torque SKODA FABIA 2000 1.G / 6Y Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 6 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20II

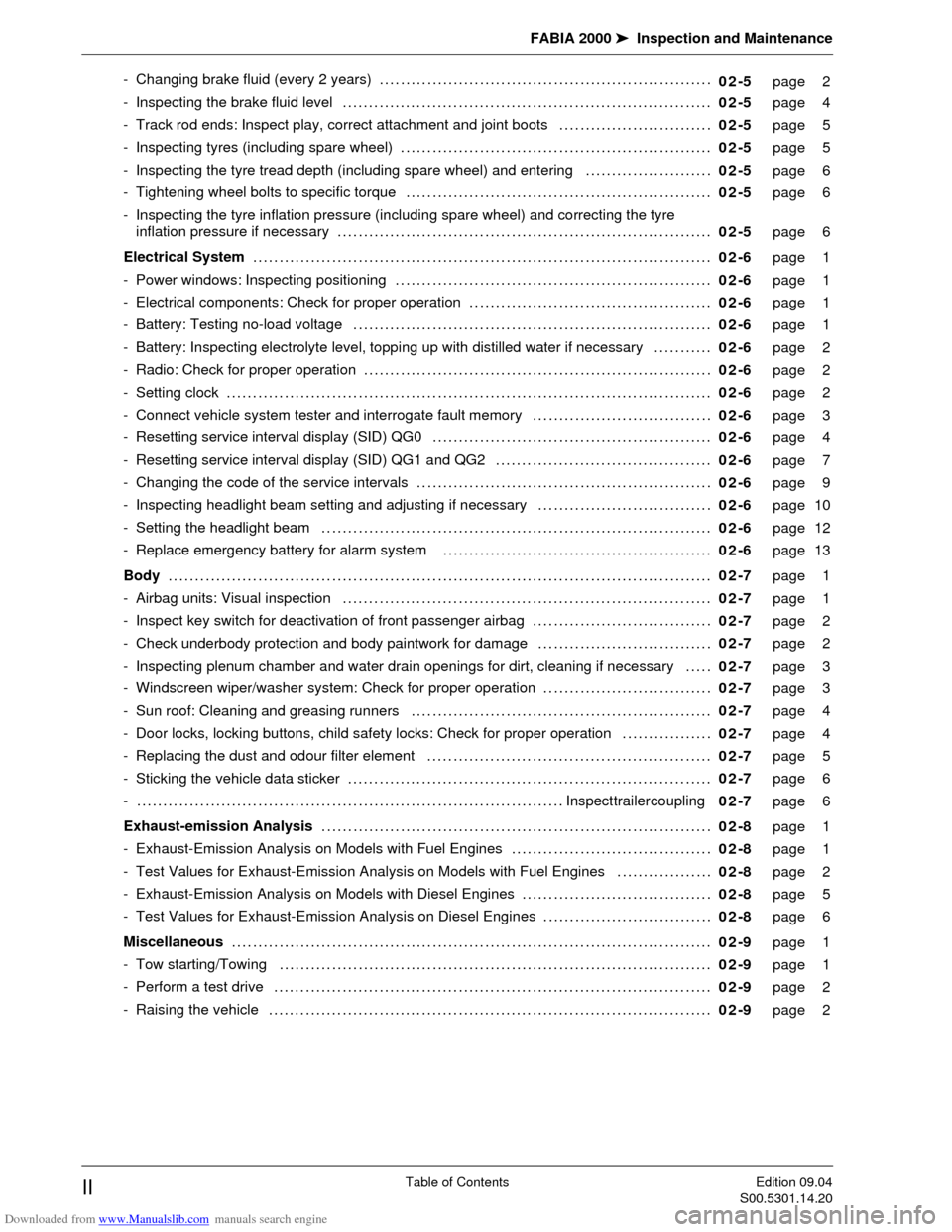

- Changing brake fluid (every 2 years)...............................................................

- Inspecting the brake fluid level ......................................................................

- Track rod ends: Inspect play, correct attachment and joint boots .............................

- Inspecting tyres (including spare wheel) ...........................................................

- Inspecting the tyre tread depth (including spare wheel) and entering ........................

- Tightening wheel bolts to specific torque ..........................................................

- Inspecting the tyre inflation pressure (including spare wheel) and correcting the tyre

inflation pressure if necessary .......................................................................

Electrical System.......................................................................................

- Power windows: Inspecting positioning ............................................................

- Electrical components: Check for proper operation ..............................................

- Battery: Testing no-load voltage ....................................................................

- Battery: Inspecting electrolyte level, topping up with distilled water if necessary ...........

- Radio: Check for proper operation..................................................................

- Setting clock ............................................................................................

- Connect vehicle system tester and interrogate fault memory..................................

- Resetting service interval display (SID) QG0 .....................................................

- Resetting service interval display (SID) QG1 and QG2 .........................................

- Changing the code of the service intervals ........................................................

- Inspecting headlight beam setting and adjusting if necessary .................................

- Setting the headlight beam ..........................................................................

- Replace emergency battery for alarm system ...................................................

Body.......................................................................................................

- Airbag units: Visual inspection ......................................................................

- Inspect key switch for deactivation of front passenger airbag ..................................

- Check underbody protection and body paintwork for damage .................................

- Inspecting plenum chamber and water drain openings for dirt, cleaning if necessary .....

- Windscreen wiper/washer system: Check for proper operation ................................

- Sun roof: Cleaning and greasing runners .........................................................

- Door locks, locking buttons, child safety locks: Check for proper operation .................

- Replacing the dust and odour filter element ......................................................

- Sticking the vehicle data sticker .....................................................................

- ................................................................................. Inspect trailer coupling

Exhaust-emission Analysis..........................................................................

- Exhaust-Emission Analysis on Models with Fuel Engines ......................................

- Test Values for Exhaust-Emission Analysis on Models with Fuel Engines..................

- Exhaust-Emission Analysis on Models with Diesel Engines ....................................

- Test Values for Exhaust-Emission Analysis on Diesel Engines................................

Miscellaneous...........................................................................................

- Tow starting/Towing ..................................................................................

- Perform a test drive ...................................................................................

