technical data SKODA OCTAVIA 2011 2.G / (1Z) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: OCTAVIA, Model: SKODA OCTAVIA 2011 2.G / (1Z)Pages: 248, PDF Size: 3.79 MB

Page 199 of 248

Accessories, changes and replacement of parts

General ŠKODA vehicles have been built according to the latest discoveries in safety engi-

neering. Thus one should not change the condition in which the vehicle was deliv-

ered from the manufacturer without some thought.

If you want to retrofit the vehicle with accessories, if a vehicle part is to be re-

placed with a new one, or when needing to make technical changes, the following

instructions must be observed:

● Advise should always be obtained from an authorised ŠKODA Service Partner

before buying any accessories or parts and before making any technical changes

⇒ .

● The guidelines and instructions issued by ŠKODA must be observed when

making technical changes.

Adhering to the prescribed procedures will prevent any kind of damage to the ve-

hicle, and its travelling and operating safety will be maintained. The vehicle also

complies with German road transport regulations (StVZO). More information is

available from an authorised

ŠKODA Service Partner who can also perform the

necessary work properly.

Interference on the electronic components and their software can lead to opera-

tional faults. This interference can also impair not directly affected systems be-

cause of the networking of the electronic components. In other words, the vehi-

cle's roadworthiness may be put at risk and increased wear on parts may arise.

Any damage which is done caused by technical changes made without consult-

ing a ŠKODA dealer is excluded from the warranty – see the warranty certificate. WARNING

● Work or modifications on your vehicle, which have been carried out unpro-

fessionally, can cause operational faults - risk of accident!

● We advise you, in your own interest, to only use ŠKODA Original Accesso-

ries and ŠKODA Original Parts which have been expressly approved for use on

your vehicle. Reliability, safety and suitability have been established for

ŠKODA Original Accessories and ŠKODA

Original Parts.

● Although we constantly monitor the market, we are not able to assess or

warrant the parts even though in some instances such parts may have a type

approval or may have been approved by a nationally recognised testing labo-

ratory. Note

● ŠKODA Original Accessories and

ŠKODA Original Parts can be bought from au-

thorised ŠKODA Service Partners who also professionally undertake the assembly

of parts which were purchased there.

● We recommend having all work undertaken by an authorised ŠKODA Service

Partner.

● All ŠKODA Original Accessories and Original Parts from the Original Accessories

catalogue, such as a towing device, child seats, etc. are authorised.

● We recommend that you also buy car stereos, aerials or other electrical acces-

sories from an authorised

ŠKODA Service Partner, who should also carry out the

installation. 197

Accessories, changes and replacement of parts Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 201 of 248

The fire extinguisher must be checked by an authorised person or company annu-

ally (please observe the differing legal requirements).

WARNING

If the fire extinguisher is not correctly attached, in case of sudden manoeu-

vres or an accident it can be “thrown” through the interior compartment and

cause injuries. Note

● The fire extinguisher must comply with the relevant and valid legal require-

ments.

● Pay attention to the expiration date of the fire extinguisher. If the fire extin-

guisher is used after the expiration date, its proper function is no longer assured.

● The fire extinguisher is only supplied in certain countries within the scope of

delivery.

Vehicle tool kit Fig. 162 Luggage compartment: Storage

compartment for vehicle too kit

The vehicle tool kit and the lifting jack with sticker are housed in a plastic box in

the spare wheel ⇒ fig. 162 or in the compartment for the spare wheel. There is al-

so space here for the removable ball for the trailer towing device. The box is at-

tached with a strap on the spare wheel. The vehicle tool kit contains the following parts (depending on equipment fitted):

● Wire clamps for removing the full wheel trims,

● Plastic clip for a wheel bolt cover,

● Wheel wrench,

● Towing eye,

● Adapter for the wheel bolts lock,

● Replacement lamp,

● Screwdriver for removing the fog lights 1)

.

Before placing the lifting jack back in its storage area, screw in the arm of the lift-

ing jack fully. WARNING

● The factory-supplied lifting jack is only intended for your model of vehicle.

On no account attempt to lift a heavier vehicle or other loads - risk of injury!

● Ensure that the vehicle tool kit is safely attached in the luggage compart-

ment. Note

Ensure that the box is always secured with the strap.

Spare wheel Fig. 163 Luggage compartment: Spare

wheel

The spare wheel lies in a well under the floor covering of the luggage compart-

ment and is fixed in place using special screws ⇒

fig. 163. £1)

Valid for Octavia RS and Octavia Scout. 199

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 203 of 248

Note

● All bolts must be clean and must turn easily.

● You must never grease or oil the wheel bolts!

● When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction ⇒ page 192

.

Subsequent steps After changing the wheel, you must perform the following steps.

–

Stow and attach the replaced wheel in the spare wheel well using a special

screw ⇒ fig. 163 .

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel just mounted as soon as possible.

– Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible. Steel and light alloy wheels must be tightened to a tight-

ening torque of 120 Nm.

