wheel SKODA 105S 1980 Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 105S, Model: SKODA 105S 1980Pages: 238, PDF Size: 47.09 MB

Page 111 of 238

1

\

I

(

r

t

(

s I

I

(

S

lf

m

gr

lir

O1

sy

ro

po

th

th

th, tir

on

m€

tht

of

onl

I

by tr

Cl

A

6-

tl-

th

th

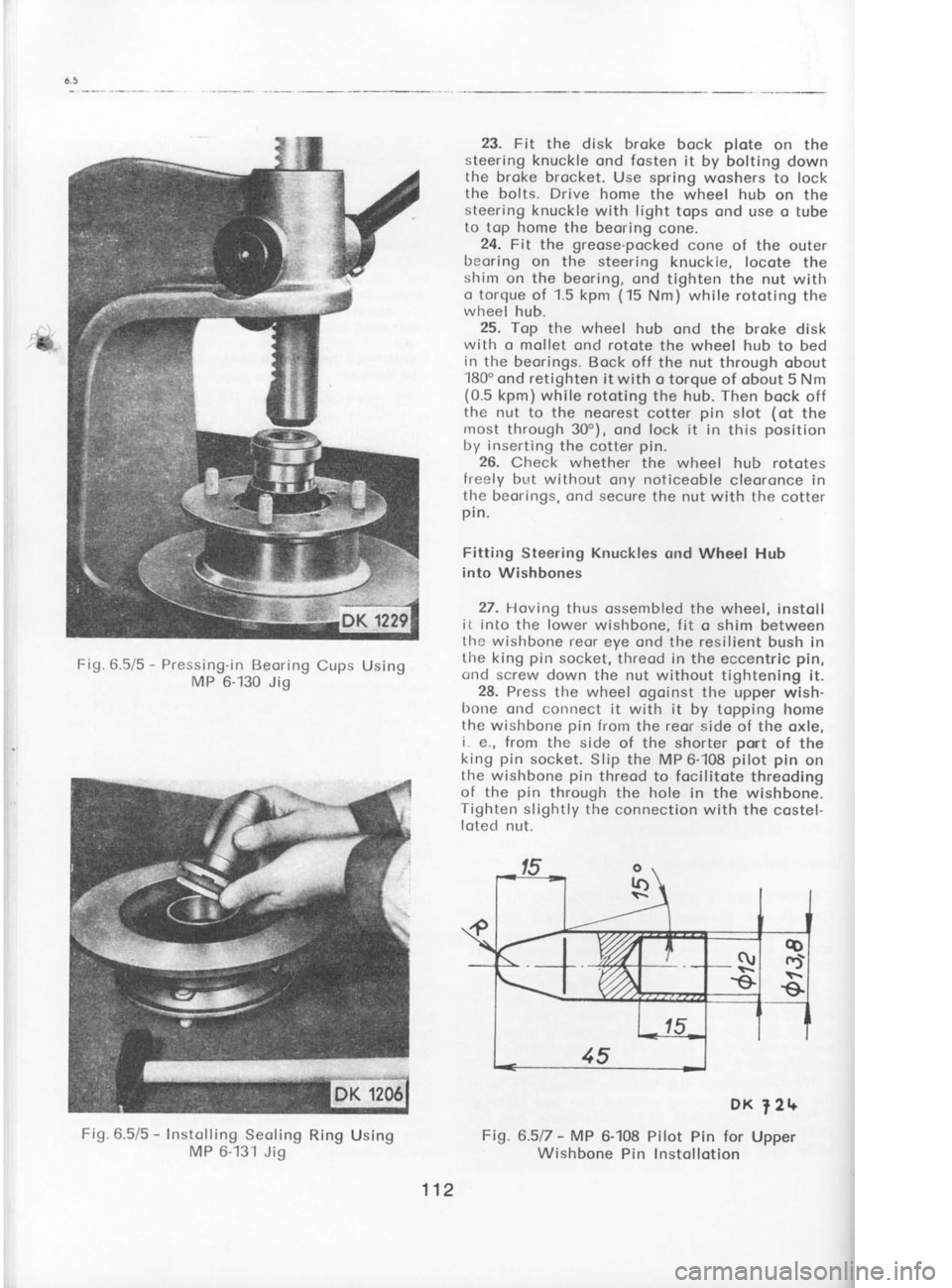

Fig.6.5/5

-

Pressing-in Beoring Cups Using

MP 6-130 Jig

Fig.6.5/5 -

Instolling Seoling Ring

Using

MP 6-131 Jig 23-

Fit the disk broke bock plote

on the

steering knuckle ond fosten it by bolting down

the broke brocket. Use spring woshers to lock

the bolts. Drive home the wheel hub

on the

steering knuckle with light tops ond use o tube

to top home the beoring cone.

24. Fit the greose-pocked

cone of the outer

beoring on the steering knuckie, locote

the

shim on the beoring, ond tighten the nut with

o torque of 1.5 kpnr (15

Nm) while rototing the

wheel hub.

25. Top

the wheel hub ond the broke disk

with o mollet ond rotote

the wheel hub to bed

in the beorings. Bock off the nut

through obout

-180o

ond retighten it with o torque of obout 5 Nm

(0.5 kpm) while rototing the hub. Then bock off

the nut to the neorest cotter pin

slot (ot

the

most through 30"), ond lock it in this position

by inserting the cotter pin.

26. Check whether the wheel hub rototes

freely br-rt without ony noticeoble

cleoronce in

the beorings, ond secure the nut with the cotter

pin.

Fittirrg Steering Knuckles ond Wheel Hub

into Wishbones

27. Hoving thus ossembled the wheel, instoll

ii into the lower

wishbone, fit

o shim between

tl-re wishbone reor eye ond the resilient bush in

the king pin socket,

threod in the eccentric pin,

cind screw down the nut without tightening it.

28. Press

the wheel ogoinst tlre

upper wish-

borre ond connect it with it

by topping home

the wishbone pin

from the reor side

of the

oxle,

i. e., from the side of the shorter port

of the

king pin

socket. Slip the MP 6-108 pilot

pin

on

the wishbone pin

threod to focilitote threoding

of the pin

through the hole in the wishbone.

Tighten slightly the connection with the costel-

loted nut.

