Lock SKODA OCTAVIA 2008 2.G / (1Z) Owners Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2008, Model line: OCTAVIA, Model: SKODA OCTAVIA 2008 2.G / (1Z)Pages: 304, PDF Size: 17.69 MB

Page 246 of 304

Breakdown assistance245

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Breakdown assistance

Breakdown assistance

First-aid box* and Warning triangle* (Octavia)

The first-aid box* is attached by a strap to the right-hand side of the luggage

compartment

The warning triangle can be at tached to the trim panel of the rear wall with rubber

straps ⇒fig. 221 .

If you wish to equip your ve hicle additionally with a warning triangle, please contact

a specialist garage.

Note

Pay attention to the use-by-date of the contents of the first-aid box.

First-aid box* and warning triangle* (Estate car)

For vehicles of the type es tate car the first-aid box and the warning triangle are

housed in a compartment on the right si de in the luggage compartment. You can

open the compartment by turning the locks in the direction of arrow ⇒fig. 222 .

If you wish to equip your ve hicle additionally with a warn ing triangle, please contact

a specialist garage.

Note

Pay attention to the use-by-date of the contents of the first-aid box.

Fire extinguisher*

The fire extinguisher is attached with straps in a holder under the driver seat.

Please read carefully the instructions which are atta ched to the fire extin-

guisher.

Fig. 221 Placing of the

warning triangle (Octavia)Fig. 222 Placing of the

warning triangle (Estate car)

20A5Facelift.book Page 245 Saturday, September 6, 2008 2:13 PM

Page 247 of 304

Breakdown assistance

246

The fire extinguisher must be checked by an authorised person or company annu-

ally (please observe the differing legal requirements).

WARNING

If the fire extinguisher is not correc tly attached, in case of sudden manoeu-

vres or an accident it can be “thrown” through the interior compartment and

cause injuries.

Note

•The fire extinguisher must comply with the relevant and valid legal require-

ments.

•Pay attention to the expiration date of the fire extinguisher. If the fire extin-

guisher is used after the expiration date, its proper function is no longer assured.

•The fire extinguisher is only supplied in certain countries within the scope of

delivery.

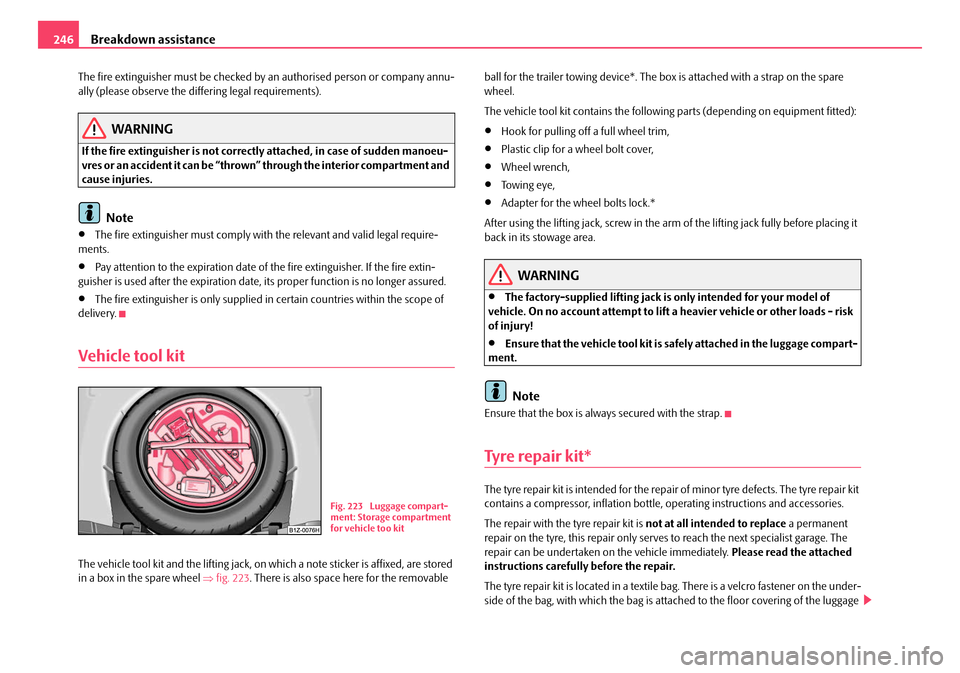

Vehicle tool kit

The vehicle tool kit and the lifting jack, on which a note sticker is affixed, are stored

in a box in the spare wheel ⇒fig. 223 . There is also space here for the removable ball for the trailer towing device*. The bo

x is attached with a strap on the spare

wheel.

