light SKODA OCTAVIA TOUR 2009 1.G / (1U) Owners Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2009, Model line: OCTAVIA TOUR, Model: SKODA OCTAVIA TOUR 2009 1.G / (1U)Pages: 224, PDF Size: 13.53 MB

Page 161 of 224

Inspecting and replenishing

160

– Take the bonnet support out of its holder and set it in the opening

designed for it

⇒

page 159, fig. 150

.

Closing the bonnet – Lift the bonnet slightly and unhook the bonnet support. Press the

bonnet support into the hold

er designed to hold it.

– Allow the bonnet to drop from a height of about 30 cm into the lock -

bonnet

do not press down on it

!

WARNING

•

Never open the bonnet if you see that steam or coolant is flowing out of

the engine compartment - risk of scaldi

ng! Wait long enough until the steam

or coolant has stopped escaping.•

For safety reasons, the bonnet must always be properly closed when

driving. One should therefore check that

the lock has in fact engaged prop-

erly after closing the bonnet.•

Stop your vehicle i

mmediately while driving if yo

u notice that the lock is

not properly engaged and close the bonn

et properly - risk of an accident!

Working in the engine compartment Particular care is required when ca

rrying out any work in the engine

compartment!There is a risk of injuries, scalding,

accidents and fire wh

en working in the

engine compartment, e.g. inspecting an

d replenishing oil and other fluids. For

this reason, it is essential to comply with the warning instructions stated below and with the general applicable

rules of safety. The engine compart-

ment of your car is a hazardous area

⇒

.

WARNING

•

Never open the bonnet if you see that steam or coolant is flowing out of

the engine compartment - risk of scaldi

ng! Wait long enough until the steam

or coolant has stopped escaping.•

Switch off the engine and pull out the ignition key.

•

Apply the handbrake firmly.

•

On vehicles fitted with a manual gearbox, move the gearshift lever into

Neutral.•

Allow the engine to cool down.

•

Keep children clear of the engine compartment.

•

Never spill oil and other fluids over the hot engine. Such fluids (e.g. the

antifreeze contained in the coolant) may ignite!•

Avoid short circuits in the electrical system - particularly on the battery.

•

Never place your hand into the radiator

fan as long as the engine is still

warm. The fan might suddenly start running!•

Never open the cap of the coolant expa

nsion bottle as long as the engine

is still warm. The cooling system is pressurized!•

Cover over the cap of the coolant expansion reservoir with a large cloth

when opening it as protection for your face, hands and arms from hot steam or hot coolant.•

Do not let objects, such as e.g cleaning cloth or tools lie in the engine

compartment.•

If you wish to work under the vehicl

e, you must secure the vehicle from

rolling away and support it

with suitable supporting blocks; the lifting jack*

is not sufficient for this - risk of injury!•

In cases where it be necessary to carry out inspection work when the

engine is running there is an additional risk from rotating parts (e.g. the V- ribbed belt, alternator, radiator fan) and from the high-voltage ignition system. Please observe in addition the following:

− Never touch the electrical cabl

es of the ignition system.

− Absolutely avoid any jewellery, loose items of clothing or long hair from getting into the rotating part

