technical data Seat Toledo 2017 User Guide

[x] Cancel search | Manufacturer: SEAT, Model Year: 2017, Model line: Toledo, Model: Seat Toledo 2017Pages: 248, PDF Size: 5.86 MB

Page 75 of 248

Transporting children safely

Read the additional information carefully

› ›

›

page 14.

The switch disables only the front passenger

front airbag.

Switching on the airbag

– Switch the ignition off.

– Open the passenger side storage compart-

ment.

– Inser

t the key into the slot of the switch for

deactivatin

g the front passenger airbag

››› Fig. 82. About 3/4 of the key should en-

ter, as far as it will go.

– Then turn the key gently to the position.

Do not

force it if you feel resistance, and

make sure you have inserted the key fully.

– Close the passenger side storage compart-

ment.

– Check, w

ith the ignition switched on, that

the contro

l lamp does not illuminate,

with the words in the

centre of the dash panel.

Control lamp with the word

(front passenger airbag disabled)

If the front passenger front airbag is disa-

bled, after switching on the ignition, the con-

trol lamp will illuminate for several seconds,

then it will switch off for about 1 s and then

switch on again. If the control lamp is flashing, there is a fault

in the disab

ling of the airbag system ››› .

Pl e

a

se go immediately to an Official Service. WARNING

● The driver of the

vehicle is responsible for

disabling or switching on the airbag.

● Always switch off the ignition before disa-

bling the fr

ont passenger airbag! Failure to do

so could result in a fault in the airbag disa-

bling system.

● Never leave the key in the airbag disabling

switc

h as it could get damaged or enable or

disable the airbag during driving.

● If the (airbag dis

abled) control lamp

flashes, the front passenger front airbag will

not trigger in the event of an accident! Have

the system immediately checked by an Offi-

cial Service. Transporting children safely

Saf ety

f

or children

Introduction For safety reasons, as we have learned from

acc

ident

statistics, we recommend that chil-

dren under 12 years of age travel in the rear

seats. Depending on their age, height and

weight, children travelling in rear seats must

use a child seat or a seat belt. For safety rea-

sons, the child seat should be installed in the

rear seat, behind the front passenger seat or

in the centre back seat.

The physical laws involved and the forces

acting in a collision apply also to children

››› page 64. But unlike adults, children do not

have fully developed muscle and bone struc-

tures. This means that children are subject to

a greater risk of injury.

To reduce the risk of injuries, children must

always use special child restraint systems

when travelling in the vehicle.

We recommend the use of child safety prod-

ucts from the SEAT Original Accessories Pro-

gramme, which includes systems for all ages

made by “Peke” (not for all countries).

These systems have been especially de-

signed and approved, complying with the

ECE-R44. regulation. »

73

Technical data

Advice

Operation

Emergencies

Safety

Page 77 of 248

Transporting children safely

Child seats Saf ety

in

structionsRead the additional information carefully

›› ›

page 16. WARNING

● When trav el

ling, children must be secured

in the vehicle with a restraint system suitable

for age, weight and size.

● Read and always observe information and

warning

s concerning the use of child seats

››› page 74. WARNING

● The ret ainin

g rings are designed only for

use with “ISOFIX” and Top Tether* system

child seats.

● Never secure other child seats that do not

have the “ISOFIX” or T

op Tether* system, or

retaining belts or objects to the fastening

rings - this can result in potentially fatal inju-

ries to the child.

● Ensure that the child seat is secured cor-

rectly u

sing the “ISOFIX” and Top Tether* se-

curing rings. Categorisation of child seats into

gr

oup

s Use only child seats that are officially ap-

pro

v

ed and suitable for the child.

Child seats are subject to the regulation ECE-

R 44. ECE-R stands for: Economic Commis-

sion for Europe Regulation.

The child seats are grouped into 5 catego-

ries:

Group 0: Up to 10 kg (up to around 9

months)

Group 0+: Up to 13 kg (up to around 18

months)

Group 1: from 9 to 18 kg (up to approx. 4

years old)

Group 2: from 15 to 25 kg (up to approx. 7

years old)

Group 3: From 22 to 36 kg (over around 7

years old)

Child seats that have been tested and ap-

proved under the ECE R44 standard bear the

test mark on the seat (the letter E in a circle

with the test number below it).

