SKODA FABIA 2000 1.G / 6Y Manual PDF

Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 71 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 3 02

The materials and the corresponding work instructions

are listed in the ⇒Technical Service Handbook, Part 6 -

Technology of paint repairs, chemical materials.

Inspecting plenum chamber and water

drain openings for dirt, cleaning if neces-

sary

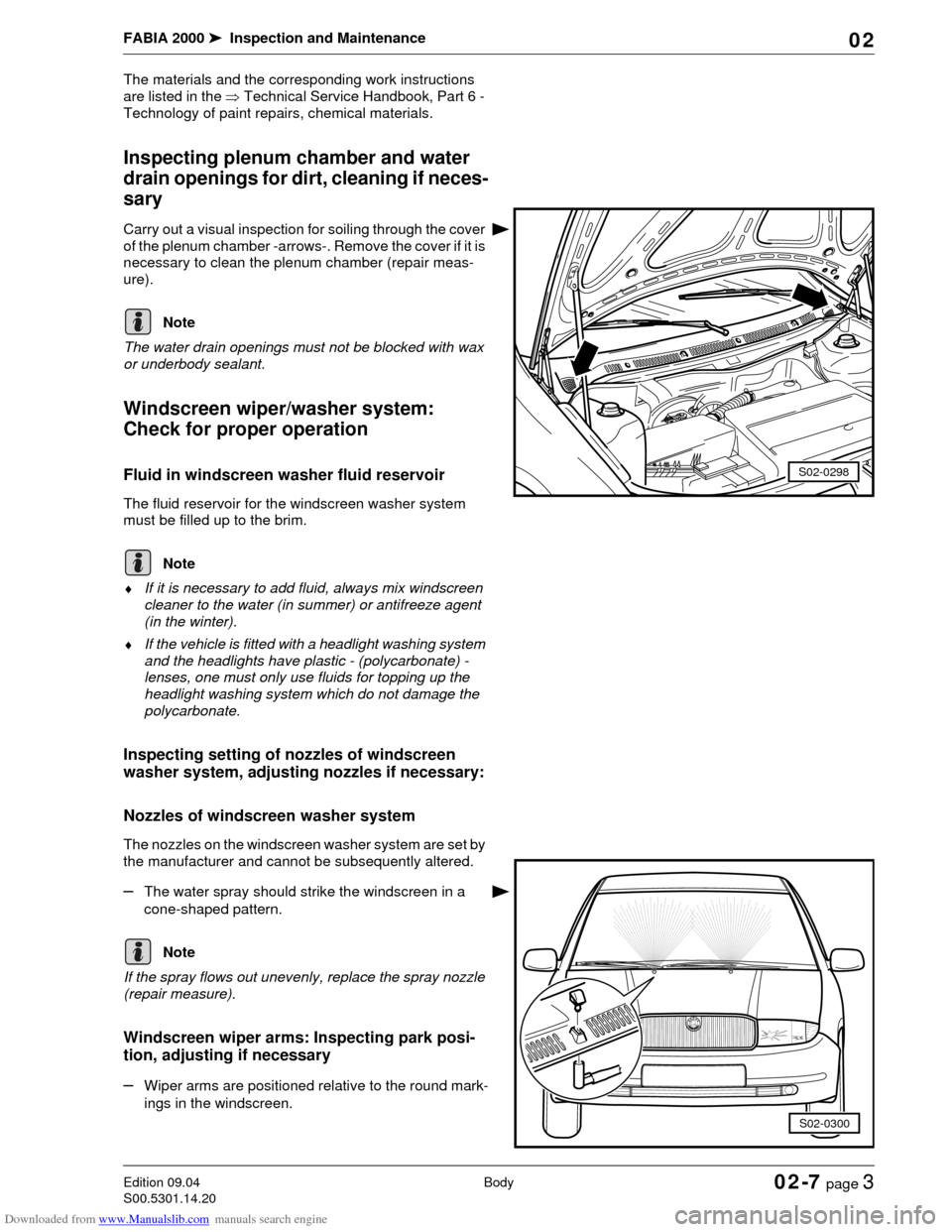

Carry out a visual inspection for soiling through the cover

of the plenum chamber -arrows-. Remove the cover if it is

necessary to clean the plenum chamber (repair meas-

ure).

The water drain openings must not be blocked with wax

or underbody sealant.

Windscreen wiper/washer system:

Check for proper operation

Fluid in windscreen washer fluid reservoir

The fluid reservoir for the windscreen washer system

must be filled up to the brim.

♦If it is necessary to add fluid, always mix windscreen

cleaner to the water (in summer) or antifreeze agent

(in the winter).

♦If the vehicle is fitted with a headlight washing system

and the headlights have plastic - (polycarbonate) -

lenses, one must only use fluids for topping up the

headlight washing system which do not damage the

polycarbonate.