s of the engine - Hazard! Therefore

s2g8.b.book Page 160 Tuesday, April 7, 2009 8:53 AM

Page 164 of 224

Inspecting and replenishing

163

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

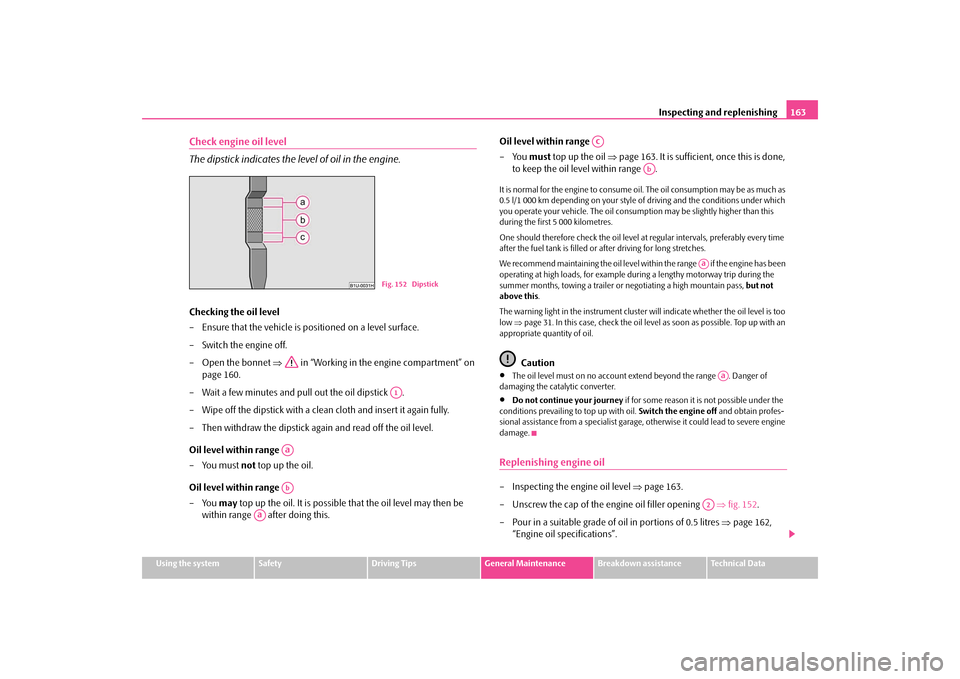

Check engine oil level The dipstick indicates the level of oil in the engine.Checking the oil level – Ensure that the vehicle is positioned on a level surface. – Switch the engine off.– Open the bonnet

⇒

in “Working in the engine compartment” on

page 160.

– Wait a few minutes and pull out the oil dipstick . – Wipe off the dipstick with a clea

n cloth and insert it again fully.

– Then withdraw the dipstick ag

ain and read off the oil level.

Oil level within range – You must

not

top up the oil.

Oil level within range – You

may

top up the oil. It is possible that the oil level may then be

within range after doing this.

Oil level within range –You

must

top up the oil

⇒

page 163. It is sufficient, once this is done,

to keep the oil level within range .

It is normal for the engine to consume oi

l. The oil consumption may be as much as

0.5 l/1 000 km depending on your style of driving and the conditions under which you operate your vehicle. The oil consumpt

ion may be slightly higher than this

during the first 5 000 kilometres. One should therefore check the oil level at regular intervals, preferably every time after the fuel tank is filled or after driving for long stretches. We recommend maintaining the oil level within the range if the engine has been operating at high loads, for example during a lengthy motorway trip during the summer months, towing a trailer or

negotiating a high mountain pass,

but not

above this

.

The warning light in the instrument cluster

will indicate whether the oil level is too

low

⇒page 31. In this case, check the oil level

as soon as possible. Top up with an

appropriate quantity of oil.

Caution

•

The oil level must on no account ex

tend beyond the range . Danger of

damaging the cata

lytic converter.

•

Do not continue your journey

if for some reason it is not possible under the

conditions prev

ailing to top up with oil.

Switch the engine off

and obtain profes-

sional assistance from a specialist garage, otherwise it could lead to severe engine damage.Replenishing engine oil– Inspecting the engine oil level

⇒

page 163.

– Unscrew the cap of the engine oil filler opening

⇒

fig. 152

.

– Pour in a suitable grade of oil in portions of 0.5 litres

⇒

page 162,

“Engine oil specifications”.

Fig. 152 DipstickA1

AaAb

Aa

Ac

Ab

Aa

Aa

A2

s2g8.b.book Page 163 Tuesday, April 7, 2009 8:53 AM

Page 167 of 224

Inspecting and replenishing

166

The coolant expansion bottle is loca

ted in the engine compartment on

the right. – Switch the engine off. – Open the bonnet

⇒

in “Working in the engine compartment” on

page 160.

– Check the level of coolant in the coolant expansion bottle

⇒

page 165, fig. 154

. When the engine is cold, the coolant level must

lie between the and markings. When the engine is warm, the level may also lie slightly above the hatched part.

If the coolant level in the reservoir is too low, this is indicated by the warning light in the instrument cluster

⇒page 30. We nevertheless recommend inspecting

the coolant level directly at th

e reservoir from time to time.

