boot SKODA OCTAVIA 2013 3.G / (5E) Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: OCTAVIA, Model: SKODA OCTAVIA 2013 3.G / (5E)Pages: 287, PDF Size: 18.55 MB

Page 95 of 287

WARNING (Continued)■When transporting objects in the luggage compartment that has been en-

larged by folding the rear seats forward, ensure the safety of the passengers

transported on the other rear seats » page 178, Correct seated position for

the passengers in the rear seats .■

Do not drive with the luggage compartment lid fully opened or slightly ajar

otherwise exhaust gases may get into the interior of the vehicle – risk of poi-

soning!

■

Do not exceed the permissible axle loads and permissible gross weight of

the vehicle – risk of accident!

■

Do not transport people in the boot!

CAUTION

Make sure that transported objects with sharp edges do not damage the threads

of the following devices.■

Rear window heater.

■

Rear window with an integrated antenna.

■

Integrated antenna in the rear side windows (Octavia Estate).

Note

Tyre pressure must be adjusted to the load » page 229, Service life of tyres .

Class N1 vehicles

First read and observe the introductory information and safety warn-

ings

on page 91.

In class N1 vehicles that are not fitted with a protective grille, a lashing set that complies with the EN 12195 standard (1-4) must be used for fastening the load.

Proper functioning of the electrical installation is essential for safe vehicle opera- tion. It is important to ensure that the electrical installation is not damaged dur-ing the adjustment process or when the storage area is being loaded and unloa-

ded.

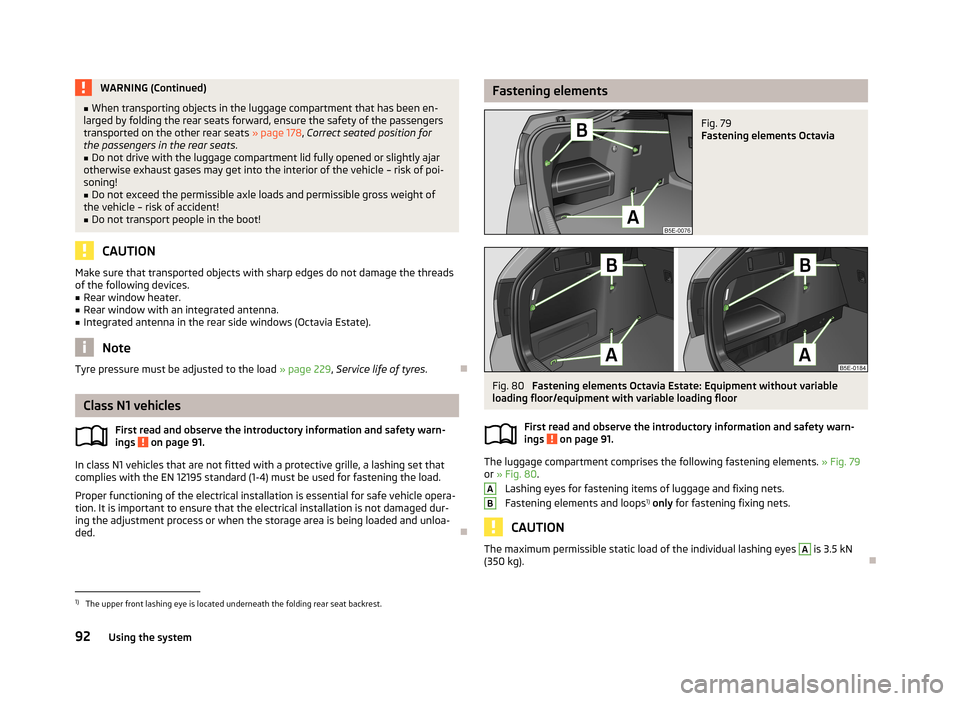

Fastening elementsFig. 79

Fastening elements Octavia

Fig. 80

Fastening elements Octavia Estate: Equipment without variable

loading floor/equipment with variable loading floor

First read and observe the introductory information and safety warn-

ings

on page 91.

The luggage compartment comprises the following fastening elements. » Fig. 79

or » Fig. 80 .

Lashing eyes for fastening items of luggage and fixing nets.

Fastening elements and loops 1)

only for fastening fixing nets.

CAUTION

The maximum permissible static load of the individual lashing eyes A is 3.5 kN

(350 kg).

AB1)

The upper front lashing eye is located underneath the folding rear seat backrest.

92Using the system

Page 98 of 287

CAUTIONThe double sided floor covering can only be used in vehicles without the variable

loading floor » page 99 - There is a risk of damage to the variable loading floor.

Note

For easier turning of the covering, use the loop attached.