DK ? 2r+

Fig. 6.517 -

MP 6--108 Pilot Pin for

Upper

Wishbone Pin lnstollotion

112

Page 113 of 238

R

tr

el o

tl

Pl

e1

th

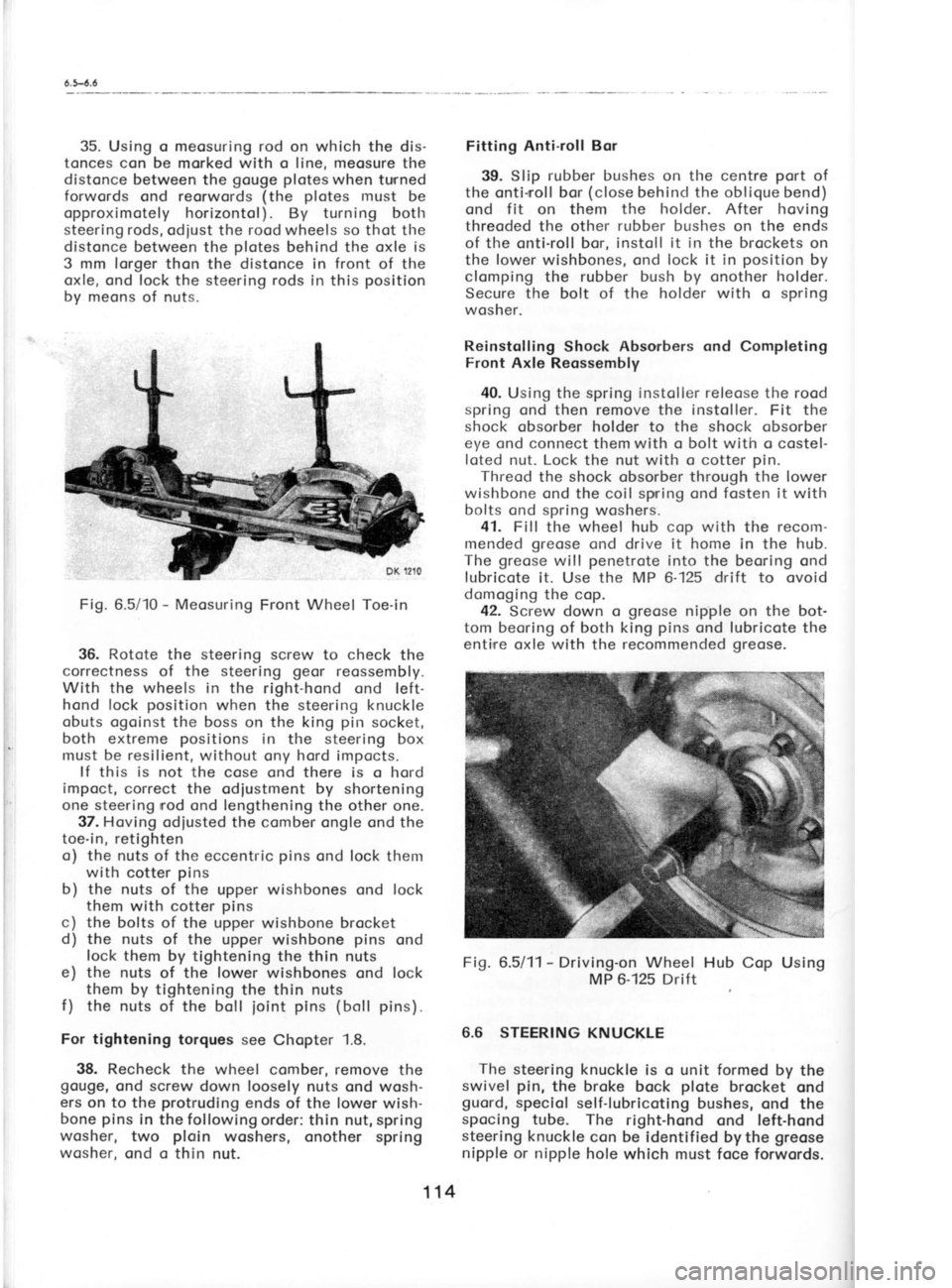

35.

Using

o meosuring rod

on which the dis-

tonces con be morked with o line, meosure the

distonce between the gouge plotes

when tunned

forwords ond reorwords (the plotes

must be

opproximotely horizontol). By turning both

steering rods, odiust the rood wheels so

thot tlre

distonce between the plotes

behind the oxle is

3 mm lorger thon the distonce in front

of the

oxle, ond lock the steering rods in

this position

by meons of nuts.

Fig. 6.5/10 -

Meosuring Front Wheel Toe-in

36. Rotote

the steering screw to check the

correctness of the steering geor

reossembly.

With the wheels in the right-hond ond left-

hond lock position

when the steering knuckle

obuts ogoinst the boss on the king pir-r

socket,

both extreme positions

in the steering

box

must be resilient,

without ony hord impocts.

lf this is

not the cose ond there is o hord

impoct, correct the odiustment by shortening

one steering nod ond lengthening

the other one.

37. Hoving odiusted the comber ongle

ond the

toe-in, retighten

o) the nuts of the eccentric pins

ond lock them

with cotter pins

b) the nuts of the upper wishbones ond lock

them with cotter pins

c) the bolts of the upper wishbone brocket

d) the nuts of the upper wishbone pins

ond

lock them by tightening the thin nuts

e) the nuts of the lower wishbones ond lock

them by tightening the thin nuts

f ) the

nuts of the boll

ioint pins (boll pins).

For tightening torques see Chopter 1.8.

38. Recheck the wheel comber, remove the

gouge, ond screw down loosely nuts ond wosh-

ers on to the protruding

ends of the lower

wish-

bone pins

in the following order: thin nut, spring

wosher, two ploin

woshers, onother spring

wosher, ond o thin nut. Fitting

Anti-roll Bor

39. Slip rubber

bushes on the centre port

of

the onti-rroll bor (close

behind the oblique bend)

ond f it on them the holder. After

hoving

threoded the other rubber bushes

on the

ends

of the onti-roll bor, instoll it in the brockets

on

the lower

wishbones, ond lock it in position

by

clomping the rubber bush by onother holder.

Secure the bolt of the holder with o spring

wosher.

Reinstolling Shock Absorbers ond Completing

Front Axle Reossembly

40. Using the spring instoller releose

the rood

spring ond then remove the instoller. Fit the

shock obsorber holder to the shock obsorber

eye ond connect them with o bolt with o costel-

loted nut. Lock the nut

with o cotter pin.

Threod the shock obsorber through the lower

wishbone ond the coil spning ond fosten it

with

bolts ond spring woshers.

41. Fill the wheel hub cop with

the recom-

mended greose

cnd drive it home

in the hub.