Loss of coolant A loss of coolant is first and foremost an

indication of a leak

in the system. You

should not merely top up the coolant in the reservoir. It is also important to have the cooling system inspected without delay by a specialist garage. Losses can only occur through the pressure

relief in the cap of the coolant expan-

sion bottle which is completely free of leak

s if the coolant boils as a result of over-

heating and is forced out of the cooling system.

WARNING

Read and observe the warning notes

⇒page 160, “Working in the engine

compartment” before working in the engine compartment.

Caution

One should contact a specialist garage as soon as possible if the source of over-heating itself cannot be

determined and removed, since there may be grave

damage to the engine.

Replenishing the coolant– Switch the engine off. – Allow the engine to cool down. – Place a cloth over the cap of the coolant expansion reservoir

⇒

page 165, fig. 154

and unscrew the cap

carefully

by turning it to the

left

⇒

.

– Top up the coolant. – Screw the cap tight until it is heard to lock.The coolant which you use for replenishing the system, must comply with one specific specification

⇒page 165, “Coolant”. Do not use an alternative additive if

the coolant additive G12 PLUS - PLUS is not av

ailable in exceptional cases. Just top

up the system with water and as soon as possible arrange adjustment to correct the mixing ratio of water and coolant additive again by a specialist garage. Only use fresh coolant for topping up the system.Do not top up the fluid above the hatched

part! Excess coolant which is heated up

is forced out of the cooling system through the pressure relief valve in the cap of the coolant compensation bottle. Wait until the engine has cooled down for a system which has suffered a major loss of coolant before pouring in coolant. This is necessary to avoid engine damage.

WARNING

•

The cooling system is pressurized! Do not open the cap of the coolant

expansion bottle if the engine is

still hot - risk of scalding!

•

The coolant additive and thus all of the coolant is harmful to your health.

Avoid contact with the coolant. Coolant vapours are also harmful to the health. It is important, therefore, to always safely store any coolant additive in its original container out of the reach of children - risk of poisoning!•

If any splashes of coolant get into yo

ur eyes, rinse out

your eyes immedi-

ately with clear water and contact a doctor as soon as possible.

Aa

Ab

s2g8.b.book Page 166 Tuesday, April 7, 2009 8:53 AM

Page 168 of 224

Inspecting and replenishing

167

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

•

You should also consult a doctor without delay if you have inadvertently

swallowed coolant.

Caution

Do not continue your journey if for some reason it is not possible under the conditions prevailing to top up with coolant. Switch the engine off

and obtain

professional assistance from a specialist garage, otherwise it could lead to severe engine damage.

For the sake of the environment

Do not re-use coolant if it is necessary to

drain the coolant in the system. It should

be collected and disposed of in comp

liance with environmental protection

regulations.Radiator fan The radiator fan may switch on suddenly.The radiator fan is driven by an electr

ic motor and controlled according to the

coolant temperature. The radiator fan may continue running fo

r up to 10 minutes after the engine has

been switched off - even if

the ignition is also off. It

may also switch on suddenly

after a certain time, if•

the coolant temperature has risen beca

use of an accumulation of heat or

•

the warm engine compartment is heated

up additionally by

strong sunlight.

WARNING

You must therefore be aware when work

ing in the engine compartment that

the fan may switch on suddenly - risk of injury!

