check engine light SKODA FABIA 2014 3.G / NJ Operating Instruction Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: FABIA, Model: SKODA FABIA 2014 3.G / NJPages: 216, PDF Size: 30.9 MB

Page 136 of 216

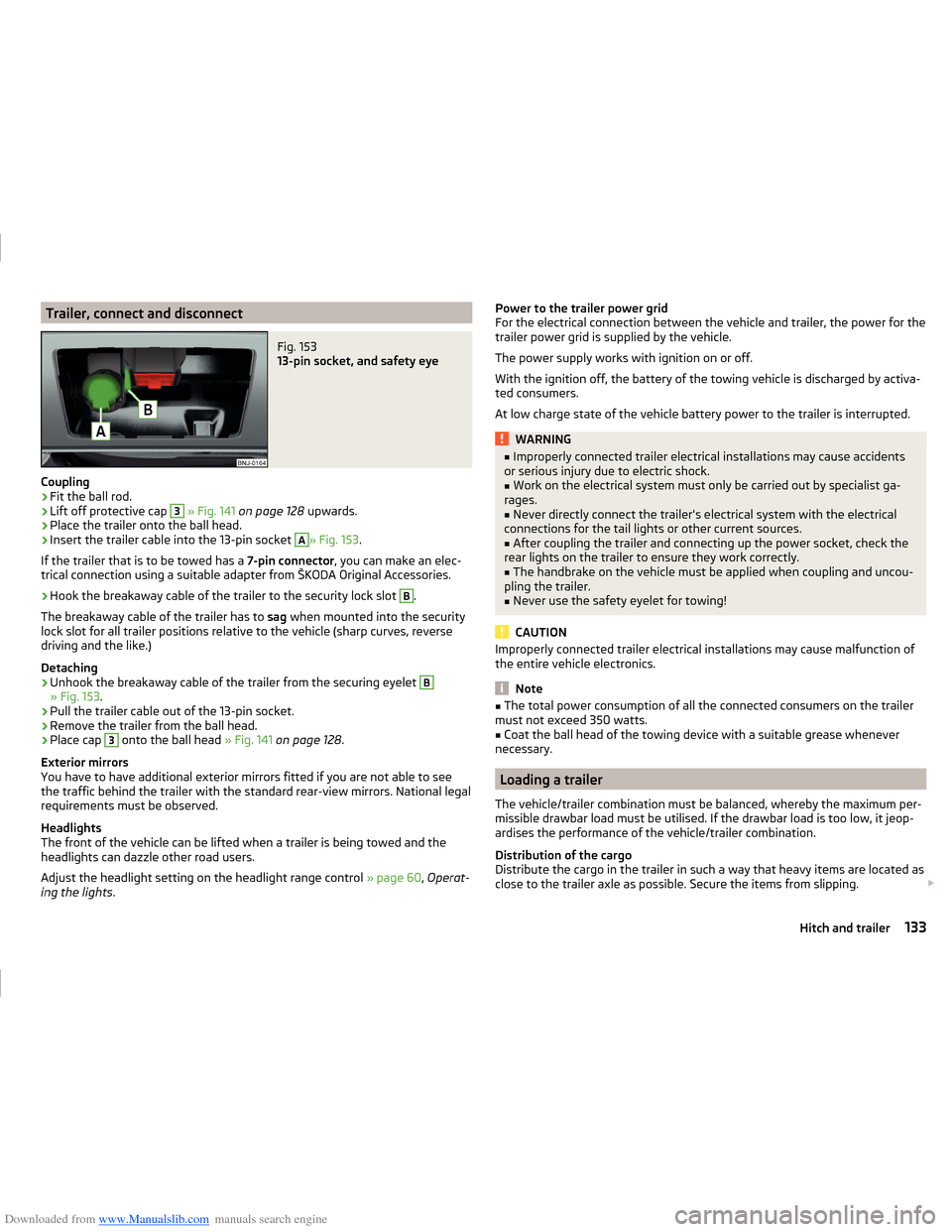

Downloaded from www.Manualslib.com manuals search engine Trailer, connect and disconnectFig. 153

13-pin socket, and safety eye

Coupling

›

Fit the ball rod.

›

Lift off protective cap

3

» Fig. 141 on page 128 upwards.

›

Place the trailer onto the ball head.

›

Insert the trailer cable into the 13-pin socket

A

» Fig. 153.

If the trailer that is to be towed has a 7-pin connector, you can make an elec-

trical connection using a suitable adapter from ŠKODA Original Accessories.

›

Hook the breakaway cable of the trailer to the security lock slot

B

.

The breakaway cable of the trailer has to sag when mounted into the security

lock slot for all trailer positions relative to the vehicle (sharp curves, reverse

driving and the like.)

Detaching

›

Unhook the breakaway cable of the trailer from the securing eyelet

B

» Fig. 153 .

›

Pull the trailer cable out of the 13-pin socket.

›

Remove the trailer from the ball head.

›

Place cap

3

onto the ball head » Fig. 141 on page 128 .

Exterior mirrors

You have to have additional exterior mirrors fitted if you are not able to see

the traffic behind the trailer with the standard rear-view mirrors. National legal

requirements must be observed.

Headlights

The front of the vehicle can be lifted when a trailer is being towed and the

headlights can dazzle other road users.

Adjust the headlight setting on the headlight range control » page 60, Operat-

ing the lights .

Power to the trailer power grid

For the electrical connection between the vehicle and trailer, the power for the

trailer power grid is supplied by the vehicle.

The power supply works with ignition on or off.

With the ignition off, the battery of the towing vehicle is discharged by activa-

ted consumers.

At low charge state of the vehicle battery power to the trailer is interrupted.WARNING■ Improperly connected trailer electrical installations may cause accidents

or serious injury due to electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting up the power socket, check the

rear lights on the trailer to ensure they work correctly.

