SKODA OCTAVIA 2009 2.G / (1Z) Owner's Manual

Manufacturer: SKODA, Model Year: 2009, Model line: OCTAVIA, Model: SKODA OCTAVIA 2009 2.G / (1Z)Pages: 304, PDF Size: 19.56 MB

Page 251 of 304

Breakdown assistance

250

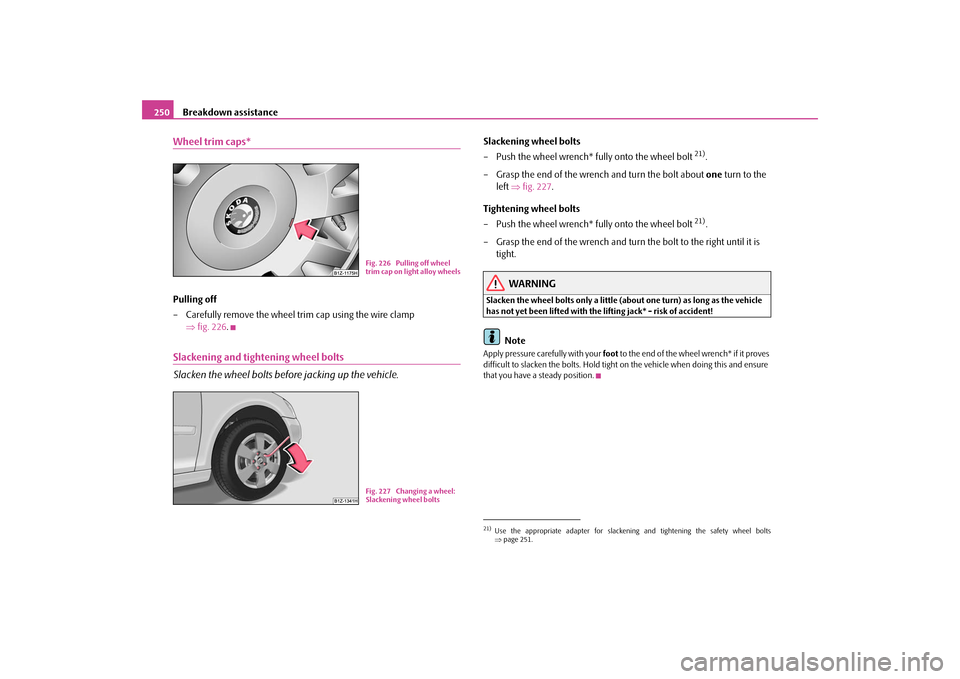

Wheel trim caps*Pulling off – Carefully remove the wheel tr

im cap using the wire clamp

⇒

fig. 226

.