Inspecting setting of nozzles of windscreen

washer system, adjusting nozzles if necessary:

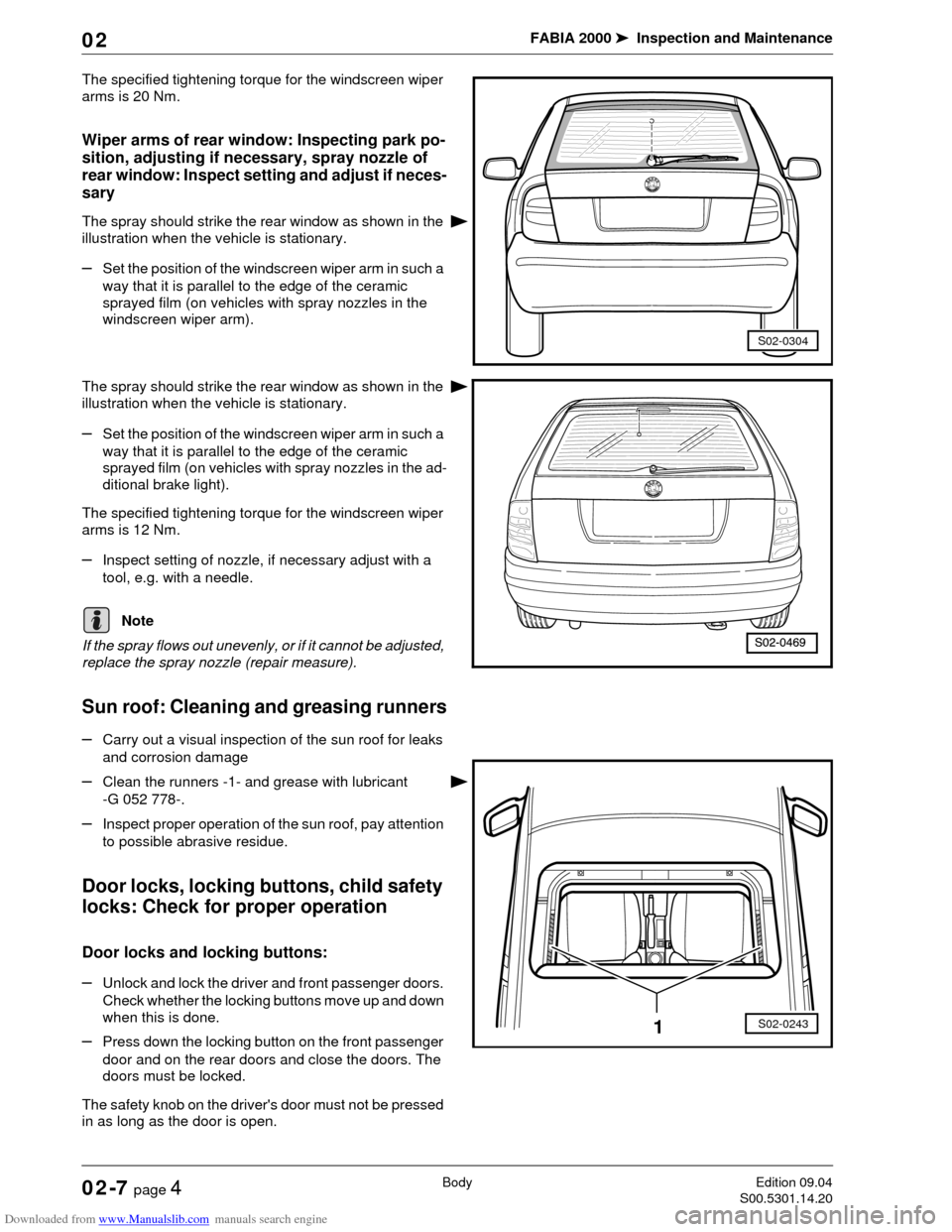

Nozzles of windscreen washer system

The nozzles on the windscreen washer system are set by

the manufacturer and cannot be subsequently altered.

–The water spray should strike the windscreen in a

cone-shaped pattern.

If the spray flows out unevenly, replace the spray nozzle

(repair measure).

Windscreen wiper arms: Inspecting park posi-

tion, adjusting if necessary

–Wiper arms are positioned relative to the round mark-

ings in the windscreen.

S02-0298

Note

Note

S02-0300

Note

Page 72 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 4 02

The specified tightening torque for the windscreen wiper

arms is 20 Nm.