■

The handbrake on the vehicle must be applied when coupling and uncou-

pling the trailer.

■

Never use the safety eyelet for towing!

CAUTION

Improperly connected trailer electrical installations may cause malfunction of

the entire vehicle electronics.

Note

■ The total power consumption of all the connected consumers on the trailer

must not exceed 350 watts.■

Coat the ball head of the towing device with a suitable grease whenever

necessary.

Loading a trailer

The vehicle/trailer combination must be balanced, whereby the maximum per-

missible drawbar load must be utilised. If the drawbar load is too low, it jeop-

ardises the performance of the vehicle/trailer combination.

Distribution of the cargo

Distribute the cargo in the trailer in such a way that heavy items are located as

close to the trailer axle as possible. Secure the items from slipping.

133Hitch and trailer

Page 155 of 216

Downloaded from www.Manualslib.com manuals search engine Radiator fanRead and observe

and on page 150 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

WARNINGThe fan can intermittently continue to run for approximately 10 minutes af-

ter the ignition is switched off.

Windscreen washer system

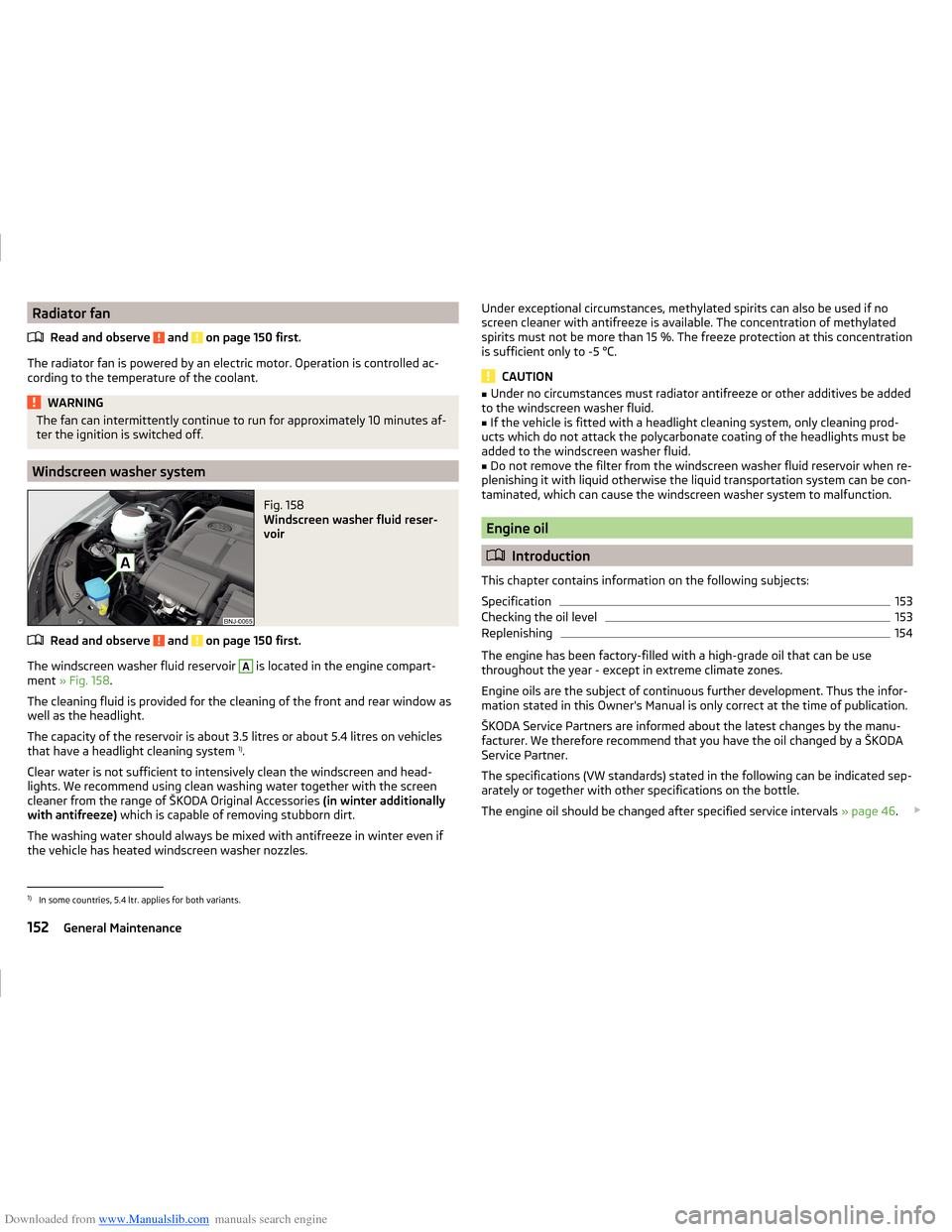

Fig. 158

Windscreen washer fluid reser-

voir

Read and observe and on page 150 first.

The windscreen washer fluid reservoir

A

is located in the engine compart-

ment » Fig. 158 .

The cleaning fluid is provided for the cleaning of the front and rear window as

well as the headlight.

The capacity of the reservoir is about 3.5 litres or about 5.4 litres on vehicles

that have a headlight cleaning system 1)

.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We recommend using clean washing water together with the screen

cleaner from the range of ŠKODA Original Accessories (in winter additionally

with antifreeze) which is capable of removing stubborn dirt.

The washing water should always be mixed with antifreeze in winter even if

the vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no

screen cleaner with antifreeze is available. The concentration of methylated

spirits must not be more than 15 %. The freeze protection at this concentration

is sufficient only to -5 °C.

CAUTION

■ Under no circumstances must radiator antifreeze or other additives be added

to the windscreen washer fluid.■

If the vehicle is fitted with a headlight cleaning system, only cleaning prod-

ucts which do not attack the polycarbonate coating of the headlights must be

added to the windscreen washer fluid.