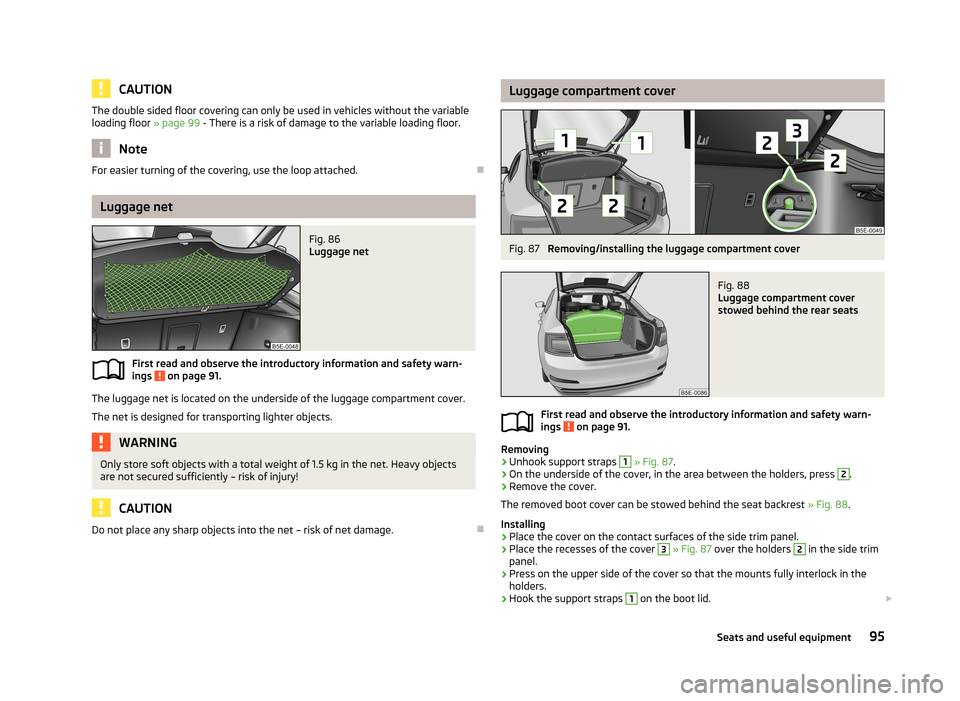

Luggage net

Fig. 86

Luggage net

First read and observe the introductory information and safety warn-

ings on page 91.

The luggage net is located on the underside of the luggage compartment cover.

The net is designed for transporting lighter objects.

WARNINGOnly store soft objects with a total weight of 1.5 kg in the net. Heavy objects are not secured sufficiently – risk of injury!

CAUTION

Do not place any sharp objects into the net – risk of net damage.

Luggage compartment coverFig. 87

Removing/installing the luggage compartment cover

Fig. 88

Luggage compartment cover

stowed behind the rear seats

First read and observe the introductory information and safety warn-

ings on page 91.

Removing

›

Unhook support straps

1

» Fig. 87 .

›

On the underside of the cover, in the area between the holders, press

2

.

›

Remove the cover.

The removed boot cover can be stowed behind the seat backrest » Fig. 88.

Installing

›

Place the cover on the contact surfaces of the side trim panel.

›

Place the recesses of the cover

3

» Fig. 87 over the holders

2

in the side trim

panel.

›

Press on the upper side of the cover so that the mounts fully interlock in the holders.

›

Hook the support straps

1

on the boot lid.

95Seats and useful equipment

Page 99 of 287

WARNINGNo objects should be placed on the luggage compartment cover, the vehicle

occupants could be endangered if there is sudden braking or the vehicle col-

lides with something.

CAUTION

■ Please ensure that the heating elements for the rear window heater are not

damaged as a result of objects placed in this area.■

When closing the boot lid, jamming and damage to the luggage compartment

cover or the side trim panel can occur if handled in an unprofessional way. The following guidelines must be observed. ■ The recesses in the cover

3

» Fig. 87 must lock in the holders in the side trim

panel

2

.

■ The items which are transported must not exceed the height of the luggage

compartment cover. ■ The cover must not be jammed in the surrounding seal of the luggage com-

partment lid when it is in the opened position. ■ There must be no object in the gap between the opened cover and the rear

backrest.

Note

Opening the boot lid also lifts up the boot cover.