- Raising the vehicle ....................................................................................02-5page 2

02-5page 4

02-5page 5

02-5page 5

02-5page 6

02-5page 6

02-5page 6

02-6page 1

02-6page 1

02-6page 1

02-6page 1

02-6page 2

02-6page 2

02-6page 2

02-6page 3

02-6page 4

02-6page 7

02-6page 9

02-6page 10

02-6page 12

02-6page 13

02-7page 1

02-7page 1

02-7page 2

02-7page 2

02-7page 3

02-7page 3

02-7page 4

02-7page 4

02-7page 5

02-7page 6

02-7page 6

02-8page 1

02-8page 1

02-8page 2

02-8page 5

02-8page 6

02-9page 1

02-9page 1

02-9page 2

02-9page 2

Page 12 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 2 02

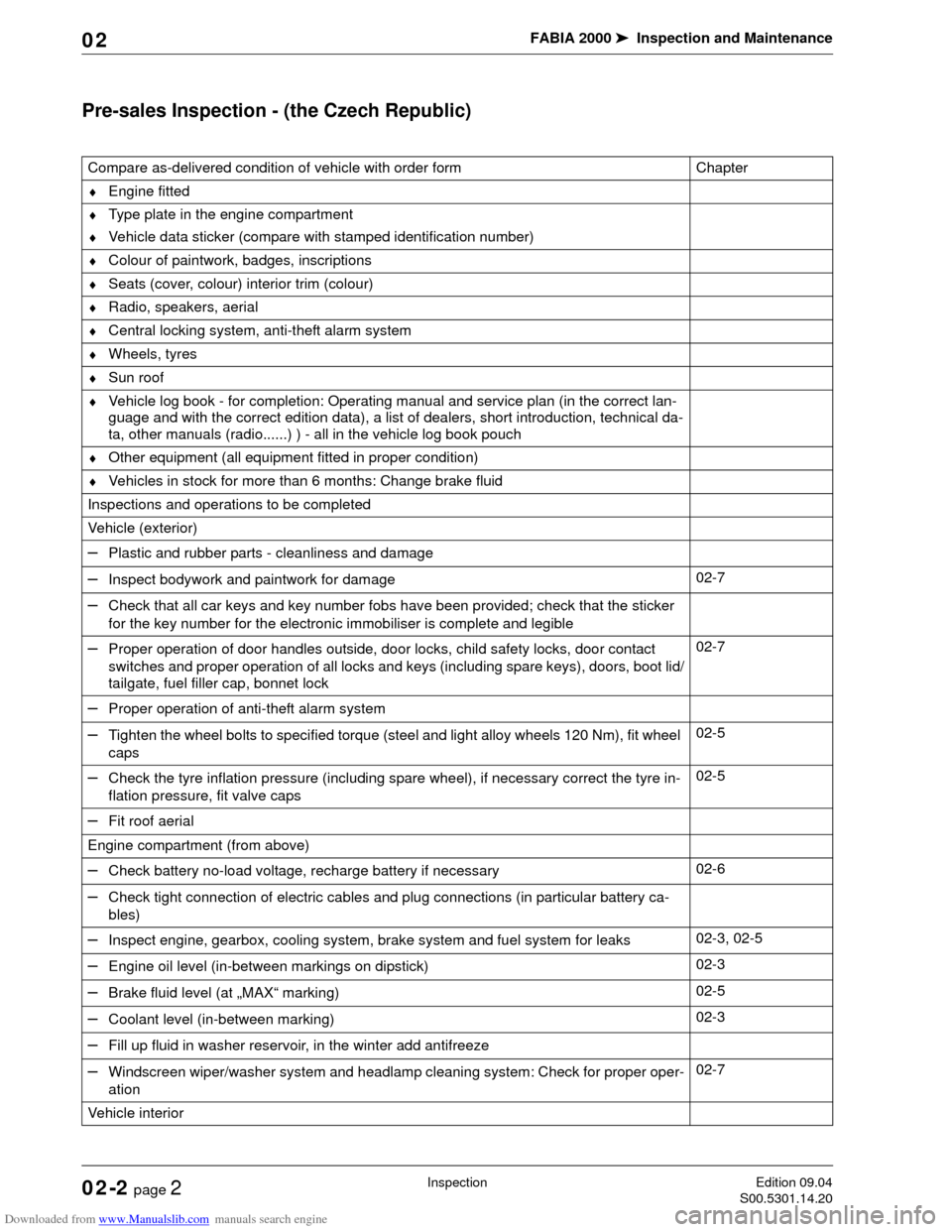

Pre-sales Inspection - (the Czech Republic)

Compare as-delivered condition of vehicle with order form Chapter

♦Engine fitted

♦Type plate in the engine compartment

♦Vehicle data sticker (compare with stamped identification number)

♦Colour of paintwork, badges, inscriptions

♦Seats (cover, colour) interior trim (colour)

♦Radio, speakers, aerial

♦Central locking system, anti-theft alarm system

♦Wheels, tyres

♦Sun roof

♦Vehicle log book - for completion: Operating manual and service plan (in the correct lan-

guage and with the correct edition data), a list of dealers, short introduction, technical da-

ta, other manuals (radio......) ) - all in the vehicle log book pouch

♦Other equipment (all equipment fitted in proper condition)

♦Vehicles in stock for more than 6 months: Change brake fluid

Inspections and operations to be completed

Vehicle (exterior)

–Plastic and rubber parts - cleanliness and damage

–Inspect bodywork and paintwork for damage02-7

–Check that all car keys and key number fobs have been provided; check that the sticker

for the key number for the electronic immobiliser is complete and legible

–Proper operation of door handles outside, door locks, child safety locks, door contact

switches and proper operation of all locks and keys (including spare keys), doors, boot lid/

tailgate, fuel filler cap, bonnet lock02-7

–Proper operation of anti-theft alarm system

–Tighten the wheel bolts to specified torque (steel and light alloy wheels 120 Nm), fit wheel

caps02-5

–Check the tyre inflation pressure (including spare wheel), if necessary correct the tyre in-

flation pressure, fit valve caps02-5

–Fit roof aerial

Engine compartment (from above)

–Check battery no-load voltage, recharge battery if necessary02-6

–Check tight connection of electric cables and plug connections (in particular battery ca-

bles)

–Inspect engine, gearbox, cooling system, brake system and fuel system for leaks02-3, 02-5

–Engine oil level (in-between markings on dipstick)02-3

–Brake fluid level (at „MAX“ marking)02-5

–Coolant level (in-between marking)02-3

–Fill up fluid in washer reservoir, in the winter add antifreeze

–Windscreen wiper/washer system and headlamp cleaning system: Check for proper oper-