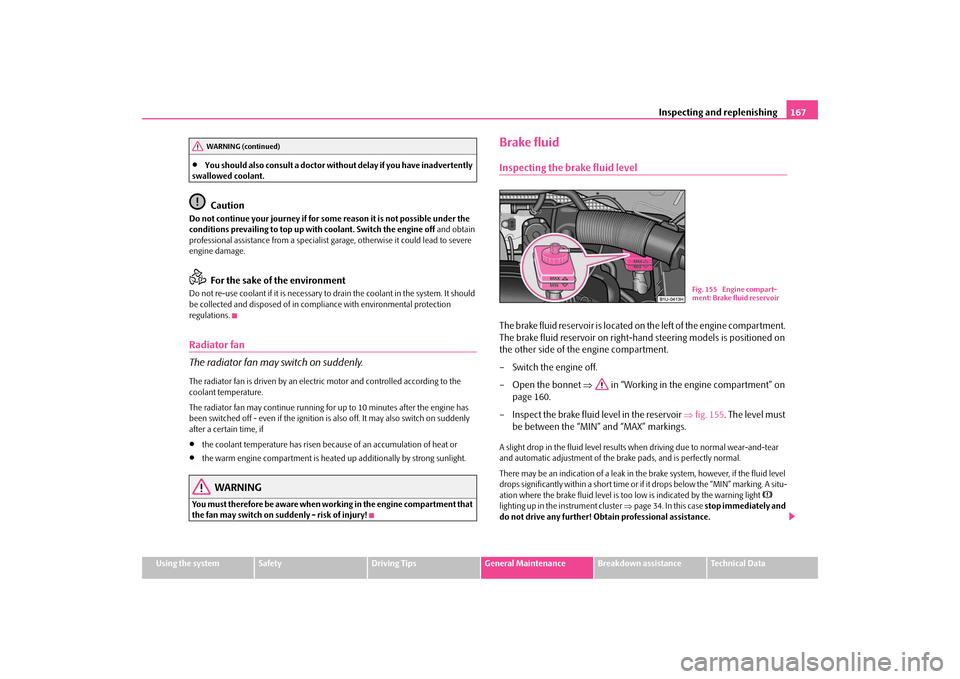

Brake fluidInspecting the brake fluid levelThe brake fluid reservoir is located on the left of the engine compartment. The brake fluid reservoir on right-hand steering models is positioned on the other side of the engine compartment. – Switch the engine off.– Open the bonnet

⇒

in “Working in the engine compartment” on

page 160.

– Inspect the brake fluid level in the reservoir

⇒

fig. 155

. The level must

be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results when driving due to normal wear-and-tear and automatic adjustment of the br

ake pads, and is perfectly normal.

There may be an indication of a leak in the brake system, however, if the fluid level drops significantly within a short time or if it drops below the “MIN” marking. A situ- ation where the brake fluid level is too low is indicated by the warning light

lighting up in the instrument cluster

⇒page 34. In this case

stop immediately and

do not drive any further! Obtain professional assistance.

WARNING (continued)

Fig. 155 Engine compart- ment: Brake fluid reservoir

s2g8.b.book Page 167 Tuesday, April 7, 2009 8:53 AM

Page 170 of 224

Inspecting and replenishing

169

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

WARNING

•

The battery acid is strongly corros

ive and must, therefore, be handled

with the greatest of care. Always we

ar protective gloves, eye and skin

protection when handling batteries. Corrosive fumes in the air irritate the air passages and lead to conjunctivitis

and inflammation of the air passages

in the lungs. Battery acid corrodes

dental enamel and creates deep wounds

after contact with the skin which take a long time to heal. Repeated contact with diluted acids causes skin diseases (inflammations, ulcers, slin cracks). Acids coming into contact with water are diluted accompanied by significant development of heat.•

Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings. Prot

ect the eyes with safety glasses or a shield! There

is the danger of suffering blindness! If

any battery electrol

yte gets into your

eye, rinse out your eye immediately

with clear water for several minutes.

Contact a doctor without delay.•

Splashes of acid on your skin or clothes should be neutralised as soon as

possible using soap suds and then rinsed with plenty of water. Contact a doctor immediately if you swallow battery electrolyte.•

Keep batteries out of the reach of children.

•

Hydrogen is released when you char

ge a battery and a highly explosive

gas mixture is produced. An explosion

can be caused through sparkling over

during unclamping or loosening of the cable plug while the ignition is on.•

Bridging of the poles will create a short circuit (e.g. through metal

objects, cables). Possible consequences of a short circuit: Melting of lead struts, explosion and burning of the battery, jets of acid spurting out.•

It is prohibited to work with a naked flame and light, to smoke or to carry

out any activities which produce sparks. Avoid creating sparks when working with cables and electrical device

s. Strong sparking represents a risk

of injury.•

Before carrying out any work on the electrical system, switch off the

engine, the ignition as well as all electrical components and disconnect the negative cable (-) on the battery. If you wish to replace a bulb it is sufficient to switch off the appropriate light.

