check engine SKODA OCTAVIA 2014 3.G / (5E) Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: OCTAVIA, Model: SKODA OCTAVIA 2014 3.G / (5E)Pages: 280, PDF Size: 35.53 MB

Page 178 of 280

Detaching›Unhook the breakaway cable of the trailer from the security eyeletB

» Fig. 178.

›

Pull the trailer cable connected out of the 13-pin socket.

›

Remove the trailer from the ball head.

›

Place cap

5

on to the ball head » Fig. 166 on page 169 .

›

Grip the 13-pin socket at point

A

and swivel in the opposite direction to the

arrow » Fig. 178 .

Exterior mirrors

You have to have additional exterior mirrors fitted if you are not able to see

the traffic behind the trailer with the standard rear-view mirrors. The national

legal requirements must be observed.

Headlights

The front of the vehicle may lift up when a trailer is being towed and the head-

lights may dazzle other road users.

Adjust the headlights using the headlight beam control » page 71, Operating

the lights 1)

.

Power to the trailer power grid

For the electrical connection between the vehicle and trailer, the trailer's pow-

er supply is provided by the vehicle.

The power supply works with ignition on or off.

WARNING■ Incorrectly or improperly connected electrical installations may cause the

entire vehicle electronics to malfunction, and may lead to accidents and se-

rious injury from electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After attaching the trailer and connecting the power socket, check that

the rear lights on the trailer are working correctly.

■

The handbrake on the vehicle must be applied when attaching and dis-

connecting the trailer.

■

Never use the safety eye to tow a vehicle!

Loading a trailer

The vehicle/trailer combination must be balanced. whereby the maximum per-

missible drawbar load must be utilised. If the drawbar load is too low, it jeop-

ardises the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as

close to the trailer axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Drive at a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on the vehicle for a “full load” » page 204.

Towing capacity and trailer weight

The permissible trailer load must not be exceeded under any circumstan-

ces » page 238 , Technical data .

The details given in the vehicle's technical documentation always take prece-

dence over the details in the Owner's Manual.

The trailer loads specified apply only to altitudes up to 1 000 metres above

mean sea level.

The engine output falls as the height increases, as does the ability to climb.

Therefore, for every additional 1000 m in height (or part), the maximum per-

missible towed weight must be reduced by 10%.

The towed weight is made up of the actual weights of the loaded towing vehi-

cle and the loaded trailer.

The trailer and drawbar load information on the type plate of the towing de-

vice are merely test data for the towing device. The vehicle-specific values are

detailed in the vehicle documents.WARNING■ The maximum permissible axle and drawbar load and the permissible

weight of the trailer must not be exceeded - risk of accident!■

Sliding cargo can significantly adversely affect stability and driving safety

- risk of accident!

1)

Applies to vehicles with bi-xenon headlights.

175Hitch and trailer

Page 188 of 280

WheelsRead and observe

and on page 182 first.

Wheel rims

Also thoroughly wash the wheel rims when washing the vehicle on a regular

basis.

Regularly remove salt and brake abrasion, otherwise the rim material will be

corroded.

Light alloy wheels

After washing thoroughly and treat the wheel rims with a protective product

for light alloy wheels.

For the treatment of wheel rims do not use products which may cause damage

to the paint on the rims.

CAUTION

■ Damage to the paint layer on the wheel rims must be touched up immediate-

ly.■

Severe layers of dirt on the wheels can also result in wheel imbalance. This

may show itself in the form of a wheel vibration which is transmitted to the

steering wheel which, in certain circumstances, can cause premature wear of

the steering. This means it is necessary to remove the dirt.

Towing hitch and mounting recess

Read and observe

and on page 182 first.

Seal the mounting recess with the cap to prevent any ingress of dirt.

In the event of dirt, clean the interior surfaces of the mounting recess and

treat with a suitable preservative.

Always check the ball head before attaching a trailer. Apply suitable grease

where necessary.

Include the protective cap when stowing away the ball rod to protect the boot

from getting contaminated.

CAUTION

Apply grease to the inner part of the mounting recess. Make sure you do not

remove any grease.Under-body protection

Read and observe

and on page 182 first.

The underside of your vehicle is already permanently protected by the factory

against chemical and mechanical influences.

It is not possible to guarantee that the protective coating will not suffer any

damage as the vehicle is driven.

We recommend having the protective coating underneath the vehicle and the

chassis checked — preferably before the beginning of winter and at the end of

winter.

WARNINGNever use additional underbody protection or anti-corrosion agents for ex-

haust pipes, catalytic converters, diesel particle filters or heat shields.

When the engine reaches its operating temperature, these substances

might ignite - risk of fire!

Wiper blades

Read and observe

and on page 182 first.

Clean the wiper blades regularly with a glass cleaner. The wiper blades should

be cleaned with a sponge or cloth if they are heavily soiled by insect residues,

for example.

The wiper blades can become soiled with wax residues after washing in auto-

matic vehicle wash systems for example » page 181.