– Change the damaged wheel or consult a specialist garage about possibilities

for getting repairs done. WARNING

It is necessary to observe the guidelines given on ⇒

page 194 if the vehicle is

subsequently fitted with tyres which are different to those it was fitted with

at the works. Note

● If you find, when changing the wheel, that the wheel bolts are corroded and

difficult to turn, the bolts must be replaced before checking the tightening torque.

● Drive cautiously and only at a moderate speed to a workshop where the tight-

ening torque can be checked.

Full wheel trim Pulling off

–

Hook the clamp found in the vehicle tool kit into the reinforced edge of the full

wheel trim. –

Push the wheel key through the clamp, support the wheel key at the tyre and

pull off the wheel trim.

Install

– First press the full wheel trim onto the wheel at the valve opening provided.

Then press the full wheel trim into the wheel in such a way that its entire cir-

cumference locks correctly in place. CAUTION

● Use the pressure of your hand, do not knock on the full wheel trim! Heavy

knocks mainly on the points where the full wheel trim has not been inserted into

the wheel, can result in damage to the guide and centring elements of the full

wheel trim.

● Check for yourself that the safety wheel bolt is located in the hole in the area

of the valve before fitting the full wheel trim onto a steel wheel which is attached

with a safety wheel bolt ⇒

page 203, Securing wheels against being stolen.

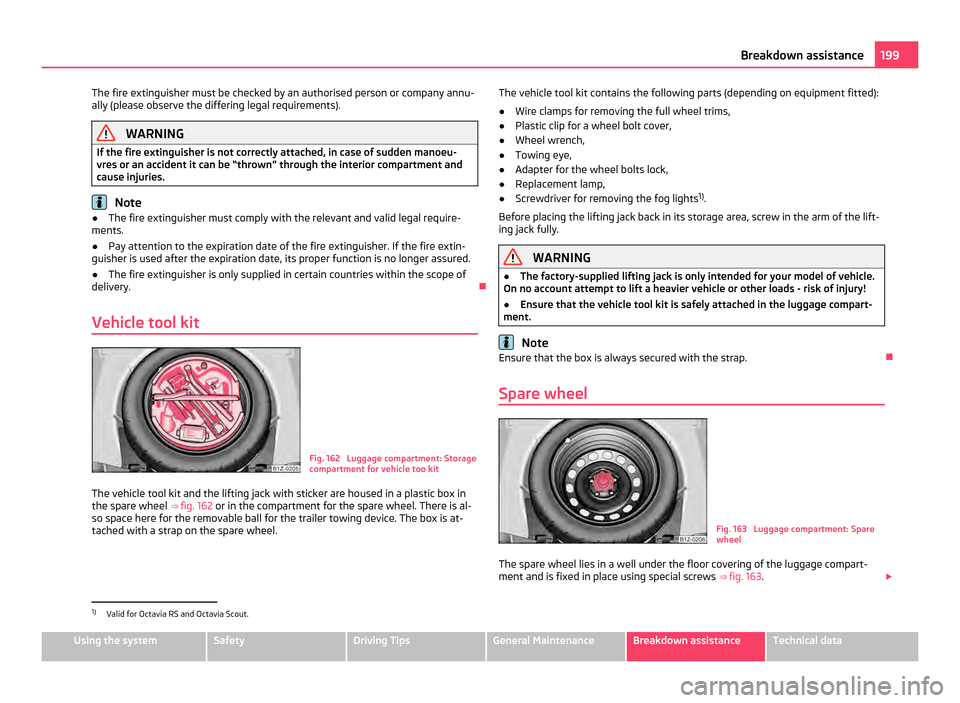

Wheel bolts with caps Fig. 164 Removing the cap.

Pulling off

– Push the plastic clip sufficiently far onto the cap until the inner catches of the

clip are positioned at the collar of the cap and detach the cap ⇒ fig. 164 .

Install

– Push the caps fully onto the wheel bolts.