The greose will penetrote

into the beoring ond

lubricote it. Use the

MP 6-125 drift to ovoid

domoging the cop.

42. Screw down o greose

nipple on the bot-

tom beoring of both

king pins

ond lubricote the

enti,re oxle with the recommended greose.

Fig. 6.5/11- Driving-on Wheel Hub Cop Using

MP 6-125 Drift

6.6 STEERING KNUCKLE The steering knuckle is o unit formed by the

swivel pin,

the broke bock plote

brocket ond

guord, speciol self-lubricoting bushes, ond the

spocing tube. The right-hond ond left-hond

steering knuckle

con be identified bythe greose

nipple or nipple hole which must foce forwords.

114

Page 115 of 238

a

a

T Cr

o

s

2

sl

a(

fil

1,

al

(2

2.

PI

thr ler

to

dti

tht

Bush inside diometer

pin diometer

Cleoronce of moximum

king pin

ond bush weor 18J 0.018

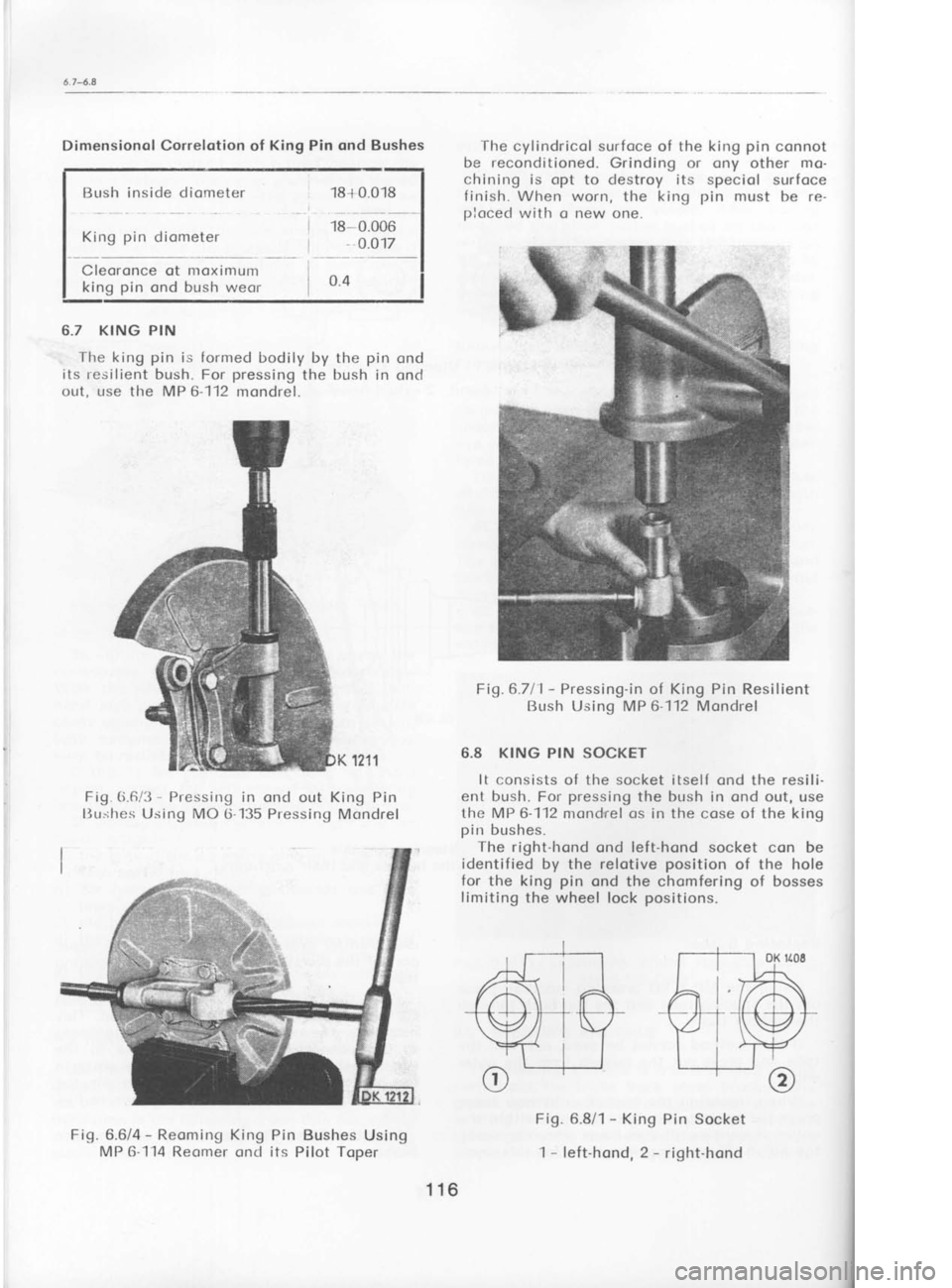

Dimensionol

Correlotion

of King Pin ond Bushes

6.7 KING PIN The king pin is formed bodily by

its resilient bush. For pressing

the

out, use the MP 6--l-12 mondrel. The

cylindricol surfoce of the king pin

connot

be reconditioned.

Grinding or ony other mo-

chining is opt to destroy its speciol surfoce

finish. When worn, the king pin must be re-

ploced with o new one.

Fig.6.7l1 -

Pressing-in of King Pin

Resilient

Br"rsh Using MP 6-112

Mondrel

6.8 KING PIN SOCKET

It consists of the socket itself ond the resili-

ent bush. For pressing

the bush

in ond out, use

the MP 6-112 mondrrel os in the cose of the king

pin bushes.

The right-hond ond left-hond socket

con be

identified by the relotive position

of the hole

for the king pin

ond the chomfering of bosses

limiting the wheel lock positions.