Interior care

Introduction

This chapter contains information on the following subjects:

Natural leather

186

Artificial leather, materials and Alcantara ®

187

Seat covers

187

Safety belts

187

185Care and maintenance

Page 191 of 280

Inspecting and replenishing

Fuel

Introduction

This chapter contains information on the following subjects:

Petrol and diesel refuelling

188

Lead-free petrol

189

Diesel fuel

190

Refuelling with CNG (compressed natural gas)

191

CNG

192

The correct fuels for your vehicle are specified on the inside of the fuel filler

flap » Fig. 180 on page 188 .

WARNING■

Observe the local regulations regarding fuel handling.■The operating instructions of the refuelling system must always be fol-

lowed.■

Do not smoke when refuelling and do not use a mobile phone.

■

The fuel and fuel vapours are explosive - risk to life!

CAUTION

■ Never drive until the fuel tank is completely empty! The irregular supply of

fuel can cause misfiring, which can result in damage to parts of the engine and

the exhaust system.■

Immediately remove any fuel that has spilled onto the vehicle's paintwork –

risk of paint damage!

■

If the vehicle was not purchased in the country where it was intended to be

operated, you should check whether the fuel specified by the manufacturer is

offered in the country where the vehicle will be operated. You should also per-

haps check whether the manufacturer has recommended a different fuel for

operation of the vehicle in the corresponding country. If no prescribed fuel is

available, then you must check whether it is permitted by the manufacturer to

operate the vehicle with another fuel type.

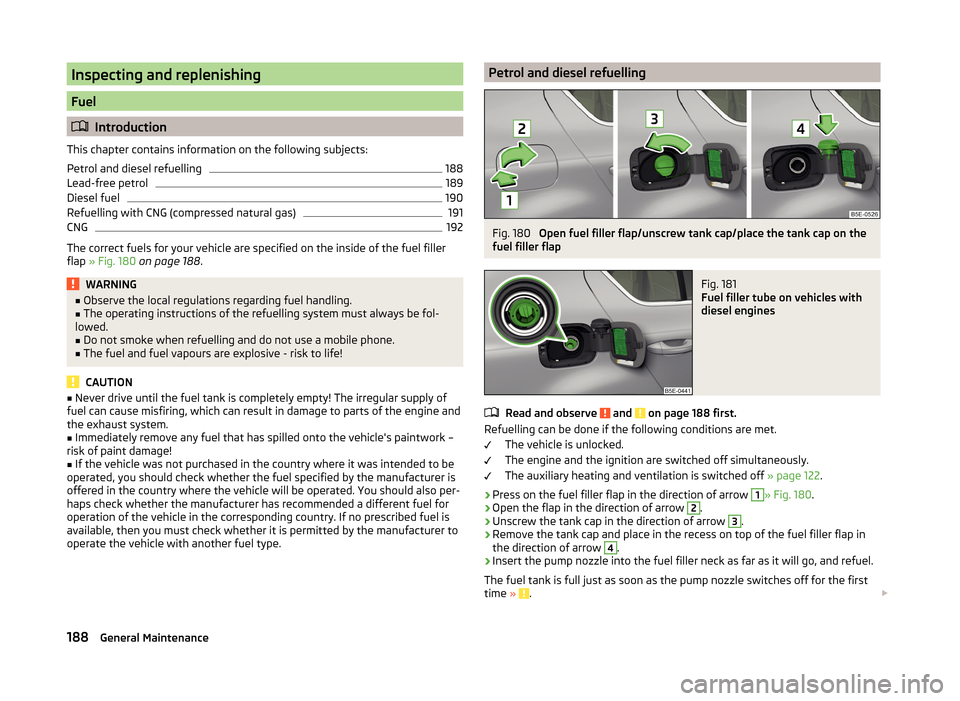

Petrol and diesel refuellingFig. 180

Open fuel filler flap/unscrew tank cap/place the tank cap on the

fuel filler flap

Fig. 181

Fuel filler tube on vehicles with

diesel engines

Read and observe and on page 188 first.

Refuelling can be done if the following conditions are met.

The vehicle is unlocked.

The engine and the ignition are switched off simultaneously.

The auxiliary heating and ventilation is switched off » page 122.

›

Press on the fuel filler flap in the direction of arrow

1

» Fig. 180.

›

Open the flap in the direction of arrow

2

.

›

Unscrew the tank cap in the direction of arrow

3

.

›

Remove the tank cap and place in the recess on top of the fuel filler flap in

the direction of arrow

4

.

›

Insert the pump nozzle into the fuel filler neck as far as it will go, and refuel.

The fuel tank is full just as soon as the pump nozzle switches off for the first

time »

.

188General Maintenance

Page 192 of 280

›Remove the pump nozzle from the fuel filler tube and put it back in the

pump.›

Place the filler cap onto the fuel filler neck and turn it in the opposite direc-

tion to arrow

3

until it securely engages.

›

Close the fuel filler flap until it clicks into place.

Check that the fuel filler flap is closed properly.