Wiper arms of rear window: Inspecting park po-

sition, adjusting if necessary, spray nozzle of

rear window: Inspect setting and adjust if neces-

sary

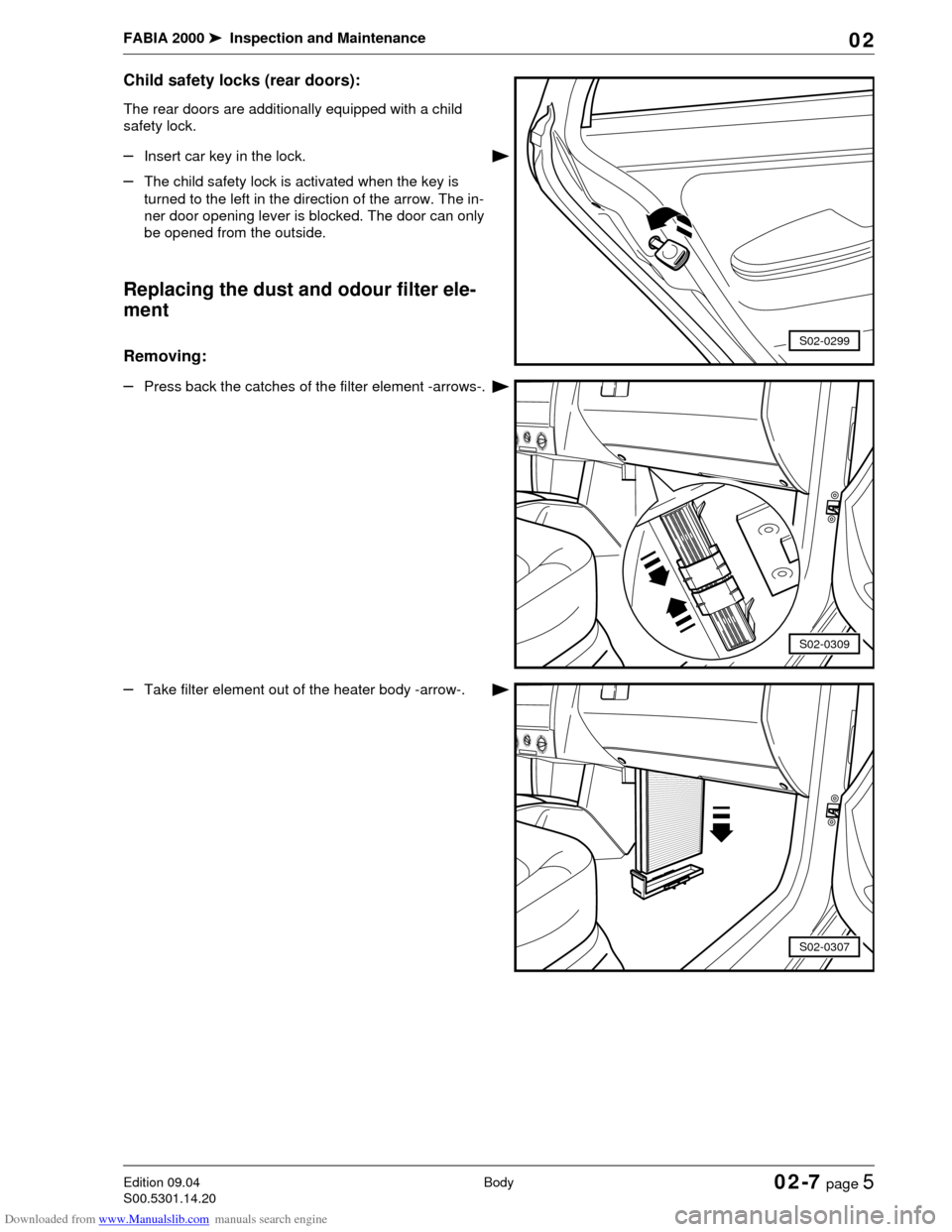

The spray should strike the rear window as shown in the

illustration when the vehicle is stationary.

–Set the position of the windscreen wiper arm in such a

way that it is parallel to the edge of the ceramic

sprayed film (on vehicles with spray nozzles in the

windscreen wiper arm).

The spray should strike the rear window as shown in the

illustration when the vehicle is stationary.

–Set the position of the windscreen wiper arm in such a

way that it is parallel to the edge of the ceramic

sprayed film (on vehicles with spray nozzles in the ad-

ditional brake light).

The specified tightening torque for the windscreen wiper

arms is 12 Nm.

–Inspect setting of nozzle, if necessary adjust with a

tool, e.g. with a needle.

If the spray flows out unevenly, or if it cannot be adjusted,

replace the spray nozzle (repair measure).