The vehicle tool kit contains the following parts (depending on equipment fitted):

•Hook for pulling off a full wheel trim,

•Plastic clip for a wheel bolt cover,

•Wheel wrench,

•To w i n g e y e ,

•Adapter for the wheel bolts lock.*

After using the lifting jack, screw in the arm of the lifting jack fully before placing it

back in its stowage area.

WARNING

•The factory-supplied lifting jack is only intended for your model of

vehicle. On no account attempt to lift a heavier vehicle or other loads - risk

of injury!

•Ensure that the vehicle tool kit is safely attached in the luggage compart-

ment.

Note

Ensure that the box is alwa ys secured with the strap.

Tyre repair kit*

The tyre repair kit is intended for the repair of minor tyre defects. The tyre repair kit

contains a compressor, inflation bottle, operating instructions and accessories.

The repair with the tyre repair kit is not at all intended to replace a permanent

repair on the tyre, this repair only serves to reach the next specialist garage. The

repair can be undertaken on the vehicle immediately. Please read the attached

instructions carefully before the repair.

The tyre repair kit is located in a textile bag. There is a velcro fastener on the under-

side of the bag, with which the bag is atta ched to the floor covering of the luggage

Fig. 223 Luggage compart-

ment: Storage compartment

for vehicle too kit

20A5Facelift.book Page 246 Saturday, September 6, 2008 2:13 PM

Page 249 of 304

Breakdown assistance

248

provisions. In this way you are protecting not only yourself but also other

road users.

•Never start the engine with the vehicle sitting on the raised jack - danger

of suffering injury.

Caution

If you have to change a wheel on a slope first block the opposite wheel with a stone

or similar object in order to secure th e vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.

Changing a wheel

Always change a wheel on a level surface as far as possible.

– Take off the full wheel trim* ⇒page 249 or the caps ⇒page 249.

– In the case of light alloy wheels remove the wheel trim cap ⇒page 250.

– First of all slacken the safety wh eel bolt * and afterwards the other

wheel bolts ⇒page 250.

– Jack up the vehicle until the wheel to be changed is clear of the ground

⇒ page 251.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel.

– Fit on the spare wheel and tighten the wheel bolts slightly.

–Lower the car. – Tighten the wheel bolts firmly, al

ternately and diagonally using the

wheel wrench (crosswise) and last the safety wheel bolt* ⇒page 250.

– Mount the full wheel trim/w heel trim cap or the caps.

Note

•All bolts must be clean and must turn easily.

•You must never grease or oil the wheel bolts!

•When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction ⇒page 237.

Subsequent steps

After changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well.

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel just mounted as soon as

possible.

– Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible. Steel and light alloy wheels must be tight-

ened to a tightening torque of 120 Nm.

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on ⇒page 239 if the vehicle is

subsequently fitted with tyres which are different to those it was fitted with

at the works.

WARNING (continued)

20A5Facelift.book Page 248 Saturday, September 6, 2008 2:13 PM

Page 250 of 304

Breakdown assistance249

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Note

•If you find, when changing the wheel, that the wheel bolts are corroded and

difficult to turn, the bolts mu st be replaced before checking the tightening torque.

•Drive cautiously and only at a moderate speed to a workshop where the tight-

ening torque can be checked.

Full wheel trim*

Pulling off

– Hook the clamp found in the vehicle tool kit into the reinforced edge of the full wheel trim.

– Push the wheel key through the clamp, support the wheel key at the tyre and pull off the wheel trim.

Installing

– First press the full wheel trim onto the wheel at the valve opening provided. Then press the full wheel trim into the wheel in such a way

that its entire circumference locks correctly in place.

Caution

•Use the pressure of your hand, do not knock on the full wheel trim! Heavy

knocks mainly on the points where the full wheel trim has not been inserted into

the wheel, can result in damage to the guide and centering elements of the full

wheel trim.

•First check for yourself that the th eft-deterrent wheel bolt is located

⇒ page 251 in the hole in the area of the valve before fitting the full wheel trim onto

a steel wheel which is attached with a theft-deterrent wheel bolt.