Follow the manufacturer's instructions and

observe any statutory requirements when in-

stalling and using child seats. We recommend you to always include the

manuf

act

urer's Child Seat Instruction Manual

together with the on-board documentation.

SEAT recommends you use child seats from

the Original Accessories Catalogue . These

child seats have been designed and tested

for use in SEAT vehicles. You can find the

right child seat for your model and age group

at SEAT dealers. WARNING

Read and always observe information and

warnin g

s concerning the use of child seats

››› page 74. 75

Technical data

Advice

Operation

Emergencies

Safety

Page 79 of 248

Self-help

distance. Observe applicable local legal regu-

lation

s.

This is for your own safety and that of

other drivers.

● If you have a flat tyre, stop the vehicle as

far aw

ay as possible from moving traffic. Stop

on flat, solid ground.

● If you have to change the tyre on a gradi-

ent, block

the wheel opposite the wheel be-

ing changed by placing a stone or similar ob-

ject under it to prevent the vehicle from roll-

ing away unexpectedly.

● If the vehicle has been fitted with tyres or

allo

ys that are different to those fitted in

manufacture, the instructions ››› page 219,

New tyres or wheels must be followed.

● Always raise the vehicle with the doors

closed.

● Nev

er place parts of your body, e.g. arms

and leg

s, underneath the vehicle when it is

supported only by the jack.

● Secure the base of the jack with suitable

suppor

ts so that it cannot slip. The jack could

slide if the ground below it is soft and slip-

pery and the vehicle could slip off it. There-

fore, place the jack on a firm surface or use a

large, stable base. On a slippery surface, e.g.

tile, use a non-slip base such as a rubber

mat.

● Never start the engine when the vehicle is

jack

ed. Risk of injury.

● The jack should only be used in the correct

jack

ing points. CAUTION

● The pre s

cribed tightening torque for wheel

bolts on steel and alloy wheels is 120 Nm.

● If the anti-theft wheel bolt is overly tight-

ened, this c

ould damage the bolt and the

adapter. Note

● The set of anti-thef

t wheel bolts or the

adapter are available from authorised SEAT

dealers.

● Please observe the relevant local legal reg-

ulation

s when changing the wheel. Wheel bolts

The wheel

bolts

ar

e m

atched to the rims.

When installing different wheels, e.g. to fit

light alloy wheels or wheels with winter tyres,

it is important to use the correct wheel bolts

with the right length and correctly shaped

bolt heads. This is essential for a secure fit of

the wheels and for proper operation of the

brake system. Note

● Never gr e

ase or oil the wheel bolts!

● If the wheel bolt is very tight, it may be

poss

ible to loosen it by pushing down the

end of the box spanner carefully with your foot. Hold on to the vehicle for support and

tak

e c

are not to slip.

● If you notice that the wheel bolts are rusty

and difficult

to turn when changing a wheel,

they must be replaced before having the

tightening torque checked. Tyre repairs

TMS Anti-p

uncture kit (Tyre Mobility

System)* Read the additional information carefully

› ›

›

page 46

The Tyre Mobility System is stored in a box

under the carpet in the boot.

Using the Tyre Mobility System you can relia-

bly seal tyres damaged by foreign bodies,

provided that cuts or punctures are no larger

than approx. 4 mm in diameter. Do not re-

move the foreign bodies, e.g. bolts or nails,

from the tyre!

The tyre must be repaired immediately.

The repair made using the Tyre Mobility Sys-

tem under no circumstances replaces perma-

nent tyre repair and should only be used to

drive to the nearest official service. »

77

Technical data

Advice

Operation

Emergencies

Safety

Page 81 of 248

Self-help

Filler tube with cap

Air c ompr

e

ssor

Tube for inflating tyres

Warning provided by tyre pressure moni-

toring system (it can also be integrated in

the compressor).

Air bleed screw (in its place, the compres-

sor may have a button).

ON/OFF switch

12 volt connector

Bottle of sealant

Spare tyre valve

The valve insert remover 1 has a gap at the

lo w

er end f

or a valve insert. The valve insert

can only be screwed or unscrewed in this

way. This also applies to its replacement part 11 .

