SKODA CITIGO 2014 1.G Owner's Manual

Manufacturer: SKODA, Model Year: 2014, Model line: CITIGO, Model: SKODA CITIGO 2014 1.GPages: 164, PDF Size: 12.08 MB

Page 131 of 164

For the sake of the environmentUsed sealant or sealant whose expiry date has passed must be disposed of in

accordance with environmental protection regulations.

Note

■ A new bottle of sealant can be purchased from ŠKODA Original Parts.■Immediately replace the tyre that was repaired using the breakdown kit, or

consult a specialist garage about repair options.

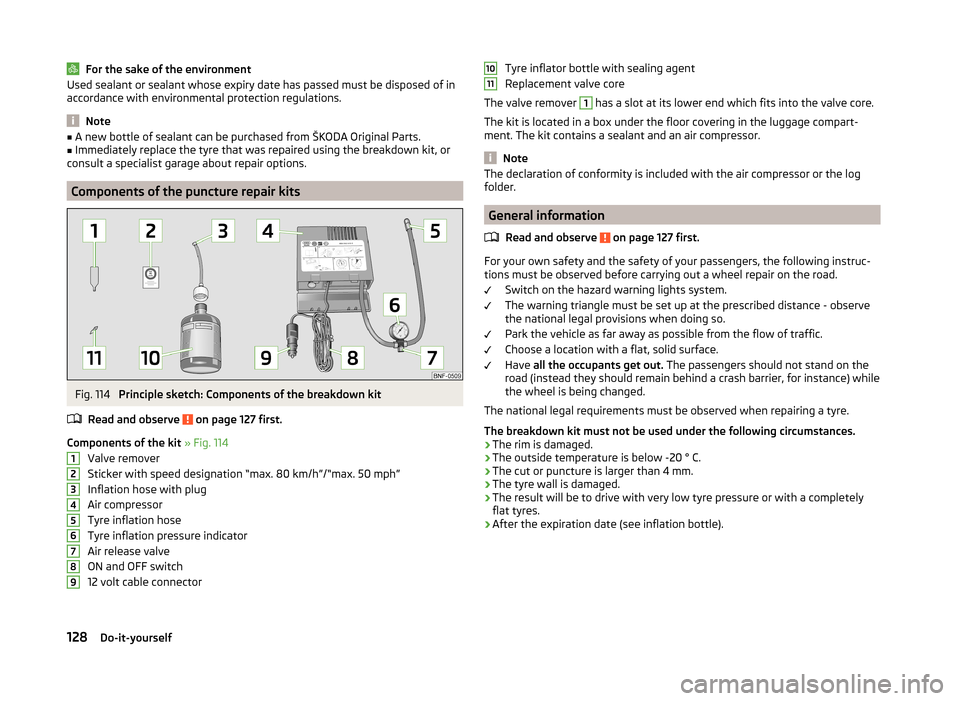

Components of the puncture repair kits

Fig. 114

Principle sketch: Components of the breakdown kit

Read and observe

on page 127 first.

Components of the kit » Fig. 114

Valve remover

Sticker with speed designation “max. 80 km/h”/“max. 50 mph” Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

123456789Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. The kit contains a sealant and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.

General information

Read and observe

on page 127 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard warning lights system.

The warning triangle must be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The national legal requirements must be observed when repairing a tyre.

The breakdown kit must not be used under the following circumstances. › The rim is damaged.

› The outside temperature is below -20 ° C.

› The cut or puncture is larger than 4 mm.

› The tyre wall is damaged.

› The result will be to drive with very low tyre pressure or with a completely

flat tyres.

› After the expiration date (see inflation bottle).

1011128Do-it-yourself

Page 132 of 164

Preparations for using the breakdown kitRead and observe

on page 127 first.

The following preparatory work must be carried out before using the puncture

repair kit.

›

Switch off the engine.

›

Select first gear or place the selector lever for automatic gearbox in the D or

R position .

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 127.

›

Remove the breakdown kit from the luggage compartment.

›

Stick the sticker

2

» Fig. 114 on page 128 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 127 first.

Sealing

›

Forcefully shake the tyre inflator bottle

10

» Fig. 114 on page 128 several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

clockwise.

The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

1

.

Inflating

›

Screw the tyre inflation hose

5

» Fig. 114 on page 128 of the air compressor

firmly onto the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 62, 12-Volt power outlet .

›

Switch on the air compressor with the ON and OFF switch

8

.

›Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre inflation pressure of 2.0 – 2.5 bar is achieved, continue the journey

at a maximum speed of 80 km/h (50 mph).

WARNING■ If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the

tyre.

Do not drive the vehicle! Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – risk of burning.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating. Allow the air compressor to cool a few minutes before

switching it on again.

Notes for driving with repaired tyres

Read and observe

on page 127 first.