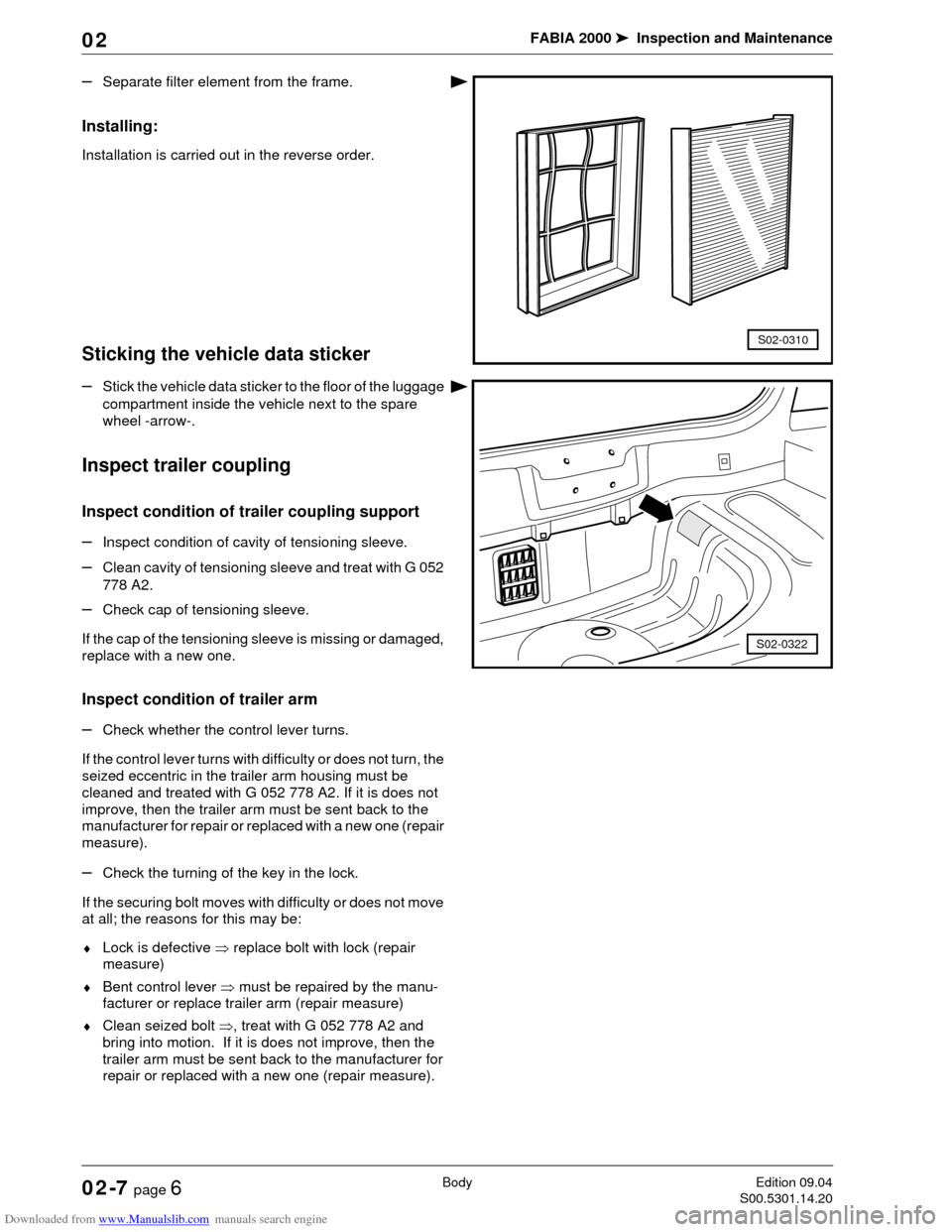

Sun roof: Cleaning and greasing runners

–Carry out a visual inspection of the sun roof for leaks

and corrosion damage

–Clean the runners -1- and grease with lubricant

-G 052 778-.

–Inspect proper operation of the sun roof, pay attention

to possible abrasive residue.

Door locks, locking buttons, child safety

locks: Check for proper operation

Door locks and locking buttons:

–Unlock and lock the driver and front passenger doors.

Check whether the locking buttons move up and down

when this is done.

–Press down the locking button on the front passenger

door and on the rear doors and close the doors. The

doors must be locked.

The safety knob on the driver's door must not be pressed

in as long as the door is open.

S02-0304

Note

S02-02431

Page 73 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 5 02

Child safety locks (rear doors):

The rear doors are additionally equipped with a child

safety lock.

–Insert car key in the lock.

–The child safety lock is activated when the key is

turned to the left in the direction of the arrow. The in-

ner door opening lever is blocked. The door can only

be opened from the outside.

Replacing the dust and odour filter ele-

ment

Removing:

–Press back the catches of the filter element -arrows-.

–Take filter element out of the heater body -arrow-.

S02-0299

S02-0309

S02-0307

Page 74 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 6 02

–Separate filter element from the frame.

Installing:

Installation is carried out in the reverse order.

Sticking the vehicle data sticker

–Stick the vehicle data sticker to the floor of the luggage

compartment inside the vehicle next to the spare

wheel -arrow-.

Inspect trailer coupling

Inspect condition of trailer coupling support

–Inspect condition of cavity of tensioning sleeve.

–Clean cavity of tensioning sleeve and treat with G 052

778 A2.

–Check cap of tensioning sleeve.

If the cap of the tensioning sleeve is missing or damaged,

replace with a new one.

Inspect condition of trailer arm

–Check whether the control lever turns.

If the control lever turns with difficulty or does not turn, the

seized eccentric in the trailer arm housing must be

cleaned and treated with G 052 778 A2. If it is does not

improve, then the trailer arm must be sent back to the

manufacturer for repair or replaced with a new one (repair

measure).

–Check the turning of the key in the lock.