WARNING

When inflating the wheel, the air compressor

and the inflat or t

ube may become hot.

● Protect hands and skin from hot parts.

● Do not place the hot flexible inflator tube or

hot air compr

essor on flammable material.

● Allow them to cool before storing the de-

vice.

● If

it is not possible to inflate the tyre to at

lea

st 2.0 bars (29 psi / 200 kPa), the tyre is

too badly damaged. The sealant is not in a 3

4

5

6

7

8

9

10

11 good condition to seal the tyre. Do not con-

tinue drivin

g.

Seek specialist assistance. CAUTION

Switch off the air compressor after a maxi-

mum of 8 operation

al minutes to avoid over-

heating! Before switching on the air compres-

sor again, let it cool for several minutes. Check after 10 minutes of driving

Screw the inflator tube

››

›

Fig. 84 5 again

and c hec

k

the pressure on the gauge 6 .

1.3 b ar (19 p

s

i / 130 kPa) and lower:

● Stop the vehicle! The tyre c

annot be sealed

sufficiently with the tyre mobility set.

● You should obtain professional assistance

›››

.

1.4 b ar (20 p

s

i / 140 kPa) and higher:

● Set the tyre pressure to the correct value

again.

● Car

efully resume your journey until you

reac

h the nearest specialised workshop with-

out exceeding 80 km/h (50 mph).

● Have the damaged tyre replaced. WARNING

Driving with an unsealed tyre is dangerous

and can c au

se accidents and serious injury.

● Do not continue driving if the tyre pressure

is 1.3

bar (19 psi / 130 kPa) and lower.

● Seek specialist assistance. Towing the vehicle

Introduction Read the additional information carefully

› ›

›

page 51.

Vehicles with manual gearbox can be towed

using a towbar or towrope. They can also be

towed with either the front or rear wheels lif-

ted off the road.

Vehicles with automatic gearbox can be tow-

ed using a towbar or towrope. They can also

be towed with the front wheels lifted off the

road. If the vehicle is towed with the rear

wheels lifted off the road the automatic gear-

box will be damaged!

Maximum towing speed is 50 km/h (31

mph). »

79

Technical data

Advice

Operation

Emergencies

Safety

Page 83 of 248

Fuses and bulbs

down on its right-hand side. The cover

mu s

t

be securely engaged.

Fitting and detaching the towline anchorage

– Screw in the towline anchorage anti-clock-

wise b

y hand as far as it will go ››› Fig. 85

.

To tighten the towline anchorage, we recom-

mend using the box spanner, the towing eye

from another vehicle or a similar object that

can be inserted through the anchorage.

– Unscrew the towline anchorage by turning

it cloc

kwise. CAUTION

The towline anchorage must be screwed in as

far a s

it will go. Otherwise there is a risk of

the screw connection shearing off during

towing or tow-starting! Fuses and bulbs

F u

se

s

Introduction Due to the constant updating of vehicles,

fu

se a

ssignments based on equipment and

the use of the same fuse for various electrical

components, it is not possible to provide an

up-to-date summary of the fuse positions for

the electrical components at the time this

manual was printed. For detailed information

about the fuse positions, please consult a

technical service.

In general, a fuse can be assigned to various

electrical components. Likewise, an electrical

component can be protected by several

fuses.

Only replace fuses when the cause of the

problem has been solved. If a newly inserted

fuse blows after a short time, you must have

the electrical system checked by a special-

ised workshop as soon as possible.

Additional information and warnings:

● Working in the engine compartment

›› ›

page 204. WARNING

The high voltages in the electrical system can

give seriou s

electrical shocks, causing burns

and even death!

● Never touch the electrical wiring of the igni-

tion syst

em.

● Take care not to cause short circuits in the

electrica

l system. WARNING

Using unsuitable fuses, repairing fuses or

bridging a c urr

ent circuit without fuses can

cause a fire and serious injury.

● Never use a fuse with a higher value. Only

repl

ace fuses with a fuse of the same amper-

age (same colour and markings) and size.

● Never repair a fuse.

● Never replace a fuse by a metal strip, staple

or simil

ar. CAUTION

● To pr ev

ent damage to the vehicle's electric

system, before replacing a fuse always turn

off the ignition, the lights and all electrical

elements and remove the key from the igni-

tion.