The inflation pressure of the repaired tyre must be checked after driving for 10

minutes.

If the tyre pressure is 1.3 bar or less

›

Do not drive the vehicle! You cannot properly seal with tyre with the

breakdown kit.

If the tyre pressure is 1.3 bar or more

›

Set the tyre pressure to the correct value.

129Emergency equipment and self-help

Page 133 of 164

›Continue driving carefully to the nearest specialist garage at a maximum

speed of 80 km/h (50 mph).WARNING■ A tyre filled with sealant has the same driving characteristics as a stand-

ard tyre.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

Jump-starting

Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

130

The battery of another vehicle can be used to jump-start your vehicle if the en-

gine will not start because the battery is flat.

WARNING■ Pay attention to the warning instructions relating to working in the en-

gine compartment » page 107.■

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not jump start with the battery of an-

other vehicle – there is a risk of explosion.

■

Keep any sources of ignition (naked flame, smouldering cigarettes, etc.)

away from the battery – risk of explosion!

■

Never jump-start vehicle batteries with insufficient acid levels – risk of

explosion and chemical burns.

■

The vent screws of the battery cells must be tightened firmly.

Note

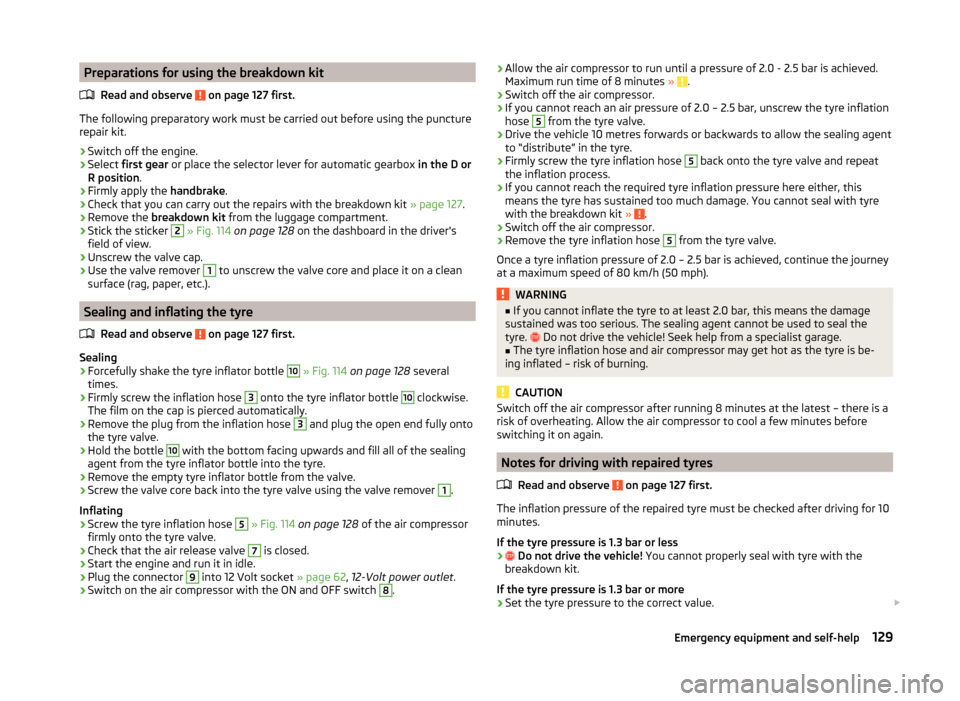

We recommend you buy jump-start cables from a car battery specialist.Jump-starting using the battery from another vehicleFig. 115

Jump-starting: A – flat battery, B

– battery providing current

Fig. 116

Engine earth: START-STOP sys-

tem

Read and observe on page 130 first.

The starting process using the battery of another vehicle requires the use of

jumper cables.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery

A

» Fig. 115 .

›

Attach clamp

2

to the positive terminal of the battery supplying power

B

.

›

Attach clamp

3

to the negative terminal of the battery supplying power

B

.

›

Attach the clamp

4

to a solid metal component firmly connected to the en-

gine block or to the engine block itself.

The jump-start cable must be connected to the engine earthing point only on

vehicles with the START-STOP system » Fig. 116.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Start the engine of the vehicle with the discharged battery.

130Do-it-yourself

Page 134 of 164

›If the engine does not start, halt the attempt to start the engine after 10 sec-

onds and wait for 30 seconds before repeating the process.›

Remove the jump start cables in the reverse order as attachment.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the bat-

tery supplying the power must not be significantly less than the capacity of

the discharged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and

insulated terminal clamps. Observe the instructions of the jumper lead manu-

facturer.

Positive cable – colour coding in the majority of cases is red.

Negative cable – colour coding in the majority of cases is black.