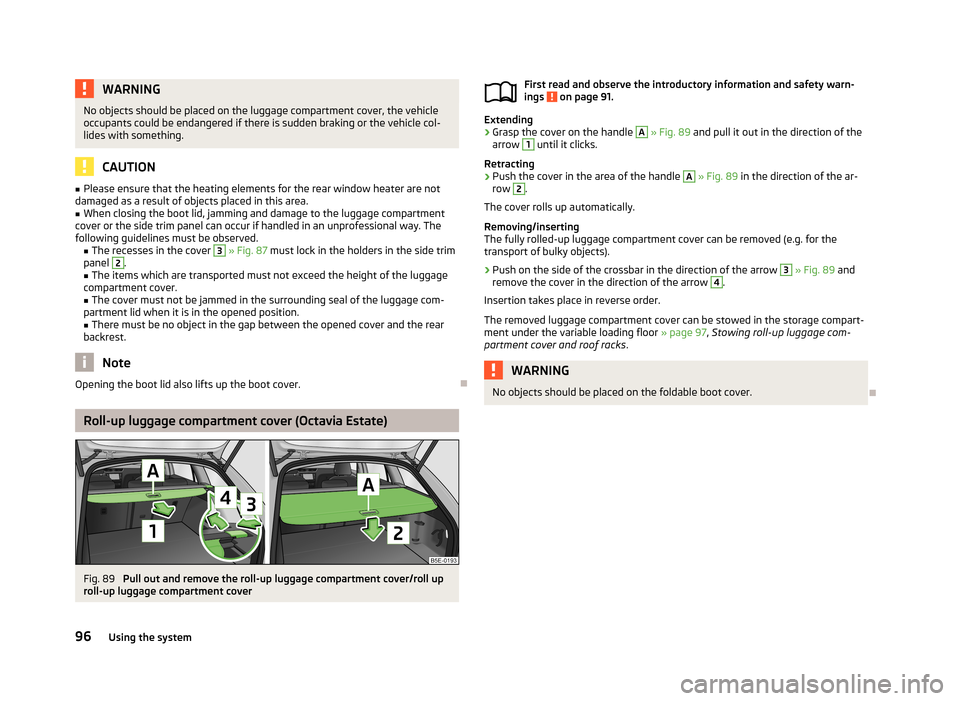

Roll-up luggage compartment cover (Octavia Estate)

Fig. 89

Pull out and remove the roll-up luggage compartment cover/roll up

roll-up luggage compartment cover

First read and observe the introductory information and safety warn-

ings on page 91.

Extending

›

Grasp the cover on the handle

A

» Fig. 89 and pull it out in the direction of the

arrow

1

until it clicks.

Retracting

›

Push the cover in the area of the handle

A

» Fig. 89 in the direction of the ar-

row

2

.

The cover rolls up automatically.

Removing/inserting

The fully rolled-up luggage compartment cover can be removed (e.g. for the

transport of bulky objects).

›

Push on the side of the crossbar in the direction of the arrow

3

» Fig. 89 and

remove the cover in the direction of the arrow

4

.

Insertion takes place in reverse order.

The removed luggage compartment cover can be stowed in the storage compart- ment under the variable loading floor » page 97, Stowing roll-up luggage com-

partment cover and roof racks .

WARNINGNo objects should be placed on the foldable boot cover.

96Using the system

Page 101 of 287

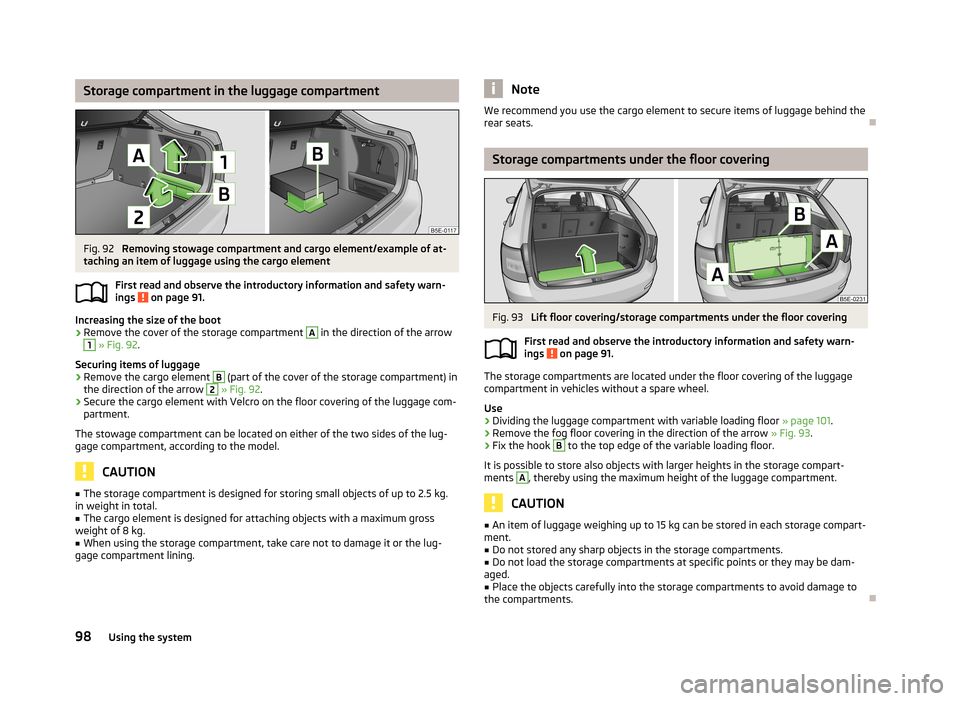

Storage compartment in the luggage compartmentFig. 92

Removing stowage compartment and cargo element/example of at-

taching an item of luggage using the cargo element

First read and observe the introductory information and safety warn-ings

on page 91.

Increasing the size of the boot

›

Remove the cover of the storage compartment

A

in the direction of the arrow

1

» Fig. 92 .