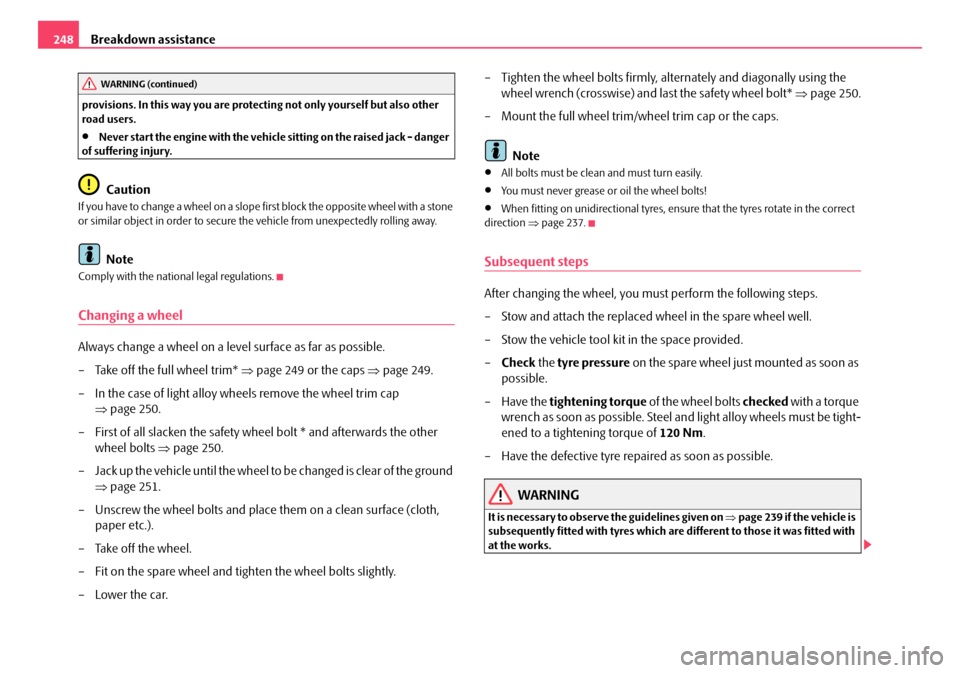

Wheel bolts with caps*

Pulling off

– Push the plastic clip sufficiently fa r onto the cap until the inner catches

of the clip are positioned at the collar of the cap and detach the cap.

Installing

– Push the caps fully onto the wheel bolts.

The caps are located in the we ll of the luggage compartment.

Fig. 225 Removing the cap.

20A5Facelift.book Page 249 Saturday, September 6, 2008 2:13 PM

Page 252 of 304

Breakdown assistance251

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

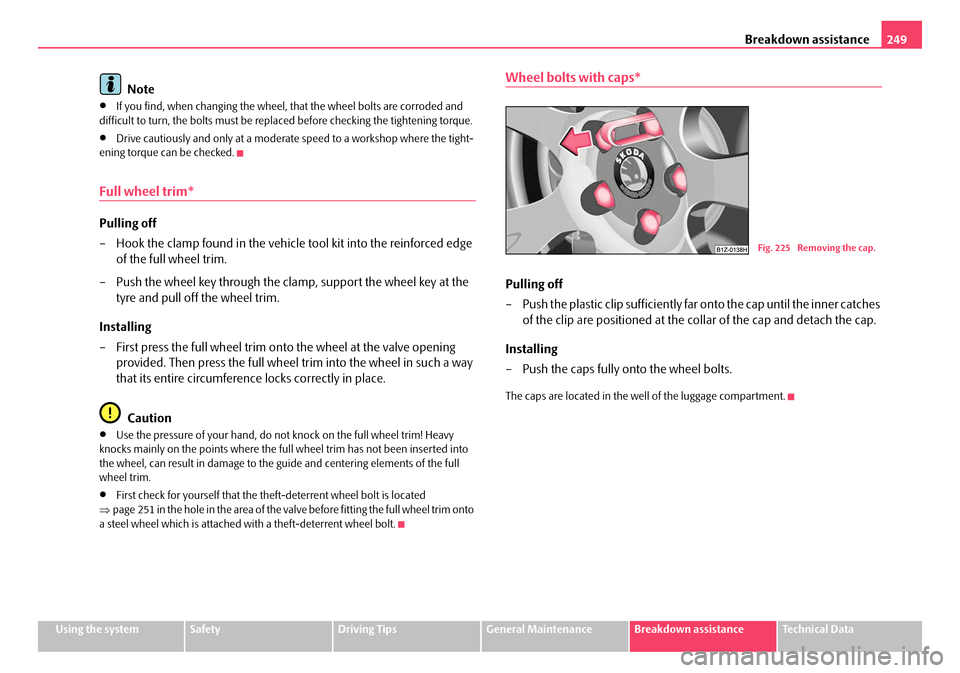

Raise vehicle

You have to raise the vehicle with a lifting jack in order to be able to

take off the wheel.