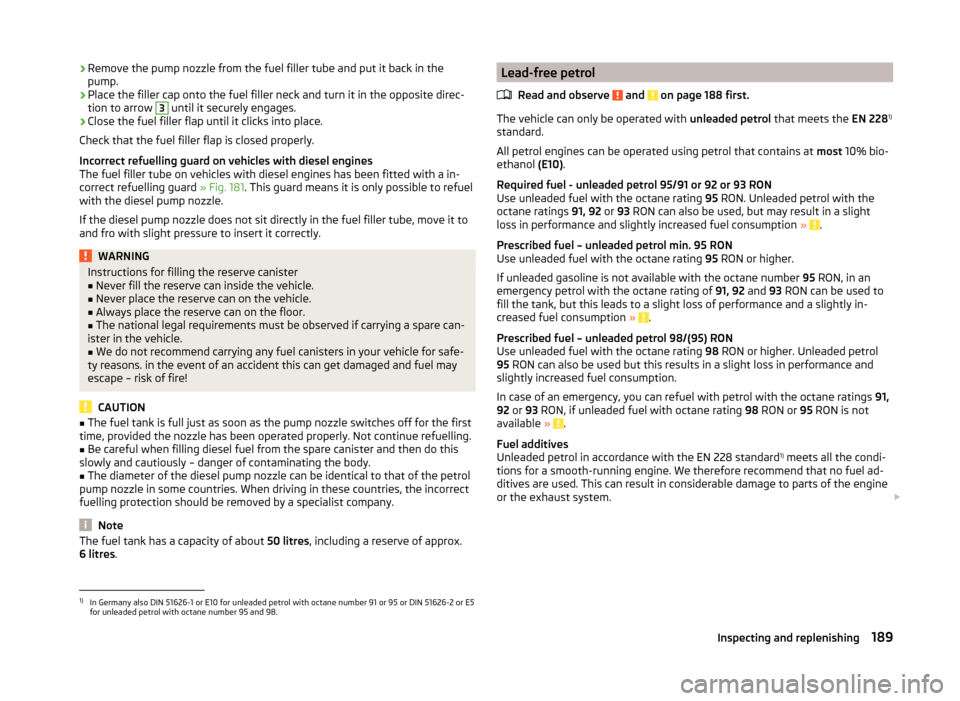

Incorrect refuelling guard on vehicles with diesel engines

The fuel filler tube on vehicles with diesel engines has been fitted with a in-

correct refuelling guard » Fig. 181. This guard means it is only possible to refuel

with the diesel pump nozzle.

If the diesel pump nozzle does not sit directly in the fuel filler tube, move it to

and fro with slight pressure to insert it correctly.

WARNINGInstructions for filling the reserve canister■Never fill the reserve can inside the vehicle.■

Never place the reserve can on the vehicle.

■

Always place the reserve can on the floor.

■

The national legal requirements must be observed if carrying a spare can-

ister in the vehicle.

■

We do not recommend carrying any fuel canisters in your vehicle for safe-

ty reasons. in the event of an accident this can get damaged and fuel may

escape – risk of fire!

CAUTION

■ The fuel tank is full just as soon as the pump nozzle switches off for the first

time, provided the nozzle has been operated properly. Not continue refuelling.■

Be careful when filling diesel fuel from the spare canister and then do this

slowly and cautiously – danger of contaminating the body.

■

The diameter of the diesel pump nozzle can be identical to that of the petrol

pump nozzle in some countries. When driving in these countries, the incorrect

fuelling protection should be removed by a specialist company.

Note

The fuel tank has a capacity of about 50 litres, including a reserve of approx.

6 litres .Lead-free petrol

Read and observe

and on page 188 first.

The vehicle can only be operated with unleaded petrol that meets the EN 2281)

standard.

All petrol engines can be operated using petrol that contains at most 10% bio-

ethanol (E10).

Required fuel - unleaded petrol 95/91 or 92 or 93 RON

Use unleaded fuel with the octane rating 95 RON. Unleaded petrol with the

octane ratings 91, 92 or 93 RON can also be used, but may result in a slight

loss in performance and slightly increased fuel consumption »

.

Prescribed fuel – unleaded petrol min. 95 RON

Use unleaded fuel with the octane rating 95 RON or higher.

If unleaded gasoline is not available with the octane number 95 RON, in an

emergency petrol with the octane rating of 91, 92 and 93 RON can be used to

fill the tank, but this leads to a slight loss of performance and a slightly in-

creased fuel consumption »

.

Prescribed fuel – unleaded petrol 98/(95) RON

Use unleaded fuel with the octane rating 98 RON or higher. Unleaded petrol

95 RON can also be used but this results in a slight loss in performance and

slightly increased fuel consumption.

In case of an emergency, you can refuel with petrol with the octane ratings 91,

92 or 93 RON, if unleaded fuel with octane rating 98 RON or 95 RON is not

available »

.

Fuel additives

Unleaded petrol in accordance with the EN 228 standard 1)

meets all the condi-

tions for a smooth-running engine. We therefore recommend that no fuel ad-

ditives are used. This can result in considerable damage to parts of the engine

or the exhaust system.

1)

In Germany also DIN 51626-1 or E10 for unleaded petrol with octane number 91 or 95 or DIN 51626-2 or E5

for unleaded petrol with octane number 95 and 98.