■

Do not remove the filter from the windscreen washer fluid reservoir when re-

plenishing it with liquid otherwise the liquid transportation system can be con-

taminated, which can cause the windscreen washer system to malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specification

153

Checking the oil level

153

Replenishing

154

The engine has been factory-filled with a high-grade oil that can be use

throughout the year - except in extreme climate zones.

Engine oils are the subject of continuous further development. Thus the infor-

mation stated in this Owner's Manual is only correct at the time of publication.

ŠKODA Service Partners are informed about the latest changes by the manu-

facturer. We therefore recommend that you have the oil changed by a ŠKODA

Service Partner.

The specifications (VW standards) stated in the following can be indicated sep-

arately or together with other specifications on the bottle.

The engine oil should be changed after specified service intervals » page 46.

1)

In some countries, 5.4 ltr. applies for both variants.

152General Maintenance

Page 156 of 216

Downloaded from www.Manualslib.com manuals search engine WARNINGThe engine compartment of your car is a hazardous area. While working in

the engine compartment, be sure to observe the following warnings

» page 149 .

CAUTION

Do not pour any additives into the engine oil – risk of serious damage to the

engine parts.

Note

■ Before a long drive we recommend that you purchase and carry with you en-

gine oil which complies with the specification for your vehicle.■

We recommend that you use oils from ŠKODA Original Accessories.

■

You must wash yourself thoroughly if your skin has come into contact with

oil.

Specification

Read and observe

and on page 153 first.

Vehicles with variable service intervals

Petrol enginesSpecification1.0 l/44, 55 kW MPI - EU6VW 504 001.2 l/66, 81 kW TSIDiesel engineSpecification1.4 l/66, 77 kW TDI CRVW 507 00

Vehicles with fixed service intervals

Petrol enginesSpecification1.0 l/44, 55 kW MPI - EU6

VW 502 00

1.0 l/55 kW MPI - EU41.2 l/66, 81 kW TSI1.6 l/66, 81 kW MPIDiesel engineSpecification1.4 l/66, 77 kW TDI CRVW 507 00CAUTION■If the above engine oils are not available, a different engine oil can be used in

an emergency. To prevent damage to the engine, a maximum of 0.5 litres only

of the following engine oils may be used: ■ For petrol engine models: ACEA A3/ACEA B4 or API SN, (API SM);

■ For diesel engine models: ACEA C3 or API CJ-4.

Checking the oil level

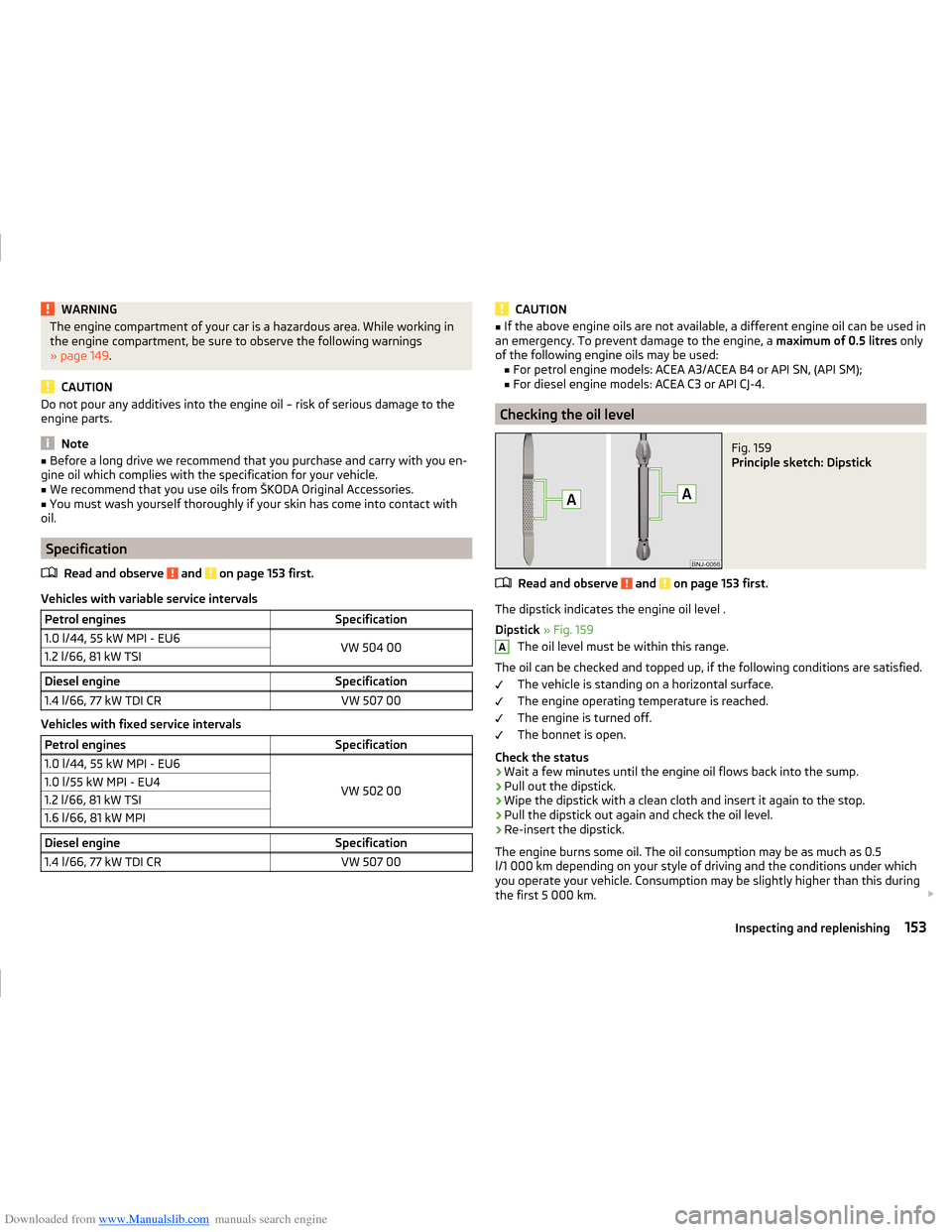

Fig. 159

Principle sketch: Dipstick

Read and observe and on page 153 first.