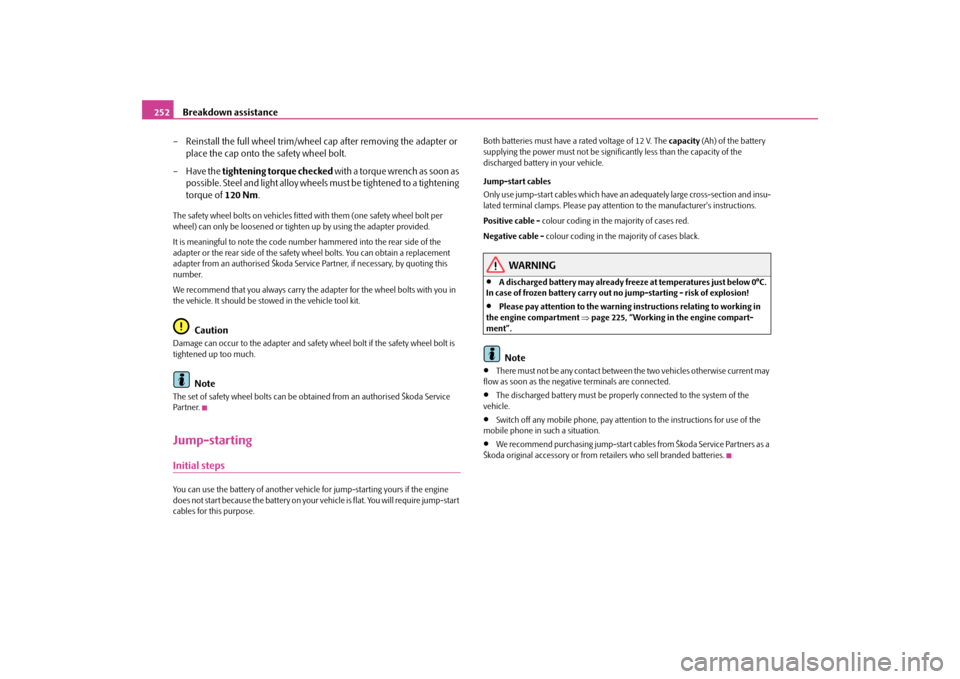

Slackening and tightening wheel bolts Slacken the wheel bolts before jacking up the vehicle.

Slackening wheel bolts – Push the wheel wrench* fully onto the wheel bolt

21).

– Grasp the end of the wrench and turn the bolt about

one

turn to the

left

⇒

fig. 227

.

Tightening wheel bolts – Push the wheel wrench* fully onto the wheel bolt

21).

– Grasp the end of the wrench and turn the bolt to the right until it is

tight.

WARNING

Slacken the wheel bolts only a little (a

bout one turn) as long as the vehicle

has not yet been lifted with the lifting jack* - risk of accident!

Note

Apply pressure carefully with your

foot

to the end of the wheel wrench* if it proves

difficult to slacken the bolts. Hold tight on the vehicle when doing this and ensure that you have a steady position.

Fig. 226 Pulling off wheel trim cap on light alloy wheelsFig. 227 Changing a wheel: Slackening wheel bolts

21)Use the appropriate adapter for slackening

and tightening the safety wheel bolts

⇒ page 251.

se0.1.book Page 250 Frida

y, April 10, 2009 3:19 PM

Page 252 of 304

Breakdown assistance

251

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Raise vehicle You have to raise the vehicle with the lifting jack* in order to be able to take off the wheel.Position the lifting jack* by selecting the jacking point which is closest to the wheel to be removed

⇒

fig. 228

. The jacking point is located directly

below the engraving in the lower sill. The engraving is only visible after opening the door. – Position the lifting jack* below the jacking point and move it up until

its claw is positioned di

rectly below the vertical web of the lower sill.

– Align the lifting jack* so that its claw grasps the web of the lower sill

and the base plate is resting flat on the floor.

– Turn the lifting jack* up further until the wheel is just clear of the

ground.

Ground which is soft and slippery

below the lifting jack* can cause the vehicle to

slip off the lifting jack*. It is therefore al

ways necessary to place the lifting jack* on

a solid surface or use a wide and stable ba

se. Use a non-slip base (e.g. a rubber foot

mat) if the

surface is smooth

, such as cobbled stones, a tiled floor, etc.

WARNING

•

Always raise the vehicle with the doors closed - risk of injury!

•

Take suitable measures to prevent the

base of the lifting jack from slip-

ping off - risk of injury!•

Not positioning the lifting jack* at

the specified points can result in

damage to the vehicle. The lifting jack* ca

n also slip off if it does not have

sufficient grip - risk of injury!•

It is important to support the vehicle with suitable supporting blocks if

you wish to work under the lifted vehicle - risk of injury!Securing wheels against being stolen* You need a special adapter for slackening the safety wheel bolts.– Pull off the full wheel trim/cap from the wheel hub or cap from the

safety wheel bolt.

– Insert the adapter with its toothed side fully into the inner toothing

of the safety wheel bolt right down in such a way that only the outer hexagon is jutting out

⇒

fig. 229

.