•

Never charge a frozen or thawed battery - risk of explosion and caustic

burns! Replace a frozen battery.•

Never use a battery which is damaged

- risk of explosion! Immediately

replace a damaged battery.

Caution

•

You must only disconnect the battery if the ignition is switched off, otherwise

the electrical system (electronic components) of the vehicle may be damaged. When disconnecting the battery from the el

ectrical system of the vehicle, first

disconnect the negative terminal (-) of th

e battery. Then disconnect the positive

terminal (+).•

When reconnecting the battery, first conne

ct the positive terminal (+) and only

then the negative terminal (-) of the batt

ery. You must on no account connect the

cables wrongly - risk of a cable fire.•

Ensure that battery acid does not come

into contact with the vehicle body

otherwise damage could

occur to the paintwork.

•

Do not place the battery in direct dayl

ight in order to protect the battery

housing from the effects of ultra-violet light.

For the sake of the environment

A removed battery is a special type of waste which is harmful to the environment - contact your specialist garage regarding disposing of the battery.

Note

Please also refer to the guidelines

⇒page 171, “Disconnecting and reconnecting

the battery”, also after connecting the battery.

WARNING (continued)

s2g8.b.book Page 169 Tuesday, April 7, 2009 8:53 AM

Page 173 of 224

Inspecting and replenishing

172

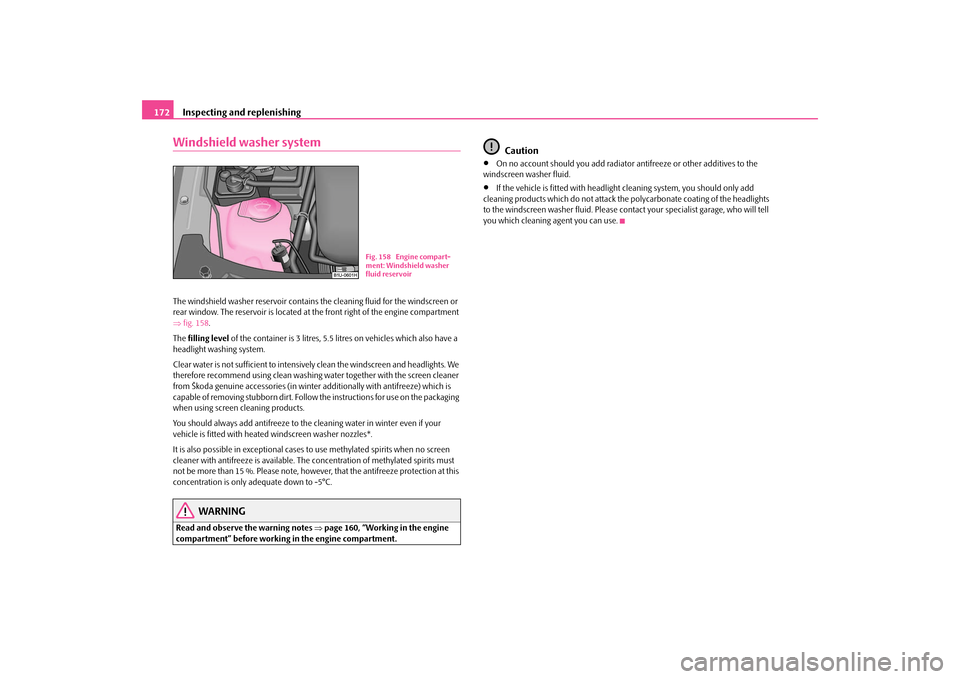

Windshield washer systemThe windshield washer reservoir contains

the cleaning fluid for the windscreen or

rear window. The reservoir is located at the front right of the engine compartment ⇒ fig. 158

.

The

filling level

of the container is 3 litres, 5.5 li

tres on vehicles which also have a

headlight washing system. Clear water is not sufficient to intensivel

y clean the windscreen

and headlights. We

therefore recommend using clean washing wa

ter together with the screen cleaner

from Škoda genuine accessorie

s (in winter additionally with antifreeze) which is

capable of removing stubborn dirt. Follow

the instructions for use on the packaging

when using screen cleaning products. You should always add antifreeze to the

cleaning water in wi

nter even if your

vehicle is fitted with heated windscreen washer nozzles*. It is also possible in exceptional cases to use methylated spirits when no screen cleaner with antifreeze is

available. The concentration

of methylated spirits must

not be more than 15 %. Please note, howeve

r, that the antifreeze protection at this

concentration is only adequate down to -5°C.