Position the lifting jack by selecting the jacking point which is closest to

the wheel to be removed ⇒fig. 228 . The jacking point is located directly

below the engraving in the lower sill. The engraving is only visible after

opening the door.

– Position the lifting jack below the jacking point and move it up until its claw is positioned directly below the vertical web of the lower sill.

– Align the car jack so that its claw grasps the web of the lower sill and the base plate is resting flat on the floor.

– Turn the lifting jack up further until the wheel is just clear of the ground.

Ground below the lifting jack which is soft and slippery can cause the vehicle to

slip off the jack. It is therefore always ne cessary to place the lifting jack on a solid

surface or use a wide and stable base. Use a non-slip base (e.g. a rubber foot mat)

if the surface is smooth , such as cobbled stones, a tiled floor, etc.

WARNING

•Always raise the vehicle with the doors closed - risk of injury!

•Take suitable measures to prevent the base of the lifting jack from slip-

ping off - risk of injury!

•Not positioning the lifting jack at the specified points can result in

damage to the vehicle. The jack can also sl ip off if it does not have sufficient

grip - risk of injury!

•It is important to support the vehicle with suitable supporting blocks if

you wish to work under the lifted vehicle - risk of injury!

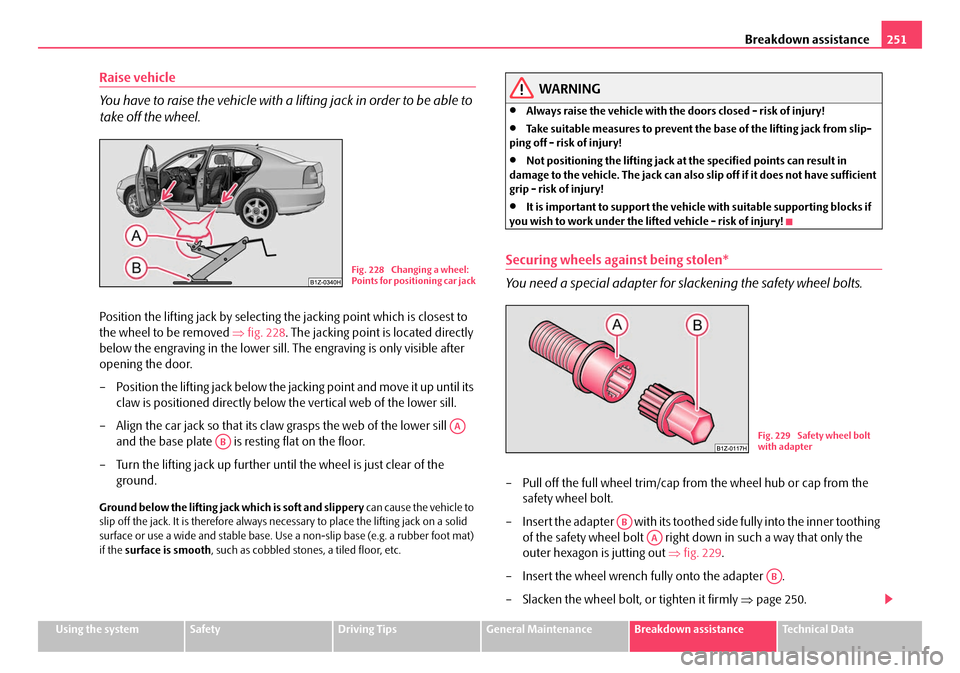

Securing wheels against being stolen*

You need a special adapter for slackening the safety wheel bolts.

– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel bolt.

– Insert the adapter with its toothed side fully into the inner toothing of the safety wheel bolt right down in such a way that only the

outer hexagon is jutting out ⇒fig. 229 .

– Insert the wheel wrench fully onto the adapter .

– Slacken the wheel bolt, or tighten it firmly ⇒page 250.