– Insert the wheel wrench* fully onto the adapter . – Slacken the wheel bolt, or tighten it firmly

⇒

page 250.

Fig. 228 Changing a wheel: Points for positioning car jac

kAA

AB

Fig. 229 Safety wheel bolt with adapter

AB

AA

AB

se0.1.book Page 251 Frida

y, April 10, 2009 3:19 PM

Page 253 of 304

Breakdown assistance

252

– Reinstall the full wheel trim/wheel cap after removing the adapter or

place the cap onto the safety wheel bolt.

– Have the

tightening torque

checked

w i t h a t o rq u e w re n c h a s s o o n a s

possible. Steel and light alloy wheels must be tightened to a tightening torque of

120 Nm

.

The safety wheel bolts on vehicles fitted with them (one safety wheel bolt per wheel) can only be loosened or tigh

ten up by using the adapter provided.

It is meaningful to note the code numbe

r hammered into the rear side of the

adapter or the rear side of the safety wheel bolts. You can obtain a replacement adapter from an authorised Škoda Service Partner, if necessary, by quoting this number. We recommend that you always carry the

adapter for the wheel bolts with you in

the vehicle. It should be st

owed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety

wheel bolt if the safety wheel bolt is

tightened up too much.

Note

The set of safety wheel bolts can be obta

ined from an authorised Škoda Service

Par tner.Jump-startingInitial stepsYou can use the battery of another vehicl

e for jump-starting yours if the engine

does not start because the battery on your

vehicle is flat. You will require jump-start

cables for this purpose.

Both batteries must have a rated voltage of 12 V. The

capacity

(Ah) of the battery

supplying the power must not be signific

antly less than the capacity of the

discharged battery

in your vehicle.

Jump-start cables Only use jump-start cables which have an

adequately large cross-section and insu-

lated terminal clamps. Please pay attent

ion to the manufacturer's instructions.

Positive cable -

colour coding in the

majority of cases red.

Negative cable -

colour coding in the majority of cases black.

WARNING

•

A discharged battery may already freeze

at temperatures just below 0°C.

In case of frozen battery carry out no jump-starting - risk of explosion!•

Please pay attention to the warning instructions relating to working in

the engine compartment

⇒page 225, “Working in the engine compart-

ment”.

Note

•

There must not be any contact between the two vehicles otherwise current may

flow as soon as the negative terminals are connected.•

The discharged battery must be proper

ly connected to the system of the

vehicle.•

Switch off any mobile phone, pay attent

ion to the instructions for use of the

mobile phone in such a situation.•

We recommend purchasing jump-start cabl

es from Škoda Service Partners as a

Škoda original accessory or from retailers who sell branded batteries.