WARNING■

Do not clamp the jump-start cable to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being star-

ted.■

The non-insulated parts of the terminal clamps must never touch each

other – there is a risk of short circuit.

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– there is a risk of short circuit.

■

Route the jump-start cables so that they cannot be caught by any rotat-

ing parts in the engine compartment.

■

There must not be any contact between the two vehicles otherwise cur-

rent may flow as soon as the negative terminals are connected.

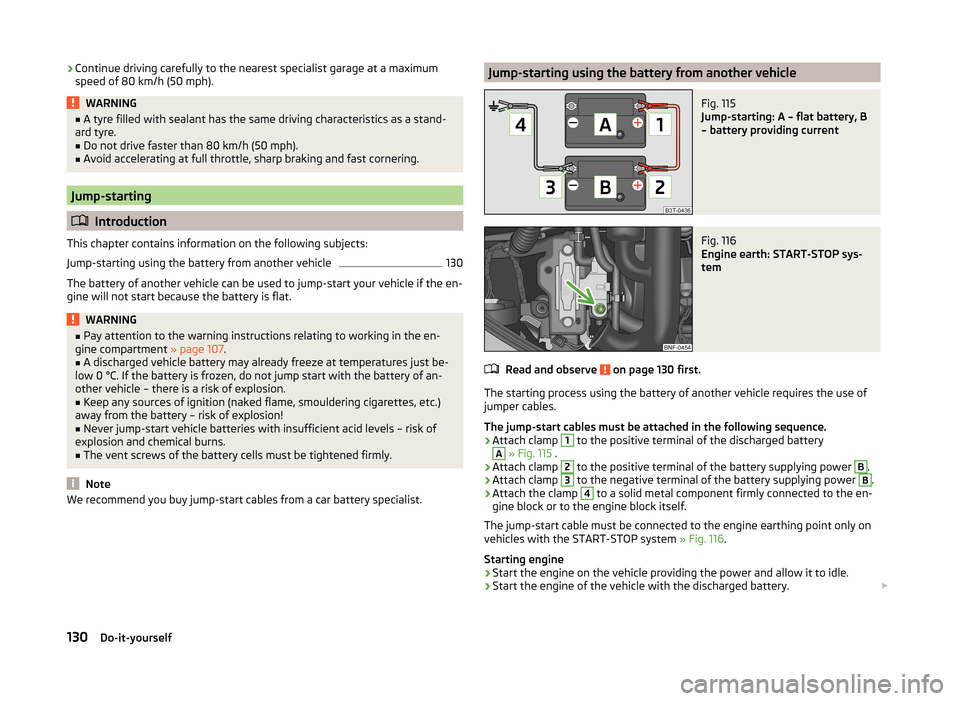

Towing the vehicle

Introduction

Fig. 117

Braided tow rope / Spiral tow rope

This chapter contains information on the following subjects:

Front towing eye

132

For towing, a braided tow rope is to be used » Fig. 117 -

.

When towing, the following guidelines must be observed.

Vehicles with manual transmission may be towed in with a tow bar or a tow

rope or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the auto-

matic gearbox is damaged!

Driver of the tow vehicle

›

Engage the clutch gently when starting off or depress the accelerator partic-

ularly gently if the vehicle is fitted with an automatic gearbox.

›

Only then approach correctly when the rope is taut.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

›

Switch on the ignition so that the steering wheel is not locked and so that

the turn-signal lights, windscreen wipers and windscreen washer system can

be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automated transmission.

131Emergency equipment and self-help

Page 135 of 164

Please note that the brake servo unit and power steering only operate if the

engine is running. If the engine is not running, significantly more physical force

is required to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

Both drivers should be familiar with the problems which might occur while a vehicle is being towed. Unskilled drivers should not attempt to tow in another

vehicle or to be towed in.

The vehicle must be transported on a special breakdown vehicle or trailer if it

is not possible to tow in the vehicle in the way described or if the towing dis-

tance is greater than 50 km.WARNING■ When towing, respect the national legal provisions, especially those

which relate to the identification of the towing vehicle and the vehicle be-

ing towed.■

When towing, exercise increased caution.

■

Do not use spiral rope for towing » Fig. 117-

, the towing eye may un-

screw from the vehicle - risk of accident.

■

Ensure tow rope is not twisted - risk of accident.

CAUTION

■ Do not tow start the engine – there is a risk of damaging the engine and the

catalytic converter. The battery from another vehicle can be used as a jump-

start aid » page 130 , Jump-starting .■

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

■

To protect both vehicles when tow-starting or towing, the tow rope should

be elastic. Thus one should only use plastic fibre rope or a rope made out of a

similarly elastic material.

■

There is always a risk of excessive stresses and damage resulting at the

points to which you attach the tow rope or tow bar when you attempt to tow a

vehicle which is not standing on a paved road.