The dipstick indicates the engine oil level .

Dipstick » Fig. 159

The oil level must be within this range.

The oil can be checked and topped up, if the following conditions are satisfied. The vehicle is standing on a horizontal surface.

The engine operating temperature is reached.

The engine is turned off.

The bonnet is open.

Check the status

›

Wait a few minutes until the engine oil flows back into the sump.

›

Pull out the dipstick.

›

Wipe the dipstick with a clean cloth and insert it again to the stop.

›

Pull the dipstick out again and check the oil level.

›

Re-insert the dipstick.

The engine burns some oil. The oil consumption may be as much as 0.5

l/1 000 km depending on your style of driving and the conditions under which

you operate your vehicle. Consumption may be slightly higher than this during

the first 5 000 km.

A153Inspecting and replenishing

Page 158 of 216

Downloaded from www.Manualslib.com manuals search engine ■Additional headlights and other attached components in front of the air inlet

impair the cooling efficiency of the coolant.■

Never cover the radiator - there is a risk of the engine overheating.

Checking the coolant level

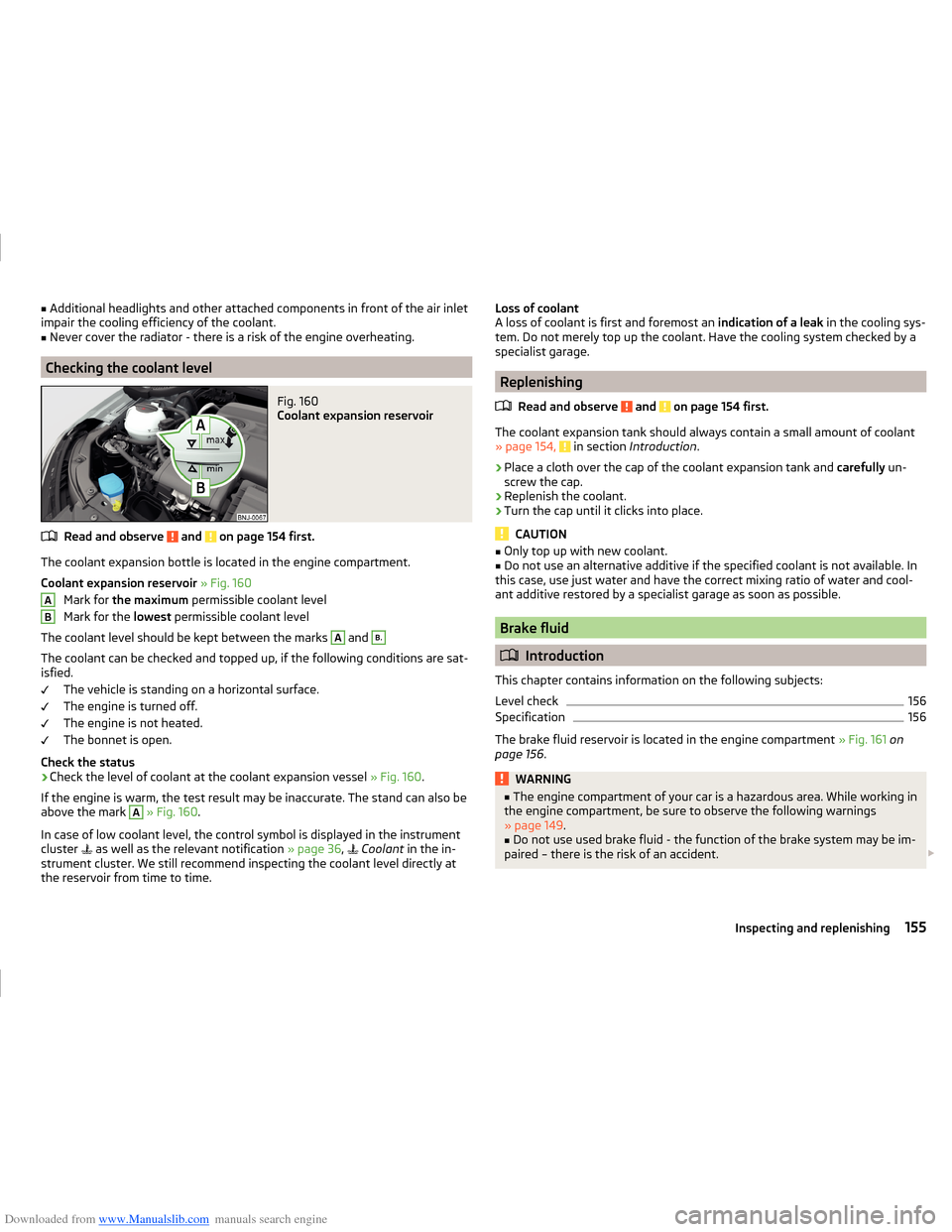

Fig. 160

Coolant expansion reservoir

Read and observe and on page 154 first.

The coolant expansion bottle is located in the engine compartment.

Coolant expansion reservoir » Fig. 160

Mark for the maximum permissible coolant level

Mark for the lowest permissible coolant level

The coolant level should be kept between the marks

A

and

B.

The coolant can be checked and topped up, if the following conditions are sat-

isfied.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The engine is not heated.

The bonnet is open.

Check the status

›

Check the level of coolant at the coolant expansion vessel » Fig. 160.

If the engine is warm, the test result may be inaccurate. The stand can also be

above the mark

A

» Fig. 160 .