Fig. 6.8/1 -

King Pin Socket

1 -

left-hond, 2 -

right-hond

the

pin

cnd

bush in crnd

1211

Fig 6.6i13 -

Pressing in

lJu:;hes U.sing MO 6 135 ond out King

Pin

Pressing Mondrel

Fig. 6.6i4 -

Reoming King

MP 6-1-14 Reomer oncl Pin Bushes

Using

its Pilot Toper

116

Page 117 of 238

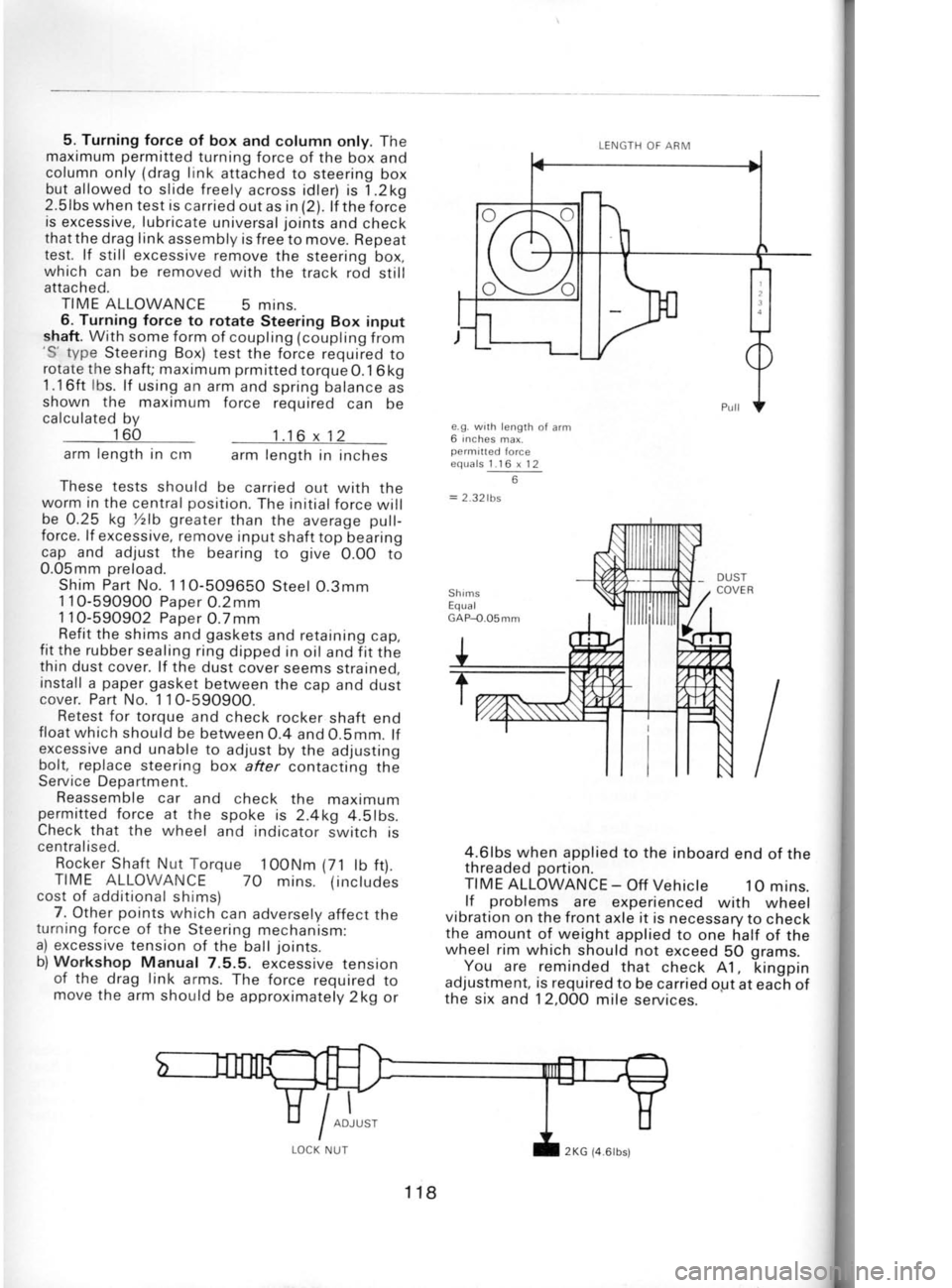

5. Turning force

of box and column only. The

maximum permitted

turning force of the box and

column only (drag

link

attached to steering box

but allowed to slide freely

across idler) is 1.2kg

2.5lbs when test is carried out as in (2).

lf the force

is excessive, lubricate

universal joints

and check

thatthe drag link assembly is free to move. Repeat

test. lf still excessive remove

the steering box,

which can be removed

with the track rod still

attached.

TIME ALLOWANCE 5 mins.

6. Turning force to rotate

Steering Box input

shaft. With some form

of coupling (coupling from

'S'

type Steering Box) test the force required to

rotate the shaft; maximum prmitted

torque0.1 6kg

1.16ft lbs.

lf using an arm and spring balance as

shown the maximum force required

can be

calculated bv

160

arm length

in crn

arm length

in inches

These tests should be carried out with the

worm in the central position.

The initial force will

be 0.25 kg %lb greater

than the average pull-

force. lf excessive, remove

input shaft top bearing

cap and adjust the

bearing to give

0.OO to

0.05mm preload.

Shim Part No. 11O-509650

Steel O.3mm

1 10-59O90O Paoer

O.2mm

1 10-590902 Paper

O.7mm

Refit the shims and gaskets

and retaining cap,

fit the rubber sealing ring

dipped in oil and f it the

thin dust cover. lf the dust cover seems strained,

install a paper

gasket

between the cap and dust

cover. Part No. 1 1O-5909O0.

Retest for torque

and check rocker

shaft end

float which should be between

O.4 and O.5mm. lf

excessive and unable to adjust by the adjusting

bolt, replace steering box after contacting

the

Service Department.

Reassemble car and check the maxtmum

permitted force at the

spoke is 2.4kg 4.5lbs.

Check that the wheel

and indicator switch is

ce ntra lised.

Rocker Shaft Nut Torque

100Nm (71

lb ft).

TIME ALLOWANCE

7O mins. (inctudes

cost of additional shims)

7. Other points

which can adversely

affect the

turning force of the

Steering mechanism:

a) excessive tension

of the ball joints.

b) Workshop

Manual 7.5.5. excessive tenston

of the drag link

arms. The force required to

move the arm should be approximately 2kg or e.g.

wrth length

of arm

6 inches

max.

permitted force

equals 1.16 x 12

6

= 2.32lbs

DUST

COVER

4.6lbs when applied to the inboard

end of the

threaded portion.

TIME ALLOWANCE -

Off Vehicte 1O mins.

lf problems

are experienced

with wheel

vibration on the front

axle it is necessary to check

the amount of weight applied to one half of the

wheel rim which should not exceed

50 grams.

You are reminded

that check A1, kingpin

adjustment, is required

to be carried ogt at each of

the six and 12,0OO mile services.