If the securing bolt moves with difficulty or does not move

at all; the reasons for this may be:

♦Lock is defective ⇒ replace bolt with lock (repair

measure)

♦Bent control lever ⇒ must be repaired by the manu-

facturer or replace trailer arm (repair measure)

♦Clean seized bolt ⇒, treat with G 052 778 A2 and

bring into motion. If it is does not improve, then the

trailer arm must be sent back to the manufacturer for

repair or replaced with a new one (repair measure).

S02-0310

S02-0322

Page 75 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 7 02

When applying G 052 778 A2 make sure that the product

does not penetrate into the gap between the lock bolt,

control lever, eccentric and trailer arm housing.

Trailer coupling: Check for proper operation

–Tighten trailer arm in the tensioning sleeve.

–Close lock and remove key.

–Check for correct closing by turning the control lever

downwards.

Note

WARNING!

If one of the measures cannot be carried out or if

the closed lever can be turned to an angle greater

than 5 , the trailer coupling is damaged and must

not be operated. The fault must be identified and

the damaged components must be replaced (repair

measure).

Page 76 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 8 02

Page 77 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Exhaust-emission AnalysisEdition 09.04

S00.5301.14.2002-8 page 1 02

02-8 Exhaust-emission Analy-

sis

The exhaust-emission analysis must be carried out ac-

cording to the relevant national legislation of the particu-

lar country.

Exhaust-Emission Analysis on Models

with Fuel Engines

Perform the following visual inspections and comply with

the setting conditions below before performing the ex-

haust-emission analysis:

Visual inspection

♦Lambda probes are connected

♦All vacuum hoses are connected

♦All wires of the activated charcoal filter system are

connected

♦All the electrical wires of the ignition and injection sys-

tem are connected

♦Hose for crankcase ventilation is connected

♦The exhaust system must be undamaged and tight

♦Catalyst must be undamaged

Test and setting conditions

•Perfect operation of the engine

•Perfect operation of the ignition system

•Intake system tight

•All electrical components are switched off (radiator fan

must not run during the test)

♦If any errors are noticed they must be repaired.

♦The idling speed, ignition point and CO content are

only measured as they cannot be adjusted.

♦The CO content is set to nominal value by the lambda

control. Faults in the lambda control are detected by

the self-diagnosis and stored in the fault memory.

♦When interrogating the fault memory (engine electron-

ics) all detected faults must be repaired and the fault

memory must be erased.

♦To prevent injury to persons and/or damage to the ig-

nition and injection system make sure the ignition is

switched off when disconnecting and connecting the

wires of the ignition system.

Connect the test equipment to the vehicle

To prevent industrial accidents or avoid causing damage

to the ignition system, pay attention to the following:

Note

Note

Note

Page 78 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Exhaust-emission AnalysisEdition 09.04

S00.5301.14.2002-8 page 2 02

♦Disconnect and connect wires of the ignition system

(including high-voltage wires) when the ignition is

switched off.

–Connect the tester in compliance with the operating

instructions.

The exhaust gas probe must be fully inserted into the ex-

haust tailpipe (do not insert into the suction tube)!

–Start engine and run in idle.

–Measure idle speed and CO content.