■

Attach the tow rope or the tow bar only to the towing eye » page 132 .

Note

We recommend using a tow rope from ŠKODA Original Accessories, which is

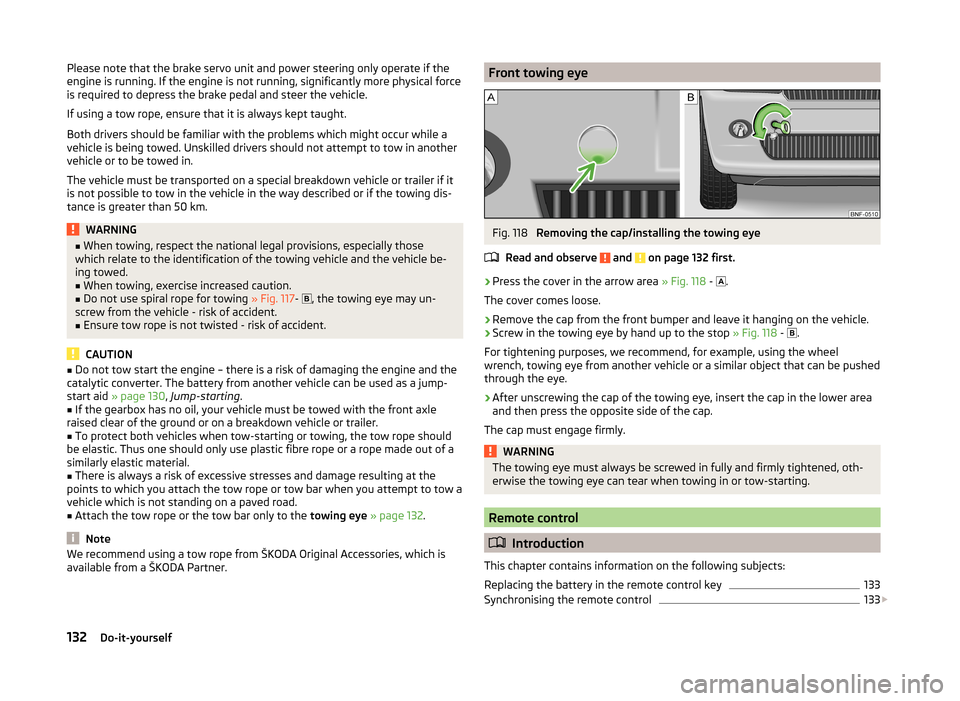

available from a ŠKODA Partner.Front towing eyeFig. 118

Removing the cap/installing the towing eye

Read and observe

and on page 132 first.

›

Press the cover in the arrow area » Fig. 118 -

.

The cover comes loose.

›

Remove the cap from the front bumper and leave it hanging on the vehicle.

›

Screw in the towing eye by hand up to the stop » Fig. 118 -

.

For tightening purposes, we recommend, for example, using the wheel

wrench, towing eye from another vehicle or a similar object that can be pushed

through the eye.

›

After unscrewing the cap of the towing eye, insert the cap in the lower area

and then press the opposite side of the cap.

The cap must engage firmly.

WARNINGThe towing eye must always be screwed in fully and firmly tightened, oth-

erwise the towing eye can tear when towing in or tow-starting.

Remote control

Introduction

This chapter contains information on the following subjects:

Replacing the battery in the remote control key

133

Synchronising the remote control

133

132Do-it-yourself

Page 136 of 164

CAUTION■The replacement battery must have the same specification as the original

battery.■

We recommend having faulty rechargeable batteries replaced by a ŠKODA

service partner.

■

Pay attention to the correct polarity when changing the battery.

For the sake of the environment

Dispose of the used battery in accordance with national legal provisions.