Securing items of luggage

›

Remove the cargo element

B

(part of the cover of the storage compartment) in

the direction of the arrow

2

» Fig. 92 .

›

Secure the cargo element with Velcro on the floor covering of the luggage com-

partment.

The stowage compartment can be located on either of the two sides of the lug-

gage compartment, according to the model.

CAUTION

■ The storage compartment is designed for storing small objects of up to 2.5 kg.

in weight in total.■

The cargo element is designed for attaching objects with a maximum gross

weight of 8 kg.

■

When using the storage compartment, take care not to damage it or the lug-

gage compartment lining.

NoteWe recommend you use the cargo element to secure items of luggage behind the

rear seats.

Storage compartments under the floor covering

Fig. 93

Lift floor covering/storage compartments under the floor covering

First read and observe the introductory information and safety warn-

ings

on page 91.

The storage compartments are located under the floor covering of the luggage compartment in vehicles without a spare wheel.

Use

›

Dividing the luggage compartment with variable loading floor » page 101.

›

Remove the fog floor covering in the direction of the arrow » Fig. 93.

›

Fix the hook

B

to the top edge of the variable loading floor.

It is possible to store also objects with larger heights in the storage compart- ments

A

, thereby using the maximum height of the luggage compartment.

CAUTION

■ An item of luggage weighing up to 15 kg can be stored in each storage compart-

ment.■

Do not stored any sharp objects in the storage compartments.

■

Do not load the storage compartments at specific points or they may be dam-

aged.

■

Place the objects carefully into the storage compartments to avoid damage to

the compartments.

98Using the system

Page 104 of 287

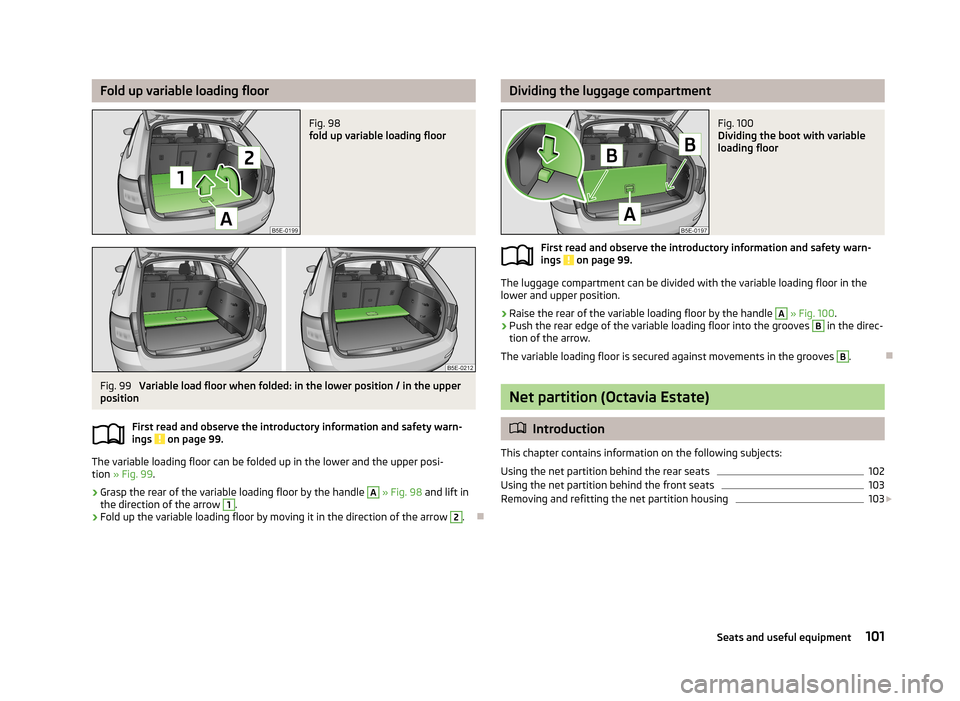

Fold up variable loading floorFig. 98

fold up variable loading floor

Fig. 99

Variable load floor when folded: in the lower position / in the upper

position

First read and observe the introductory information and safety warn-

ings

on page 99.

The variable loading floor can be folded up in the lower and the upper posi-

tion » Fig. 99 .

›

Grasp the rear of the variable loading floor by the handle

A

» Fig. 98 and lift in

the direction of the arrow

1

.

›

Fold up the variable loading floor by moving it in the direction of the arrow

2

.