se0.1.book Page 252 Frida

y, April 10, 2009 3:19 PM

Page 254 of 304

Breakdown assistance

253

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

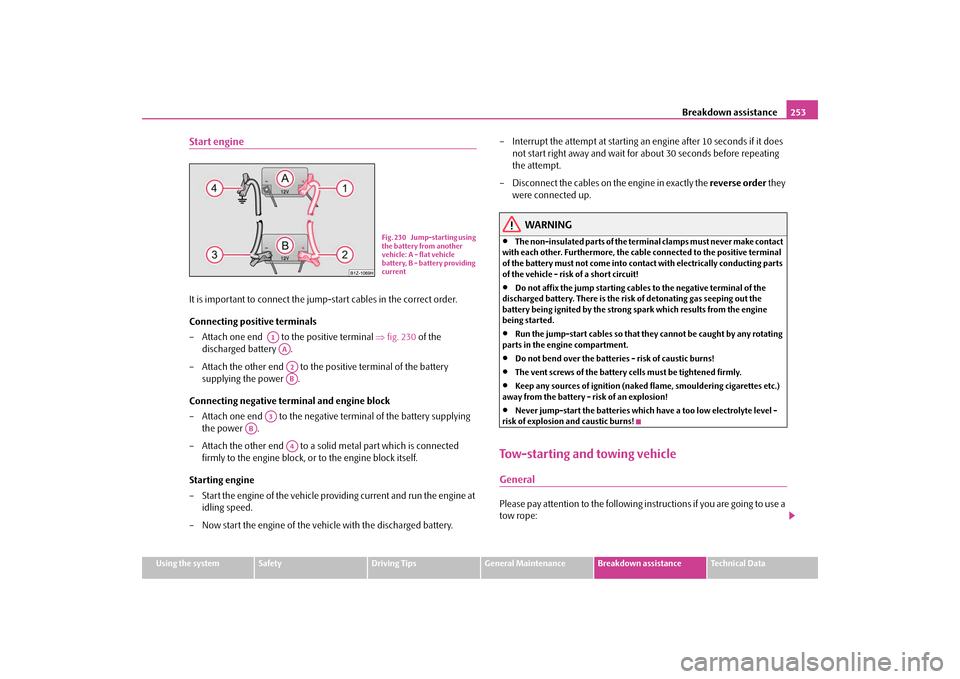

Start engineIt is important to connect the jump

-start cables in the correct order.

Connecting positive terminals – Attach one end to the positive terminal

⇒

fig. 230

of the

discharged battery .

– Attach the other end to the positive terminal of the battery

supplying the power .

Connecting negative term

inal and engine block

– Attach one end to the negative

terminal of the battery supplying

the power .

– Attach the other end to a solid metal part which is connected

firmly to the engine block, or

to the engine block itself.

Starting engine – Start the engine of the vehicle providing current and run the engine at

idling speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does

not start right away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables on the engine in exactly the

reverse order

they

were connected up.

WARNING

•

The non-insulated parts of the terminal clamps must never make contact

with each other. Furthermore, the cable connected to the positive terminal of the battery must not come into contact with electrically conducting parts of the vehicle - risk of a short circuit!•

Do not affix the jump starting cables to the negative terminal of the

discharged battery. There is the risk

of detonating gas seeping out the

battery being ignited by the strong

spark which results from the engine

being started.•

Run the jump-start cables so that th

ey cannot be caught

by any rotating

parts in the engine compartment.•

Do not bend over the batteries - risk of caustic burns!

•

The vent screws of the battery cells must be tightened firmly.

•

Keep any sources of ignition (naked

flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!•

Never jump-start the batteries which have a too low electrolyte level -

risk of explosion and caustic burns!Tow-starting and towing vehicleGeneralPlease pay attention to the following in

structions if you are going to use a

tow rope:

Fig. 230 Jump-starting using the battery from another vehicle: A - flat vehicle battery, B - battery providing current

A1AAA2AB

A3

AB

A4

se0.1.book Page 253 Frida

y, April 10, 2009 3:19 PM

Page 255 of 304

Breakdown assistance

254

Driver of the towing vehicle – Do not drive off until the tow rope is taught. – Release the clutch particularly gent

ly when starting off or depress the

accelerator particularly gently if yo

ur vehicle is fitted with an auto-

matic gearbox.

Driver of the towed vehicle – Switch the ignition on so that the steering wheel is not blocked and

you can also operate the turn signal

lights, the headlight flasher, the

windscreen wipers and wi

ndscreen washer system.

– Take the vehicle out of gear or move

the selector lever into position

N

if your vehicle is fitted with an automatic gearbox.

– Note that the brake servo unit and power steering only operate if the

engine is running. You will require si

gnificantly greater physical force

to depress the brake pedal and to steer the vehicle if the engine is not running.

– Ensure that the tow rope is always kept taught.Tow rope or tow bar A tow

bar

is safest way of towing a vehicle and also minimizes any shocks. You can

use a tow

rope

only if a suitable tow bar is not available.

The tow rope must be elastic to protect

the vehicle. Thus one should only use

plastic fibre rope or a rope made

out of a similarly elastic material.