189Inspecting and replenishing

Page 194 of 280

CAUTION■Just filling the tank once with diesel fuel that does not comply with the

standard, can cause severe damage to parts of the engine, the fuel and ex-

haust system!■

If a different fuel other than diesel fuel, which complies to the above men-

tioned standards (e.g. petrol) is used, do not start the engine or switch on the

ignition! Extensive damage to engine parts can occur!

■

Water which has collected in the fuel filter can cause engine faults.

CAUTION

■ The vehicle cannot be operated with bio fuel RME, therefore this fuel must

not be filled in the tank and used for driving the vehicle. The use of biofuel

RME can cause considerable damage to parts of the engine or fuel system.■

Do not mix any fuel additives, so-called “flow improvers” (petrol and similar

agents) into the diesel. This can result in considerable damage to parts of the

engine or the exhaust system.

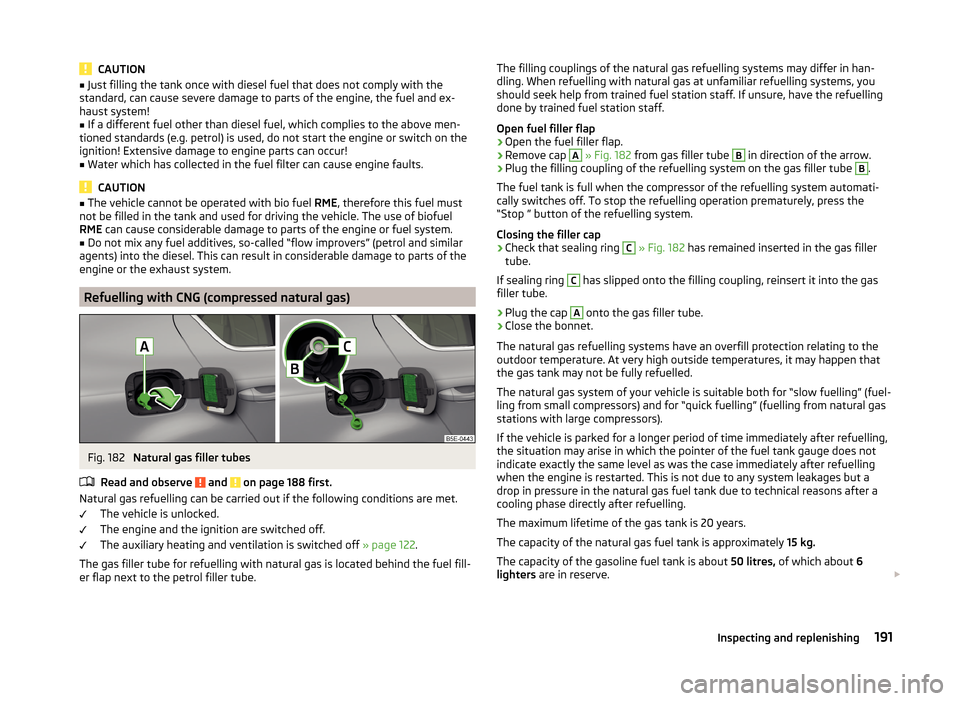

Refuelling with CNG (compressed natural gas)

Fig. 182

Natural gas filler tubes

Read and observe

and on page 188 first.

Natural gas refuelling can be carried out if the following conditions are met. The vehicle is unlocked.

The engine and the ignition are switched off.

The auxiliary heating and ventilation is switched off » page 122.

The gas filler tube for refuelling with natural gas is located behind the fuel fill- er flap next to the petrol filler tube.

The filling couplings of the natural gas refuelling systems may differ in han-

dling. When refuelling with natural gas at unfamiliar refuelling systems, you

should seek help from trained fuel station staff. If unsure, have the refuelling done by trained fuel station staff.

Open fuel filler flap›

Open the fuel filler flap.

›

Remove cap

A

» Fig. 182 from gas filler tube

B

in direction of the arrow.

›

Plug the filling coupling of the refuelling system on the gas filler tube

B

.

The fuel tank is full when the compressor of the refuelling system automati-

cally switches off. To stop the refuelling operation prematurely, press the

“Stop ” button of the refuelling system.

Closing the filler cap

›

Check that sealing ring

C

» Fig. 182 has remained inserted in the gas filler

tube.

If sealing ring

C

has slipped onto the filling coupling, reinsert it into the gas

filler tube.

›

Plug the cap

A

onto the gas filler tube.

›

Close the bonnet.

The natural gas refuelling systems have an overfill protection relating to the

outdoor temperature. At very high outside temperatures, it may happen that

the gas tank may not be fully refuelled.

The natural gas system of your vehicle is suitable both for “slow fuelling” (fuel-

ling from small compressors) and for “quick fuelling” (fuelling from natural gas

stations with large compressors).

If the vehicle is parked for a longer period of time immediately after refuelling,

the situation may arise in which the pointer of the fuel tank gauge does not

indicate exactly the same level as was the case immediately after refuelling

when the engine is restarted. This is not due to any system leakages but a

drop in pressure in the natural gas fuel tank due to technical reasons after a

cooling phase directly after refuelling.