The caps are located in the well of the luggage compartment. 201

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 205 of 248

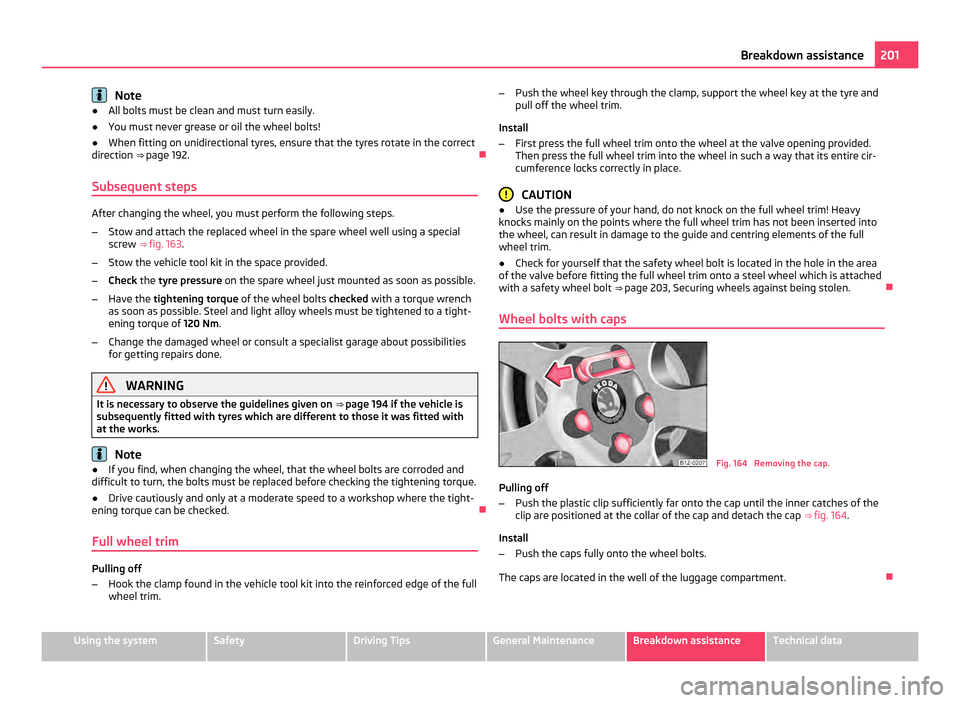

Raise vehicle

You have to raise the vehicle with a lifting jack in order to be able

to take off the wheel.

Fig. 167 Changing a wheel: Jacking

points for positioning lifting jack

Fig. 168 Attach lifting jack

Position the lifting jack by selecting the jacking point which is closest to the wheel

to be removed

⇒ fig. 167 . The jacking point is located directly below the engraving

in the lower sill. The engraving is only visible after opening the door.

– Position the lifting jack below the jacking point and move it up until its claw is

positioned directly below the vertical web of the lower sill.

– Align the lifting jack so that its claw grasps the web ⇒ fig. 168 at the right be-

low the embossing in the side surface of the base plate.

– Make sure that the base plate of the lifting jack rests with its entire surface on

level ground and is located vertical to the point ⇒

fig. 168 where the claw

grasps the web.

– Turn the lifting jack up further until the wheel is just clear of the ground. WARNING

● Always raise the vehicle with the doors closed - risk of injury.

● Never position any body parts such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack.

● Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always neces-

sary to place the lifting jack on a solid surface or use a wide and stable base.

Use a non-slip base (e.g. a rubber foot mat) if the

surface is smooth, such as

cobbled stones, a tiled floor, etc.

● Attach the lifting jack only at the attachment points provided for this pur-

pose.

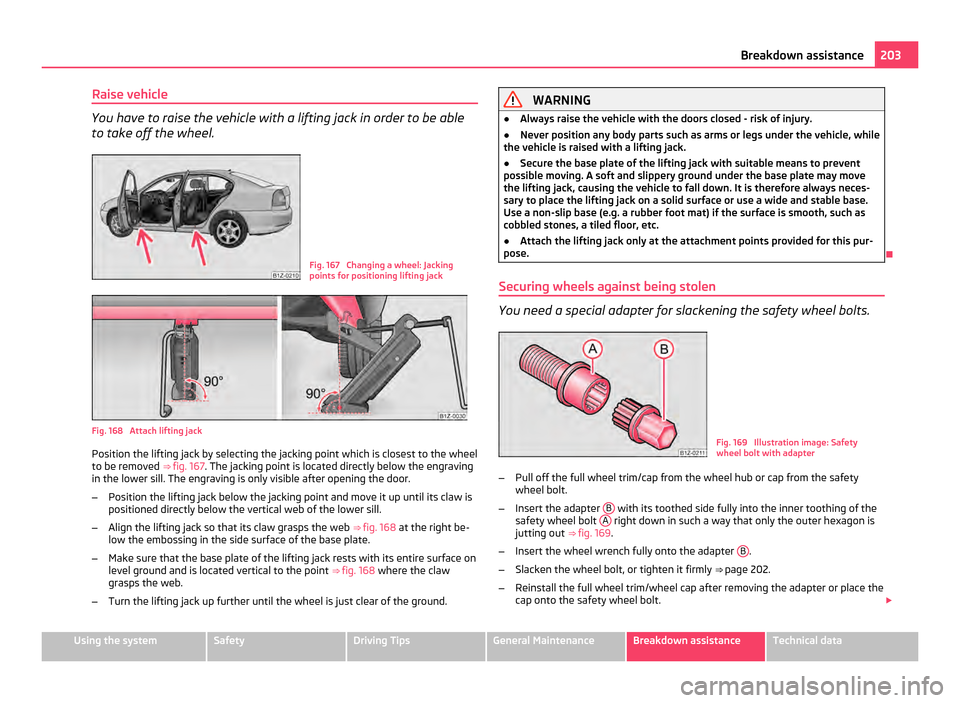

Securing wheels against being stolen You need a special adapter for slackening the safety wheel bolts.

Fig. 169 Illustration image: Safety

wheel bolt with adapter

– Pull off the full wheel trim/cap from the wheel hub or cap from the safety

wheel bolt.

– Insert the adapter B with its toothed side fully into the inner toothing of the

safety wheel bolt A right down in such a way that only the outer hexagon is

jutting out ⇒ fig. 169 .

– Insert the wheel wrench fully onto the adapter B .