Only attach the tow rope to the

towing eyes

provided for this purpose

⇒page 254

and

⇒page 256.

Driving style Towing another vehicle requires a certain

amount of practice. Both drivers should

be familiar with the particular points

about towing a vehicle. Unskilled drivers

should not attempt to tow in another vehicle or to be towed in. One should be constantly vigilant not to allow impermissibly high towing forces or jerky loadings. There is always a risk of excessive stresses and damage resulting at

the points to which you attach the tow ro

pe or tow bar when you attempt to tow a

vehicle which is not standing on a paved road.

Caution

If the gearbox of your vehicle no longer

contains any oil because of a defect, your

vehicle must only be towed in with the driven wheels raised clear of the ground, or on a special vehicle transporter or trailer.

Note

•

Please comply with any legal requirements particularly regarding the switched

on signal systems, when towing in

or tow-starting another vehicle.

•

The tow rope must not be twisted as it may in certain circumstances result in the

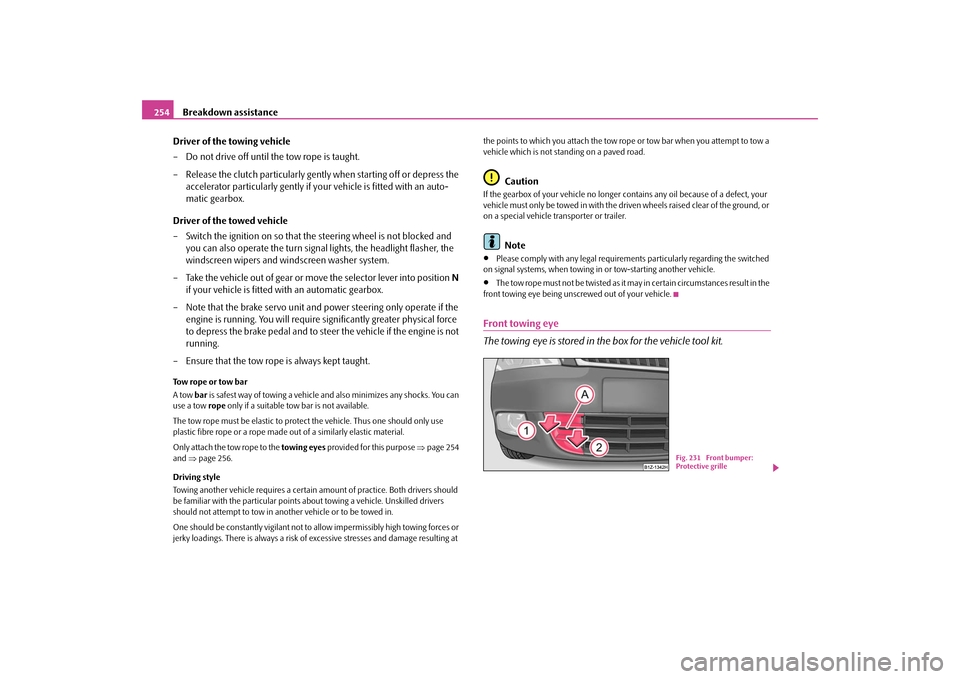

front towing eye being unscrewed out of your vehicle.Front towing eye The towing eye is stored in the box for the vehicle tool kit.