The maximum lifetime of the gas tank is 20 years.

The capacity of the natural gas fuel tank is approximately 15 kg.

The capacity of the gasoline fuel tank is about 50 litres, of which about 6

lighters are in reserve.

191Inspecting and replenishing

Page 195 of 280

WARNING■When refuelling, never get into the vehicle. If you have to get into your

vehicle in exceptional cases, touch a metal surface before you touch the

filling coupling again. This will avoid electrostatic discharges, which may

generate sparks. Sparks can cause a fire during refuelling.■

Natural gas is highly explosive and highly flammable.

Note

During the filling process sounds are heard which are harmless. If you are un-

sure which service station staff to use, ask the petrol station staff.

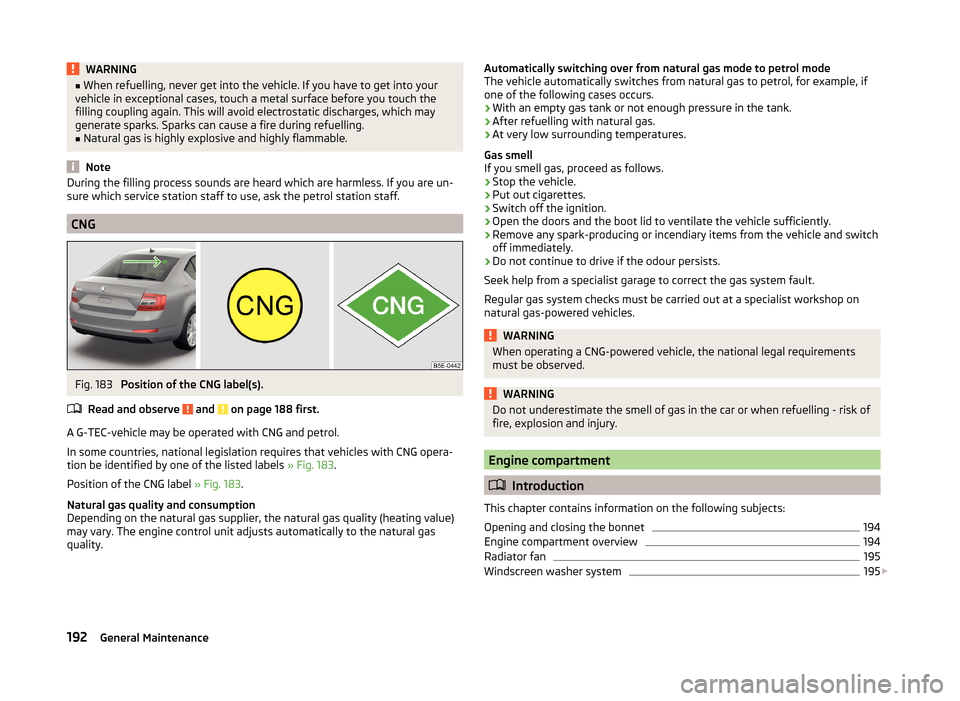

CNG

Fig. 183

Position of the CNG label(s).

Read and observe

and on page 188 first.

A G-TEC-vehicle may be operated with CNG and petrol.

In some countries, national legislation requires that vehicles with CNG opera-

tion be identified by one of the listed labels » Fig. 183.

Position of the CNG label » Fig. 183.

Natural gas quality and consumption

Depending on the natural gas supplier, the natural gas quality (heating value)

may vary. The engine control unit adjusts automatically to the natural gas

quality.

Automatically switching over from natural gas mode to petrol mode

The vehicle automatically switches from natural gas to petrol, for example, if

one of the following cases occurs.

› With an empty gas tank or not enough pressure in the tank.

› After refuelling with natural gas.

› At very low surrounding temperatures.

Gas smell

If you smell gas, proceed as follows.

› Stop the vehicle.

› Put out cigarettes.

› Switch off the ignition.

› Open the doors and the boot lid to ventilate the vehicle sufficiently.

› Remove any spark-producing or incendiary items from the vehicle and switch

off immediately.

› Do not continue to drive if the odour persists.

Seek help from a specialist garage to correct the gas system fault.

Regular gas system checks must be carried out at a specialist workshop on natural gas-powered vehicles.WARNINGWhen operating a CNG-powered vehicle, the national legal requirements

must be observed.WARNINGDo not underestimate the smell of gas in the car or when refuelling - risk of

fire, explosion and injury.