– Slacken the wheel bolt, or tighten it firmly ⇒ page 202.

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the

cap onto the safety wheel bolt. £ 203

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 207 of 248

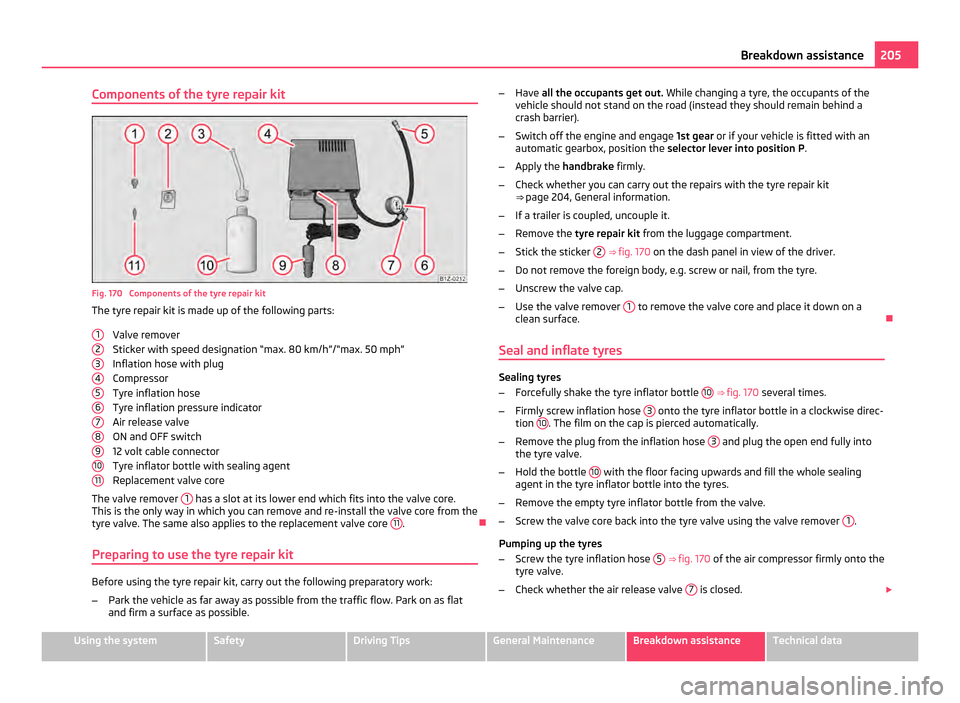

Components of the tyre repair kit

Fig. 170 Components of the tyre repair kit

The tyre repair kit is made up of the following parts:

Valve remover

Sticker with speed designation

“max. 80 km/h”/“max. 50 mph”

Inflation hose with plug

Compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1 has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from the

tyre valve. The same also applies to the replacement valve core 11 .

Preparing to use the tyre repair kit Before using the tyre repair kit, carry out the following preparatory work:

–

Park the vehicle as far away as possible from the traffic flow. Park on as flat

and firm a surface as possible.

1 2

3

4

5

6

7

8

9

10

11 –

Have all the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a

crash barrier).

– Switch off the engine and engage 1st gear or if your vehicle is fitted with an

automatic gearbox, position the selector lever into position P .

– Apply the handbrake firmly.

– Check whether you can carry out the repairs with the tyre repair kit

⇒ page 204, General information

.

– If a trailer is coupled, uncouple it.

– Remove the tyre repair kit from the luggage compartment.

– Stick the sticker 2

⇒

fig. 170 on the dash panel in view of the driver.

– Do not remove the foreign body, e.g. screw or nail, from the tyre.

– Unscrew the valve cap.

– Use the valve remover 1 to remove the valve core and place it down on a

clean surface.

Seal and inflate tyres Sealing tyres

–

Forcefully shake the tyre inflator bottle 10

⇒ fig. 170 several times.

– Firmly screw inflation hose 3 onto the tyre inflator bottle in a clockwise direc-

tion 10 . The film on the cap is pierced automatically.

– Remove the plug from the inflation hose 3 and plug the open end fully into

the tyre valve.

– Hold the bottle 10 with the floor facing upwards and fill the whole sealing

agent in the tyre inflator bottle into the tyres.

– Remove the empty tyre inflator bottle from the valve.

– Screw the valve core back into the tyre valve using the valve remover 1 .

Pumping up the tyres

– Screw the tyre inflation hose 5

⇒

fig. 170 of the air compressor firmly onto the

tyre valve.

– Check whether the air release valve 7 is closed.

£ 205

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 209 of 248

WARNING

● A discharged battery may already freeze at temperatures just below 0 °C.

In case of frozen battery carry out no jump-starting - risk of explosion!

● Please pay attention to the warning instructions relating to working in the

engine compartment ⇒ page 181, Working in the engine compartment

.Note

● There must not be any contact between the two vehicles otherwise current

may flow as soon as the negative terminals are connected.

● The discharged battery must be properly connected to the system of the vehi-

cle.

● Switch off any mobile phone, pay attention to the instructions for use of the

mobile phone in such a situation.

● We recommend you buy jump-start cables from a car battery specialist.