ation02-7

Vehicle interior

Page 13 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 3 02

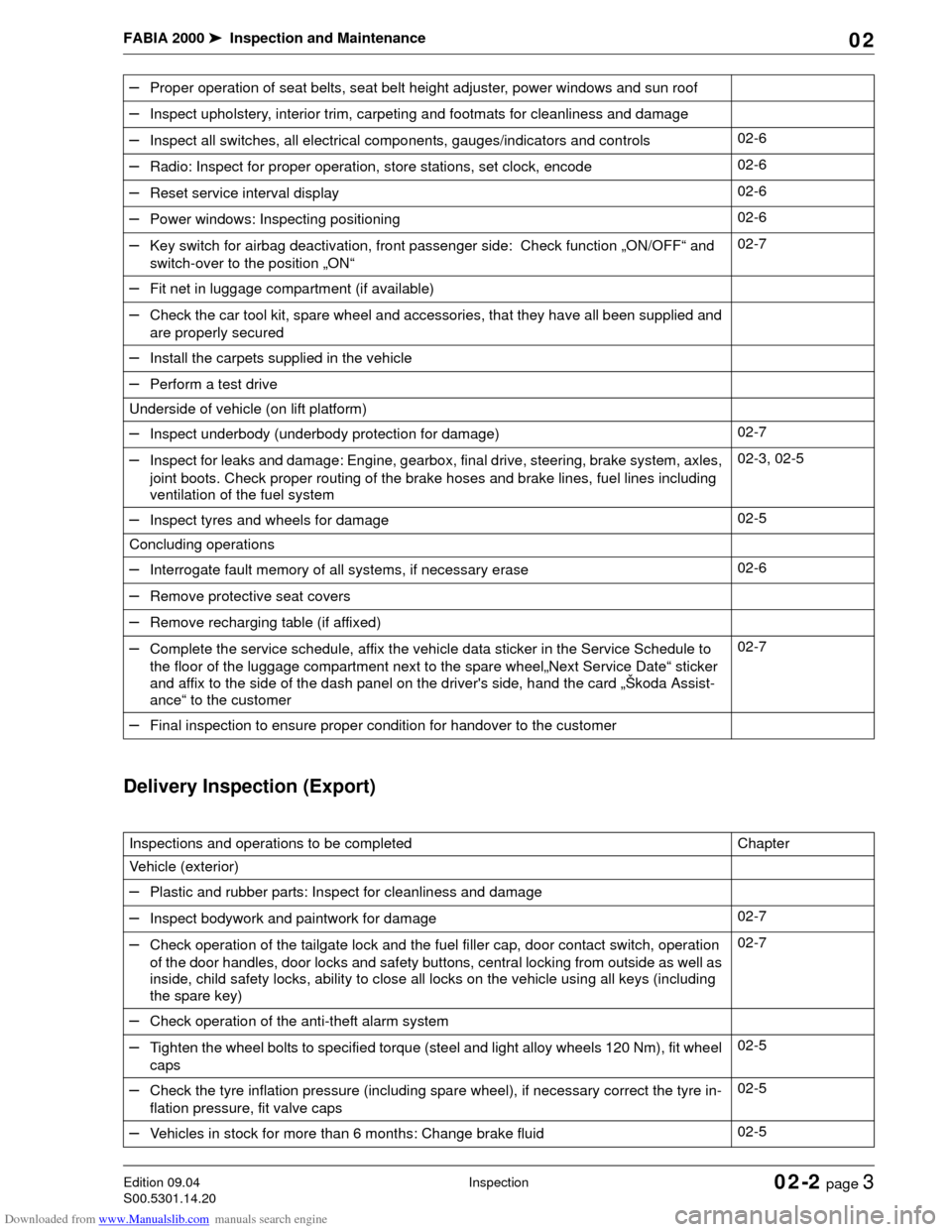

Delivery Inspection (Export)

–Proper operation of seat belts, seat belt height adjuster, power windows and sun roof

–Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

–Inspect all switches, all electrical components, gauges/indicators and controls02-6

–Radio: Inspect for proper operation, store stations, set clock, encode02-6

–Reset service interval display02-6

–Power windows: Inspecting positioning02-6

–Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“02-7

–Fit net in luggage compartment (if available)

–Check the car tool kit, spare wheel and accessories, that they have all been supplied and

are properly secured

–Install the carpets supplied in the vehicle

–Perform a test drive

Underside of vehicle (on lift platform)

–Inspect underbody (underbody protection for damage)02-7

–Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system02-3, 02-5

–Inspect tyres and wheels for damage02-5

Concluding operations

–Interrogate fault memory of all systems, if necessary erase02-6

–Remove protective seat covers

–Remove recharging table (if affixed)

–Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel„Next Service Date“ sticker

and affix to the side of the dash panel on the driver's side, hand the card „Škoda Assist-

ance“ to the customer02-7

–Final inspection to ensure proper condition for handover to the customer

Inspections and operations to be completed Chapter

Vehicle (exterior)

–Plastic and rubber parts: Inspect for cleanliness and damage

–Inspect bodywork and paintwork for damage02-7

–Check operation of the tailgate lock and the fuel filler cap, door contact switch, operation

of the door handles, door locks and safety buttons, central locking from outside as well as

inside, child safety locks, ability to close all locks on the vehicle using all keys (including

the spare key)02-7

–Check operation of the anti-theft alarm system

–Tighten the wheel bolts to specified torque (steel and light alloy wheels 120 Nm), fit wheel

caps02-5

–Check the tyre inflation pressure (including spare wheel), if necessary correct the tyre in-