Engine compartment

Introduction

This chapter contains information on the following subjects:

Opening and closing the bonnet

194

Engine compartment overview

194

Radiator fan

195

Windscreen washer system

195

192General Maintenance

Page 197 of 280

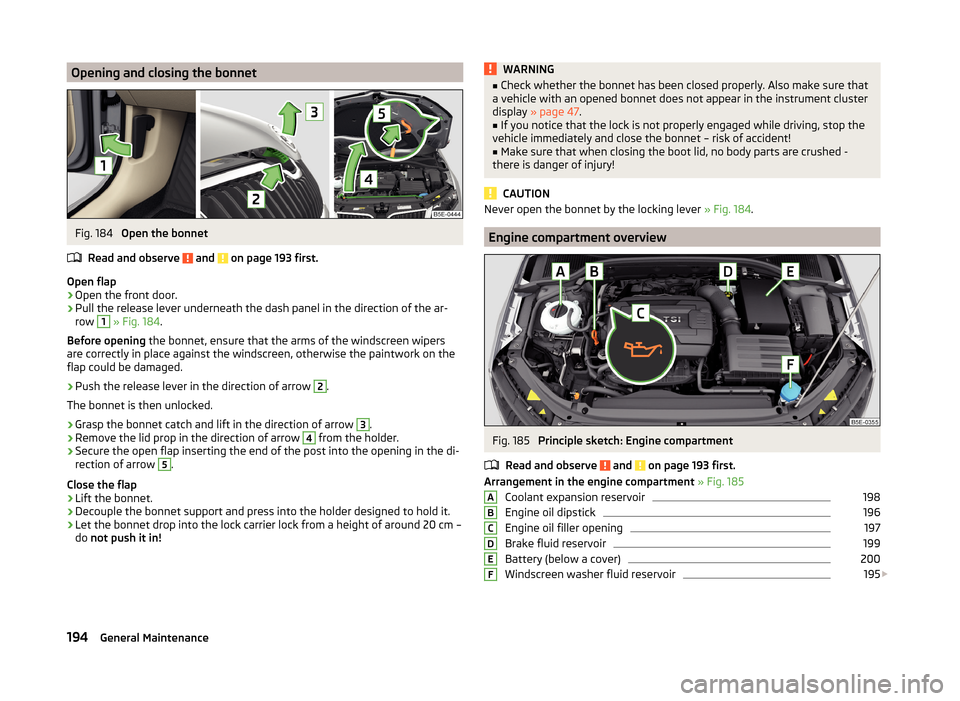

Opening and closing the bonnetFig. 184

Open the bonnet

Read and observe

and on page 193 first.

Open flap

›

Open the front door.

›

Pull the release lever underneath the dash panel in the direction of the ar-

row

1

» Fig. 184 .

Before opening the bonnet, ensure that the arms of the windscreen wipers

are correctly in place against the windscreen, otherwise the paintwork on the

flap could be damaged.

›

Push the release lever in the direction of arrow

2

.

The bonnet is then unlocked.

›

Grasp the bonnet catch and lift in the direction of arrow

3

.

›

Remove the lid prop in the direction of arrow

4

from the holder.

›

Secure the open flap inserting the end of the post into the opening in the di-

rection of arrow

5

.

Close the flap

›

Lift the bonnet.

›

Decouple the bonnet support and press into the holder designed to hold it.

›

Let the bonnet drop into the lock carrier lock from a height of around 20 cm – do not push it in!

WARNING■

Check whether the bonnet has been closed properly. Also make sure that

a vehicle with an opened bonnet does not appear in the instrument cluster

display » page 47 .■

If you notice that the lock is not properly engaged while driving, stop the

vehicle immediately and close the bonnet – risk of accident!

■

Make sure that when closing the boot lid, no body parts are crushed -

there is danger of injury!

CAUTION

Never open the bonnet by the locking lever » Fig. 184.

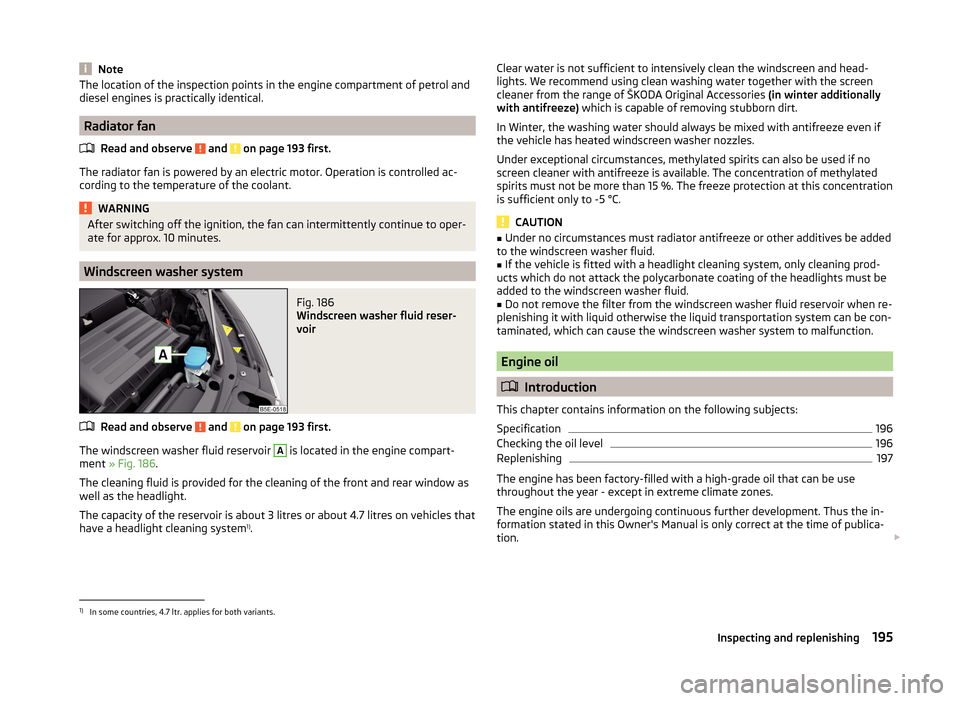

Engine compartment overview

Fig. 185

Principle sketch: Engine compartment

Read and observe

and on page 193 first.