WARNING

Read and observe the warning notes

⇒page 160, “Working in the engine

compartment” before working in the engine compartment.

Caution

•

On no account should you add radiator

antifreeze or other additives to the

windscreen washer fluid.•

If the vehicle is fitted with headlight

cleaning system, you should only add

cleaning products which do not attack th

e polycarbonate coating of the headlights

to the windscreen washer fluid. Please contact your specialist garage, who will tell you which cleaning agent you can use.

Fig. 158 Engine compart- ment: Windshield washer fluid reservoir

s2g8.b.book Page 172 Tuesday, April 7, 2009 8:53 AM

Page 177 of 224

Wheels and Tyres

176

The date of manufacture

is a lso s tated on the tyre wal l (poss ibly o nl y on the

inside

of wheel):

DOT ... 50 08...

means, for example, that the tyre was manufactured in the 50th week of the year 2008. If the

spare wheel*

differs from the tyres fitted to the vehicle (e.g. winter tyres or

low-profile tyres), the spare wheel* should only be used for a short time in the event of a puncture and when adopting an

appropriately cautious style of driving.

It should be replaced as quickl

y as possible by a normal wheel.

WARNING

•

Only use those tyres or wheel rims

which have been approved for your

model of Škoda Auto vehicle. Failure to observe this instruction will adversely affect the road safety of your vehicle - risk of accident! Approval and licencing of your vehicle on public roads may also become void as a result.•

You must on no account drive at a higher speed than is permissible for

y our t yre s - ris k of a n ac cid e n t re su lti ng fro m ty re d a m ag e a nd lo ss o f c ont rol over your vehicle.•

Tyres which are 6 years old or more should only be fitted in exceptional

cases and when adopting an appropriately cautious style of driving.•

Never fit tyres which have already been used without having adequate

knowledge of their previous history. Ty

res age even if they have not been

used at all or only very little. A spare tyre must only be used in exceptional cases and only then when adopting an appropriately cautious style of driving.•

Do not, where possible, replace indivi

dual tyres but at least replace them

on both wheels of a given axle at the same time. Always fit the tyres with the deeper tread depth to the front wheels.

For the sake of the environment

Old tyres must be disposed

of in conformity with the appropriate regulations.

Note

It is not normally possible to fit wheels

from other models of cars for technical

reasons. This may also apply in certain

circumstances to the wheels of the same

type of vehicle.Wheel boltsWheels and

wheel bolts

are matched to each other in

terms of design. Each time

you fit other wheels - e.g. light alloy wheels

or wheels with winter tyres - you must

therefore also use the matching wheel bolts of the correct length and shape of spherical cap. This is essent

ial to ensure that the wheels are tightly fitted and that

the brake system operates properly. If you retrofit

wheel trims

(or have this done), please also ensure that an adequate

flow of air remains assured for cooling the brake system. The specialist garages are informed abou

t the technical possibilities which exist

regarding converting or retrofitti

ng wheels, tyres and wheel trims.

WARNING

•

In case of incorrect treatment of th

e wheel bolts, the

wheel can loosen

when the car is moving - risk of accident!•

The wheel bolts must be clean and must

turn easily. However, they must

never be treated with grease or oil.•

If the wheel bolts are tightened to a too low tightening torque, the rim

can lossen when the car is moving - risk of accident! A tightening torque which is too high can damage the bolts and threads and this can result in permanent deformation of the contact surfaces on the rims.