flation pressure, fit valve caps02-5

–Vehicles in stock for more than 6 months: Change brake fluid02-5

Page 21 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 1 02

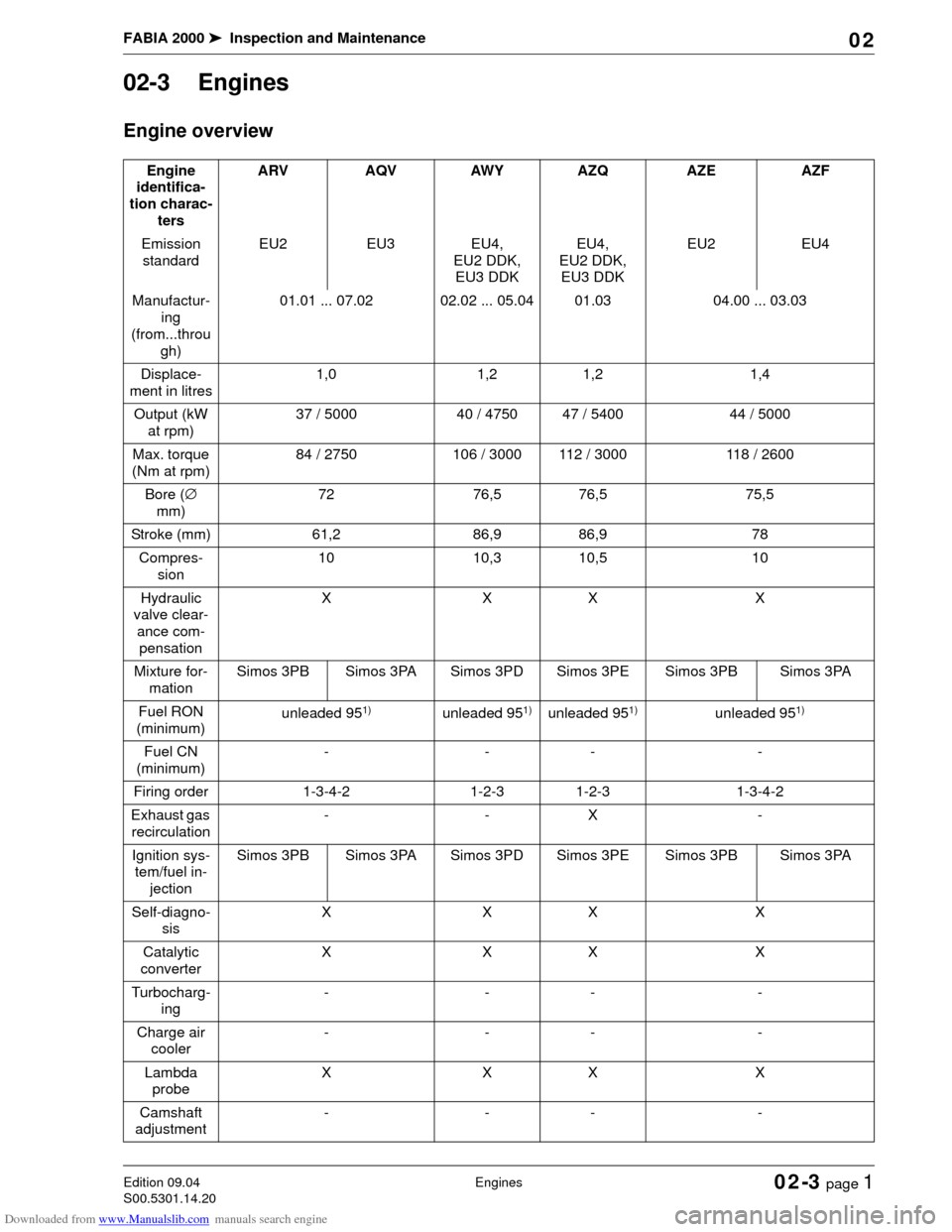

02-3 Engines

Engine overview

Engine

identifica-

tion charac-

tersARV AQV AWY AZQ AZE AZF

Emission

standardEU2 EU3 EU4,

EU2 DDK,

EU3 DDKEU4,

EU2 DDK,

EU3 DDKEU2 EU4

Manufactur-

ing

(from...throu

gh)01.01 ... 07.02 02.02 ... 05.04 01.03 04.00 ... 03.03

Displace-

ment in litres1,0 1,2 1,2 1,4

Output (kW

at rpm)37 / 5000 40 / 4750 47 / 5400 44 / 5000

Max. torque

(Nm at rpm)84 / 2750 106 / 3000 112 / 3000 118 / 2600

Bore (∅

mm)72 76,5 76,5 75,5

Stroke (mm) 61,2 86,9 86,9 78

Compres-

sion10 10,3 10,5 10

Hydraulic

valve clear-

ance com-

pensationXXX X

Mixture for-

mationSimos 3PB Simos 3PA Simos 3PD Simos 3PE Simos 3PB Simos 3PA

Fuel RON

(minimum)unleaded 95

1)unleaded 951)unleaded 951)unleaded 951)

Fuel CN

(minimum)--- -

Firing order 1-3-4-2 1-2-3 1-2-3 1-3-4-2

Exhaust gas

recirculation--X -

Ignition sys-

tem/fuel in-

jectionSimos 3PB Simos 3PA Simos 3PD Simos 3PE Simos 3PB Simos 3PA

Self-diagno-

sisXXX X

Catalytic

converterXXX X

Turbocharg-

ing--- -

Charge air

cooler--- -

Lambda

probeXXX X

Camshaft

adjustment--- -

Page 22 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 2 02

1)Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

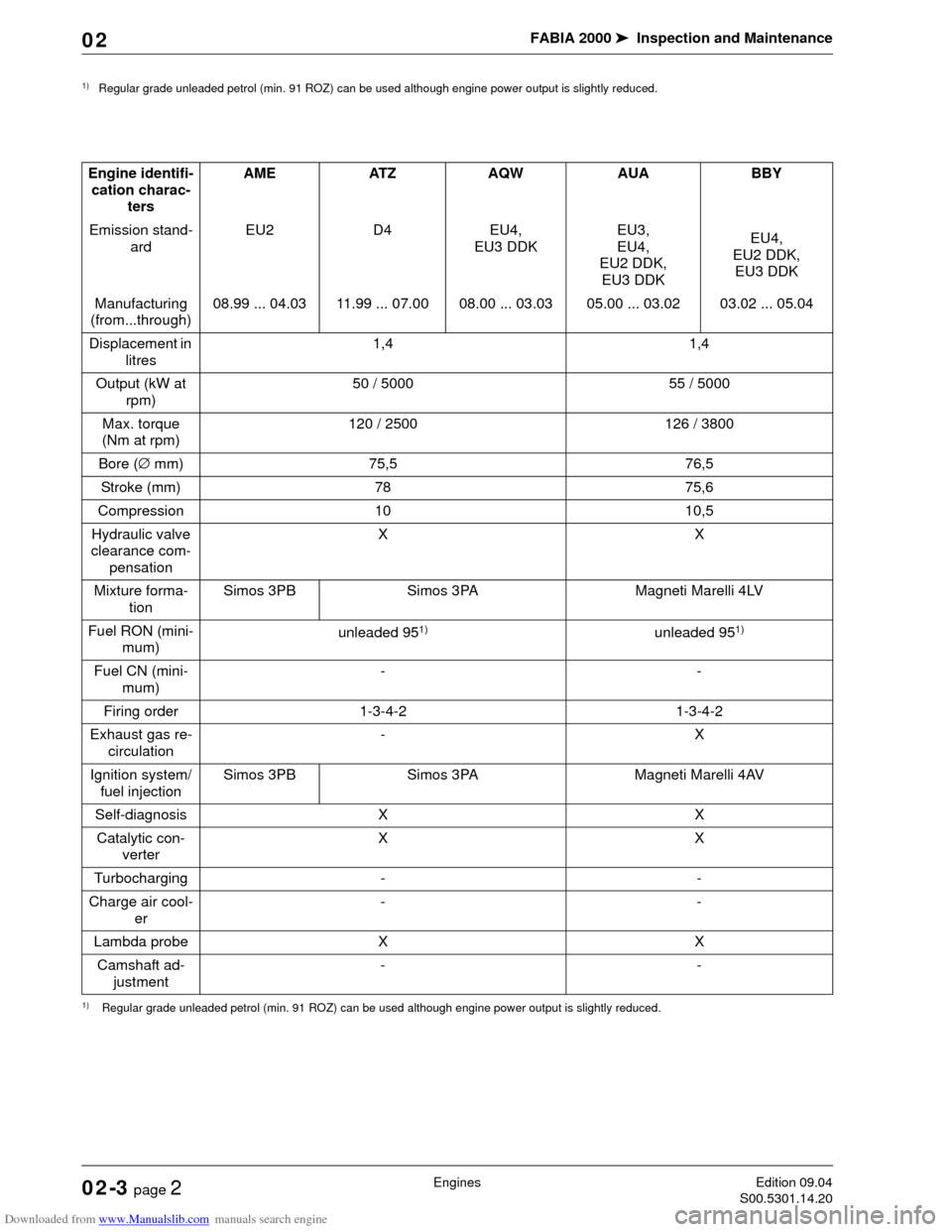

Engine identifi-

cation charac-

tersAME ATZ AQW AUA BBY

Emission stand-

ardEU2 D4 EU4,

EU3 DDKEU3,

EU4,

EU2 DDK,

EU3 DDKEU4,

EU2 DDK,

EU3 DDK

Manufacturing

(from...through)08.99 ... 04.03 11.99 ... 07.00 08.00 ... 03.03 05.00 ... 03.02 03.02 ... 05.04