Fig. 228 Changing a wheel:

Points for positioning car jack

AA

ABFig. 229 Safety wheel bolt

with adapter

AB

AA

AB

20A5Facelift.book Page 251 Saturday, September 6, 2008 2:13 PM

Page 254 of 304

Breakdown assistance253

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

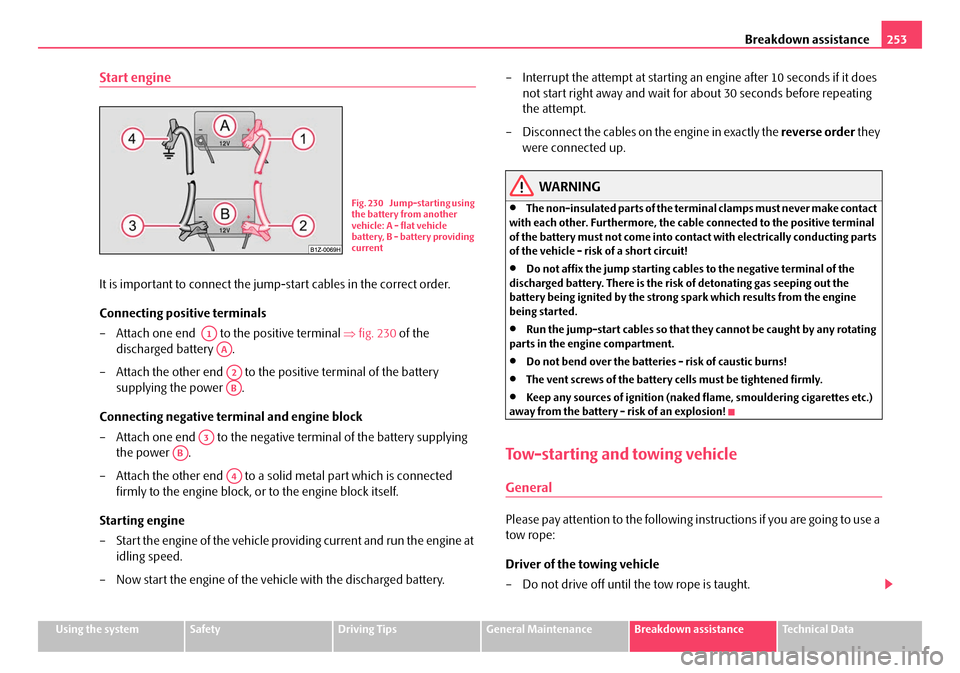

Start engine

It is important to connect the jump -start cables in the correct order.

Connecting positive terminals

– Attach one end to the positive terminal ⇒fig. 230 of the

discharged battery .

– Attach the other end to the positive terminal of the battery supplying the power .

Connecting negative term inal and engine block

– Attach one end to the negative terminal of the battery supplying

the power .

– Attach the other end to a solid metal part which is connected firmly to the engine block, or to the engine block itself.

Starting engine

– Start the engine of the vehicle providing current and run the engine at idling speed.

– Now start the engine of the vehicle with the discharged battery. – Interrupt the attempt at starting an engine after 10 seconds if it does

not start right away and wait for about 30 seconds before repeating

the attempt.

– Disconnect the cables on the engine in exactly the reverse order they

were connected up.

WARNING

•The non-insulated parts of the terminal clamps must never make contact

with each other. Furthermore, the cable connected to the positive terminal

of the battery must not come into contact with electrically conducting parts

of the vehicle - risk of a short circuit!

•Do not affix the jump starting cables to the negative terminal of the

discharged battery. There is the risk of detonating gas seeping out the

battery being ignited by the strong spark which results from the engine

being started.

•Run the jump-start cables so that th ey cannot be caught by any rotating

parts in the engine compartment.

•Do not bend over the batteries - risk of caustic burns!

•The vent screws of the battery cells must be tightened firmly.

•Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

Tow-starting and towing vehicle

General

Please pay attention to the following in structions if you are going to use a

tow rope:

Driver of the towing vehicle

– Do not drive off until the tow rope is taught.

Fig. 230 Jump-starting using

the battery from another

vehicle: A - flat vehicle

battery, B - battery providing

current

A1

AA

A2

AB

A3

AB

A4

20A5Facelift.book Page 253 Saturday, September 6, 2008 2:13 PM

Page 255 of 304

Breakdown assistance

254

– Release the clutch particularly gent ly when starting off or depress the

accelerator particularly gently if yo ur vehicle is fitted with an auto-

matic gearbox.

Driver of the towed vehicle

– Switch the ignition on so that the steering wheel is not blocked and you can also operate the turn signal lights, the headlight flasher, the

windscreen wipers and wi ndscreen washer system.