● If you replace a fuse with higher-rating

fuse,

you could cause damage to another part

of the electrical system. » 81

Technical data

Advice

Operation

Emergencies

Safety

Page 85 of 248

Fuses and bulbsNo.Consumer

24Air conditioning fan, heating, control unit for air

conditioning, heating

26Front seat heating switch.

27Rear window wiper

29Airbag

30

Electric windows, reversing light switch, air con-

ditioning control unit, Park Assist control unit,

exterior mirror, power supply for middle button

bar, power supply for the side button bar, interi-

or mirror

31Fuel pump, radiator fan control unit, cruise con-

trol, relay coil for the windscreen and rear win-

dow washer system, switch for the lights

32Diagnostics socket, headlight range regulator,

control lever under the steering wheel, ambient

lighting regulator

33Ignition relay coil, clutch pedal switch

34Heatable washer jets of windscreen washer

36USB charging socket

37Radar

39Additional electric heating

41Rear window heater

42Electric windows - passenger

43Towing bracket - Connector contact

No.Consumer

4412 V connection in the interior, 12 V connection

in the boot

45Rear right window

46Windshield and front window washing system,

control lever under the steering wheel

47Towing bracket - Connector contact

48Towing bracket - Right hand light

49Fuel pump control unit

50Radio

51Heat for exterior mirrors

52Keyless Access

53Steering lock (Keyless Access)

54ABS/ESC control unit

56Diagnosis

59Full LED

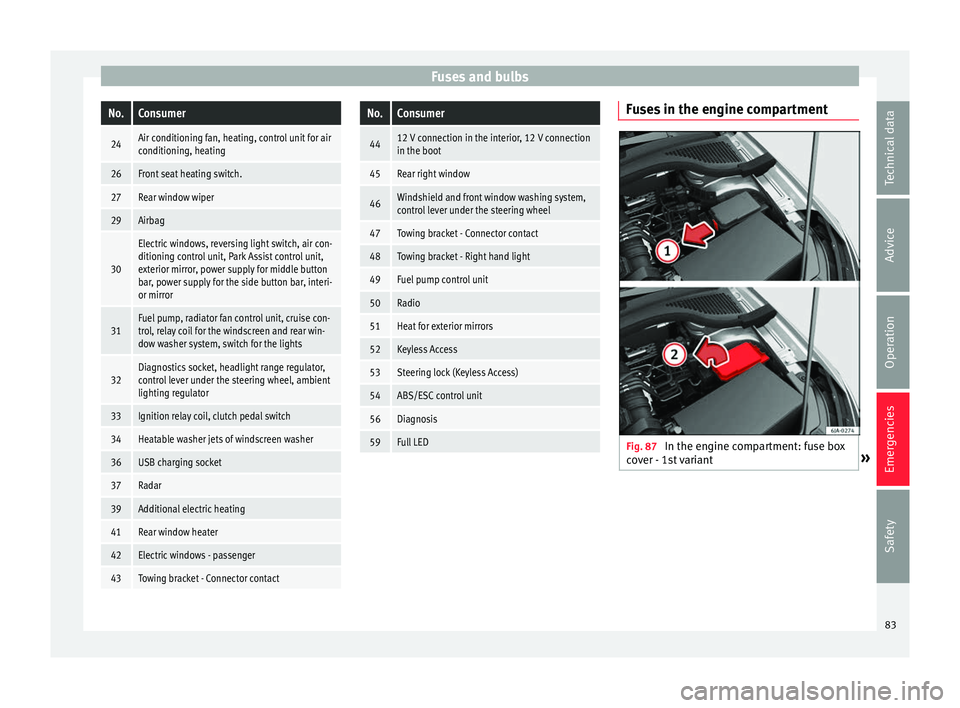

Fuses in the engine compartment

Fig. 87

In the engine compartment: fuse box

c o

v

er - 1st variant » 83

Technical data

Advice

Operation

Emergencies

Safety

Page 87 of 248

Fuses and bulbs

Full-LED headlight system*

F u

l

l-LED headlights handle all light functions

(daylight, side light, turn signal, dipped

beam and route light) with light emitting di-

odes (LEDs) as a light source.