In case of low coolant level, the control symbol is displayed in the instrument

cluster as well as the relevant notification

» page 36,

Coolant

in the in-

strument cluster. We still recommend inspecting the coolant level directly at

the reservoir from time to time.

ABLoss of coolant

A loss of coolant is first and foremost an indication of a leak in the cooling sys-

tem. Do not merely top up the coolant. Have the cooling system checked by a

specialist garage.

Replenishing

Read and observe

and on page 154 first.

The coolant expansion tank should always contain a small amount of coolant» page 154, in section Introduction .

›

Place a cloth over the cap of the coolant expansion tank and carefully un-

screw the cap.

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

CAUTION

■ Only top up with new coolant.■Do not use an alternative additive if the specified coolant is not available. In

this case, use just water and have the correct mixing ratio of water and cool-

ant additive restored by a specialist garage as soon as possible.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Level check

156

Specification

156

The brake fluid reservoir is located in the engine compartment » Fig. 161 on

page 156 .

WARNING■

The engine compartment of your car is a hazardous area. While working in

the engine compartment, be sure to observe the following warnings

» page 149 .■

Do not use used brake fluid - the function of the brake system may be im-

paired – there is the risk of an accident.

155Inspecting and replenishing

Page 159 of 216

Downloaded from www.Manualslib.com manuals search engine CAUTION■Do not continue your journey if the fluid level has dropped below the “MIN”

marking » Fig. 161 on page 156 , - there is a risk of an accident! Seek help

from a specialist garage.■

Brake fluid damages the paintwork of the vehicle.

Note

■ The brake fluid is changed as part of a prescribed inspection service.■We recommend using oils from the ŠKODA Original Accessories range.

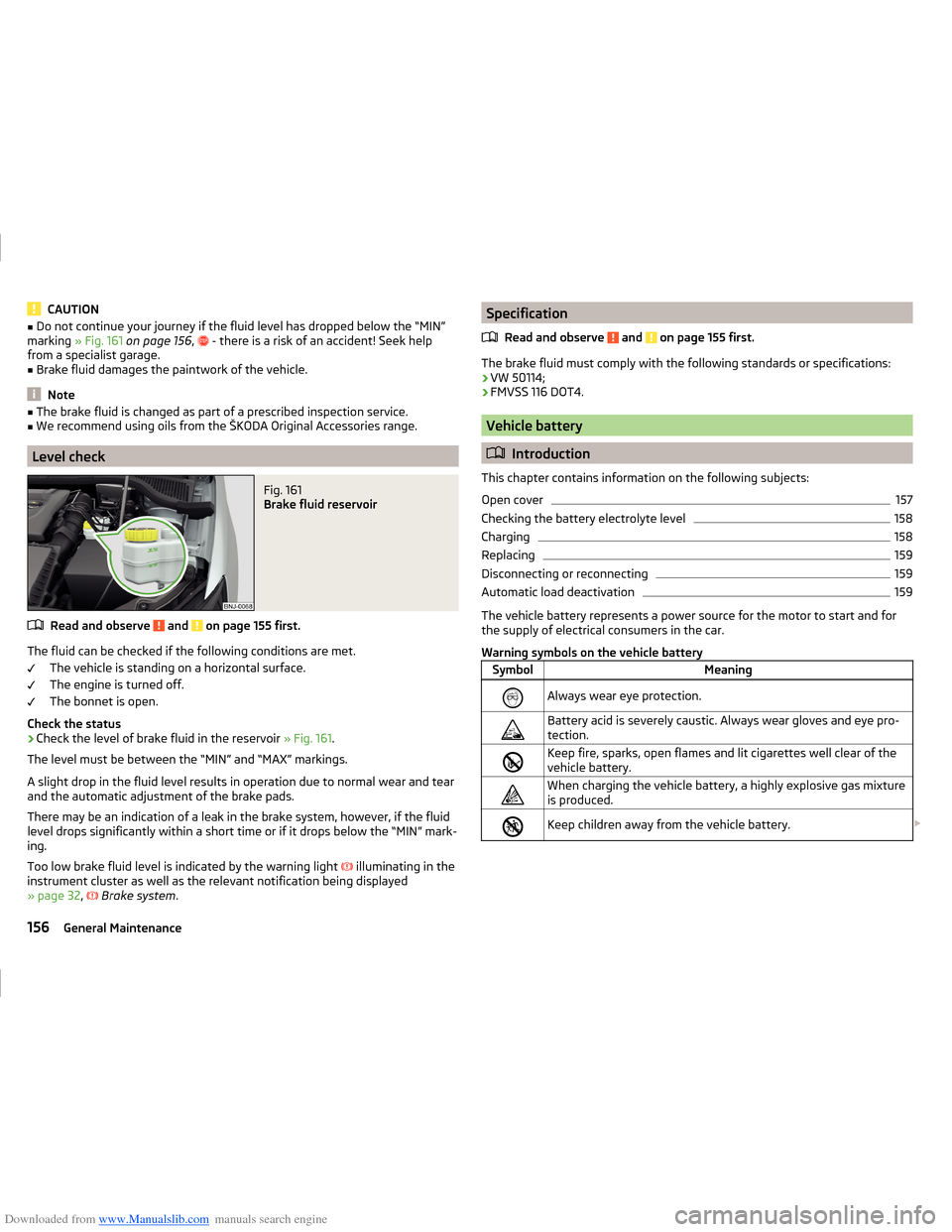

Level check

Fig. 161

Brake fluid reservoir

Read and observe and on page 155 first.

The fluid can be checked if the following conditions are met.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The bonnet is open.

Check the status

›

Check the level of brake fluid in the reservoir » Fig. 161.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results in operation due to normal wear and tear

and the automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid level drops significantly within a short time or if it drops below the “MIN” mark-

ing.

Too low brake fluid level is indicated by the warning light

illuminating in the

instrument cluster as well as the relevant notification being displayed

» page 32 ,

Brake system .