Fig. 231 Front bumper: Protective grille

se0.1.book Page 254 Frida

y, April 10, 2009 3:19 PM

Page 256 of 304

Breakdown assistance

255

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

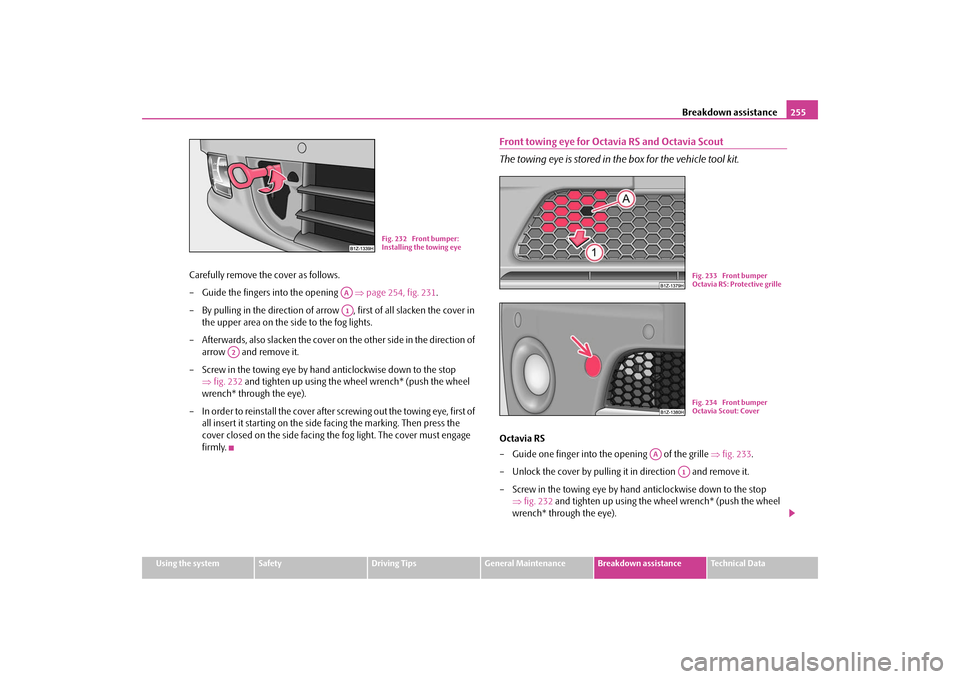

Carefully remove the cover as follows. – Guide the fingers into the opening

⇒

page 254, fig. 231

.

– By pulling in the direction of arrow , first of all slacken the cover in

the upper area on the side to the fog lights.

– Afterwards, also slacken the cover on the other side in the direction of

arrow and remove it.

– Screw in the towing eye by hand anticlockwise down to the stop

⇒

fig. 232

and tighten up using the wheel wrench* (push the wheel

wrench* through the eye).

– In order to reinstall the cover after sc

rewing out the towing eye, first of

all insert it starting on the side facing the marking. Then press the cover closed on the side facing the fog light. The cover must engage firmly.

Front towing eye for Octavia RS and Octavia Scout The towing eye is stored in th

e box for the vehicle tool kit.

Octavia RS – Guide one finger into the opening of the grille

⇒

fig. 233

.

– Unlock the cover by pulling it in direction and remove it.– Screw in the towing eye by hand anticlockwise down to the stop

⇒

fig. 232

and tighten up using the wheel wrench* (push the wheel

wrench* through the eye).

Fig. 232 Front bumper: Installing the towing eye

AAA1

A2

Fig. 233 Front bumper Octavia RS: Protective grilleFig. 234 Front bumper Octavia Scout: Cover

AA

A1

se0.1.book Page 255 Frida

y, April 10, 2009 3:19 PM

Page 257 of 304

Breakdown assistance

256

– After screwing out the towing eye,

reinsert the cover and lock it in

place. The cover must engage firmly.

Octavia Scout – Press on the upper part of the cover

⇒

page 255, fig. 234

and remove

it.

– Screw in the towing eye by hand anticlockwise down to the stop

⇒

page 255, fig. 232

and tighten up using the wheel wrench* (push

the wheel wrench* through the eye).

– After screwing out the towing eye,

reinsert the cover and lock it in

place. The cover must engage firmly.