– Take the vehicle out of gear or move the selector lever into position N

if your vehicle is fitted with an automatic gearbox.

– Note that the brake servo unit and power steering only operate if the engine is running. You will require si gnificantly greater physical force

to depress the brake pedal and to steer the vehicle if the engine is not

running.

– Ensure that the tow rope is always kept taught.

Tow rope or tow bar

A tow bar is safest way of towing a vehicle and also minimizes any shocks. You can

use a tow rope only if a suitable tow bar is not available.

The tow rope must be elastic to protect the vehicle. Thus one should only use

plastic fibre rope or a rope made out of a similarly elastic material.

Only attach the tow rope to the towing eyes provided for this purpose ⇒page 254

and ⇒page 255.

Driving style

Towing another vehicle requires a certain amount of practice. Both drivers should

be familiar with the particular points about towing a vehicle. Unskilled drivers

should not attempt to tow in another vehicle or to be towed in.

One should be constantly vigilant not to allow impermissibly high towing forces or

jerky loadings. There is always a risk of excessive stresses and damage resulting at

the points to which you attach the tow ro pe or tow bar when you attempt to tow a

vehicle which is not standing on a paved road.

Caution

If the gearbox of your vehicle no longer contains any oil because of a defect, your

vehicle must only be towed in with the driven wheels raised clear of the ground, or

on a special vehicle transporter or trailer.

Note

•Please comply with any legal requirements particularly regarding the switched

on signal systems, when towing in or tow-starting another vehicle.

•The tow rope must not be twisted as it may in certain circumstances result in the

front towing eye being unscrewed out of your vehicle.

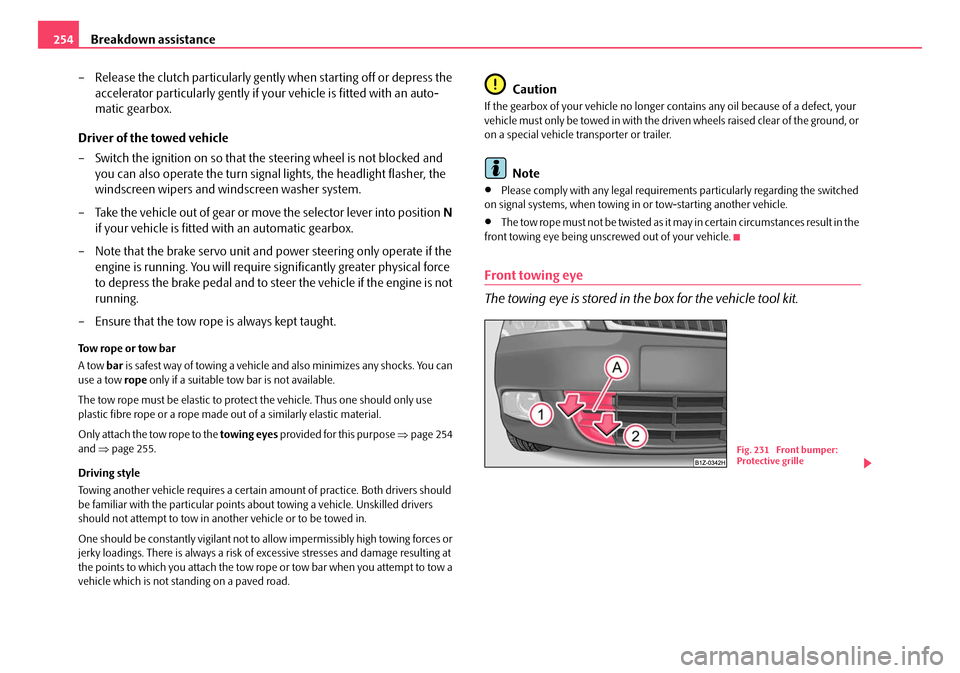

Front towing eye

The towing eye is stored in the box for the vehicle tool kit.

Fig. 231 Front bumper:

Protective grille

20A5Facelift.book Page 254 Saturday, September 6, 2008 2:13 PM

Page 256 of 304

Breakdown assistance255

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Carefully remove the cover as follows.

– Insert the fingers in the opening ⇒page 254, fig. 231 .

– By pulling in the direction of arrow , first of all slacken the cover in the upper area on the side to the fog lights.

– Afterwards, also slacken the cover on the other side in the direction of arrow and remove it.