Caution

The prescribed tightening torque of the wh

eel bolts for steel and light alloy wheels

is 120 Nm.

s2g8.b.book Page 176 Tuesday, April 7, 2009 8:53 AM

Page 184 of 224

Breakdown assistance

183

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

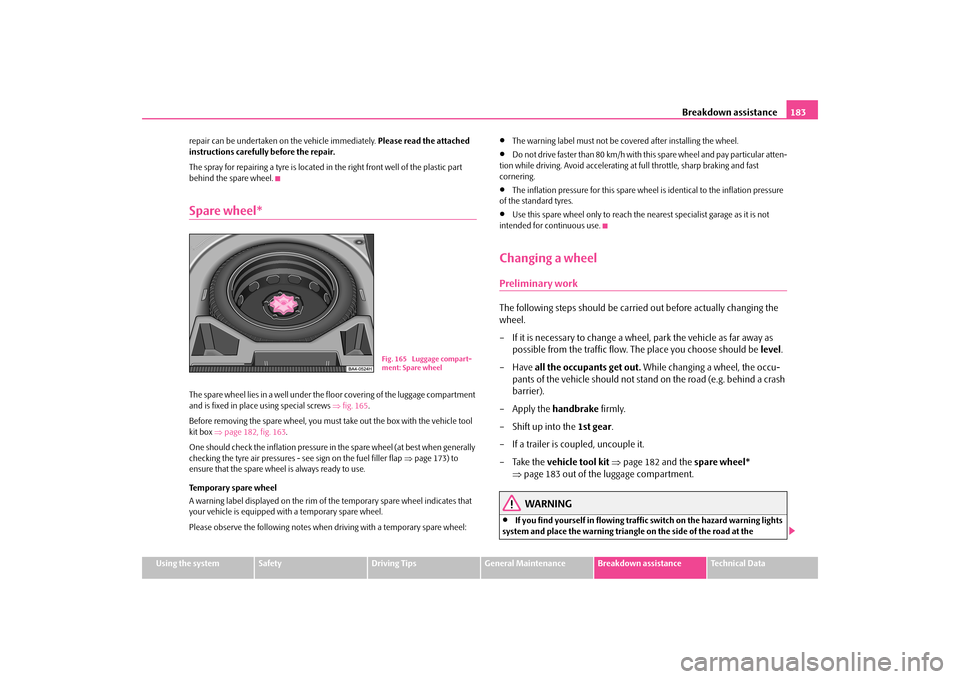

repair can be undertaken on

the vehicle immediately.

Please read the attached

instructions carefully before the repair. The spray for repairing a tyre is located in

the right front well of the plastic part

behind the spare wheel.Spare wheel*The spare wheel lies in a well under the floor covering of the luggage compartment and is fixed in place using special screws

⇒fig. 165

.

Before removing the spare wheel, you must take out the box with the vehicle tool kit box

⇒page 182, fig. 163

.

One should check the inflation pressure in the spare wheel (at best when generally checking the tyre air pressures - see sign on the fuel filler flap

⇒page 173) to

ensure that the spare wheel is always ready to use. Temporary spare wheel A warning label displayed on the rim of the temporary spare wheel indicates that your vehicle is equipped with a temporary spare wheel. Please observe the following notes when driving with a temporary spare wheel:

•

The warning label must not be covered after installing the wheel.

•

Do not drive faster than 80 km/h with th

is spare wheel and pay particular atten-

tion while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.•

The inflation pressure for this spare wheel is identical to the inflation pressure

of the standard tyres.•

Use this spare wheel only to reach the nearest specialist garage as it is not

intended for continuous use.Changing a wheelPreliminary workThe following steps should be carried out before actually changing the wheel. – If it is necessary to change a wheel, park the vehicle as far away as

possible from the traffic flow. The place you choose should be

level

.

–Have

all the occupants get out.

While changing a wheel, the occu-

pants of the vehicle should not stan

d on the road (e.g. behind a crash

barrier).

– Apply the

handbrake

firmly.

– Shift up into the

1st gear

.

– If a trailer is coupled, uncouple it. – Take the

vehicle tool kit

⇒

page 182 and the

spare wheel*

⇒

page 183 out of the luggage compartment.WARNING

•

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle

on the side of the road at the

Fig. 165 Luggage compart- ment: Spare wheel

s2g8.b.book Page 183 Tuesday, April 7, 2009 8:53 AM

Page 185 of 224

Breakdown assistance

184

prescribed distance from your vehicl

e while observing all national legal

provisions. In this way you are protecting not only yourself but also other road users.•

Never start the engine with the vehicle

sitting on the raised jack - danger

of suffering injury.