Displacement in

litres1,4 1,4

Output (kW at

rpm)50 / 5000 55 / 5000

Max. torque

(Nm at rpm)120 / 2500 126 / 3800

Bore (∅ mm) 75,5 76,5

Stroke (mm) 78 75,6

Compression 10 10,5

Hydraulic valve

clearance com-

pensationXX

Mixture forma-

tionSimos 3PB Simos 3PA Magneti Marelli 4LV

Fuel RON (mini-

mum)unleaded 95

1)

1) Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

unleaded 951)

Fuel CN (mini-

mum)--

Firing order 1-3-4-2 1-3-4-2

Exhaust gas re-

circulation-X

Ignition system/

fuel injectionSimos 3PB Simos 3PA Magneti Marelli 4AV

Self-diagnosis X X

Catalytic con-

verterXX

Turbocharging - -

Charge air cool-

er--

Lambda probe X X

Camshaft ad-

justment--

Page 23 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 3 02

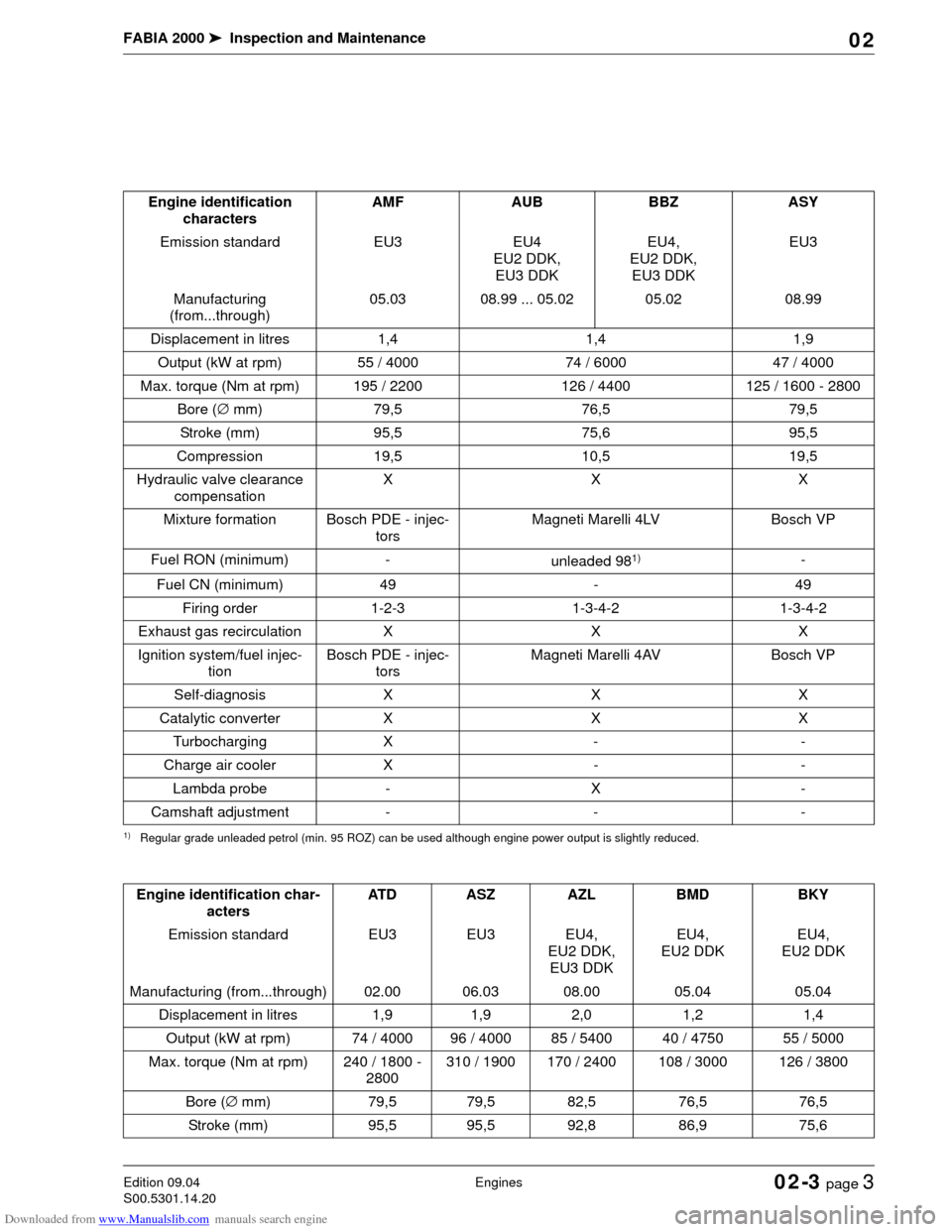

Engine identification

charactersAMF AUB BBZ ASY

Emission standard EU3 EU4

EU2 DDK,

EU3 DDKEU4,

EU2 DDK,

EU3 DDKEU3

Manufacturing

(from...through)05.03 08.99 ... 05.02 05.02 08.99

Displacement in litres 1,4 1,4 1,9

Output (kW at rpm) 55 / 4000 74 / 6000 47 / 4000

Max. torque (Nm at rpm) 195 / 2200 126 / 4400 125 / 1600 - 2800

Bore (∅ mm) 79,5 76,5 79,5

Stroke (mm) 95,5 75,6 95,5

Compression 19,5 10,5 19,5

Hydraulic valve clearance

compensationXXX

Mixture formation Bosch PDE - injec-

torsMagneti Marelli 4LV Bosch VP

Fuel RON (minimum) -

unleaded 98

1)

1)Regular grade unleaded petrol (min. 95 ROZ) can be used although engine power output is slightly reduced.