Full-LED headlights are designed to last the

lifetime of the car and light bulbs cannot be

replaced. In case of headlight failure, go to

an authorised workshop to have it replaced.

Double headlight bulb change

Changing bulbs requires a certain degree of

practical skill. If in doubt, we recommend you

have defective bulbs changed by a special-

ised service or, in case of an emergency,

seek professional assistance.

● Switch off the ignition and all of the lights

before c

hanging a bulb.

● Do not touch the glass part of the bulb with

your bar

e hands. The fingerprints left on the

glass will vaporise as a result of the heat gen-

erated by the bulb, reducing bulb life and

causing condensation on the reflector sur-

face, thus reducing effectiveness.

● A bulb must only be replaced by one of the

same type. The type i

s indicated on the bulb,

either on the glass part or on the base.

● There is a storage area for the bulb box in

the spar

e wheel well or below the carpet in

the luggage compartment. WARNING

● Tak e p

articular care when working on com-

ponents in the engine compartment if the en-

gine is warm. Risk of burns.

● Bulbs are highly sensitive to pressure. The

glas

s can break when you touch the bulb,

causing injury.

● When changing bulbs, please take care not

to injure

yourself on sharp parts in the head-

light housing. CAUTION

● Remo v

e the ignition key before working on

the electric system. Otherwise, a short circuit

could occur.

● Switch off the lights and the parking light

before c

hanging a bulb. For the sake of the environment

Please ask your specialist retailer how to dis-

pose of u

sed bulbs in the proper manner. Note

● Dependin g on w

eather conditions (cold or

wet), the front lights, the fog lights, the rear

lights and the turn signals may be temporari-

ly misted. This has no influence on the useful

life of the lighting system. By switching on

the lights, the area through which the beam

of light is projected will quickly be demisted.

However, the edges may continue to be mis-

ted. ●

Ple a

se check at regular intervals that all

lighting (especially the exterior lighting) on

your vehicle is functioning properly. This is

not only in the interest of your own safety,

but also that of all other road users.

● Before changing a bulb, make sure you

have the c

orrect new bulb.

● Do not touch the glass part of the bulb with

your bar

e hands, use a cloth or paper towel

instead. Otherwise, the fingerprints left on

the glass will vaporise as a result of the heat

generated by the bulb, they will be deposited

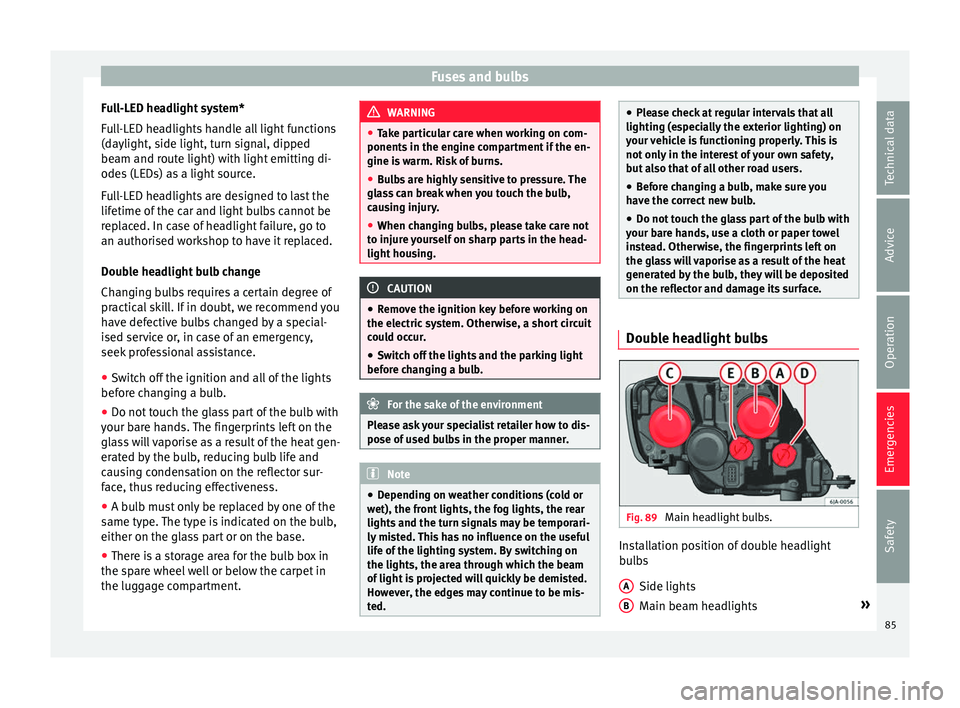

on the reflector and damage its surface. Double headlight bulbs

Fig. 89

Main headlight bulbs. Installation position of double headlight

b

u

l

bs

Side lights

Main beam headlights »