Specification

Read and observe

and on page 155 first.

The brake fluid must comply with the following standards or specifications:› VW 50114;

› FMVSS 116 DOT4.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Open cover

157

Checking the battery electrolyte level

158

Charging

158

Replacing

159

Disconnecting or reconnecting

159

Automatic load deactivation

159

The vehicle battery represents a power source for the motor to start and for

the supply of electrical consumers in the car.

Warning symbols on the vehicle battery

SymbolMeaningAlways wear eye protection.Battery acid is severely caustic. Always wear gloves and eye pro-

tection.Keep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery.When charging the vehicle battery, a highly explosive gas mixture

is produced.Keep children away from the vehicle battery. 156General Maintenance

Page 161 of 216

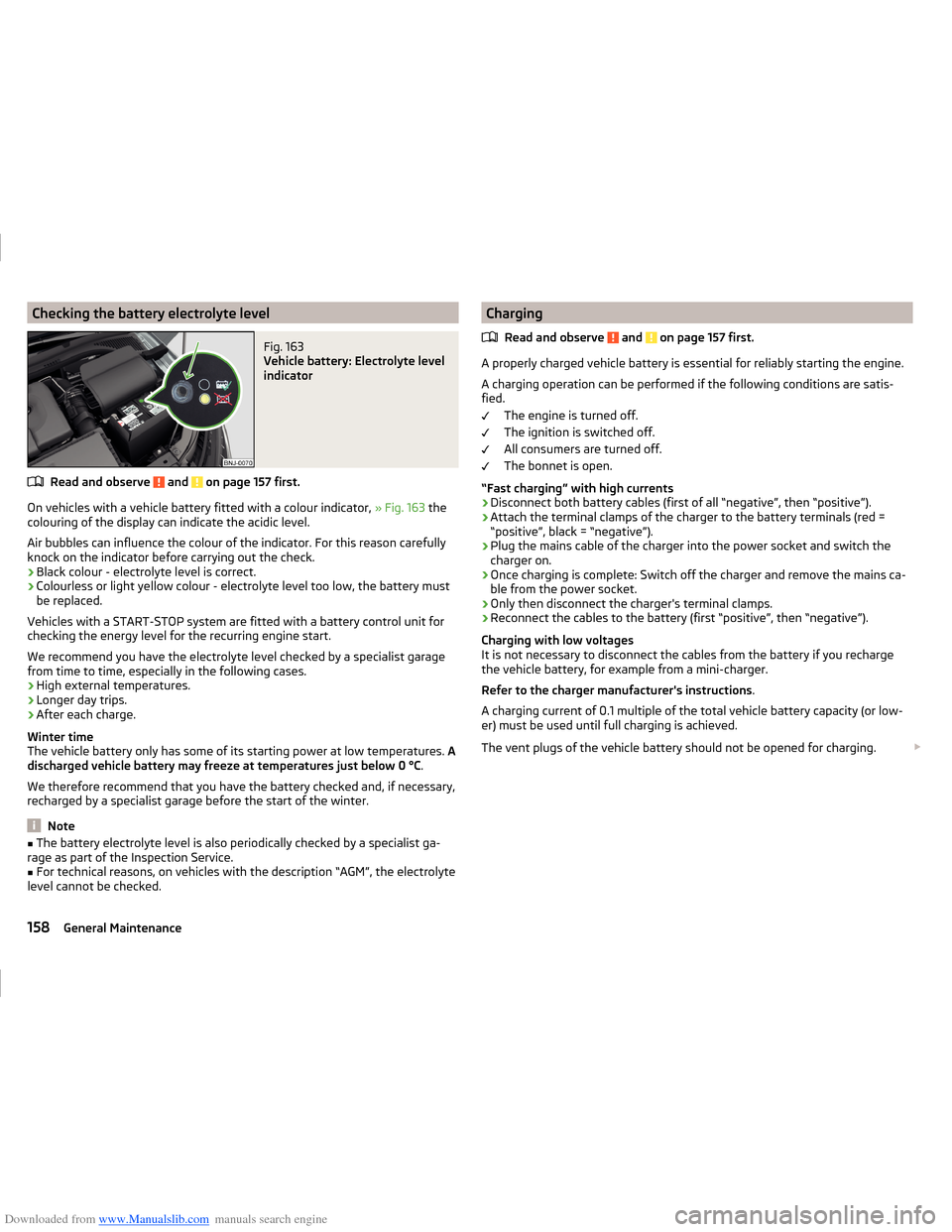

Downloaded from www.Manualslib.com manuals search engine Checking the battery electrolyte levelFig. 163

Vehicle battery: Electrolyte level

indicator

Read and observe and on page 157 first.

On vehicles with a vehicle battery fitted with a colour indicator, » Fig. 163 the

colouring of the display can indicate the acidic level.

Air bubbles can influence the colour of the indicator. For this reason carefully knock on the indicator before carrying out the check.

› Black colour - electrolyte level is correct.

› Colourless or light yellow colour - electrolyte level too low, the battery must

be replaced.

Vehicles with a START-STOP system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

We recommend you have the electrolyte level checked by a specialist garage from time to time, especially in the following cases.

› High external temperatures.

› Longer day trips.

› After each charge.

Winter time

The vehicle battery only has some of its starting power at low temperatures. A

discharged vehicle battery may freeze at temperatures just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary,

recharged by a specialist garage before the start of the winter.

Note

■ The battery electrolyte level is also periodically checked by a specialist ga-

rage as part of the Inspection Service.■

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

Charging

Read and observe

and on page 157 first.

A properly charged vehicle battery is essential for reliably starting the engine.A charging operation can be performed if the following conditions are satis-

fied.

The engine is turned off.

The ignition is switched off.

All consumers are turned off.

The bonnet is open.

“Fast charging” with high currents

›

Disconnect both battery cables (first of all “negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch the

charger on.