1.16 x12

UST

I

ADJ

UT LENGTH

OF ARM

118 2KG

{4.6lbs)

Page 119 of 238

\''

I

t- rL:

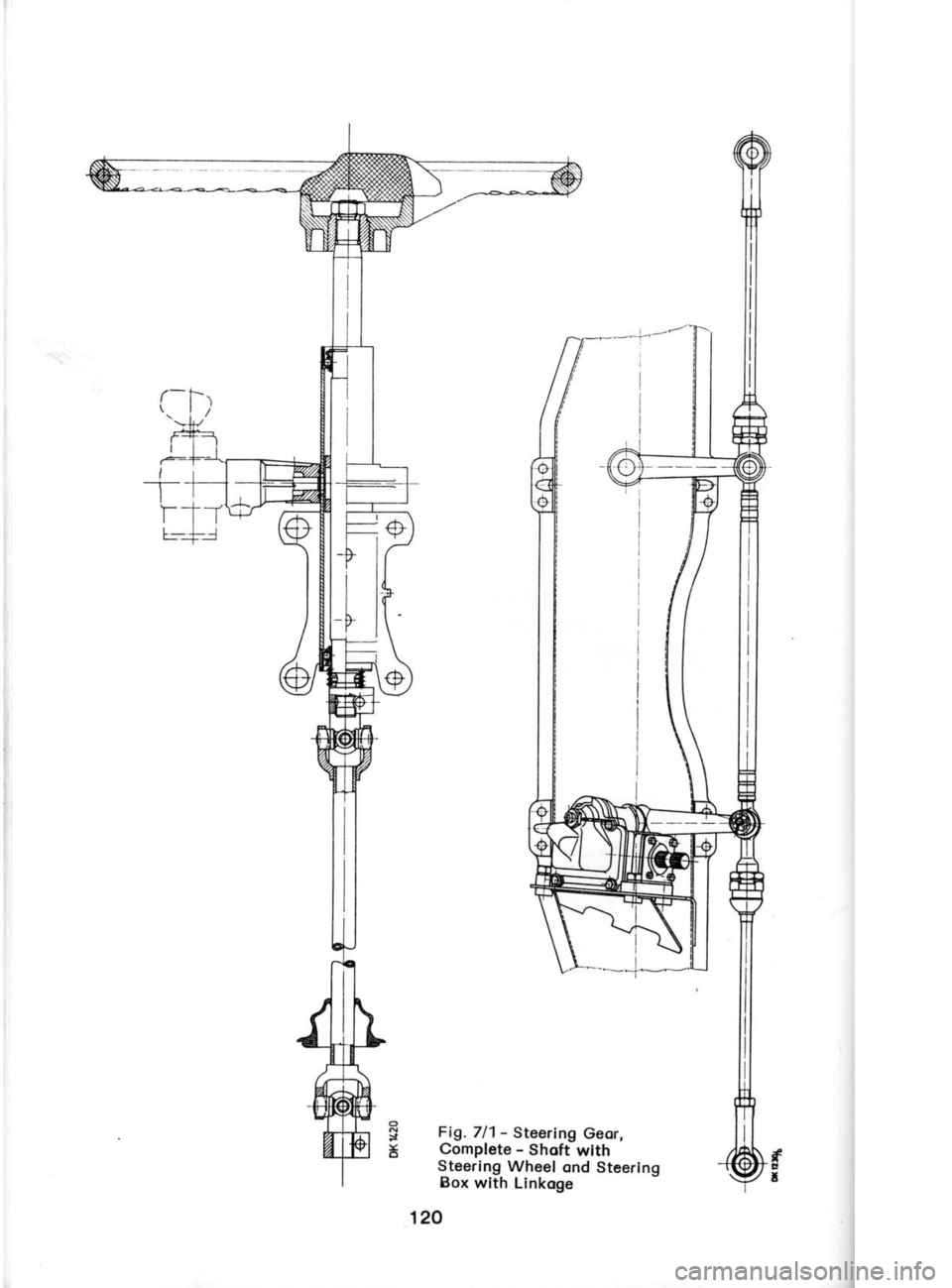

Flg. 711 -

Steertng Geor,

Complete -

Shoft wtth

Steerlng Wheel ond Stcerlng

Box wlth Llnkoge

120

Page 123 of 238

7

.7-1.8

(

t

t

t

; (

(

b

tl

ir

tl

p il

o

tl

p

odiust,

if necessory, the driving dog of the di-

rection indicotor switch -

see Chopter 13.17.

Refit the steering wheel so thot its spokes

ore horizontol, lock it in position

with the nut

(for tightening torque, see

Chopter 1.8), ond

bolt down the spoke shroud.