Replacing the battery in the remote control key

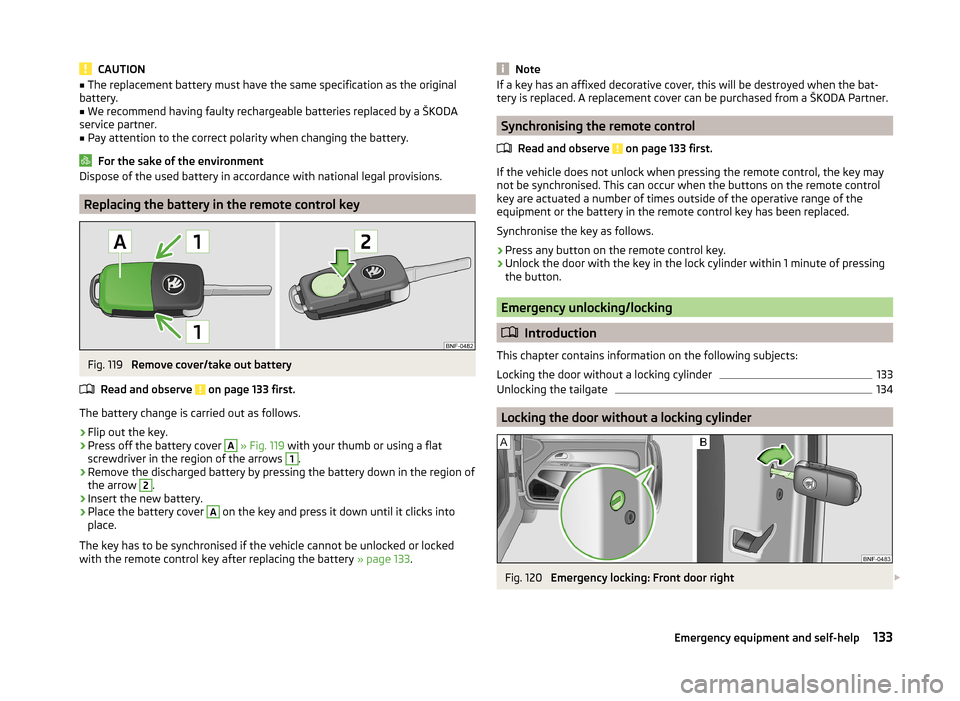

Fig. 119

Remove cover/take out battery

Read and observe

on page 133 first.

The battery change is carried out as follows.

›

Flip out the key.

›

Press off the battery cover

A

» Fig. 119 with your thumb or using a flat

screwdriver in the region of the arrows

1

.

›

Remove the discharged battery by pressing the battery down in the region of

the arrow

2

.

›

Insert the new battery.

›

Place the battery cover

A

on the key and press it down until it clicks into

place.

The key has to be synchronised if the vehicle cannot be unlocked or locked

with the remote control key after replacing the battery » page 133.

NoteIf a key has an affixed decorative cover, this will be destroyed when the bat-

tery is replaced. A replacement cover can be purchased from a ŠKODA Partner.

Synchronising the remote control

Read and observe

on page 133 first.

If the vehicle does not unlock when pressing the remote control, the key may

not be synchronised. This can occur when the buttons on the remote control

key are actuated a number of times outside of the operative range of the

equipment or the battery in the remote control key has been replaced.

Synchronise the key as follows.

›

Press any button on the remote control key.

›

Unlock the door with the key in the lock cylinder within 1 minute of pressing the button.

Emergency unlocking/locking

Introduction

This chapter contains information on the following subjects:

Locking the door without a locking cylinder

133

Unlocking the tailgate

134

Locking the door without a locking cylinder

Fig. 120

Emergency locking: Front door right

133Emergency equipment and self-help

Page 137 of 164

An emergency locking mechanism is located on the face side of the doors

which have no locking cylinder, it is only visible after opening the door.›

Insert the key into the slot » Fig. 120 -

.

›

Turn the key in the right-hand door is in the horizontal position in the direc-

tion of arrow » Fig. 120 -

and turn it against the direction of the arrow for

the left door.

After closing the door, it cannot be opened from the outside. The door is un-

locked by pulling on the door opening lever and is then opened from the out-

side.

Unlocking the tailgate

Fig. 121

Emergency unlocking of the lug-

gage compartment lid

The boot lid can be unlocked manually in an emergency.

›

Insert the vehicle key into the slot

A

» Fig. 121 in the trim panel as far as it

goes .

›

Unlock the lid by moving it in the direction of the arrow.

›

Open the boot lid.

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing the windscreen wiper blades

134

Replacing the rear window wiper blade

135WARNINGReplace the windscreen wiper blades once or twice a year for safety rea-

sons. These can be purchased from a ŠKODA Partner.CAUTIONIf the windscreen wipers are handled carelessly, there is a risk of damage to

the windscreen.