-

Fuel CN (minimum) 49 - 49

Firing order 1-2-3 1-3-4-2 1-3-4-2

Exhaust gas recirculation X X X

Ignition system/fuel injec-

tionBosch PDE - injec-

torsMagneti Marelli 4AV Bosch VP

Self-diagnosis X X X

Catalytic converter X X X

Turbocharging X - -

Charge air cooler X - -

Lambda probe - X -

Camshaft adjustment - - -

Engine identification char-

actersATD ASZ AZL BMD BKY

Emission standard EU3 EU3 EU4,

EU2 DDK,

EU3 DDKEU4,

EU2 DDKEU4,

EU2 DDK

Manufacturing (from...through) 02.00 06.03 08.00 05.04 05.04

Displacement in litres 1,9 1,9 2,0 1,2 1,4

Output (kW at rpm) 74 / 4000 96 / 4000 85 / 5400 40 / 4750 55 / 5000

Max. torque (Nm at rpm) 240 / 1800 -

2800310 / 1900 170 / 2400 108 / 3000 126 / 3800

Bore (∅ mm) 79,5 79,5 82,5 76,5 76,5

Stroke (mm) 95,5 95,5 92,8 86,9 75,6

Page 27 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 7 02

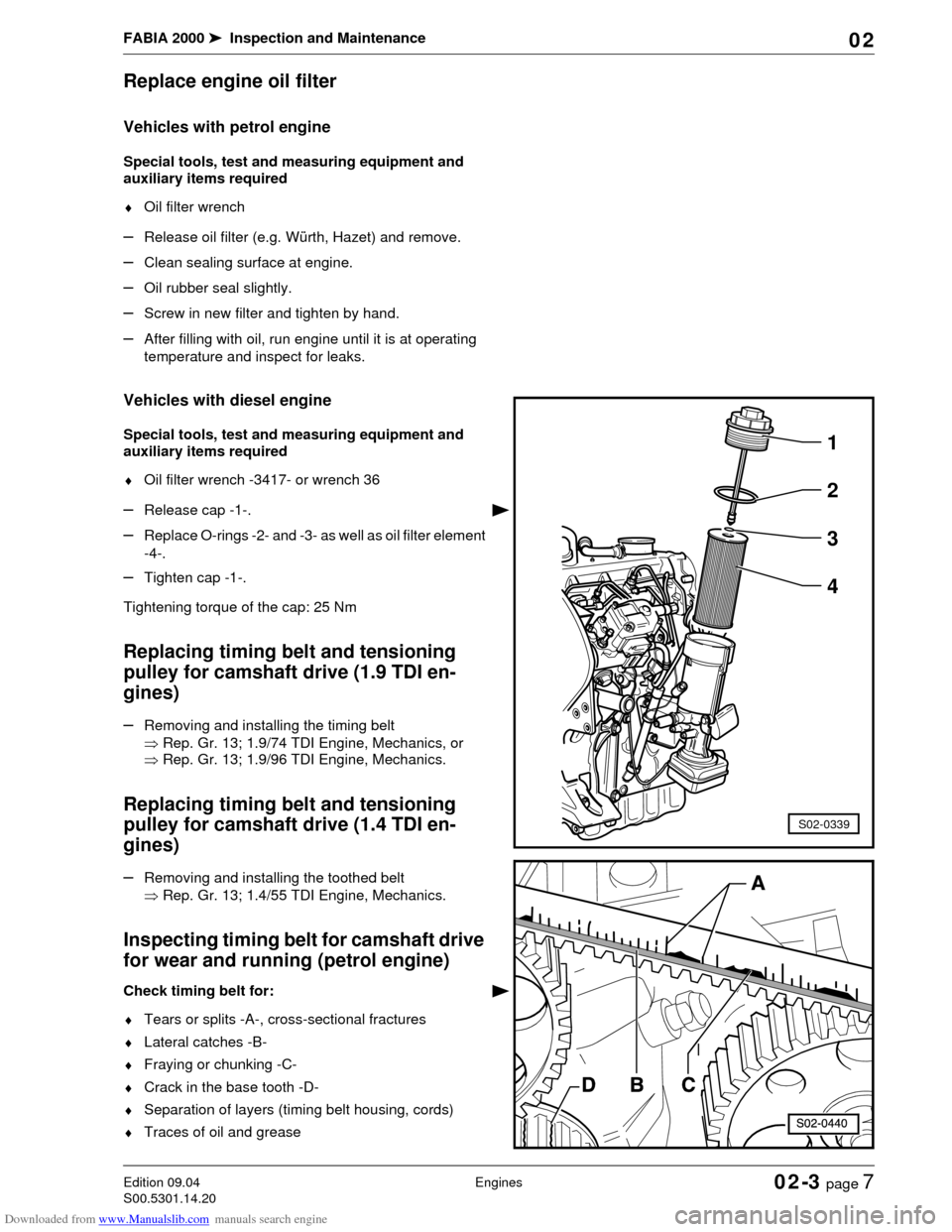

Replace engine oil filter

Vehicles with petrol engine

Special tools, test and measuring equipment and

auxiliary items required

♦Oil filter wrench

–Release oil filter (e.g. Würth, Hazet) and remove.

–Clean sealing surface at engine.

–Oil rubber seal slightly.

–Screw in new filter and tighten by hand.

–After filling with oil, run engine until it is at operating

temperature and inspect for leaks.

Vehicles with diesel engine

Special tools, test and measuring equipment and

auxiliary items required

♦Oil filter wrench -3417- or wrench 36

–Release cap -1-.

–Replace O-rings -2- and -3- as well as oil filter element

-4-.

–Tighten cap -1-.

Tightening torque of the cap: 25 Nm

Replacing timing belt and tensioning

pulley for camshaft drive (1.9 TDI en-

gines)

–Removing and installing the timing belt

⇒Rep. Gr. 13; 1.9/74 TDI Engine, Mechanics, or

⇒Rep. Gr. 13; 1.9/96 TDI Engine, Mechanics.

Replacing timing belt and tensioning

pulley for camshaft drive (1.4 TDI en-

gines)

–Removing and installing the toothed belt

⇒Rep. Gr. 13; 1.4/55 TDI Engine, Mechanics.

Inspecting timing belt for camshaft drive

for wear and running (petrol engine)

Check timing belt for:

♦Tears or splits -A-, cross-sectional fractures

♦Lateral catches -B-

♦Fraying or chunking -C-

♦Crack in the base tooth -D-

♦Separation of layers (timing belt housing, cords)