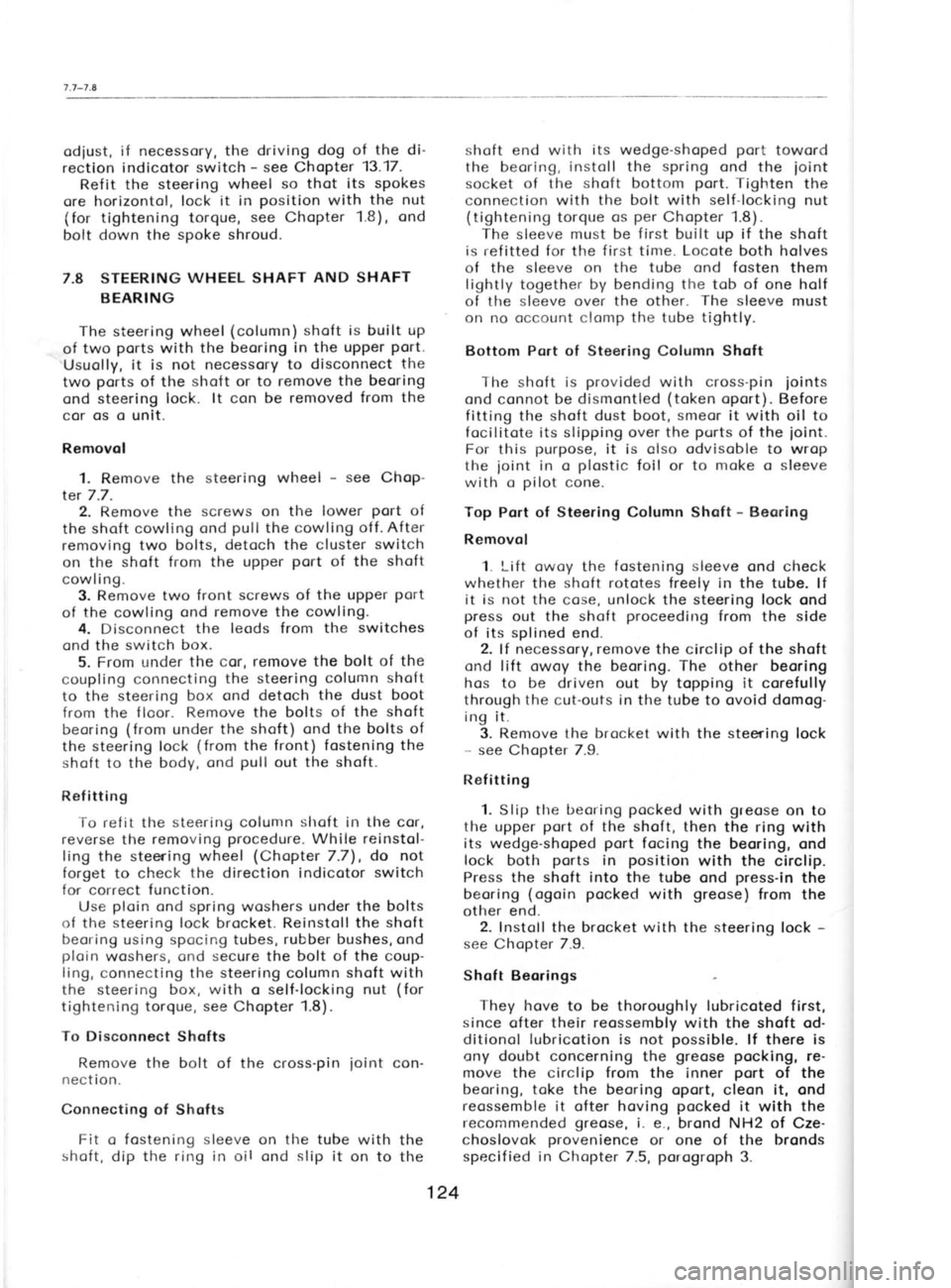

7.8 STEERING WHEEL SHAFT AND SHAFT

BEARING

The steering wheel (column) shoft is built

up

of two ports

with the beoring in the uPPer port.

Usuolly, it is not necessory to disconnect the

two ports

of the shoft or to remove the beoring

ond steering lock. lt

con be removed from the

cor os o unit.

Removol 1. Remove the steering wheel -

see Chop-

ter 7.7. 2. Remove the screws on the lower port

of

the shoft cowling ond pull

the cowling off.After

removing two bolts, detoch the cluster switch

on the shoft from the upper port

of the shoft

cowling. 3. Remove two front screws of the upper

Port

of the cowling ond remove the cowling.

4. Disconnect the leods

from the switches

ond the switch box.

5. From under the cor, remove the bolt of the

coupling connecting the steering

column shoft

to the steering box ond detoch the dust boot

from the floor. Remove the

bolts of the shoft

beoring (from

under the shoft)

ond the bolts of

the steering lock (from

the front) fostening the

shoft to the body, ond pull

out the shoft.

Ref itting To ref it the steering column shoft

in the cor,

reverse the removing procedure. While reinstol-

ling the steering wheel (Chopter

7.7), do not

forget to check the direction indicotor switch

for correct function.

Use ploin

ond spring woshers under the bolts

of the steering lock

brocket. Reinstoll the shoft

beoring using spocing tubes, rubber bushes, ond

ploin woshers, ond secure the bolt of

the coup-

ling, connecting the steering

column shoft with

the steering box, with

o self-locking nut (for

tightening torque, see

Chopter 1.8).

To Disconnect Shofts

Remove the bolt

of the cross-pin

ioint con-

nection.

Connecting of Shofts

Fit o fostening sleeve on the tube

with the

shoft, dip the ring in oil ond slip

it on to the shoft end with

its wedge-shoped port

toword

the beoring, instoll the spring

ond the

ioint

socket of

the shoft bottom port.

Tighten

the

connection with the bolt with self-locking

nut

(tightening torque os per

Chopter 1.8).

The sleeve must be f irst built up if

the shoft

is refitted for the first time. Locote

both holves

of the sleeve on the tube ond fosten

them

lightly together by bending the tob of one holf

of ttre sleeve over the

other. The

sleeve must

on no occount clomp the tube tightly.

Bottom Port of Steering

Column Shoft

The shoft is provided

with cross-pin

ioints

ond connot be dismontled (token

oport). Before

fitting the shoft dust boot, smeor

it with

oil to

focilitote its slipping over the pcrrts

of the joint.

For this purpose,

it is clso odvisoble to wrop

the joint

in o plostic

foil or to moke o sleeve

with o pilot

cone.

Top Port of Steering Column

Shoft -

Beoring

Removol 1. l-ift owoy the fostening sleeve

ond check

whether the shoft rototes

freely in the tube. lf

it is not the cose, unlock the steering lock ond

press out the shoft proceedirrg

from the side

of its splined

end.

2. lf necessory, remove

the circlip of the shoft

ond lift owoy the beoring. The other beoring

hos to be driven out by topping it corefully

through the cut-outs in

the tube to ovoid domog-

ing it. 3. Remove the brocket with the steering

lock

- see Chopter 7.9.

Ref itting

1. Slip tlre beoring pocked

with greose

on to

the upper port

of the shoft, then the ring with

its wedge-shoped port

focing the beoring, ond

lock both ports

in position

with the circlip.

Press the shoft into the tube ond press-in

the

beoring (ogoin pocked

with greose)

from the

other end.

2. lnstoll the brocket with the steering lock -

see Chopter 7.9.

Shoft Beorings They hove to be thoroughly lubricoted

first,

since ofter their reossembly with the shoft od-

ditionol lubricotion is not possible.

lf there is

ony doubt concerning the greose

pocking,

re-

move the circlip f

rom the inner port

of the

beoring, toke the beoring oport, cleon it, ond

reossemble it ofter hoving pocked

it with the

recommended greose,

i. e., brond NH2 of Cze-

choslovok provenience

or one of the bronds

specif ied in Chopter 7.5, porogroph

3.

124

Page 127 of 238

Shr

C

cle,

the

1

fittr

bor

(Im(

2

wit

woI

pisl

wor

the loc<(11,

3.

obo (M(

I nst

rod

the

oil' into

4.

witt

Con

prot

Inod

On f(

Inodr

oll c(

Excer

on c(

8.3 SHOCK ABSORBERS

The shock obsorbers ore of

the hydroulic,

telescopic, double-octing type of the PAL

moke.

The domping effect depends on the speed

of the

relotive movements of the oxle ond body. Doto

required for testing ond odiusting the shock

obsorbers ore given

in the following Tobles.