Arrangement in the engine compartment » Fig. 185

Coolant expansion reservoir

198

Engine oil dipstick

196

Engine oil filler opening

197

Brake fluid reservoir

199

Battery (below a cover)

200

Windscreen washer fluid reservoir

195

ABCDEF194General Maintenance

Page 198 of 280

NoteThe location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

Read and observe

and on page 193 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

WARNINGAfter switching off the ignition, the fan can intermittently continue to oper-

ate for approx. 10 minutes.

Windscreen washer system

Fig. 186

Windscreen washer fluid reser-

voir

Read and observe and on page 193 first.

The windscreen washer fluid reservoir

A

is located in the engine compart-

ment » Fig. 186 .

The cleaning fluid is provided for the cleaning of the front and rear window as

well as the headlight.

The capacity of the reservoir is about 3 litres or about 4.7 litres on vehicles that

have a headlight cleaning system 1)

.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We recommend using clean washing water together with the screen

cleaner from the range of ŠKODA Original Accessories (in winter additionally

with antifreeze) which is capable of removing stubborn dirt.

In Winter, the washing water should always be mixed with antifreeze even if

the vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no

screen cleaner with antifreeze is available. The concentration of methylated

spirits must not be more than 15 %. The freeze protection at this concentration

is sufficient only to -5 °C.

CAUTION

■ Under no circumstances must radiator antifreeze or other additives be added

to the windscreen washer fluid.■

If the vehicle is fitted with a headlight cleaning system, only cleaning prod-

ucts which do not attack the polycarbonate coating of the headlights must be

added to the windscreen washer fluid.

■

Do not remove the filter from the windscreen washer fluid reservoir when re-

plenishing it with liquid otherwise the liquid transportation system can be con-

taminated, which can cause the windscreen washer system to malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specification

196

Checking the oil level

196

Replenishing

197

The engine has been factory-filled with a high-grade oil that can be use

throughout the year - except in extreme climate zones.

The engine oils are undergoing continuous further development. Thus the in- formation stated in this Owner's Manual is only correct at the time of publica-

tion.

1)

In some countries, 4.7 ltr. applies for both variants.

195Inspecting and replenishing

Page 199 of 280

ŠKODA Service Partners are informed about the latest changes by the manu-

facturer. We therefore recommend that the oil change be completed by a

ŠKODA Service Partner.

The specifications (VW standards) stated in the following can be indicated sep-

arately or together with other specifications on the bottle.

The engine oil should be changed after specified service intervals » page 53.WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 192.

CAUTION

Do not pour any additives into the engine oil – risk of serious damage to the

engine parts!

Note

■ Before a long drive we recommend that you purchase and carry with you en-

gine oil which complies with the specification for your vehicle.■

We recommend that you use oils from ŠKODA Original Accessories.

■

If your skin has come into contact with oil, it must be washed thoroughly.

Specification

Read and observe

and on page 196 first.

Vehicles with variable service intervals

Petrol enginesSpecification1.2 l/63, 77 kW TSI

VW 504 00

1.4 l/103 kW TSI1,8 l/132 kW TSI2,0 l/162 kW TSIDiesel engines a)Specification1.6 l/66, 77, 81 kW TDIVW 507 002.0 l/110, 135 kW TDI CRa)

Engine oil VW 505 01 can optionally be used in diesel engines without a

DPF.

Vehicles with fixed service intervalsPetrol enginesSpecification1.2 l/63, 77 kW TSI

VW 502 00

1.4 l/81 kW TSI G-TEC1.4 l/103 kW TSI1.6 l/81 kW MPI1.8 l/132 kW TSI2.0 l/162 kW TSIDiesel engines a)Specification1.6 l/66, 77, 81 kW TDIVW 507 002.0 l/105, 110, 135 kW TDIa)

Engine oil VW 505 01 can optionally be used in diesel engines without a

DPF.

CAUTION

■

If the above engine oils are not available, a different engine oil can be used in

an emergency. To prevent damage to the engine, a maximum of 0.5 litres only

of the following engine oils may be used: ■ For petrol engine models: ACEA A3/ACEA B4 or API SN, (API SM);

■ for diesel engines: ACEA C3 or API CJ-4.