♦Traces of oil and grease

S02-0339

2

1

4

3

Page 29 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 9 02

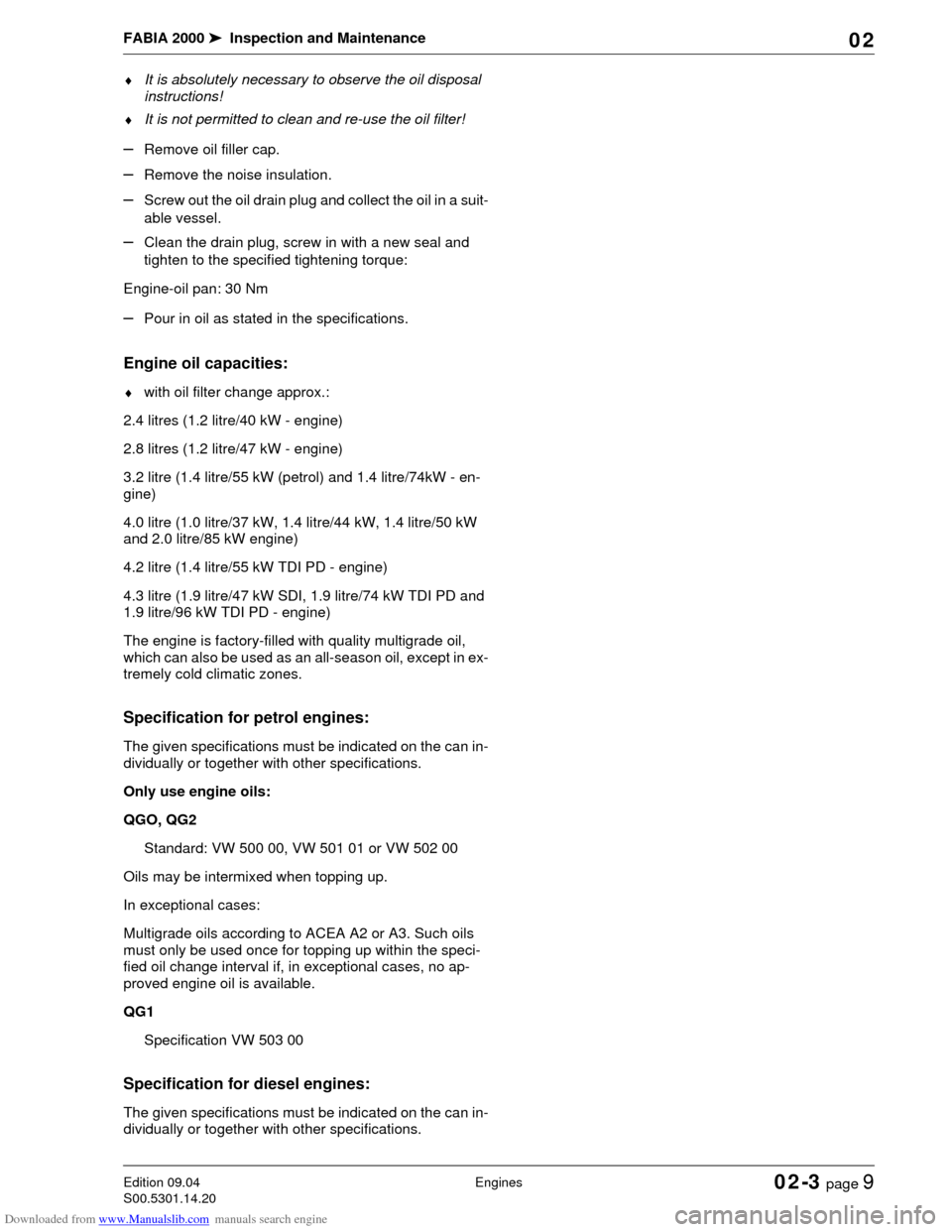

♦It is absolutely necessary to observe the oil disposal

instructions!

♦It is not permitted to clean and re-use the oil filter!

–Remove oil filler cap.

–Remove the noise insulation.

–Screw out the oil drain plug and collect the oil in a suit-

able vessel.

–Clean the drain plug, screw in with a new seal and

tighten to the specified tightening torque:

Engine-oil pan: 30 Nm

–Pour in oil as stated in the specifications.

Engine oil capacities:

♦with oil filter change approx.:

2.4 litres (1.2 litre/40 kW - engine)

2.8 litres (1.2 litre/47 kW - engine)

3.2 litre (1.4 litre/55 kW (petrol) and 1.4 litre/74kW - en-

gine)

4.0 litre (1.0 litre/37 kW, 1.4 litre/44 kW, 1.4 litre/50 kW

and 2.0 litre/85 kW engine)

4.2 litre (1.4 litre/55 kW TDI PD - engine)

4.3 litre (1.9 litre/47 kW SDI, 1.9 litre/74 kW TDI PD and

1.9 litre/96 kW TDI PD - engine)

The engine is factory-filled with quality multigrade oil,

which can also be used as an all-season oil, except in ex-

tremely cold climatic zones.

Specification for petrol engines:

The given specifications must be indicated on the can in-

dividually or together with other specifications.

Only use engine oils:

QGO, QG2

Standard: VW 500 00, VW 501 01 or VW 502 00

Oils may be intermixed when topping up.

In exceptional cases:

Multigrade oils according to ACEA A2 or A3. Such oils

must only be used once for topping up within the speci-

fied oil change interval if, in exceptional cases, no ap-

proved engine oil is available.

QG1

Specification VW 503 00

Specification for diesel engines:

The given specifications must be indicated on the can in-

dividually or together with other specifications.