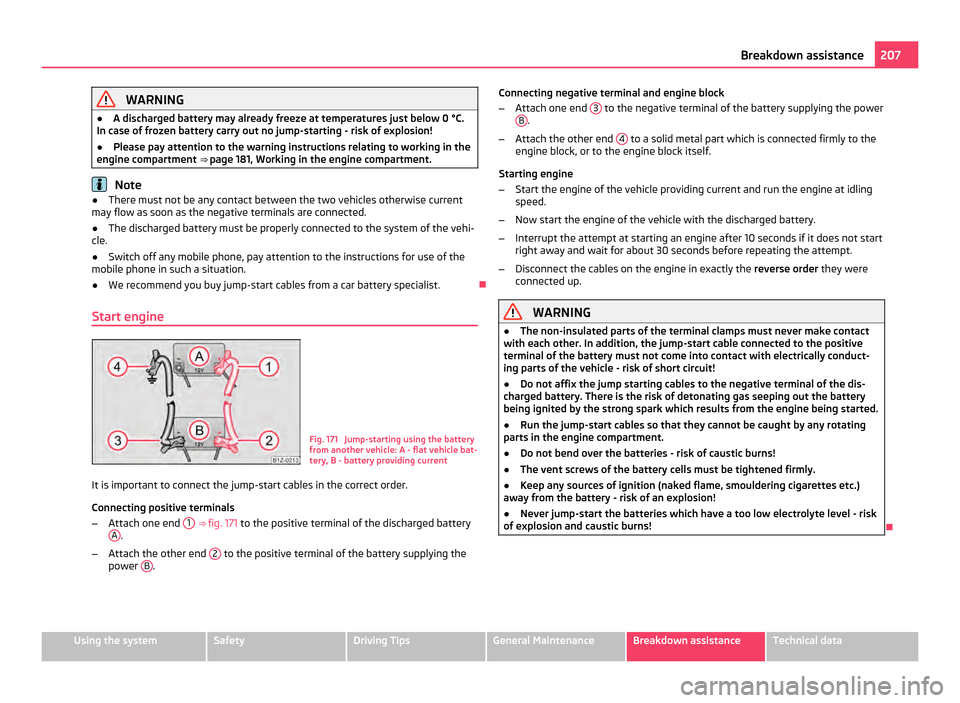

Start engine Fig. 171 Jump-starting using the battery

from another vehicle: A - flat vehicle bat-

tery, B - battery providing current

It is important to connect the jump-start cables in the correct order.

Connecting positive terminals

– Attach one end 1

⇒

fig. 171 to the positive terminal of the discharged battery

A .

– Attach the other end 2 to the positive terminal of the battery supplying the

power B . Connecting negative terminal and engine block

– Attach one end 3 to the negative terminal of the battery supplying the power

B .

– Attach the other end 4 to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.

Starting engine

– Start the engine of the vehicle providing current and run the engine at idling

speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start

right away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables on the engine in exactly the reverse order they were

connected up. WARNING

● The non-insulated parts of the terminal clamps must never make contact

with each other. In addition, the jump-start cable connected to the positive

terminal of the battery must not come into contact with electrically conduct-

ing parts of the vehicle - risk of short circuit!

● Do not affix the jump starting cables to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

● Run the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

● Do not bend over the batteries - risk of caustic burns!

● The vent screws of the battery cells must be tightened firmly.

● Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

● Never jump-start the batteries which have a too low electrolyte level - risk

of explosion and caustic burns! 207

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 211 of 248

Note

● We recommend a tow rope from the range of ŠKODA Original Accessories that

you can purchase from an authorised ŠKODA Service Partner.

● Towing another vehicle requires a certain amount of practice. Both drivers

should be familiar with the particular points about towing a vehicle. Unskilled driv-

ers should not attempt to tow in another vehicle or to be towed in.

● When towing, respect the national legal provisions, especially those which re-

late to the identification of the towing vehicle and the vehicle being towed.

● The tow rope must not be twisted as it may in certain circumstances result in

the front towing eye being unscrewed out of your vehicle.