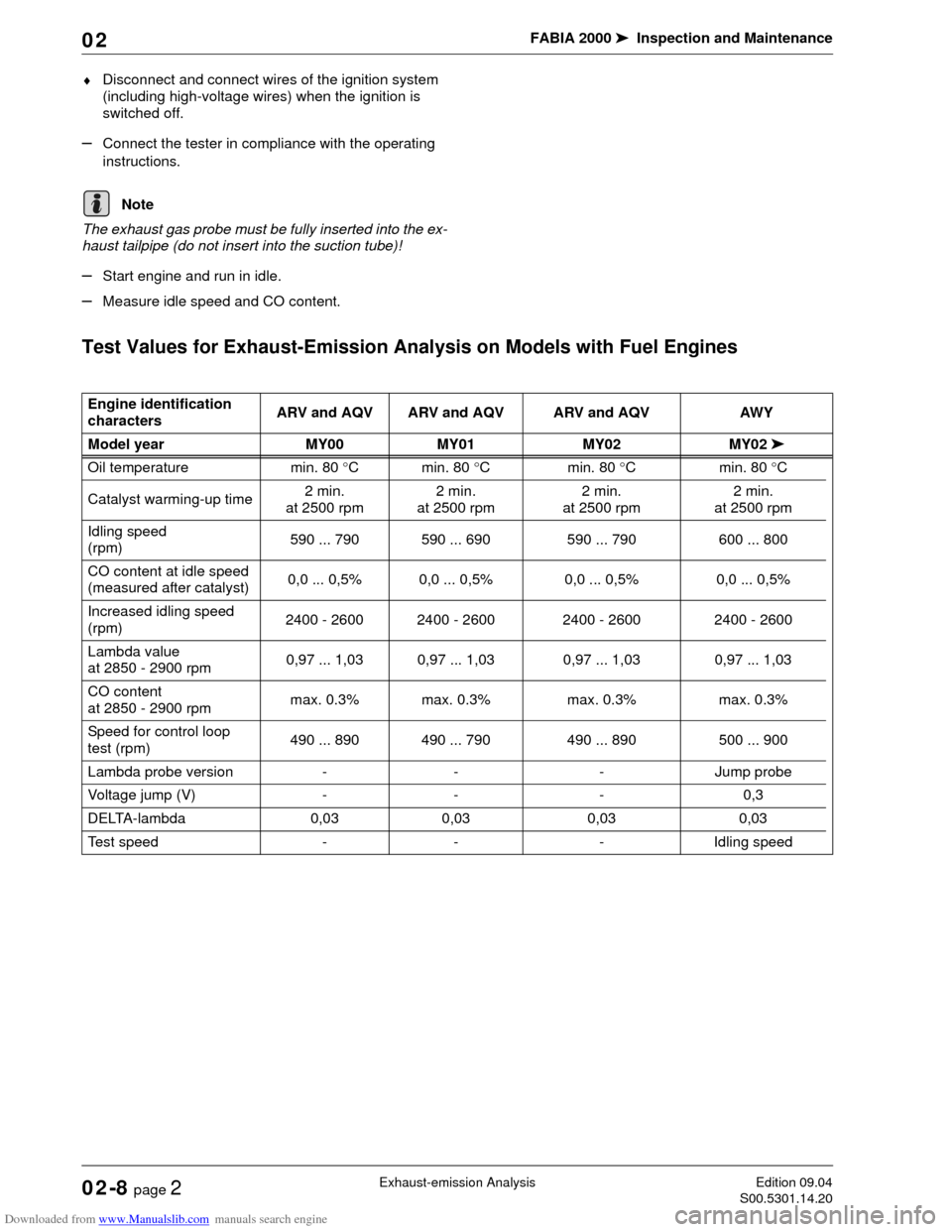

Test Values for Exhaust-Emission Analysis on Models with Fuel Engines

Note

Engine identification

charactersARV and AQV ARV and AQV ARV and AQV AWY

Model year MY00 MY01 MY02 MY02 ➤

Oil temperature min. 80 °Cmin. 80 °C min. 80 °Cmin. 80 °C

Catalyst warming-up time2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm

Idling speed

(rpm)590 ... 790 590 ... 690 590 ... 790 600 ... 800

CO content at idle speed

(measured after catalyst)0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5%

Increased idling speed

(rpm)2400 - 2600 2400 - 2600 2400 - 2600 2400 - 2600

Lambda value

at 2850 - 2900 rpm0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03

CO content

at 2850 - 2900 rpmmax. 0.3% max. 0.3% max. 0.3% max. 0.3%

Speed for control loop

test (rpm)490 ... 890 490 ... 790 490 ... 890 500 ... 900

Lambda probe version - - - Jump probe

Voltage jump (V) - - - 0,3

DELTA-lambda 0,03 0,03 0,03 0,03

Test speed - - - Idling speed

Page 79 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Exhaust-emission AnalysisEdition 09.04