Front Shock Absorber -

see Fig.8.3/1

type PT 26x110,

Ser. No.443.621-215.000

1977-74 1 978 on

Maximum stroks llO mm 110 mm

Damping torce during

down stroke (compr€s-

sion 470N

500N

Damping force

during

upward stroke (expan-

sion) loSN

1

300N

Filling capacity lOO cc1OO

cc

Reor Shock Absorber

type T 26x175; Ser. No. 443.621.247.OO1

1977-78 1 978 on Both

types of shock obsorbers ore of similor

design, only their bottom fostening

is different

(the front shock obsorber hos o fostening eye,

the reor shock obsorber hos

o bolt ond locks

the outer protective

tube). They hove

o differ-

ent stroke, domping force, ond filling

copocity.

Removing ond Refitting When removing or refitting o shock

obsorber,

retoin the piston

rod (upper

fostening) by hold-

ing the flottened end of the threod in o sponner.

In the cose of

the reor shock cbsorber, retoin

the piston

rod in the bottom port

by holding the

heod of the bolt connecting it to the shock

obsorber cylinder.

The ossembly of the rubber bushes of the

respective shock obsorber mounting

con be seen

in Fig.8.3/1.

Access to the upper mountings of 'the

front

shock obsorbers is from the luggoge boot

(under the floor). The

threod is protected

by

o cop nut. The

mountings of

the reor shock

obsorbers ore occessible from the reor luggoge

comportment behing the reor seot bockrests ofter folding owoy the upholstery on the wheel

orch. The mounting is in the cyllndricol exten-

sion piece

in the scuttle

of the reor dosh.

Shock Absorbor Dismcntling

Dismontling is o routine procedure

beginning

with screwing out the plug

(1)

ofter the pro-

tective sleeve (tube)

hos been removed. Never

dismontle the piston

volves since there is o risk

of impoiring the domping force

by mixlng up

the volves.

o

o

*)

At o

temperoture ol 25

to 30oC,

of 100 strokes per

minute, ond

100 mm. frequency

stroke of

Fig.8.3/1 -

Front Shock Absorber -

Sectionol View

Maximum stroke

175 mm

175 mm

Damping force during

down stroke (compres-

ston, 470N

500N

Damping force during

upward stroke {expan-

sronl 950N

r

200N

Filling capacity 160

cc 160 cc

130

Page 133 of 238

tr

c

\

c'

pl

r€

o1.

tt pl

tt

r€

ol

w

ot

iu

ol

dt

is

ol

sl

Rr

ot

th

th

c0

c0

Broke

Shoes ond Broke Drums

When refitting

o broke shoe with o portiolly

worn lining moke sure thot it hos o thickness

sufficient to lost till the periodic

inspection

(ofter every 20,000 kilometres). The new lining

is 5 mm thick. When it is worn down to 1.5

to 'l

mm (4

to 3.5 mm when meosured

with the

shoe), the broke shoe hos to be reploced

with

o new.or

o reconditioned

shoe with glued-on

new lining. Be sure to reploce

the respective

broke shoes in both wheels to preserve

o uni-

form broking effect.

Speciol glues or cements

ond hordening ot

high temperotures

ore required when relining

the broke shoes so thot this

iob con

be done in

speciolized repoir shops

only. For informotion,

opply to the broke monufocturer -

Autobrzdy

Not. Corp., Joblonec

nod Nisou.

Broke drums are grey

cost-iron costings. Their

unequol weor

con be rectified

by mochining to

o 231 mm diometer.

No tool morks must be left

on their surfoce

which hos to be perfectly

smooth. The olignment deviotion

ond mochin-

ing toleronce should

not exceed 0.1 mm. The

moximum permissible weor is up Lo 232

mm in

diometer.

Only broke drums

with on identicol

diometer

ore permitted

to be mounted on one ond the

some oxle.

9.2 FRONT BRAKE

ASSEMBLY

Disnrontling ond Reossembly

1. Detoch

the broke fluid supply piping

from

the broke. Absolute cleonliness is o must.

Otherwise dirt ond foreign

motterwill penetrote

into the piping.

2. Renrove bolts lrolding

down the broke yoke

crnd lift owoy rlre broke

ossembly.

3. Use the MP 6-132 gouge

to set correctly

the broke (new

or repoired)

on reinstollotion.

4. Select the shims required

to fill the gop

between the end of the gouge

ond the foce of

the fostening lug.To position

correctly the

broke, insert shims

between the fostening lugs

cnd yokes. You con, however,

meosure direct

the distonce

between the fostening

lug ond the

trroke disk

ond set this distonce

in complionce

with Fig. 9.211 by odding pocking

pieces

to the

shim pock.

5. Using the respective

copscrews ond spring

'.^roshers, bolt down the yoke

to the lugs.

6. Attoch the supply hoses ond bleed

the

broke.

Replocing the Brake

Disk

A worn brol

grinding it to o thickness

of 7.5 mm. lf necess-

cry, reploce it with o new one 9 mm thick. The lowest

limit of thickness

of o still usoble

broke disk is 6.5 mm. The

moximum permissible

run-out of the friction surfoce is

0.15 mm.

1. After hoving lifted owoy

the broke os-

sembly, remove the wheel hub

ond then the

broke disk. 2. Reossemble the broke disk

with the wheel

hub using copscrews with spring

woshers.

3. Top

rrp or chonge the lubricont

in the

wheel

hub beorings ond reinstoll the broke ossembly

Replocing Broke Pods

The overoll thickness of o broke pod

with

new lining is 15 mm. When worn down to 7 mm

(with the lining 1.5 mm thick), the pod

is

unusoble.

Alwoys reploce

broke pods

on both ends of

the oxle of the some time so

thot their weor is

uniform. With regord to the coefficient of fric-

tion, they hove to be of the some

type ond

rnoke.

1. Suck off the hydroulic fluid from the tonk

so thot it is only holf filled.

2. Remove cotter pins

ond lift

owoy the broke

lining cover.

3. Remove the friction pod,

cleon thoroughly

the covities of the yokes, piston

ports,

ond dust

boots.

4. Fit the MP 6-134 force-off lever over the

broke disc ond drive the pistons

into the

cylinder bottoms by the presswe

of levers.

5. Ploce o new friction pod

into the broke

ossembly moking sure thot the clomp of the

thrust plote

fits into the collor of the piston

foce.