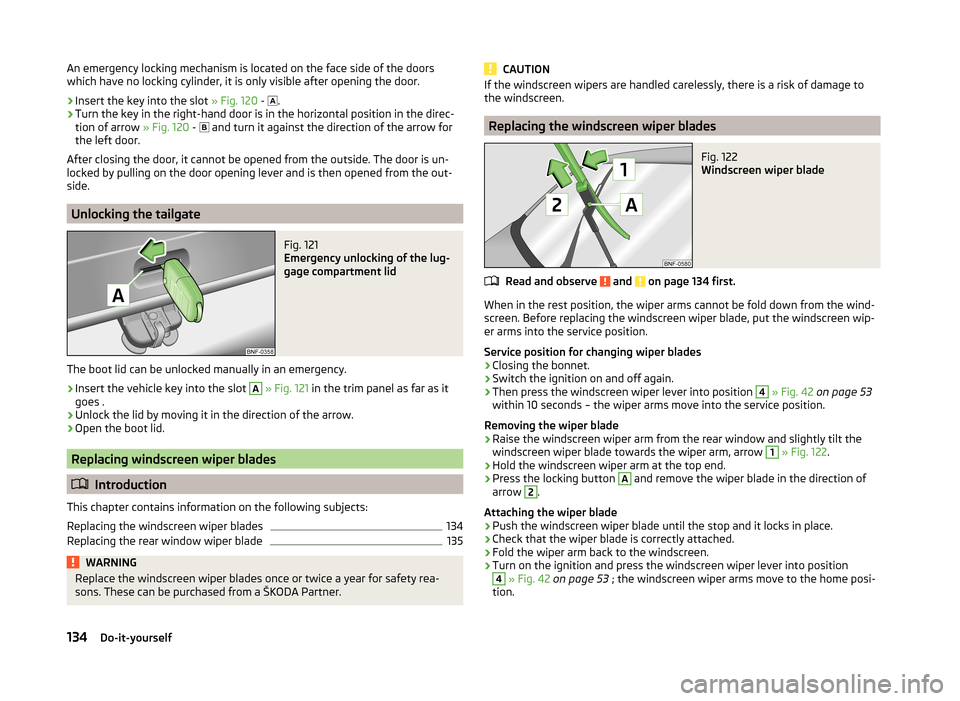

Replacing the windscreen wiper blades

Fig. 122

Windscreen wiper blade

Read and observe and on page 134 first.

When in the rest position, the wiper arms cannot be fold down from the wind- screen. Before replacing the windscreen wiper blade, put the windscreen wip-

er arms into the service position.

Service position for changing wiper blades

›

Closing the bonnet.

›

Switch the ignition on and off again.

›

Then press the windscreen wiper lever into position

4

» Fig. 42 on page 53

within 10 seconds – the wiper arms move into the service position.

Removing the wiper blade

›

Raise the windscreen wiper arm from the rear window and slightly tilt the

windscreen wiper blade towards the wiper arm, arrow

1

» Fig. 122 .

›

Hold the windscreen wiper arm at the top end.

›

Press the locking button

A

and remove the wiper blade in the direction of

arrow

2

.

Attaching the wiper blade

›

Push the windscreen wiper blade until the stop and it locks in place.

›

Check that the wiper blade is correctly attached.

›

Fold the wiper arm back to the windscreen.

›

Turn on the ignition and press the windscreen wiper lever into position

4

» Fig. 42 on page 53 ; the windscreen wiper arms move to the home posi-

tion.

134Do-it-yourself

Page 138 of 164

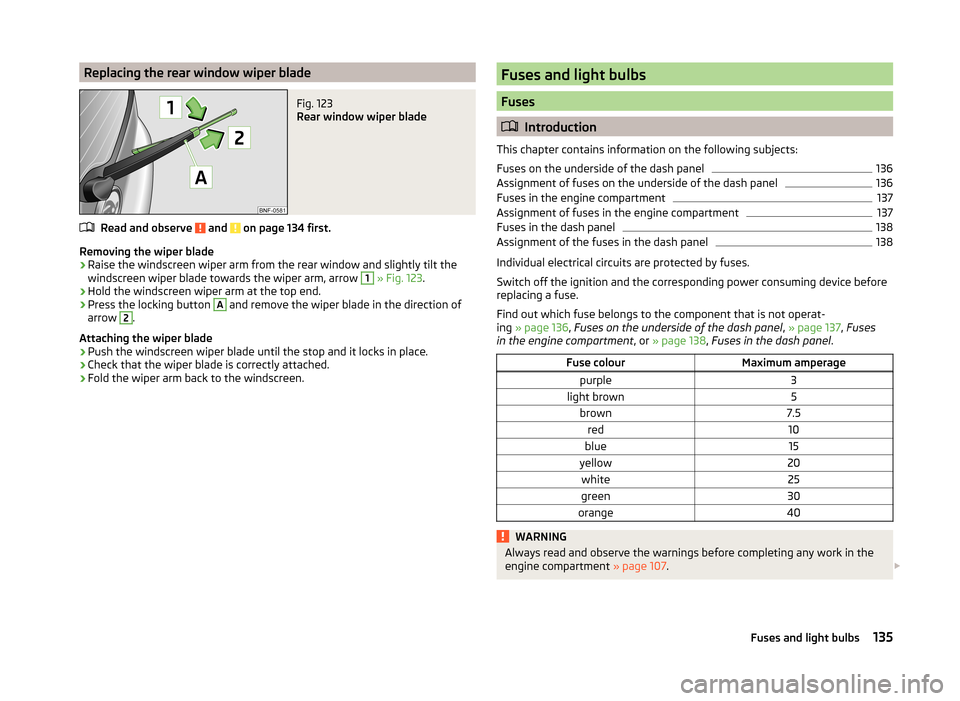

Replacing the rear window wiper bladeFig. 123

Rear window wiper blade

Read and observe and on page 134 first.