A B

85

Technical data

Advice

Operation

Emergencies

Safety

Page 89 of 248

Fuses and bulbs

– Remo

v

e connector ››› Fig. 93 1 by pulling

outw ar

d.

– Unc

lip the retainer spring ›››

Fig. 93 2 pressing clockwise and inwards.

– Extract the bulb and fit the replacement so

th at

the lug on the b

ase fits into the recess

on the reflector.

– Fit the connector.

– Fit the protective cover. Make sure that the

cov

er fits correctly on the housing during

operation.

– Replace the wheel housing cover.

– Check whether the new bulb is working.

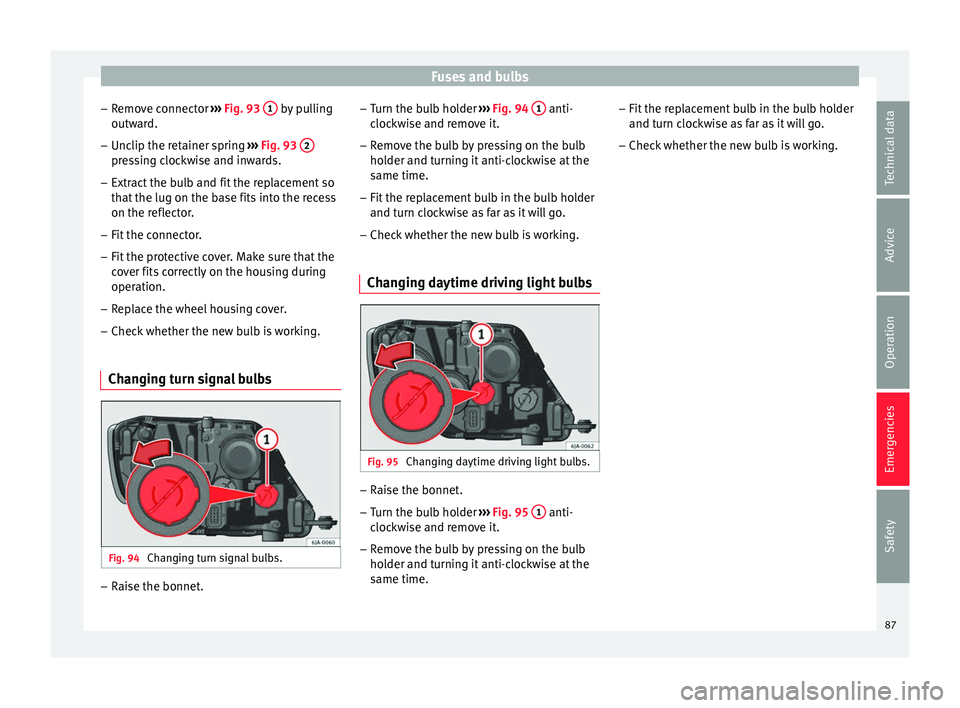

Changing turn signal bulbs Fig. 94

Changing turn signal bulbs. –

Raise the bonnet. –

Turn the b

u

lb holder ››› Fig. 94 1 anti-

c loc

k

wise and remove it.

– Remove the bulb by pressing on the bulb

holder and t

urning it anti-clockwise at the

same time.

– Fit the replacement bulb in the bulb holder

and turn cloc

kwise as far as it will go.

– Check whether the new bulb is working.

Changing daytime driving light bulbs Fig. 95

Changing daytime driving light bulbs. –

Raise the bonnet.

– Turn the bulb holder ›

››

Fig. 95 1 anti-

c loc

k

wise and remove it.