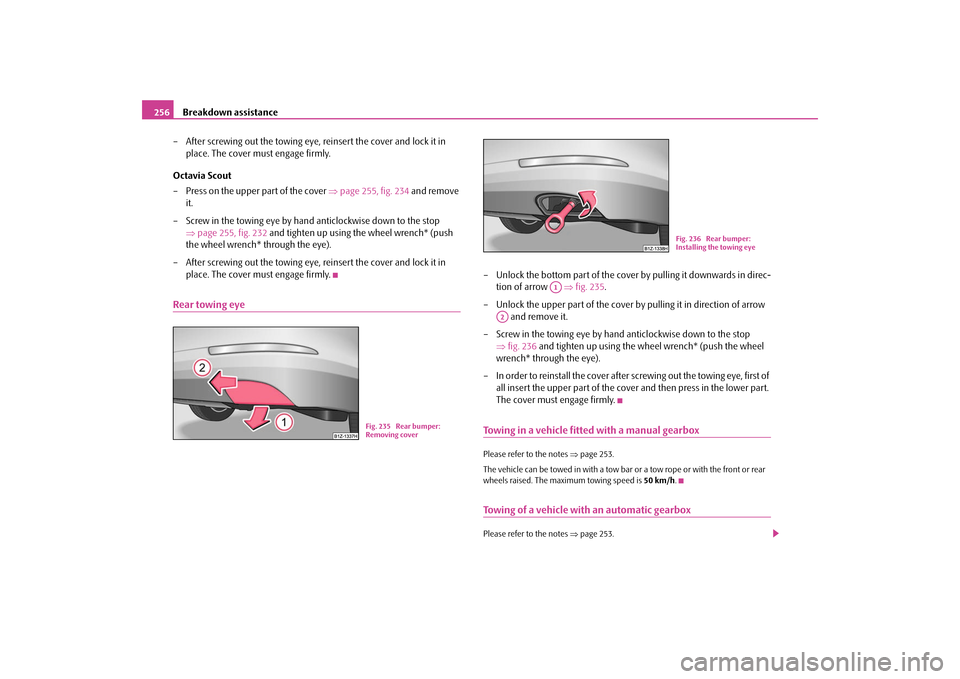

Rear towing eye

– Unlock the bottom part of the cover by pulling it downwards in direc-

tion of arrow

⇒

fig. 235

.

– Unlock the upper part of the cover by pulling it in direction of arrow

and remove it.

– Screw in the towing eye by hand

anticlockwise down to the stop

⇒

fig. 236

and tighten up using the wheel wrench* (push the wheel

wrench* through the eye).

– In order to reinstall the cover after screwing out the towing eye, first of

all insert the upper part of the cover and then press in the lower part. The cover must engage firmly.

Towing in a vehicle fitted with a manual gearboxPlease refer to the notes

⇒page 253.

The vehicle can be towed in with a tow bar or a tow rope or with the front or rear wheels raised. The maximum towing speed is

50 km/h

.

Towing of a vehicle with an automatic gearboxPlease refer to the notes

⇒page 253.

Fig. 235 Rear bumper: Removing cover

Fig. 236 Rear bumper: Installing the towing eye

A1

A2

se0.1.book Page 256 Frida

y, April 10, 2009 3:19 PM

Page 258 of 304

Breakdown assistance

257

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

The car can be towed in with a tow bar or

a tow rope. Refer at the same time to the

following guidelines:•

Move

selector lever into N

.

•

The maximum towing speed is

50 km/h

.

•

The maximum permissible towing distance is

50 km

. The gear oil pump does

not operate when the engine is not runni

ng; the gearbox would not be adequately

lubricated at higher speeds an

d over longer towing distance.

Caution

If the vehicle is towed in by a recovery vehi

cle, it should only be towed in with the

front wheels raised. If the vehicle is raised at rear, the automatic gearbox is damaged! (Does not apply to the automatic gearbox DSG).

Note

The vehicle must be transported on a special ve

hicle or trailer if it is not possible to

tow in the vehicle in the way described or if the towing distance is greater than 50 km.Towing a vehicle with four-wheel drivePlease refer to the notes

⇒page 253.