Fig.9.2l1- Front Wheel Broke Mechonism

ond Mounting (setting)

Dimensions

1 -

Broke disk

2 -

Broke

3 -

Shims

A -

Broke setting climension -

18.7+O.2

136

Page 135 of 238

Reossemble the

pressure-relief

following order: dust cup, spring,

ond seol. Nicks ond burrs

ore opt to domoge

the dust

boot ond prevent

its perfect

odhesion to the

cylinder. Every boot must be odequotely pre-

stressed (topered)

so thot its seoling edge con

be in permonent

contoct with the cylinder sur-

foce. A decreosed prestress

signols excessive

weor of the dust boot or its fotigue. For the

cleoning ond lubricotion of working ports,

see

the instructions in

Chopter 9.3.

9.5 FRONT BRAKE WHEEL CYLINDERS

Wheel cylinders ore ossemblies formed

by

one cylinderwith the yoke

ond onother cylinder

with the f longe ond occessories. Fig. 9.5/1

shows the loyout. For cieoning ond lubricotion

of the working surfoces, see the informotion

in Chopter 9.3.

Dismontling

1. After hoving removed the broke pods,

disconnect ond lift owoy the interconnecting

piping, cnd then remove f our copscrews to

seporote the cylinder with the yoke

from the

flonged cylinder.

2. Pull off the retoining

ring of the dust boot

ond lift owoy the dust boot.

Connect o com-

pressed oir supply (or

the broke moster cylinder)

ond use it to force the piston

out of the

Fig. 9.5/1 -

Front Broke Wheel Cylinder c/w

Broke Pods

volve in the

spring plote,

Fig. 9.312 -

Secondory Piston Cup Mounting

Fixture for dio. 12 mm

Moster Cylinder

(1 -

guide bush, 2 -

clomping ring)

Fig. 9.3/3 -

Secondory Piston Cup Mounting

Fixture for dio. 22

mm Moster Cylinder

(1- guide

bush, 2 -

clomping ring)

9.4 REAR BRAKE WHEEL

CYLINDER

'l-he wheel cylinder requires procticolly

no

servicing. Whenever removing

the broke drums,

exomine the rubber dust boots.They hove

to be

perfectly tight, flexible,

ond undomoged. When

replocing them, exomine the inner surfoce of

the wheel cylinder ond the surfoce

of the piston.

Fig. 9.4/1 -

Sectionol View of Wheel

Cylinder

138

Page 137 of 238

I

I

T

!

(

(

t I

t

t

t I

'l

(

r

o cc

fold

ot the moment of

the opplicotion of the

brokes, ond led

through o rubber hose (tube)

to

the booster.

Removol ond Refitting

The broke booster is held down on the pedol

brocket by nuts ond spring

woshers. The lug of

the control volve press

button connects it with

the broke pedol,

on which it is secured by o re-

toining ring. These

mounting ports

or the con-

nections of the vocuum supply

ore to be hondl-

ed only when removing

or refitting the broke

booster.

However, we odvise you

to hove this

iob done

in o speciolized

repoir shop properly

instructed

by the broke

monufocturer. All rubber ports (in

the terms of current mointenonce,

this is

procticolly the seol of the press

button control-

ling the moster cylinder)

must be protected

from the effects of the broke fluid or other

lubriconts. Use petrol

for cleoning the rubben

ports.

Adiustment 1. Adiust the cleononce

between the broke

booster press

button ond the cylinder piston

whenever the moster

cylinder or the'broke

booster ore reploced,

or whenever there is ony

doubt concerning

the correctness

of the os-

sembly of the moster cylinder

with the broke

booster. Meosure the distonce between the

cylinder bottom recess

ond the cylinder flonge

nroting surfoce os well os the length of the

press button protruding

over the moting surfoce

of the booster.

Compore the meosurings

ond

odiust the length of the press

button by rototing

its threoded

end to obtoin o cleoronce of 0.5 to

1 mm between the press

button ond the piston.

Still better, you

can use special

tools Mp6.

'14'lA.

Fit it on the

moster cylinder, push

its spindle into the cylinder till its rounded

end

rests ogoinst

the piston,

ond lock it in this po-

sitio-n with the respective

retoining screw.

Apply

the fixture to the booster

ond rotote the boostei press

button so thot it

iust touches the

lower

flot port

of the fixture spindle.

2. lf it is necessory

to level

the broke pedol

with the clutch pedol,

odiust the length

of the

contnol volve press

button lug.

Remove the broke

booster from the pedol

brocket, slip off the collor (cup),

connect the

booster with the pedol,

ond refit it tempororily

to the brocket.

Now rotote the hexogon on the

threods of the lug till both the clutch ond broke

pedol ore level. Remove once more the booster

from the pedol

ond pedol

brocket, neinstoll the

collor (cup),

ond complete the f inol reossembly.

9.7 BRAKE FLUID TANK, PIPING AND HOSES

Tonk ond Filling Hose

The broke fluid tonk is held in position

in its

brocket by o slip-over

clomp. Speciol rubber

hoses connect it with the broke ond clutch

moster cylinders.

Hose clips ore used to secure

the hoses on the tonk outlet sockets.

Both the

side ond centre outlet of the tonk ore con-

nected to the bnoke moster cylinder, the third

outlet being connected to the clutch moster

cylinder (see Fig. 12.111).

Pressure Piping ond Hoses

The rigid port

of the hydroulic line consists

of speciol steel pipes.

Their connections with

other ports of the line ore seoled off by clomp-

ing on the conicol surfoces-

lf these conicol surfoces

become domoged,

remove them ond form new ones by floring the

pipes. To do this, use the coulking holder,

type

MP 9-151. Clomp the pipe

in the holder so thot

it is level with its upper edge ond flore the pipe

with c coulking chisel. The holder is designed

to be clomped in o vice.

The holder

hos two drilled holes of 5 ond

6 mm in diometer so thot it con be used olso for

repoirs of pipes

of the clutch line. For dio.

5 mm holes, use the MP 9-152 ond for dio. 6 mm

holes, the MP 9-153 coulking chisel.

The flexiblepqrt

of the hydroulic line consists

of speciol hoses.

When fitting them to the reor

wheel cylinders, turn them in o position

which

will prevent

their contoct with ony ports

of the

cor in both extreme positions

of the cor sus-

pension. This is why the nipples ot the reor

wheels ore inclined

downword through on

ongle of 30 degrees from

the horizontol plone.

9.8 HAND BRAKE

The hond-broke

lever between the front seots

controls the tie-rod which octuotes the rocker

(see Fig.9.8/1). Cobles connected

to the rocker

Fig. 9.612

-

Broke Booster Press

Button

Adiusting Fixture

MP6 141A tx r5?2

140