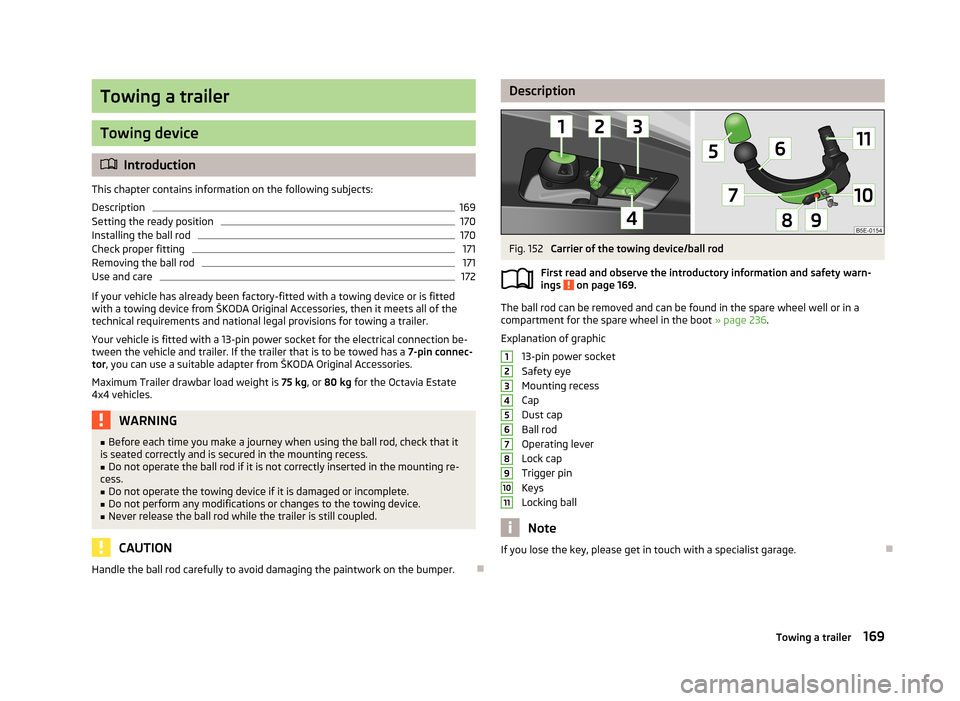

Dividing the luggage compartmentFig. 100

Dividing the boot with variable

loading floor

First read and observe the introductory information and safety warn-

ings on page 99.

The luggage compartment can be divided with the variable loading floor in the

lower and upper position.

›

Raise the rear of the variable loading floor by the handle

A

» Fig. 100 .

›

Push the rear edge of the variable loading floor into the grooves

B

in the direc-

tion of the arrow.

The variable loading floor is secured against movements in the grooves

B

.

Net partition (Octavia Estate)

Introduction

This chapter contains information on the following subjects: Using the net partition behind the rear seats

102

Using the net partition behind the front seats

103

Removing and refitting the net partition housing

103

101Seats and useful equipment

Page 172 of 287

Towing a trailer

Towing device

Introduction

This chapter contains information on the following subjects:

Description

169

Setting the ready position

170

Installing the ball rod

170

Check proper fitting

171

Removing the ball rod

171

Use and care

172

If your vehicle has already been factory-fitted with a towing device or is fitted

with a towing device from ŠKODA Original Accessories, then it meets all of the

technical requirements and national legal provisions for towing a trailer.

Your vehicle is fitted with a 13-pin power socket for the electrical connection be-tween the vehicle and trailer. If the trailer that is to be towed has a 7-pin connec-

tor , you can use a suitable adapter from ŠKODA Original Accessories.

Maximum Trailer drawbar load weight is 75 kg, or 80 kg for the Octavia Estate

4x4 vehicles.

WARNING■ Before each time you make a journey when using the ball rod, check that it

is seated correctly and is secured in the mounting recess.■

Do not operate the ball rod if it is not correctly inserted in the mounting re-

cess.

■

Do not operate the towing device if it is damaged or incomplete.

■

Do not perform any modifications or changes to the towing device.

■

Never release the ball rod while the trailer is still coupled.

CAUTION

Handle the ball rod carefully to avoid damaging the paintwork on the bumper.