– Remove the bulb by pressing on the bulb

holder and t

urning it anti-clockwise at the

same time. –

Fit the rep

lacement bulb in the bulb holder

and turn clockwise as far as it will go.

– Check whether the new bulb is working.

87

Technical data

Advice

Operation

Emergencies

Safety

Page 91 of 248

Fuses and bulbs

– Open the lug g

ag

e compartment to access

the rainduct area.

– Take the screwdriver or a Torx 20 key (T20)

from the v

ehicle tool kit and loosen (turn-

ing anti-clockwise) and remove the two re-

taining screws that secure the front of the

light ››› Fig. 98 1 , taking care not to lose

them.

– Pull the rear light unit backward ( ››

›

Fig. 98

2 ) to remove the light from its housing.

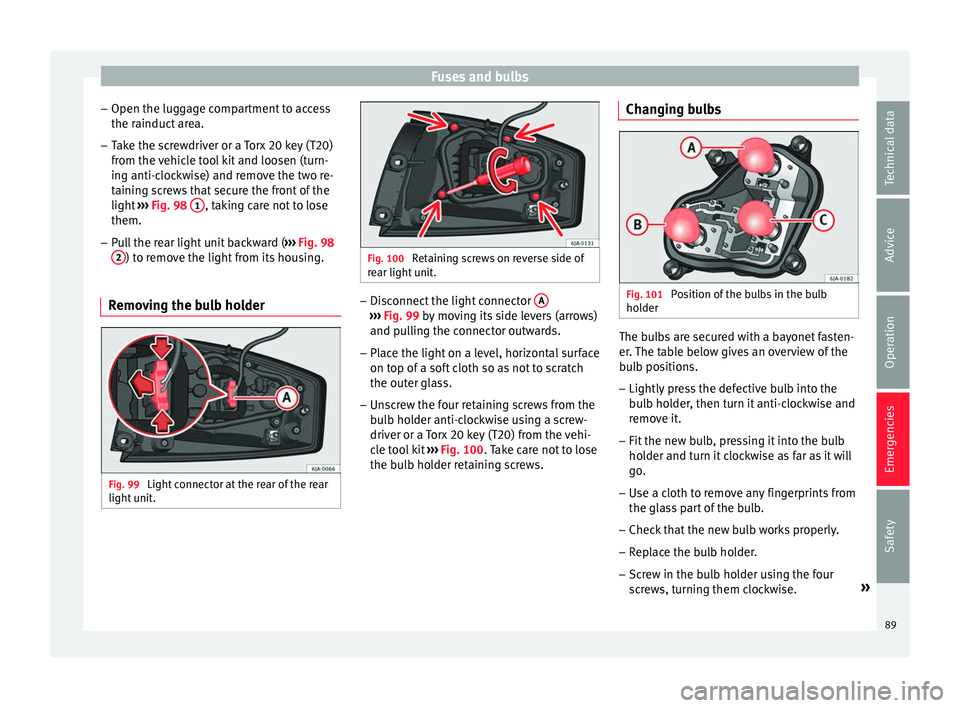

Removing the bulb holder Fig. 99

Light connector at the rear of the rear

light u

nit

. Fig. 100

Retaining screws on reverse side of

re ar light

unit. –

Disconnect the light connector A ›››

Fig. 99 by mo

ving its side levers (arrows)

and pulling the connector outwards.

– Place the light on a level, horizontal surface

on top of a sof

t cloth so as not to scratch

the outer glass.

– Unscrew the four retaining screws from the

bul

b holder anti-clockwise using a screw-

driver or a Torx 20 key (T20) from the vehi-

cle tool kit ››› Fig. 100. Take care not to lose

the bulb holder retaining screws. Changing bulbs Fig. 101

Position of the bulbs in the bulb

ho l

der The bulbs are secured with a bayonet fasten-

er

.

The t

able below gives an overview of the

bulb positions.

– Lightly press the defective bulb into the

bul

b holder, then turn it anti-clockwise and

remove it.

– Fit the new bulb, pressing it into the bulb

holder and t

urn it clockwise as far as it will

go.

– Use a cloth to remove any fingerprints from

the glas

s part of the bulb.

– Check that the new bulb works properly.

– Replace the bulb holder.