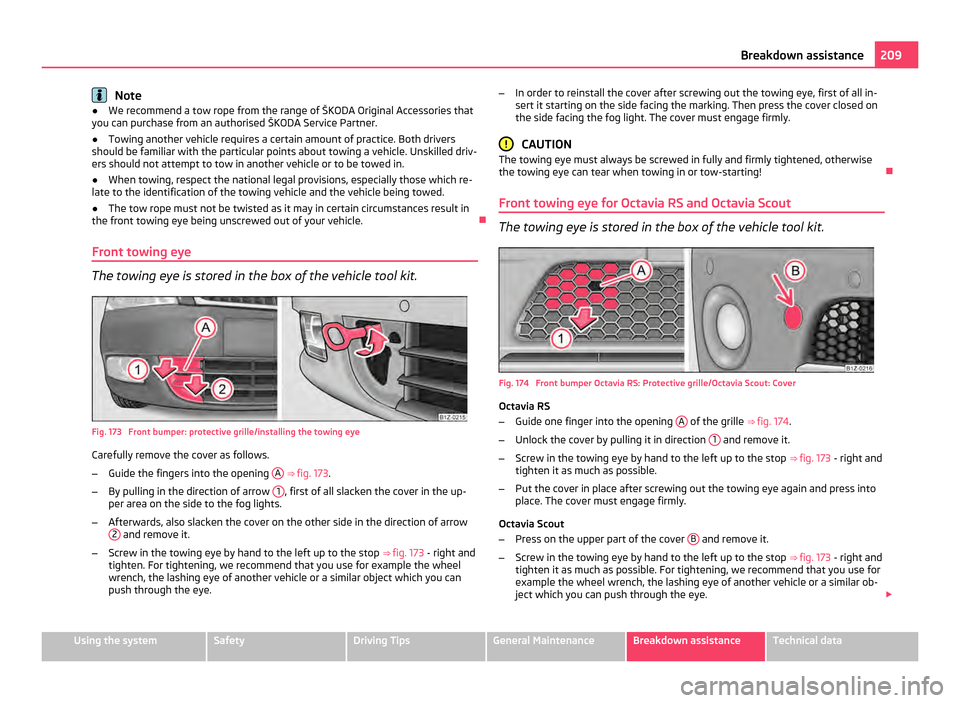

Front towing eye The towing eye is stored in the box of the vehicle tool kit.

Fig. 173 Front bumper: protective grille/installing the towing eye

Carefully remove the cover as follows.

–

Guide the fingers into the opening A

⇒

fig. 173.

– By pulling in the direction of arrow 1 , first of all slacken the cover in the up-

per area on the side to the fog lights.

– Afterwards, also slacken the cover on the other side in the direction of arrow

2 and remove it.

– Screw in the towing eye by hand to the left up to the stop ⇒ fig. 173 - right and

tighten. For tightening, we recommend that you use for example the wheel

wrench, the lashing eye of another vehicle or a similar object which you can

push through the eye. –

In order to reinstall the cover after screwing out the towing eye, first of all in-

sert it starting on the side facing the marking. Then press the cover closed on

the side facing the fog light. The cover must engage firmly. CAUTION

The towing eye must always be screwed in fully and firmly tightened, otherwise

the towing eye can tear when towing in or tow-starting!

Front towing eye for Octavia RS and Octavia Scout The towing eye is stored in the box of the vehicle tool kit.

Fig. 174 Front bumper Octavia RS: Protective grille/Octavia Scout: Cover

Octavia RS

–

Guide one finger into the opening A of the grille

⇒ fig. 174 .

– Unlock the cover by pulling it in direction 1 and remove it.

– Screw in the towing eye by hand to the left up to the stop ⇒ fig. 173 - right and

tighten it as much as possible.

– Put the cover in place after screwing out the towing eye again and press into

place. The cover must engage firmly.

Octavia Scout

– Press on the upper part of the cover B and remove it.

– Screw in the towing eye by hand to the left up to the stop ⇒ fig. 173 - right and

tighten it as much as possible. For tightening, we recommend that you use for

example the wheel wrench, the lashing eye of another vehicle or a similar ob-

ject which you can push through the eye. £ 209

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 213 of 248

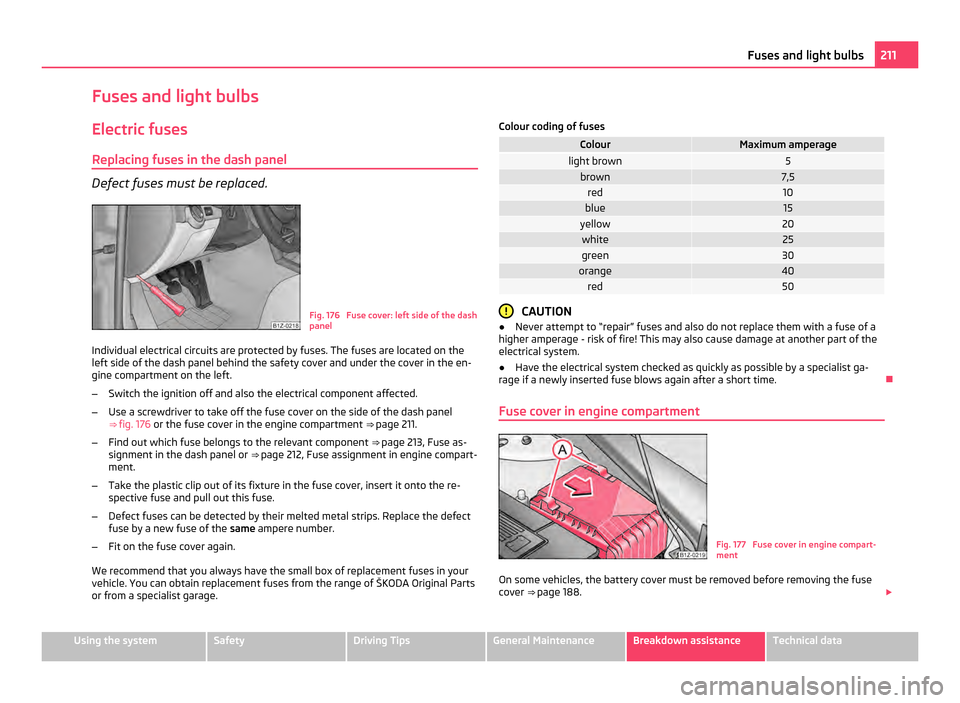

Fuses and light bulbs

Electric fuses Replacing fuses in the dash panel Defect fuses must be replaced.