Removing the wiper blade

›

Raise the windscreen wiper arm from the rear window and slightly tilt the

windscreen wiper blade towards the wiper arm, arrow

1

» Fig. 123 .

›

Hold the windscreen wiper arm at the top end.

›

Press the locking button

A

and remove the wiper blade in the direction of

arrow

2

.

Attaching the wiper blade

›

Push the windscreen wiper blade until the stop and it locks in place.

›

Check that the wiper blade is correctly attached.

›

Fold the wiper arm back to the windscreen.

Fuses and light bulbs

Fuses

Introduction

This chapter contains information on the following subjects:

Fuses on the underside of the dash panel

136

Assignment of fuses on the underside of the dash panel

136

Fuses in the engine compartment

137

Assignment of fuses in the engine compartment

137

Fuses in the dash panel

138

Assignment of the fuses in the dash panel

138

Individual electrical circuits are protected by fuses.

Switch off the ignition and the corresponding power consuming device before

replacing a fuse.

Find out which fuse belongs to the component that is not operat-

ing » page 136 , Fuses on the underside of the dash panel , » page 137 , Fuses

in the engine compartment , or » page 138 , Fuses in the dash panel .

Fuse colourMaximum amperagepurple3light brown5brown7.5red10blue15yellow20white25green30orange40WARNINGAlways read and observe the warnings before completing any work in the

engine compartment » page 107. 135Fuses and light bulbs

Page 139 of 164

CAUTION■“Never repair” fuses and also do not replace them with a fuse of a higher am-

perage – risk of fire! This may also cause damage at another part of the electri-

cal system.■

A blown fuses is recognisable by the molten metal strip. Replace the faulty

fuse with a new one of the same amperage.

■

If a newly inserted fuse burns through again, then a specialist should be con-

sulted immediately.

Note

■ We recommend always carrying replacement fuses in the vehicle. A box of

replacement fuses can be purchased from ŠKODA Original Accessories.■

There can be several power consuming devices for one fuse.

■

Multiple fuses may exist for a single power consuming device.

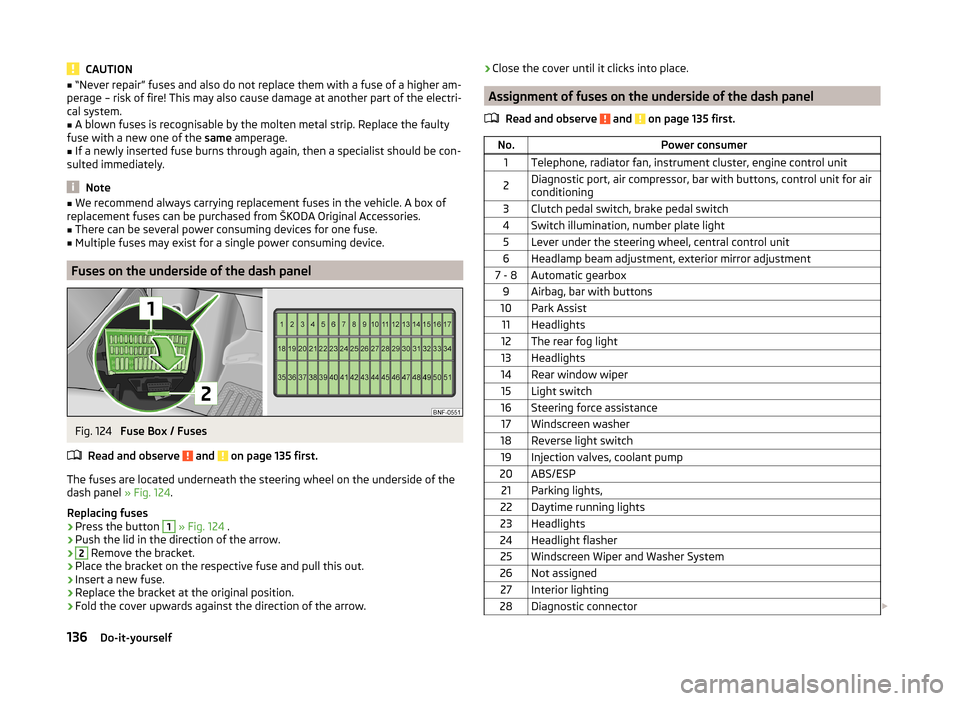

Fuses on the underside of the dash panel

Fig. 124

Fuse Box / Fuses

Read and observe

and on page 135 first.

The fuses are located underneath the steering wheel on the underside of the

dash panel » Fig. 124.

Replacing fuses

›

Press the button

1

» Fig. 124 .

