correct wheel bolts

with the right length and correctly shaped

bolt heads. This is essential for a secure fit of

the wheels and for proper operation of the

brake system. Note

● Never gr e

ase or oil the wheel bolts!

● If the wheel bolt is very tight, it may be

poss

ible to loosen it by pushing down the

end of the box spanner carefully with your foot. Hold on to the vehicle for support and

tak

e c

are not to slip.

● If you notice that the wheel bolts are rusty

and difficult

to turn when changing a wheel,

they must be replaced before having the

tightening torque checked. Tyre repairs

TMS Anti-p

uncture kit (Tyre Mobility

System)* Read the additional information carefully

› ›

›

page 46

The Tyre Mobility System is stored in a box

under the carpet in the boot.

Using the Tyre Mobility System you can relia-

bly seal tyres damaged by foreign bodies,

provided that cuts or punctures are no larger

than approx. 4 mm in diameter. Do not re-

move the foreign bodies, e.g. bolts or nails,

from the tyre!

The tyre must be repaired immediately.

The repair made using the Tyre Mobility Sys-

tem under no circumstances replaces perma-

nent tyre repair and should only be used to

drive to the nearest official service. »

77

Technical data

Advice

Operation

Emergencies

Safety