– Screw in the towing eye anticlockwise down to the stop ⇒fig. 232 and

tighten up using the wheel wrench (push the wheel wrench through

eye).

– The cover can be reinstalled after screwing out the towing eye starting on the side of the marking. Then press the cover closed on the side to

the fog lights. The cover must engage firmly.

Rear towing eye

– Take the cover out of the bumper ⇒fig. 233.

– Screw in the towing eye anticlockwise down to the stop ⇒ fig. 234 and

tighten up using the wheel wrench (push the wheel wrench through

eye).

– The cover can be reinstalled after sc rewing out the towing eye starting

on the upper side of the cover. The cover must engage firmly.

Fig. 232 Front bumper:

Installing the towing eye

AA

A1

A2

Fig. 233 Rear bumper:

Removing cover

Fig. 234 Rear bumper:

Installing the towing eye

20A5Facelift.book Page 255 Saturday, September 6, 2008 2:13 PM

Page 259 of 304

Fuses and light bulbs

258

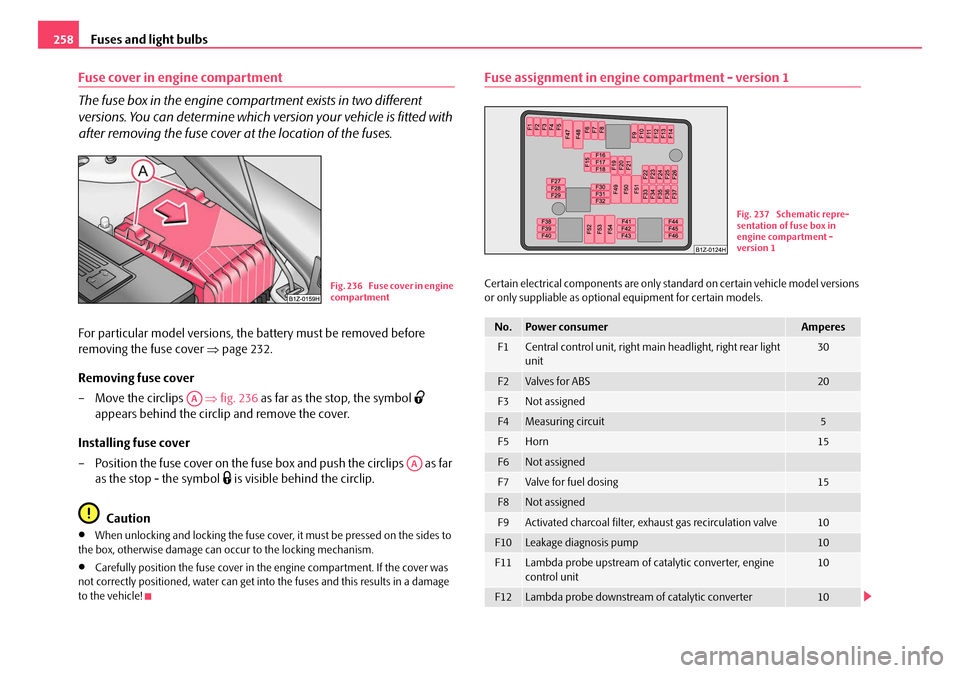

Fuse cover in engine compartment

The fuse box in the engine comp artment exists in two different

versions. You can determine which vers ion your vehicle is fitted with

after removing the fuse cover at the location of the fuses.

For particular model versions, the battery must be removed before

removing the fuse cover ⇒page 232.

Removing fuse cover

– Move the circlips ⇒fig. 236 as far as the stop, the symbol

appears behind the circlip and remove the cover.

Installing fuse cover

– Position the fuse cover on the fuse box and push the circlips as far as the stop - the symbol

is visible behind the circlip.

Caution

•When unlocking and locking the fuse cover, it must be pressed on the sides to

the box, otherwise damage can occur to the locking mechanism.

•Carefully position the fuse cover in the engine compartment. If the cover was

not correctly positioned, water can get into the fuses and this results in a damage

to the vehicle!