Fig. 176 Fuse cover: left side of the dash

panel

Individual electrical circuits are protected by fuses. The fuses are located on the

left side of the dash panel behind the safety cover and under the cover in the en-

gine compartment on the left.

– Switch the ignition off and also the electrical component affected.

– Use a screwdriver to take off the fuse cover on the side of the dash panel

⇒ fig. 176 or the fuse cover in the engine compartment ⇒ page 211.

– Find out which fuse belongs to the relevant component ⇒ page 213, Fuse as-

signment in the dash panel or ⇒ page 212, Fuse assignment in engine compart-

ment.

– Take the plastic clip out of its fixture in the fuse cover, insert it onto the re-

spective fuse and pull out this fuse.

– Defect fuses can be detected by their melted metal strips. Replace the defect

fuse by a new fuse of the same ampere number.

– Fit on the fuse cover again.

We recommend that you always have the small box of replacement fuses in your

vehicle. You can obtain replacement fuses from the range of

ŠKODA Original Parts

or from a specialist garage. Colour coding of fuses Colour Maximum amperage

light brown 5

brown 7,5

red 10

blue 15

yellow 20

white 25

green 30

orange 40

red 50

CAUTION

● Never attempt to

“repair” fuses and also do not replace them with a fuse of a

higher amperage - risk of fire! This may also cause damage at another part of the

electrical system.

● Have the electrical system checked as quickly as possible by a specialist ga-

rage if a newly inserted fuse blows again after a short time.

Fuse cover in engine compartment Fig. 177 Fuse cover in engine compart-

ment

On some vehicles, the battery cover must be removed before removing the fuse

cover ⇒ page 188

. £ 211

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 215 of 248

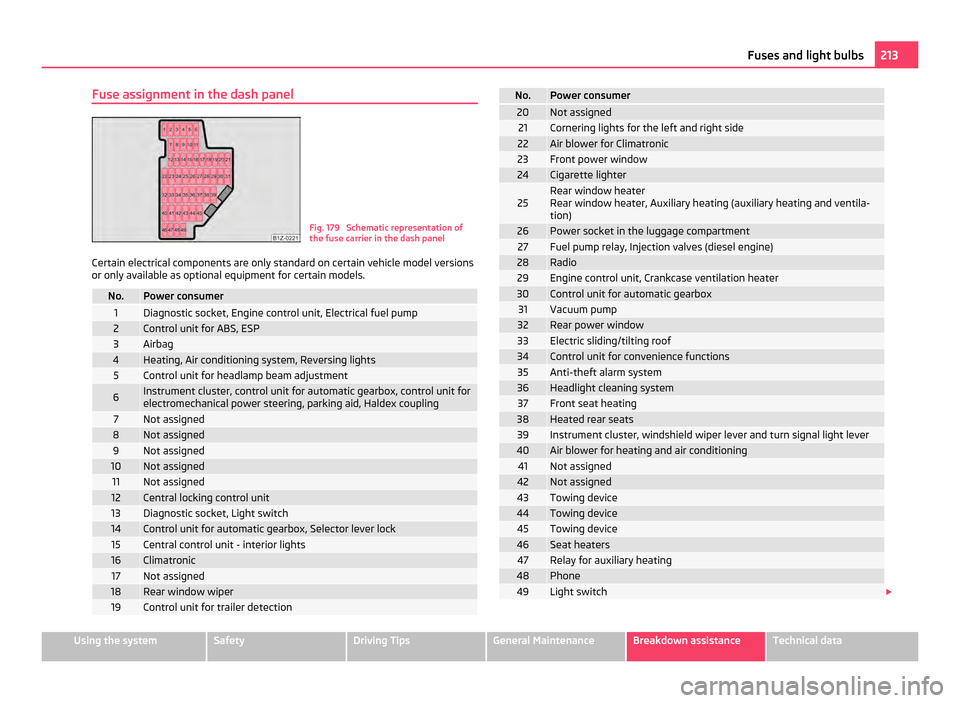

Fuse assignment in the dash panel

Fig. 179 Schematic representation of

the fuse carrier in the dash panel

Certain electrical components are only standard on certain vehicle model versions

or only available as optional equipment for certain models. No. Power consumer

1 Diagnostic socket, Engine control unit, Electrical fuel pump

2 Control unit for ABS, ESP

3 Airbag

4 Heating, Air conditioning system, Reversing lights

5 Control unit for headlamp beam adjustment

6 Instrument cluster, control unit for automatic gearbox, control unit for

electromechanical power steering, parking aid, Haldex coupling 7 Not assigned

8 Not assigned

9 Not assigned

10 Not assigned

11 Not assigned

12 Central locking control unit

13 Diagnostic socket, Light switch

14 Control unit for automatic gearbox, Selector lever lock

15 Central control unit - interior lights

16 Climatronic

17 Not assigned

18 Rear window wiper

19 Control unit for trailer detection No. Power consumer

20 Not assigned

21 Cornering lights for the left and right side

22 Air blower for Climatronic

23 Front power window

24 Cigarette lighter

25 Rear window heater

Rear window heater, Auxiliary heating (auxiliary heating and ventila-

tion)