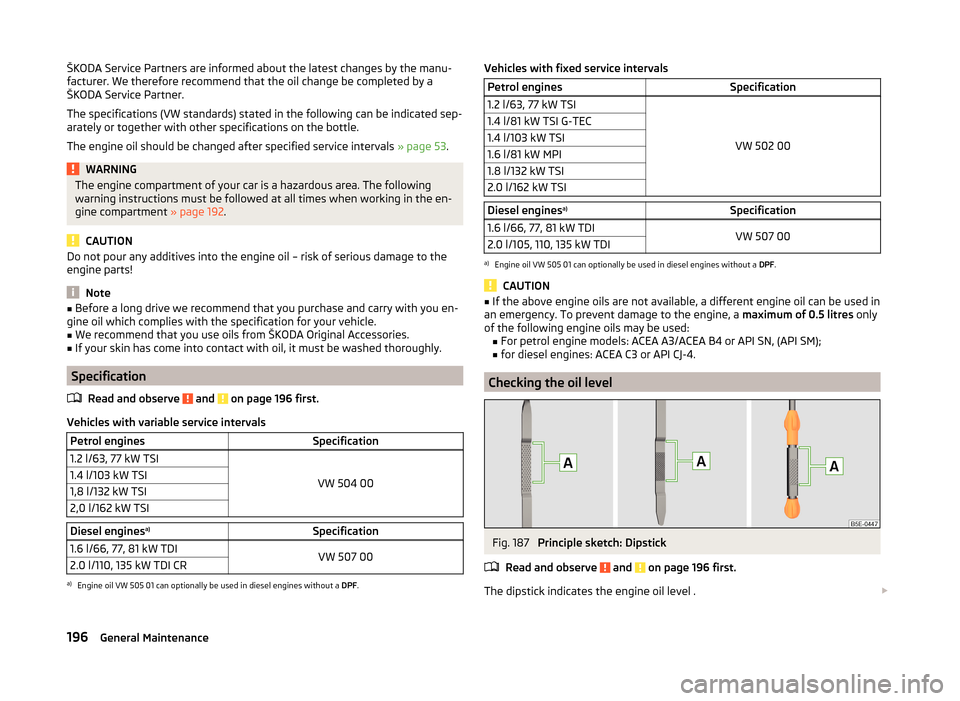

Checking the oil level

Fig. 187

Principle sketch: Dipstick

Read and observe

and on page 196 first.

The dipstick indicates the engine oil level .

196General Maintenance

Page 200 of 280

Dipstick » Fig. 187

The oil level must be within this range.

The oil can be checked and topped up, if the following conditions are satisfied. The vehicle stands on a horizontal surface.

The engine operating temperature is reached.

The engine is turned off.

The bonnet is open.

Checking the level›

Wait a few minutes until the engine oil flows back into the oil trough.

›

Pull out the dipstick.

›

Wipe the dipstick with a clean cloth and insert it again to the stop.

›

Pull the dipstick out again and check the oil level.

›

Re-insert the dipstick.

The engine consumes a little oil. The oil consumption may be as much as 0.5 l/

1000 km depending on your style of driving and the conditions under which

you operate your vehicle. Consumption may be slightly higher than this during

the first 5 000 km.

The oil level must be checked at regular intervals.

In case of low oil level, the display of the instrument cluster shows a check

mark and the corresponding message

» page 42. Check the oil level using

the dipstick as soon as possible. Add oil accordingly.

CAUTION

■ The oil level must never be above the A range » Fig. 187 – there is a risk of

damaging the exhaust system!■

If for some reason it is not possible to top up the engine oil under the current

circumstances,

do not continue driving! Switch off the engine and seek as-

sistance from a specialist garage.

■

If the oil level is above level

A

,

do not continue to drive! Switch off the

engine and seek assistance from a specialist garage.

Replenishing

Read and observe

and on page 196 first.

›

Unscrew the cap of the engine oil filler opening » Fig. 185 on page 194 .

›

Replenish the oil in portions of 0.5 litres in accordance with the correct speci-

fications » page 196 .

›

Check the oil level » page 196.

A›Screw the lid of the engine oil filler closed carefully.›Pull the dipstick out as far as the stop.

Coolant

Introduction

This chapter contains information on the following subjects:

Checking the coolant level

198

Replenishing

198

The coolant provides cooling for the motor.

It consists of water and coolant additive with additives that protect the cooling

system against corrosion and prevents furring.

The coolant additive level in the coolant must be at least 40%.

The coolant additive may be increased to a maximum of 60%.

The correct mixing ratio of water and coolant additive is to be checked if nec- essary by a specialist garage or is to be restored if necessary.

The description of the coolant is shown in the coolant expansion reser-

voir » Fig. 188 on page 198 .

WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en- gine compartment » page 192.■

The coolant is harmful to health.

■

Avoid contact with the coolant.

■

Coolant vapours are harmful to health.

■

Never open the end cover of the coolant expansion reservoir while the

engine is still warm. The cooling system is pressurized!

■

When opening the end cover of the coolant expansion reservoir, cover it

with a cloth to protect your face, hands and arms from hot steam or hot

coolant.

■

If any coolant splashes into your eyes, immediately rinse out your eyes

with clear water and contact a doctor as soon as possible.

■

Always keep the coolant in the original container, safe from people who

are not completely independent, especially children - there is a danger of

poisoning!

197Inspecting and replenishing