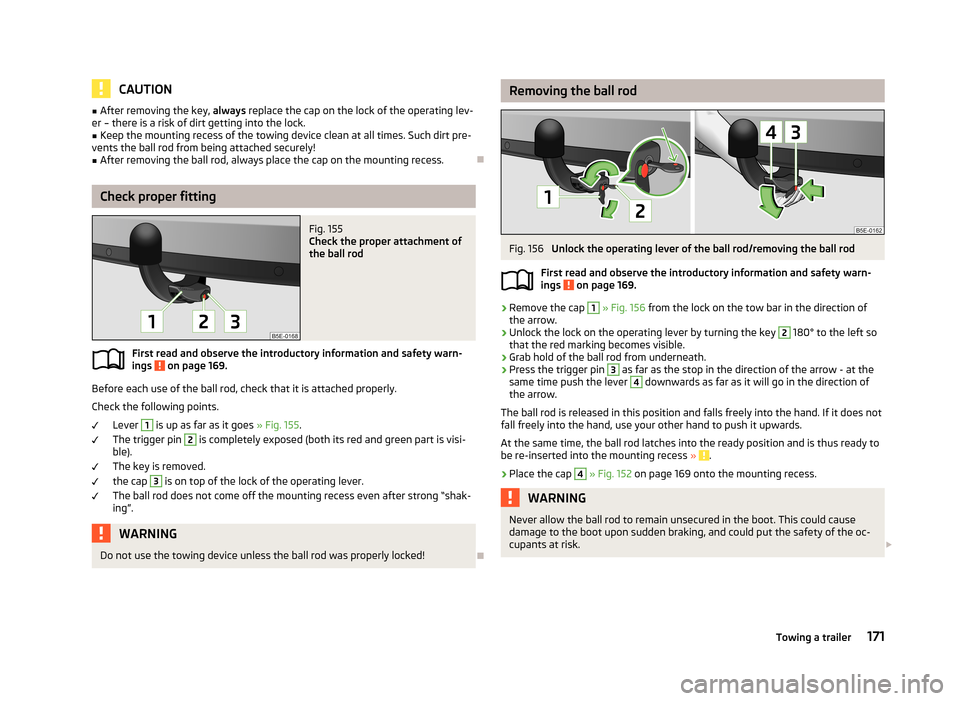

DescriptionFig. 152

Carrier of the towing device/ball rod

First read and observe the introductory information and safety warn-

ings

on page 169.

The ball rod can be removed and can be found in the spare wheel well or in a

compartment for the spare wheel in the boot » page 236.

Explanation of graphic 13-pin power socket

Safety eye

Mounting recess

Cap

Dust cap

Ball rod

Operating lever

Lock cap

Trigger pin

Keys

Locking ball

Note

If you lose the key, please get in touch with a specialist garage.

1234567891011169Towing a trailer

Page 174 of 287

CAUTION■After removing the key, always replace the cap on the lock of the operating lev-

er – there is a risk of dirt getting into the lock.■

Keep the mounting recess of the towing device clean at all times. Such dirt pre-

vents the ball rod from being attached securely!

■

After removing the ball rod, always place the cap on the mounting recess.

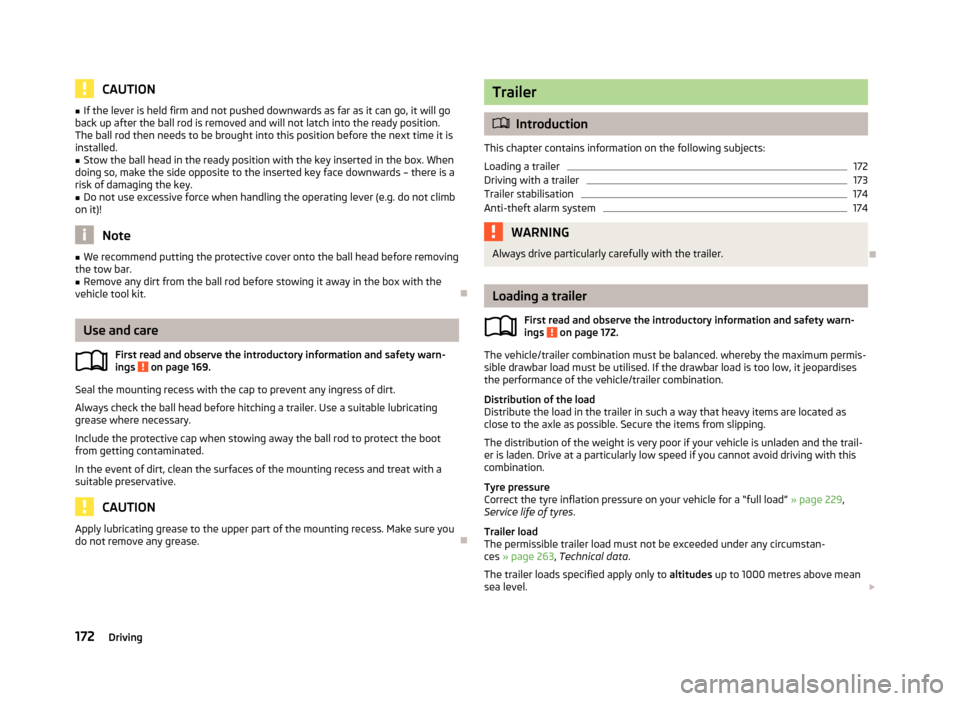

Check proper fitting

Fig. 155

Check the proper attachment of

the ball rod

First read and observe the introductory information and safety warn-

ings on page 169.

Before each use of the ball rod, check that it is attached properly.

Check the following points.

Lever

1

is up as far as it goes » Fig. 155.

The trigger pin

2

is completely exposed (both its red and green part is visi-

ble).

The key is removed.

the cap

3

is on top of the lock of the operating lever.

The ball rod does not come off the mounting recess even after strong “shak- ing”.

WARNINGDo not use the towing device unless the ball rod was properly locked!

Removing the ball rodFig. 156

Unlock the operating lever of the ball rod/removing the ball rod

First read and observe the introductory information and safety warn-

ings

on page 169.

›

Remove the cap

1

» Fig. 156 from the lock on the tow bar in the direction of

the arrow.

›

Unlock the lock on the operating lever by turning the key

2

180° to the left so

that the red marking becomes visible.