The vehicle can be towed in using a tow ba

r or a tow rope or with the front axle

raised. The maximum towing speed is

50 km/h

, the maximum permissible towing

distance is

50 km

.

Note

The vehicle must be transported on a special ve

hicle or trailer if it is not possible to

tow in the vehicle in the way described or if the towing distance is greater than 50 km.

se0.1.book Page 257 Frida

y, April 10, 2009 3:19 PM

Page 259 of 304

Fuses and light bulbs

258

Fuses and light bulbsElectric fusesReplacing fuses Defect fuses must be replaced.Individual electrical circuits are prot

ected by fuses. The fuses are located

on the left side of the dash panel behind the safety cover and under the cover in the engine compartment on the left. – Switch the ignition off and also the electrical component affected.– Use a screwdriver to take off the fuse cover on the side of the dash

panel

⇒

fig. 237

or the fuse cover in the engine compartment

⇒

page 259.

– Find out which fuse belongs to the relevant component

⇒

page 260,

“Fuse assignment in the dash panel” or

⇒

page 259, “Fuse assignment

in engine compartment”.

– Take the plastic clip out of its fixture in the fuse cover, insert it onto the

respective fuse and pull out this fuse.

– Defect fuses can be detected by th

eir melted metal st

rips. Replace the

defect fuse by a new fuse of the

same

ampere number.

– Fit on the fuse cover again.We recommend that you always have the

small box of replacement fuses in your

vehicle. You can obtain replacement fuses from Škoda original accessories or from a specialist garage

22).

Colour coding of fuses

Caution

•

Never attempt to “repair” fuses and also do not replace them with a fuse of a

higher amperage - risk of fire! This may

also cause damage at another part of the

electrical system.•

Have the electrical system checked as quickly as possible by a specialist garage

if a newly inserted fuse blows again after a short time.

Fig. 237 Fuse cover: left side of the dash panel

22)The small box with replacement fuses is part of the basic equipping of the vehicle in somecountries.

Colour

Maximum amperage

light brown

5

brown

7,5

red

10

blue

15

yellow

20

white

25

green

30

orange

40

red

50

se0.1.book Page 258 Frida

y, April 10, 2009 3:19 PM

Page 260 of 304

Fuses and light bulbs

259

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Fuse cover in engine compartment The fuse box in the engine comp

artment exists in two different

versions. You can determine which version your vehicle is fitted with after removing the fuse cover at the location of the fuses.On some vehicles, the battery cover

must be removed before removing

the fuse cover

⇒

page 232.

Removing fuse cover – Move the circlips

⇒

fig. 238

as far as the stop, the symbol

appears behind the circlip and remove the cover.

Installing fuse cover – Position the fuse cover on the fuse box and push the circlips as far

as the stop - the symbol

is visible behind the circlip.

Caution

•

When unlocking and locking the fuse cover,

it must be pressed on the sides to

the box, otherwise damage can

occur to the locking mechanism.

•

Carefully position the fuse cover in th

e engine compartment. If the cover was

not correctly positioned, water can get into

the fuses and this results in a damage

to the vehicle!

Fuse assignment in engine compartmentCertain electrical components are only standard on certain vehicle model versions or only suppliable as optional

equipment for certain models.

Fig. 238 Fuse cover in engine compartment

AA

AA

No.

Power consumer

Amperes

F1

Not assigned

F2

Control unit for automatic gearbox DQ 200

30

F3

Measuring circuit

5

F4

Valves for ABS

30/20

F5

Control unit for automatic gearbox

15

F6

Instrument cluster, windshield

wiper lever and turn sig-

nal light lever

5

F7

Power suppy terminal 15, Starter

40

F8

Radio

15

F9

Phone

5

F10

Engine control unit, Main relay

5/10

F11

Control unit for auxiliary heating

20

F12

Control unit for CAN databus

5

Fig. 239 Schematic repre- sentation of fuse carrier in engine compartment

se0.1.book Page 259 Frida

y, April 10, 2009 3:19 PM