›

Push the lid in the direction of the arrow.

›2

Remove the bracket.

›

Place the bracket on the respective fuse and pull this out.

›

Insert a new fuse.

›

Replace the bracket at the original position.

›

Fold the cover upwards against the direction of the arrow.

›Close the cover until it clicks into place.

Assignment of fuses on the underside of the dash panel

Read and observe

and on page 135 first.

No.Power consumer1Telephone, radiator fan, instrument cluster, engine control unit2Diagnostic port, air compressor, bar with buttons, control unit for air

conditioning3Clutch pedal switch, brake pedal switch4Switch illumination, number plate light5Lever under the steering wheel, central control unit6Headlamp beam adjustment, exterior mirror adjustment7 - 8Automatic gearbox9Airbag, bar with buttons10Park Assist11Headlights12The rear fog light13Headlights14Rear window wiper15Light switch16Steering force assistance17Windscreen washer18Reverse light switch19Injection valves, coolant pump20ABS/ESP21Parking lights,22Daytime running lights23Headlights24Headlight flasher25Windscreen Wiper and Washer System26Not assigned27Interior lighting28Diagnostic connector 136Do-it-yourself

Page 140 of 164

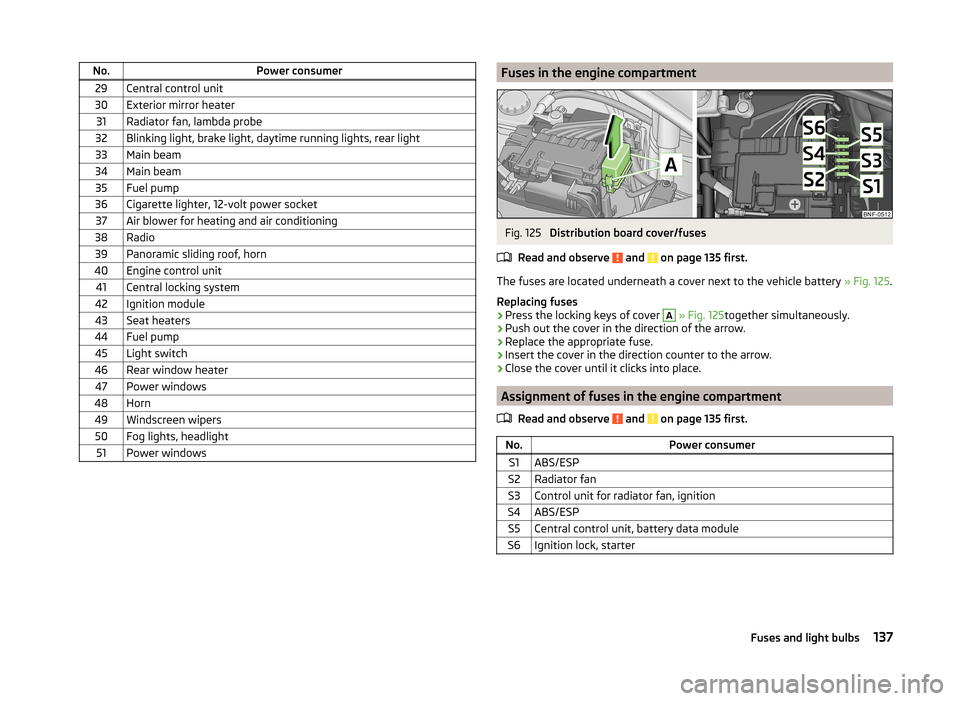

No.Power consumer29Central control unit30Exterior mirror heater31Radiator fan, lambda probe32Blinking light, brake light, daytime running lights, rear light33Main beam34Main beam35Fuel pump36Cigarette lighter, 12-volt power socket37Air blower for heating and air conditioning38Radio39Panoramic sliding roof, horn40Engine control unit41Central locking system42Ignition module43Seat heaters44Fuel pump45Light switch46Rear window heater47Power windows48Horn49Windscreen wipers50Fog lights, headlight51Power windowsFuses in the engine compartmentFig. 125

Distribution board cover/fuses

Read and observe

and on page 135 first.

The fuses are located underneath a cover next to the vehicle battery » Fig. 125.

Replacing fuses

›

Press the locking keys of cover

A

» Fig. 125 together simultaneously.

›

Push out the cover in the direction of the arrow.

›

Replace the appropriate fuse.

›

Insert the cover in the direction counter to the arrow.

›

Close the cover until it clicks into place.

Assignment of fuses in the engine compartment

Read and observe

and on page 135 first.

No.Power consumerS1ABS/ESPS2Radiator fanS3Control unit for radiator fan, ignitionS4ABS/ESPS5Central control unit, battery data moduleS6Ignition lock, starter137Fuses and light bulbs