S00.5301.14.2002-8 page 3 02

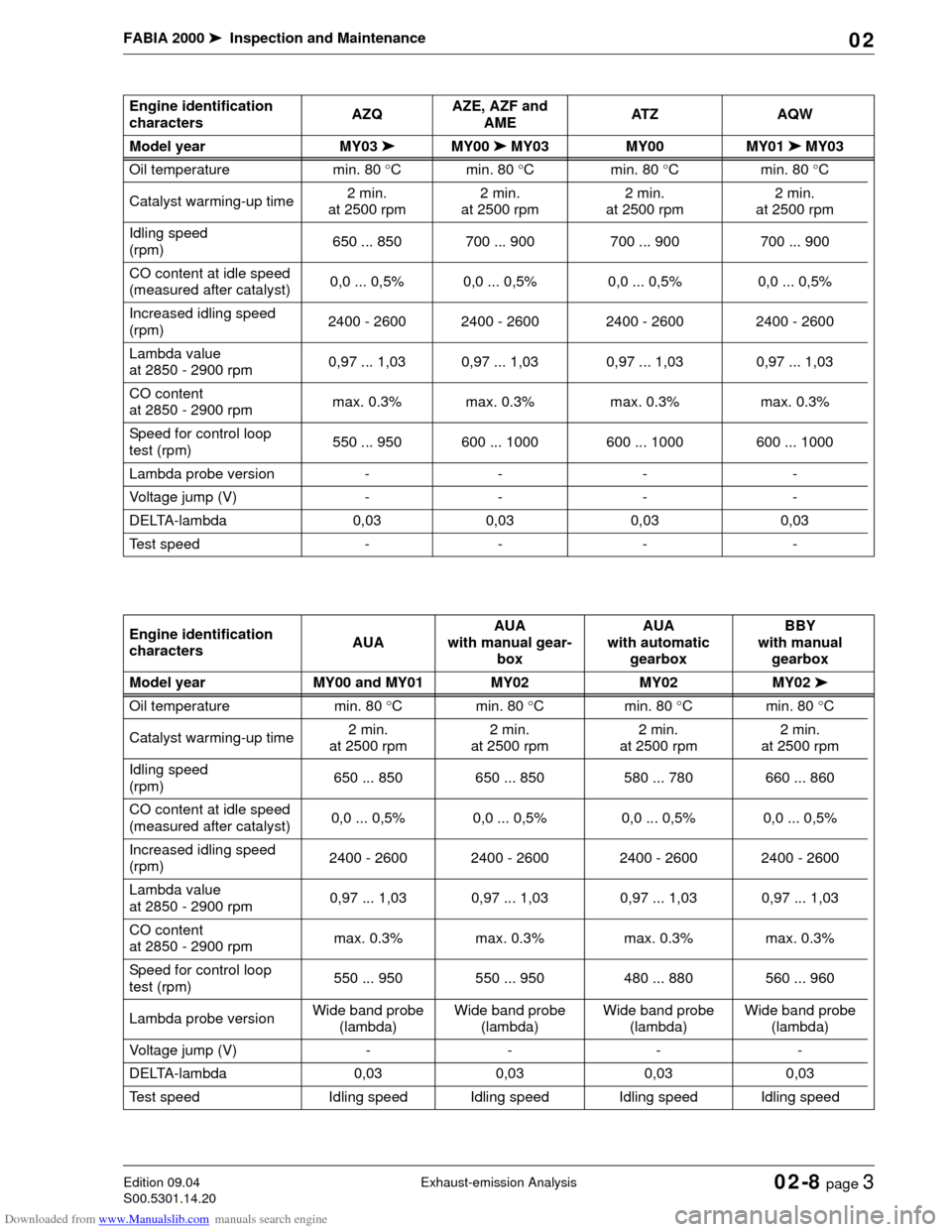

Engine identification

charactersAZQAZE, AZF and

AMEAT Z A Q W

Model year MY03 ➤MY00 ➤ MY03 MY00 MY01 ➤ MY03

Oil temperature min. 80 °Cmin. 80 °C min. 80 °Cmin. 80 °C

Catalyst warming-up time2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm

Idling speed

(rpm)650 ... 850 700 ... 900 700 ... 900 700 ... 900

CO content at idle speed

(measured after catalyst)0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5%

Increased idling speed

(rpm)2400 - 2600 2400 - 2600 2400 - 2600 2400 - 2600

Lambda value

at 2850 - 2900 rpm0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03

CO content

at 2850 - 2900 rpmmax. 0.3% max. 0.3% max. 0.3% max. 0.3%

Speed for control loop

test (rpm)550 ... 950 600 ... 1000 600 ... 1000 600 ... 1000

Lambda probe version - - - -

Voltage jump (V) - - - -

DELTA-lambda 0,03 0,03 0,03 0,03

Test speed - - - -

Engine identification

charactersAUAAUA

with manual gear-

boxAUA

with automatic

gearboxBBY

with manual

gearbox

Model year MY00 and MY01 MY02 MY02 MY02 ➤

Oil temperature min. 80 °C min. 80 °C min. 80 °Cmin. 80 °C

Catalyst warming-up time2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm

Idling speed

(rpm)650 ... 850 650 ... 850 580 ... 780 660 ... 860

CO content at idle speed

(measured after catalyst)0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5%

Increased idling speed

(rpm)2400 - 2600 2400 - 2600 2400 - 2600 2400 - 2600

Lambda value

at 2850 - 2900 rpm0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03

CO content

at 2850 - 2900 rpmmax. 0.3% max. 0.3% max. 0.3% max. 0.3%

Speed for control loop

test (rpm)

550 ... 950 550 ... 950 480 ... 880 560 ... 960

Lambda probe versionWide band probe

(lambda)Wide band probe

(lambda)Wide band probe

(lambda)Wide band probe

(lambda)

Voltage jump (V) - - - -

DELTA-lambda 0,03 0,03 0,03 0,03

Test speed Idling speed Idling speed Idling speed Idling speed

Page 80 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Exhaust-emission AnalysisEdition 09.04