›

Once charging is complete: Switch off the charger and remove the mains ca-

ble from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

Charging with low voltages

It is not necessary to disconnect the cables from the battery if you recharge

the vehicle battery, for example from a mini-charger.

Refer to the charger manufacturer's instructions .

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

The vent plugs of the vehicle battery should not be opened for charging.

158General Maintenance

Page 164 of 216

Downloaded from www.Manualslib.com manuals search engine Notes on using wheelsRead and observe

on page 160 first.

During the first 500 km, new tyres do not offer optimum grip and appropriate

care should therefore be taken when driving.

Always fit the tyres with the deeper tread depth to the front wheels.

Tyre storage

Mark the tyres as you remove them so that you are able to refit them to run in

the same direction.

Always store wheels or tyres in a cool, dry and, where possible, dark place.

Tyres which are not fixed to a wheel trim should be stored upright.

Tyre age

Tyres age losing their original characteristics, even if they are not used. The

service life of the tyres is 6 years. Therefore, we recommend not using tyres

older than 6 years.

Wheel bolts

Wheels and wheel bolts are matched to each other in terms of design. There-

fore we recommend that you use wheel rims and wheel bolts from ŠKODA

Original Accessories.

WARNINGNever use tyres if you do not know anything about the condition and age.

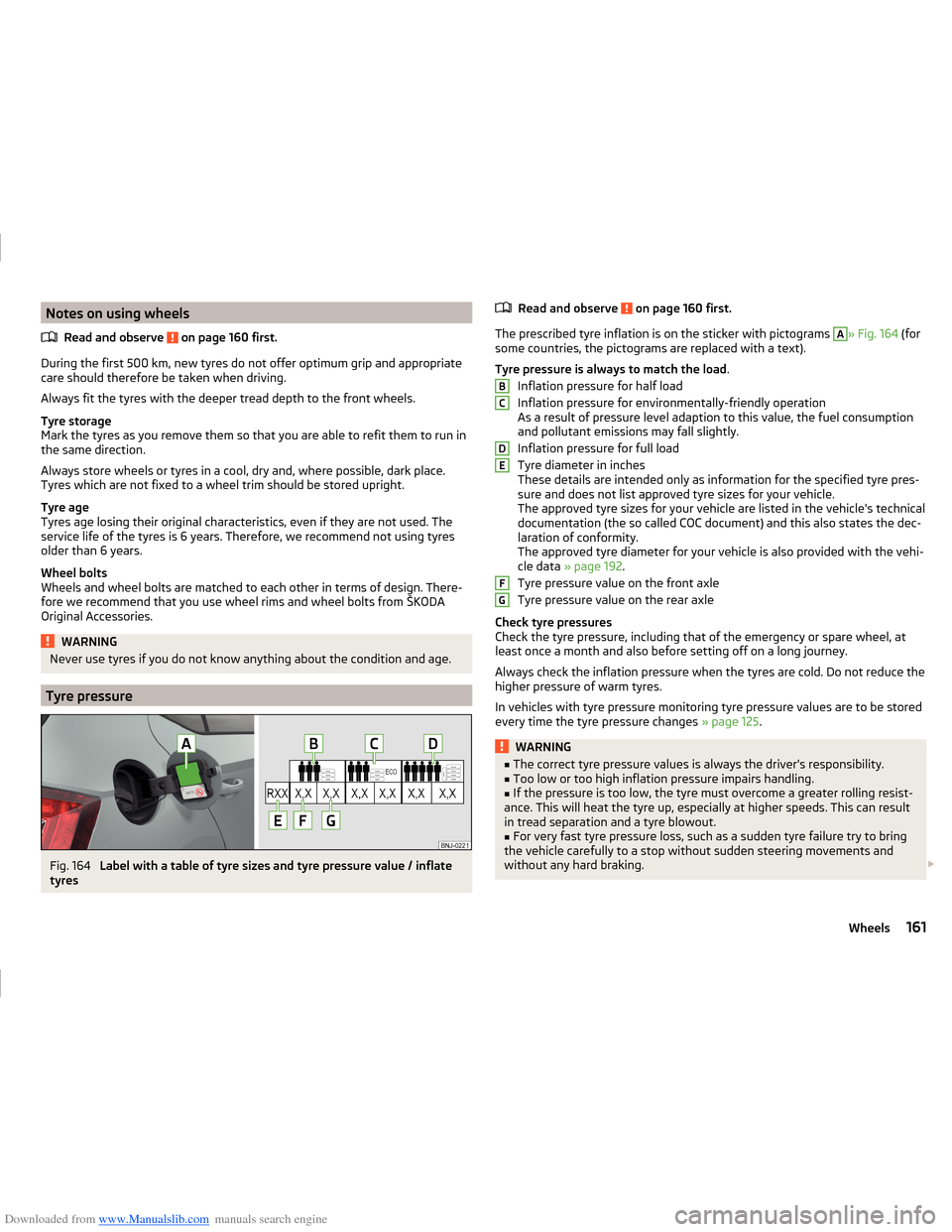

Tyre pressure

Fig. 164

Label with a table of tyre sizes and tyre pressure value / inflate

tyres

Read and observe on page 160 first.

The prescribed tyre inflation is on the sticker with pictograms

A

» Fig. 164 (for

some countries, the pictograms are replaced with a text).

Tyre pressure is always to match the load .

Inflation pressure for half load

Inflation pressure for environmentally-friendly operation

As a result of pressure level adaption to this value, the fuel consumption

and pollutant emissions may fall slightly.

Inflation pressure for full load

Tyre diameter in inches

These details are intended only as information for the specified tyre pres-

sure and does not list approved tyre sizes for your vehicle.

The approved tyre sizes for your vehicle are listed in the vehicle's technical

documentation (the so called COC document) and this also states the dec-

laration of conformity.

The approved tyre diameter for your vehicle is also provided with the vehi-

cle data » page 192 .