– Screw in the bulb holder using the four

scr

ews, turning them clockwise. »

89

Technical data

Advice

Operation

Emergencies

Safety

Page 93 of 248

Fuses and bulbs

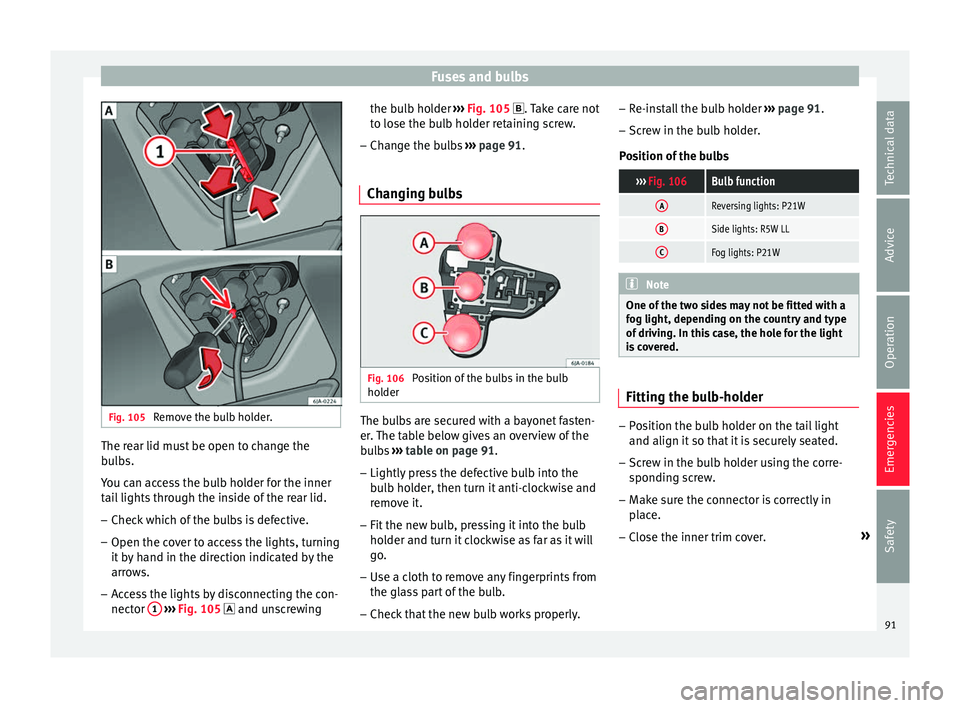

Fig. 105

Remove the bulb holder. The rear lid must be open to change the

b

u

l

bs.

You can access the bulb holder for the inner

tail lights through the inside of the rear lid.

– Check which of the bulbs is defective.

– Open the cover to access the lights, turning

it by

hand in the direction indicated by the

arrows.

– Access the lights by disconnecting the con-

nector 1

› ›

› Fig. 105

and unscrewing the bulb holder

›››

Fig. 105 . Take care not

to lose the bulb holder retaining screw.

– Change the bulbs ›››

page 91.

Changing bulbs Fig. 106

Position of the bulbs in the bulb

ho l

der The bulbs are secured with a bayonet fasten-

er

.

The t

able below gives an overview of the

bulbs ››› table on page 91.

– Lightly press the defective bulb into the

bul

b holder, then turn it anti-clockwise and

remove it.

– Fit the new bulb, pressing it into the bulb

holder and t

urn it clockwise as far as it will

go.

– Use a cloth to remove any fingerprints from

the glas

s part of the bulb.

– Check that the new bulb works properly. –

Re-ins

tall the bulb holder ››› page 91.

– Screw in the bulb holder.

Pos

ition of the bulbs

››› Fig. 106Bulb function

AReversing lights: P21W

BSide lights: R5W LL

CFog lights: P21W Note

One of the two sides may not be fitted with a

fog light, depending on the c

ountry and type

of driving. In this case, the hole for the light

is covered. Fitting the bulb-holder

–

Position the bulb holder on the tail light

and align it so th

at

it is securely seated.

– Screw in the bulb holder using the corre-

sponding s

crew.

– Make sure the connector is correctly in

plac

e.

– Close the inner trim cover. »

91

Technical data

Advice

Operation

Emergencies

Safety