Page 37 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 17 02

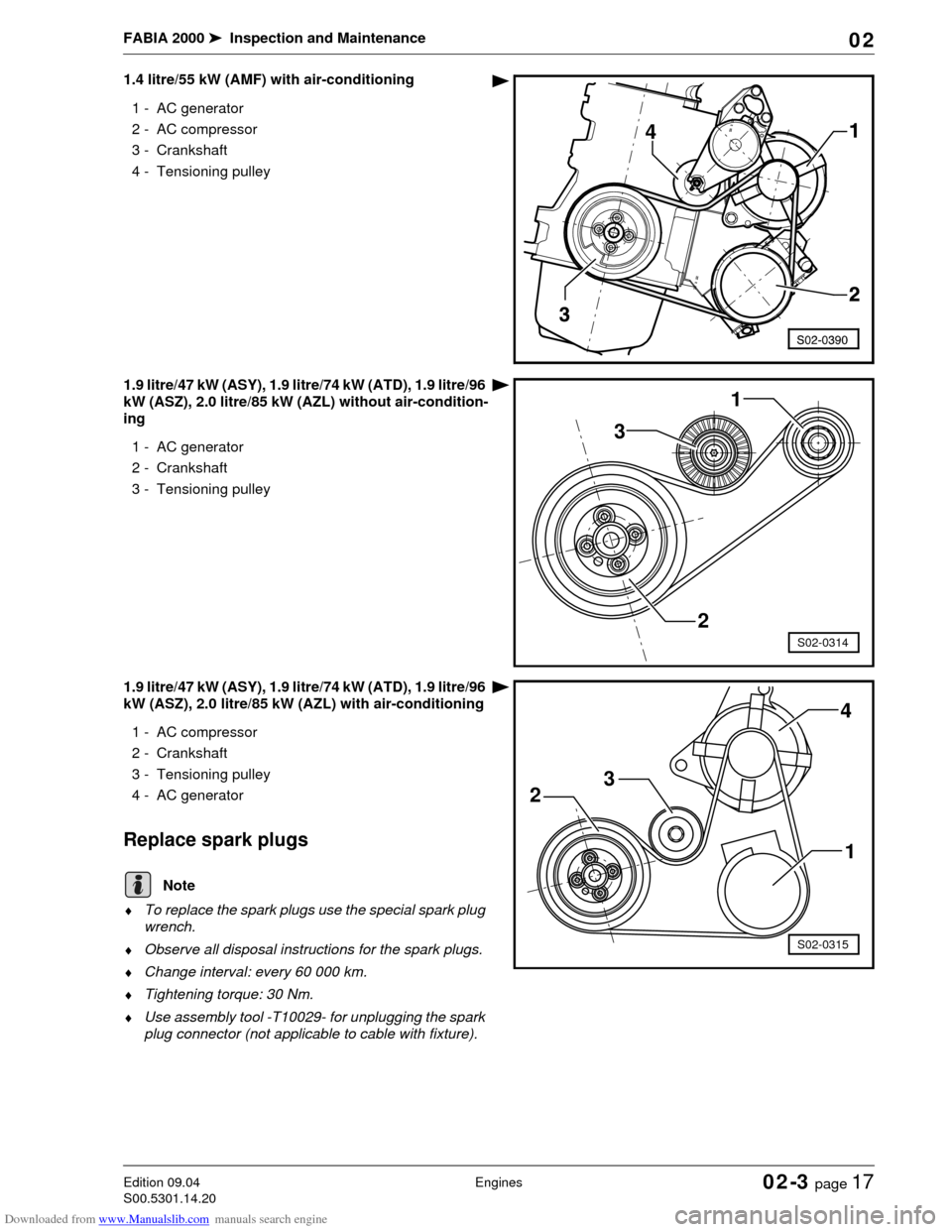

1.4 litre/55 kW (AMF) with air-conditioning

1 - AC generator

2- AC compressor

3 - Crankshaft

4 - Tensioning pulley

1.9 litre/47 kW (ASY), 1.9 litre/74 kW (ATD), 1.9 litre/96

kW (ASZ), 2.0 litre/85 kW (AZL) without air-condition-

ing

1 - AC generator

2 - Crankshaft

3 - Tensioning pulley

1.9 litre/47 kW (ASY), 1.9 litre/74 kW (ATD), 1.9 litre/96

kW (ASZ), 2.0 litre/85 kW (AZL) with air-conditioning

1- AC compressor

2 - Crankshaft

3 - Tensioning pulley

4 - AC generator

Replace spark plugs

♦To replace the spark plugs use the special spark plug

wrench.

♦Observe all disposal instructions for the spark plugs.

♦Change interval: every 60 000 km.

♦Tightening torque: 30 Nm.

♦Use assembly tool -T10029- for unplugging the spark

plug connector (not applicable to cable with fixture).

2

S02-0314

1

3

4

S02-0315

1 23

Note

Page 42 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

GearboxEdition 07.03

S00.5301.12.2002-4 page 2 02

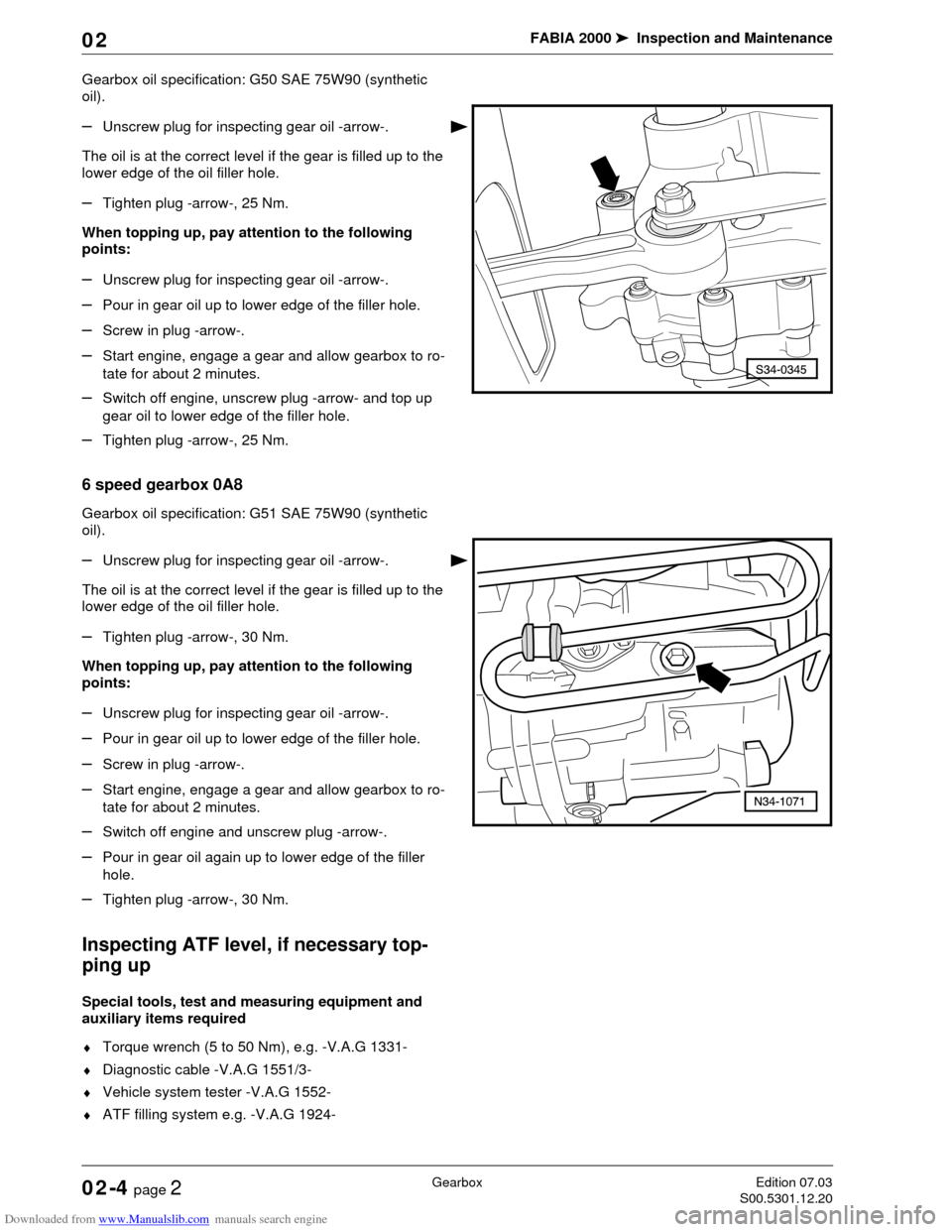

Gearbox oil specification: G50 SAE 75W90 (synthetic

oil).

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 25 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

–Tighten plug -arrow-, 25 Nm.

6 speed gearbox 0A8

Gearbox oil specification: G51 SAE 75W90 (synthetic

oil).

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 30 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine and unscrew plug -arrow-.

–Pour in gear oil again up to lower edge of the filler

hole.

–Tighten plug -arrow-, 30 Nm.

Inspecting ATF level, if necessary top-

ping up

Special tools, test and measuring equipment and

auxiliary items required

♦Torque wrench (5 to 50 Nm), e.g. -V.A.G 1331-

♦Diagnostic cable -V.A.G 1551/3-

♦Vehicle system tester -V.A.G 1552-

♦ATF filling system e.g. -V.A.G 1924-