Tyre pressure value on the front axle

Tyre pressure value on the rear axle

Check tyre pressures

Check the tyre pressure, including that of the emergency or spare wheel, at

least once a month and also before setting off on a long journey.

Always check the inflation pressure when the tyres are cold. Do not reduce the

higher pressure of warm tyres.

In vehicles with tyre pressure monitoring tyre pressure values are to be stored

every time the tyre pressure changes » page 125.

WARNING■

The correct tyre pressure values is always the driver's responsibility.■Too low or too high inflation pressure impairs handling.■

If the pressure is too low, the tyre must overcome a greater rolling resist-

ance. This will heat the tyre up, especially at higher speeds. This can result

in tread separation and a tyre blowout.

■

For very fast tyre pressure loss, such as a sudden tyre failure try to bring

the vehicle carefully to a stop without sudden steering movements and

without any hard braking.

BCDEFG161Wheels

Page 174 of 216

Downloaded from www.Manualslib.com manuals search engine ›Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking point

» Fig. 176 -

.›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 176 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ Choose a flat and firm surface for jacking the vehicle.■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

Make sure that the jack is attached correctly to the web on the lower sil, oth-

erwise there is a risk of damage to the vehicle.

Remove the wheel / fix

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the wheel and slightly screw on the wheel bolts.

› Lower the vehicle.›Tighten the opposite wheel bolts alternately (cross-wise) with the wheel

wrench. Tighten the anti-theft wheel bolt last.›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 163 .

WARNING■

Undo the wheel bolts only a little (about one turn) until the vehicle has

been jacked up. Otherwise the wheel could become loose and fall off.■

All bolts must be clean and must turn easily.

■

If it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

■

Under no circumstances grease or oil the wheel bolts!

Subsequent steps

After changing the wheel, the following work should be carried out.

›

Stow the replaced wheel in the wheel well and secure it with a special screw.

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, save tyre pressure values » page 125.

Change the damaged wheel or consult a specialist garage about repair possi-

bilities.

WARNINGInformation on the wheel bolts■The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

171Emergency equipment, and self-help

Page 176 of 216

Downloaded from www.Manualslib.com manuals search engine General informationRead and observe

on page 172 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard lights.

The warning triangle must be set up at the prescribed distance - observe

the national legal provisions when doing so.

Park the vehicle as far away as possible from the flow of traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The national legal requirements must be observed when repairing a tyre.

The breakdown kit must not be used under the following circumstances. › The rim is damaged.

› The outside temperature is below -20 ° C.

› The cut or puncture is larger than 4 mm.

› The tyre wall is damaged.

› After the expiration date (see inflation bottle).

Preparations for using the breakdown kit

Read and observe

on page 172 first.

The following preparatory work must be carried out before using the break-

down kit.

›

Switch off the engine.

›

Select the first gear or move the selector lever for the automatic gearbox

into position P .

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit » page 173,

General information .

›

Uncouple trailer, if attached.

›

Remove the breakdown kit from the boot.

›

Stick the corresponding sticker

1

» Fig. 177 on page 172 on the dashboard in

the driver's field of view.

›

Unscrew the valve cap.

› Use the valve remover 2 to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 172 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 177 on page 172 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and push the open end fully on-

to the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the air compressor tyre inflation hose

7

» Fig. 177 on page 172 firmly

onto the tyre valve.

›

For vehicles with Manual transmission move the lever into the neutral posi-

tion and apply the parking brake firmly.

›

For vehicles with Automatic transmission move the selector lever to position

P and apply the parking brake firmly.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 volt socket » page 78.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

If you still cannot reach the required tyre inflation pressure, this means the

tyre has sustained too much damage. You cannot seal with tyre with the

breakdown kit »

.

›

Switch off the air compressor.

173Emergency equipment, and self-help

Page 187 of 216

Downloaded from www.Manualslib.com manuals search engine No.Power consumer11Not assigned12Engine components13Brake pedal switch14Engine components, coil of the fuel pump relay15Engine control unit16Starter17Engine control unit18Engine components, coils of the relay for auxiliary electric heater, radi-

ator fan19Lambda probe20Engine components, control unit for glow plug system, heating the

crankcase ventilation

Replacing bulbs

Introduction

This chapter contains information on the following subjects:

Bulb arrangement in the headlights

185

Removing and installing the cover in the front wheel arch

185

Fitting and removing the wash water container nozzle

185

Replacing the low beam and high beam bulb (halogen headlights)

186

Change bulb for turn signal switch (halogen headlight)

186

Replacing the parking light bulb (halogen headlights)

187

Changing bulb for daytime running lights switch (halogen headlight)

187

Replacing the dipped beam bulb (halogen projector headlights)

187

Replacing the high beam bulb (halogen projector headlights)

188

Replacing the turn signal switch bulb (halogen projector headlights)

188

Replacing the bulb for the fog light

189

Changing the licence plate light bulb

189

Rear Light

190

Replacing bulbs in rear light

190

Some manual skills are required to change a bulb. For this reason, if uncertain,

we recommend that bulbs are replaced by a specialist garage or other expert

help is sought.

› Switch off the ignition and all of the lights before replacing a bulb.

› Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

› A stowage compartment for replacement bulbs is located in a plastic box in

the spare wheel or underneath the floor covering in the boot.WARNING■ Always read and observe the warnings before completing any work in the

engine compartment » page 149.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

Bulbs H8, H7 and H4 are pressurised and may burst when changed - there

is a risk of injury! We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Switch off the respective vehicle light when changing the bulb.

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

light bulbs should be changed by your specialist garage.■

We recommend that you always carry a box of replacement bulbs in the vehi-

cle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

■

We recommend having the headlight settings checked by a specialist garage

after replacing a bulb in the main beam, low beam or fog lights.

■

Visit a specialist garage if an LED is faulty.

184Do-it-yourself