26 Power socket in the luggage compartment

27 Fuel pump relay, Injection valves (diesel engine)

28 Radio

29 Engine control unit, Crankcase ventilation heater

30 Control unit for automatic gearbox

31 Vacuum pump

32 Rear power window

33 Electric sliding/tilting roof

34 Control unit for convenience functions

35 Anti-theft alarm system

36 Headlight cleaning system

37 Front seat heating

38 Heated rear seats

39 Instrument cluster, windshield wiper lever and turn signal light lever

40 Air blower for heating and air conditioning

41 Not assigned

42 Not assigned

43 Towing device

44 Towing device

45 Towing device

46 Seat heaters

47 Relay for auxiliary heating

48 Phone

49 Light switch

£ 213

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data

Page 217 of 248

WARNING

● Bulbs H7 and H1 are pressurised and may burst when changing the bulb -

risk of injury!

● It is recommended to wear gloves and safety glasses when changing a

bulb.

● Gas discharge bulbs (xenon bulbs) operate with a high voltage, professio-

nal knowledge is required - danger to life! CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest amount

of dirt reduces the working life of the light bulb). Use a clean cloth, serviette or

something similar. Note

This Owner's Manual only describes the replacement of bulbs where it is assumed

that no major complications will arise. Other light bulbs should be changed by your

specialist garage.

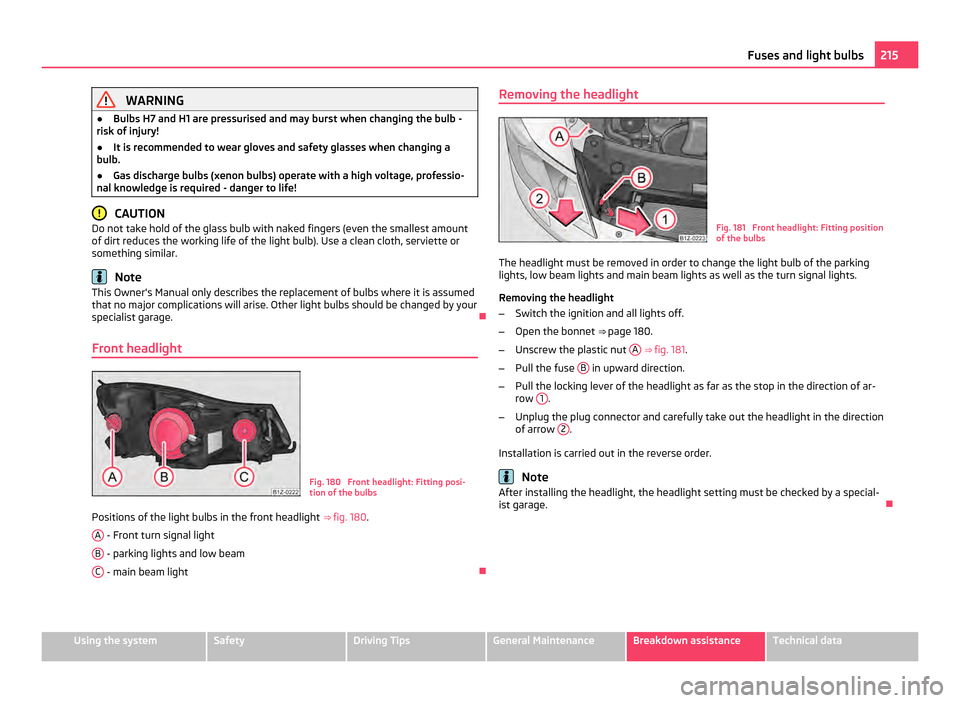

Front headlight Fig. 180 Front headlight: Fitting posi-

tion of the bulbs

Positions of the light bulbs in the front headlight ⇒ fig. 180 .

A - Front turn signal light

B - parking lights and low beam

C - main beam light

Removing the headlight

Fig. 181 Front headlight: Fitting position

of the bulbs

The headlight must be removed in order to change the light bulb of the parking

lights, low beam lights and main beam lights as well as the turn signal lights.

Removing the headlight

– Switch the ignition and all lights off.

– Open the bonnet ⇒ page 180 .

– Unscrew the plastic nut A

⇒ fig. 181 .

– Pull the fuse B in upward direction.

– Pull the locking lever of the headlight as far as the stop in the direction of ar-

row 1 .

– Unplug the plug connector and carefully take out the headlight in the direction

of arrow 2 .

Installation is carried out in the reverse order. Note

After installing the headlight, the headlight setting must be checked by a special-

ist garage. 215

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assistance Technical data