›

Grab hold of the ball rod from underneath.

›

Press the trigger pin

3

as far as the stop in the direction of the arrow - at the

same time push the lever

4

downwards as far as it will go in the direction of

the arrow.

The ball rod is released in this position and falls freely into the hand. If it does not

fall freely into the hand, use your other hand to push it upwards.

At the same time, the ball rod latches into the ready position and is thus ready to

be re-inserted into the mounting recess »

.

›

Place the cap

4

» Fig. 152 on page 169 onto the mounting recess.

WARNINGNever allow the ball rod to remain unsecured in the boot. This could cause

damage to the boot upon sudden braking, and could put the safety of the oc-

cupants at risk. 171Towing a trailer

Page 175 of 287

CAUTION■If the lever is held firm and not pushed downwards as far as it can go, it will go

back up after the ball rod is removed and will not latch into the ready position.

The ball rod then needs to be brought into this position before the next time it is installed.■

Stow the ball head in the ready position with the key inserted in the box. When

doing so, make the side opposite to the inserted key face downwards – there is a

risk of damaging the key.

■

Do not use excessive force when handling the operating lever (e.g. do not climb

on it)!

Note

■ We recommend putting the protective cover onto the ball head before removing

the tow bar.■

Remove any dirt from the ball rod before stowing it away in the box with the

vehicle tool kit.

Use and care

First read and observe the introductory information and safety warn-

ings

on page 169.

Seal the mounting recess with the cap to prevent any ingress of dirt.

Always check the ball head before hitching a trailer. Use a suitable lubricating grease where necessary.

Include the protective cap when stowing away the ball rod to protect the boot

from getting contaminated.

In the event of dirt, clean the surfaces of the mounting recess and treat with a

suitable preservative.

CAUTION

Apply lubricating grease to the upper part of the mounting recess. Make sure you

do not remove any grease.

Trailer

Introduction

This chapter contains information on the following subjects:

Loading a trailer

172

Driving with a trailer

173

Trailer stabilisation

174

Anti-theft alarm system

174WARNINGAlways drive particularly carefully with the trailer.

Loading a trailer

First read and observe the introductory information and safety warn-

ings

on page 172.

The vehicle/trailer combination must be balanced. whereby the maximum permis-

sible drawbar load must be utilised. If the drawbar load is too low, it jeopardises the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as close to the axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the trail-

er is laden. Drive at a particularly low speed if you cannot avoid driving with this

combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 229,

Service life of tyres .

Trailer load

The permissible trailer load must not be exceeded under any circumstan-

ces » page 263 , Technical data .

The trailer loads specified apply only to altitudes up to 1000 metres above mean

sea level.

172Driving

Page 201 of 287

General Maintenance

Vehicle care

Service intervals

Introduction

This chapter contains information on the following subjects:

Overview of service intervals

198

Fixed service intervals QI1 - QI4

199

Variable service interval QI6

199

Information about the ŠKODA service

199

The service interval display in the instrument cluster will remind you to carry out every service stipulated by the manufacturer at the right time in order to prevent you from forgetting any.

Timely and proper performance of servicing works is one of the requirements for the settlement of potential warranty claims.

The completion of services can be verified by the validated service certificate and the corresponding receipts.

The specified service intervals are tailored to normal operating conditions.

In the case of difficult operating conditions, it is necessary to have some service

work performed before the date of the next service or between the specified

service intervals. This applies mainly to the cleaning or the replacement of the air

filter insert in regions with heavy dust pollution as well as checking and replacing

the toothed belt, but also to vehicles with diesel particle filters, which can put

greater strain on the engine oil.

These difficult conditions are: › Fuel with sulphur content;

› Frequent short trips;

› Longer periods of engine idling (e.g. taxis);

› Operation in areas with heavy dust pollution;

› Frequent trailer operation;

›

Predominantly stop-and-go traffic as is often the case in city driving, for exam-

ple;

› Operation predominantly during winter.

A service consultant at the specialist garage will tell you whether the operating conditions of your vehicle may make it necessary for service work to be carried

out between the normal service intervals.

Different service charges may apply from the particular scope of work required,

depending on the vehicle type and equipment and the status of your vehicle.

Note

■ The customer is responsible for covering the cost of all services including

changing or replenishing the oil, even during the warranty period, unless stated otherwise in the ŠKODA AUTO a.s. warranty terms or other agreements.■

You will be informed about the current service scopes for the particular service

work by the specialist garage.

Overview of service intervals

Fig. 176

Vehicle data sticker: Service in-

terval

First read and observe the introductory information given on page 198.

The service interval specified by the manufacturer is indicated on the vehicle data sticker » Fig. 176 under the floor covering in the boot.

One of the following service intervals applies for your vehicle: › Fixed service interval QI1;

› Fixed service interval QI2;

› Fixed service interval QI3;

› Fixed service interval QI4;

› Variable service interval QI6.

198General Maintenance

Page 235 of 287

›The wheels of one axle are loaded more heavily (e.g. when towing a trailer or

when driving uphill or downhill).