S00.5301.14.2002-8 page 4 02

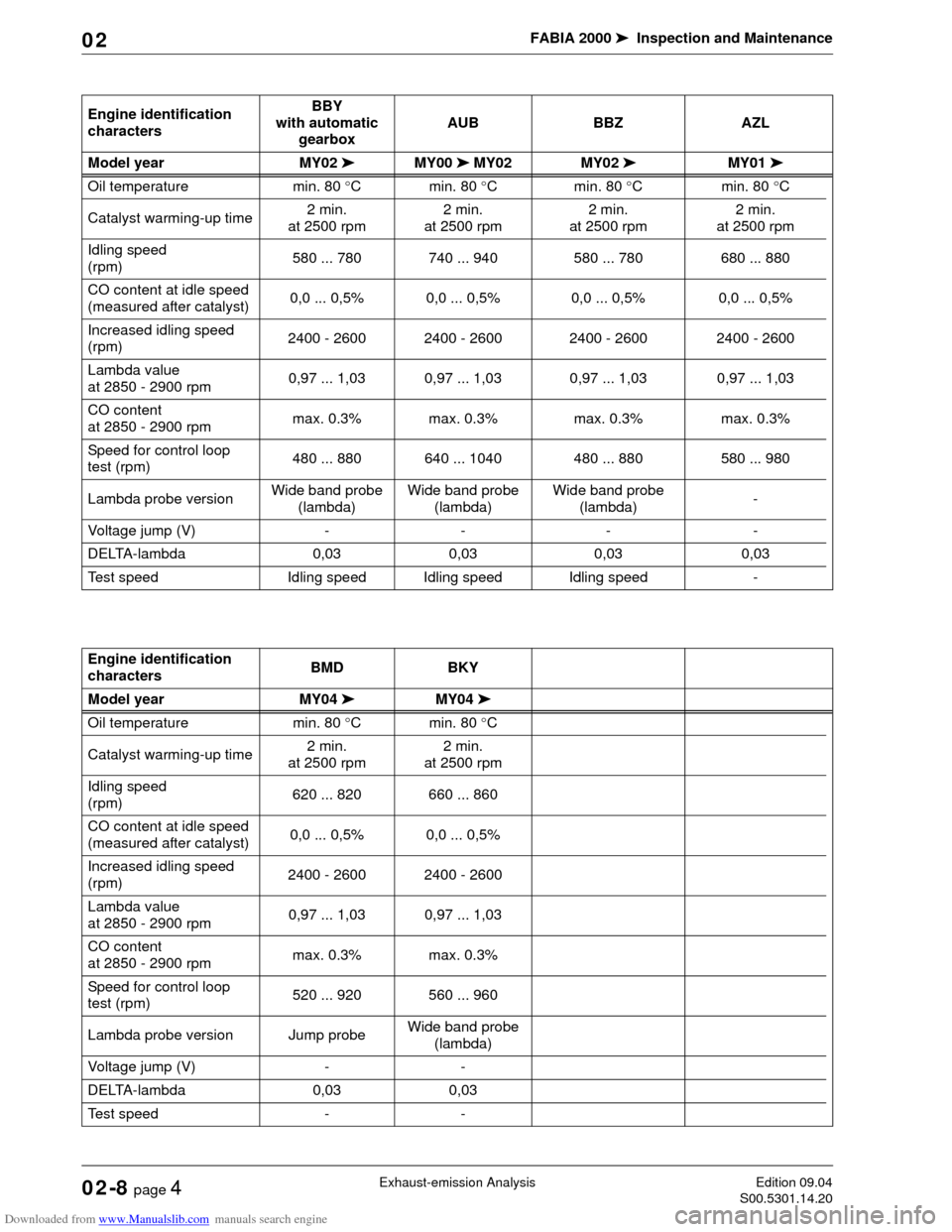

Engine identification

charactersBBY

with automatic

gearboxAUB BBZ AZL

Model year MY02 ➤MY00 ➤ MY02 MY02 ➤MY01 ➤

Oil temperature min. 80 °C min. 80 °C min. 80 °Cmin. 80 °C

Catalyst warming-up time2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm2 min.

at 2500 rpm

Idling speed

(rpm)580 ... 780 740 ... 940 580 ... 780 680 ... 880

CO content at idle speed

(measured after catalyst)0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5% 0,0 ... 0,5%

Increased idling speed

(rpm)2400 - 2600 2400 - 2600 2400 - 2600 2400 - 2600

Lambda value

at 2850 - 2900 rpm0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03 0,97 ... 1,03

CO content

at 2850 - 2900 rpmmax. 0.3% max. 0.3% max. 0.3% max. 0.3%

Speed for control loop

test (rpm)480 ... 880 640 ... 1040 480 ... 880 580 ... 980

Lambda probe versionWide band probe

(lambda)Wide band probe

(lambda)Wide band probe

(lambda)-

Voltage jump (V) - - - -

DELTA-lambda 0,03 0,03 0,03 0,03

Test speed Idling speed Idling speed Idling speed -

Engine identification

charactersBMD BKY

Model year MY04 ➤MY04 ➤

Oil temperature min. 80 °C min. 80 °C

Catalyst warming-up time2 min.

at 2500 rpm2 min.

at 2500 rpm

Idling speed

(rpm)620 ... 820 660 ... 860

CO content at idle speed

(measured after catalyst)0,0 ... 0,5% 0,0 ... 0,5%

Increased idling speed

(rpm)2400 - 2600 2400 - 2600

Lambda value

at 2850 - 2900 rpm0,97 ... 1,03 0,97 ... 1,03

CO content

at 2850 - 2900 rpmmax. 0.3% max. 0.3%

Speed for control loop

test (rpm)520 ... 920 560 ... 960

Lambda probe version Jump probeWide band probe

(lambda)

Voltage jump (V) - -

DELTA-lambda 0,03 0,03

Test speed - -