Fuse assignment in engine compartment - version 1

Certain electrical components are only standard on certain vehicle model versions

or only suppliable as optional equipment for certain models.Fig. 236 Fuse cover in engine

compartment

AA

AA

No.Power consumerAmperes

F1Central control unit, right main headlight, right rear light

unit30

F2Valves for ABS20

F3Not assigned

F4Measuring circuit5

F5Horn15

F6Not assigned

F7Valve for fuel dosing15

F8Not assigned

F9Activated charcoal filter, exhaust gas recirculation valve10

F10Leakage diagnosis pump10

F11Lambda probe upstream of catalytic converter, engine

control unit10

F12Lambda probe downstream of catalytic converter10

Fig. 237 Schematic repre-

sentation of fuse box in

engine compartment -

version 1

20A5Facelift.book Page 258 Saturday, September 6, 2008 2:13 PM

Page 262 of 304

Fuses and light bulbs261

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

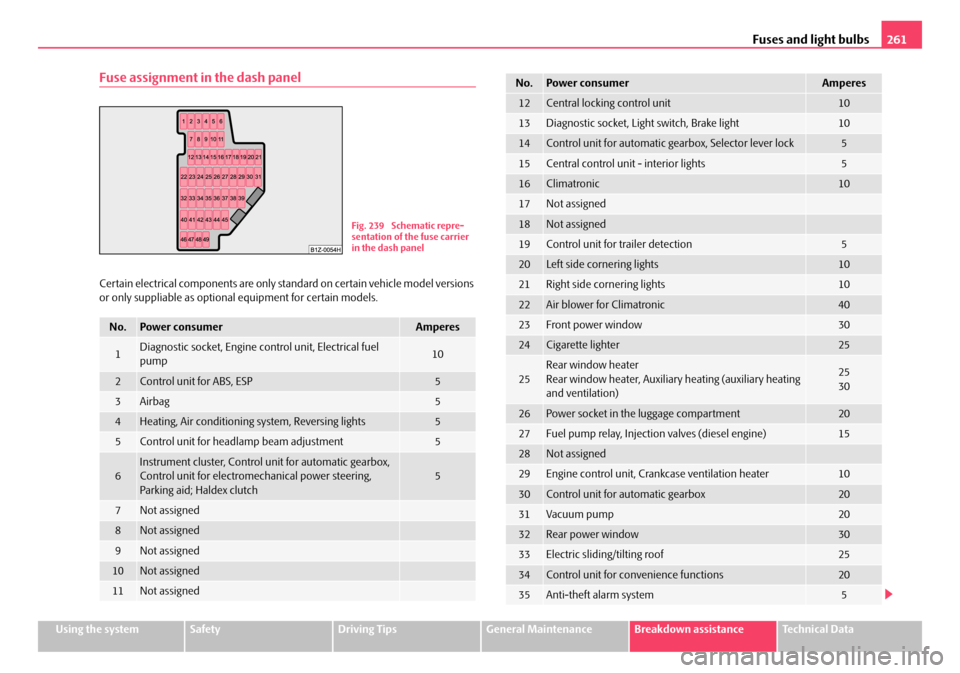

Fuse assignment in the dash panel

Certain electrical components are only standard on certain vehicle model versions

or only suppliable as optional equipment for certain models.

No.Power consumerAmperes

1Diagnostic socket, Engine control unit, Electrical fuel

pump10

2Control unit for ABS, ESP5

3Airbag5

4Heating, Air conditioning system, Reversing lights5

5Control unit for headlamp beam adjustment5

6Instrument cluster, Control unit for automatic gearbox,

Control unit for electromec hanical power steering,

Parking aid; Haldex clutch5

7Not assigned

8Not assigned

9Not assigned

10Not assigned

11Not assigned

Fig. 239 Schematic repre-

sentation of the fuse carrier

in the dash panel

12Central locking control unit10

13Diagnostic socket, Light switch, Brake light10

14Control unit for automatic gearbox, Selector lever lock5

15Central control unit - interior lights5

16Climatronic10

17Not assigned

18Not assigned

19Control unit for trailer detection5

20Left side cornering lights10

21Right side cornering lights10

22Air blower for Climatronic40

23Front power window30

24Cigarette lighter25

25Rear window heater

Rear window heater, Auxiliar y heating (auxiliary heating

and ventilation)25

30

26Power socket in the luggage compartment20

27Fuel pump relay, Injection valves (diesel engine)15

28Not assigned

29Engine control unit, Cran kcase ventilation heater10

30Control unit for automatic gearbox20

31Vacuum pump20

32Rear power window30

33Electric sliding/tilting roof25

34Control unit for convenience functions20

35Anti-theft alarm system5

No.Power consumerAmperes

20A5Facelift.book Page 261 Saturday, September 6, 2008 2:13 PM