› Snow chains are mounted.

› The spare wheel is mounted.

› One wheel per axle was changed.

For vehicles with Infotainment 1)

it can be determined which tyres should be

checked » Manual Infotainment , chapter Vehicle settings (key CAR) .WARNING■

When the warning light illuminates, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Stop the vehicle as soon as

possible and inspect the tyres and their inflation pressure.■

Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the may light up after a delay, or not at all.

CAUTION

■

The tyre control display does therefore not replace the regular tyre inflation

pressure control, as the system cannot detect an even loss of pressure.■

The system cannot warn in case of very rapid tyre inflation pressure loss, e.g. in

case of sudden tyre damage. In this case carefully bring the vehicle to a standstill

without sudden steering movements or sharp braking.

■

To ensure a proper functioning of the tyre control display, it is necessary to re-

peat the basic setting every 10000 km or once a year.

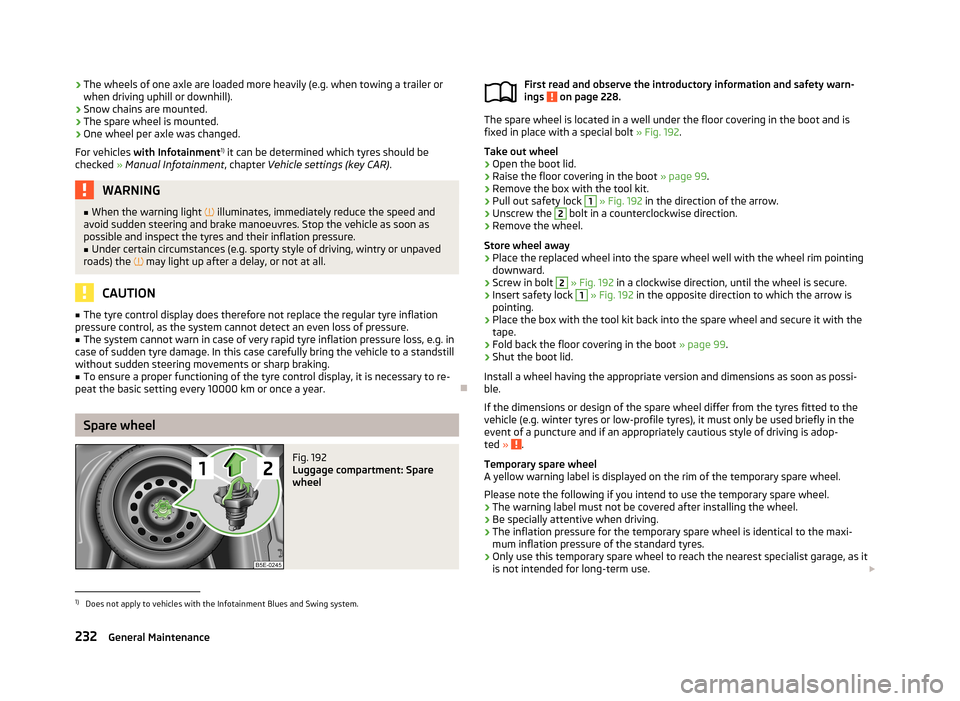

Spare wheel

Fig. 192

Luggage compartment: Spare

wheel

First read and observe the introductory information and safety warn-

ings on page 228.

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt » Fig. 192.

Take out wheel

›

Open the boot lid.

›

Raise the floor covering in the boot » page 99.

›

Remove the box with the tool kit.

›

Pull out safety lock

1

» Fig. 192 in the direction of the arrow.

›

Unscrew the

2

bolt in a counterclockwise direction.

›

Remove the wheel.

Store wheel away

›

Place the replaced wheel into the spare wheel well with the wheel rim pointing

downward.

›

Screw in bolt

2

» Fig. 192 in a clockwise direction, until the wheel is secure.

›

Insert safety lock

1

» Fig. 192 in the opposite direction to which the arrow is

pointing.

›

Place the box with the tool kit back into the spare wheel and secure it with the

tape.

›

Fold back the floor covering in the boot » page 99.

›

Shut the boot lid.

Install a wheel having the appropriate version and dimensions as soon as possi-

ble.

If the dimensions or design of the spare wheel differ from the tyres fitted to the

vehicle (e.g. winter tyres or low-profile tyres), it must only be used briefly in the

event of a puncture and if an appropriately cautious style of driving is adop-

ted »

.

Temporary spare wheel

A yellow warning label is displayed on the rim of the temporary spare wheel.

Please note the following if you intend to use the temporary spare wheel. › The warning label must not be covered after installing the wheel.

› Be specially attentive when driving.

› The inflation pressure for the temporary spare wheel is identical to the maxi-

mum inflation pressure of the standard tyres.

› Only use this temporary spare wheel to reach the nearest specialist garage, as it

is not intended for long-term use.

1)

Does not apply to vehicles with the Infotainment Blues and Swing system.

232General Maintenance