Caution

If you have to change a wheel on a slope

first block the opposite wheel with a stone

or similar object in order to secure th

e vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.Changing a wheelAlways change a wheel on a level surface as far as possible. – Take off the full wheel trim*

⇒

page 185 or the caps

⇒

page 185.

– In the case of light alloy wheels remove the wheel trim cap

⇒

page 186.

– Slacken the wheel bolts

⇒

page 186.

– Jack up the vehicle until the wheel to

be changed is clear of the ground

⇒

page 187.

– Unscrew the wheel bolts and place them on a clean surface (cloth,

paper etc.).

– Take off the wheel.– Fit on the new spare wheel* and tighten the wheel bolts slightly. –Lower the car.

– Tighten the wheel bolts firmly, al

ternately and diagonally using the

wrench* (crosswise)

⇒

page 186.

– Mount the full wheel trim/w

heel trim cap or the caps.

Note

•

All bolts must be clean

and must turn easily.

•

You must never grease or oil the wheel bolts!

•

When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction

⇒page 173.

Subsequent stepsAfter changing the wheel, you must perform the following steps. – Stow and attach the replaced wheel in the spare wheel well. – Stow the vehicle tool kit in the space provided.–

Check

the

tyre pressure

on the spare wheel* just mounted as soon

as possible.

– Have the

tightening torque

of the wheel bolts

checked

with a torque

wrench as soon as possible. Steel and light alloy wheels must be tight-ened to a tightening torque of

120 Nm

.

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on

⇒page 175, “New tyres

and wheels” if the vehicle is subseq

uently fitted with tyres which are

different to those it was fitted with at the works.

WARNING (continued)

s2g8.b.book Page 184 Tuesday, April 7, 2009 8:53 AM

Page 187 of 224

Breakdown assistance

186

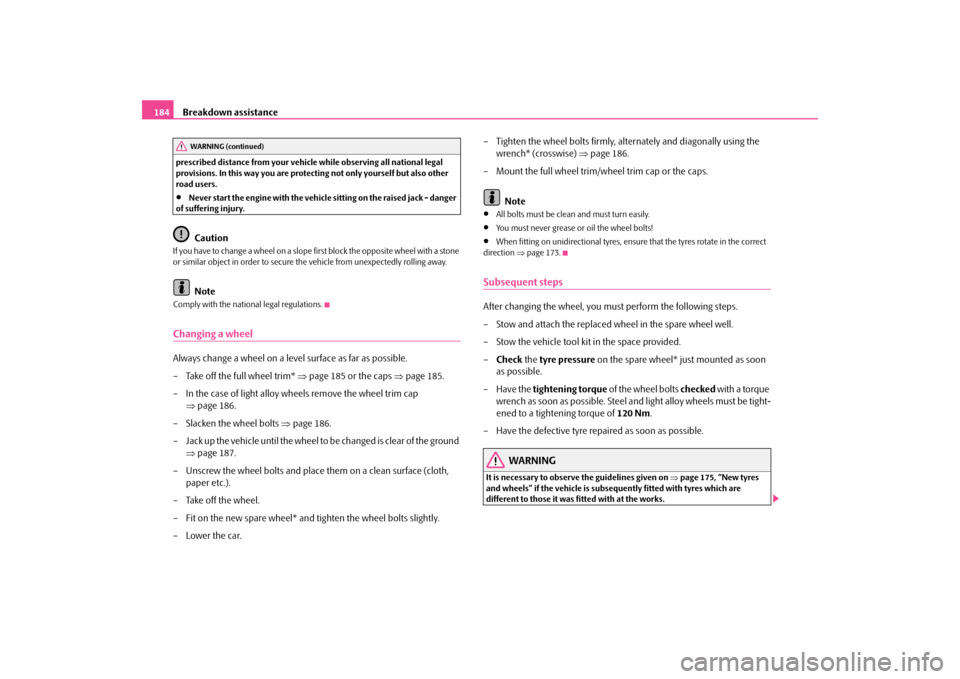

Wheel trim caps*Pulling off – Carefully remove the wheel tr

im cap using the wire clamp

⇒

fig. 168

.

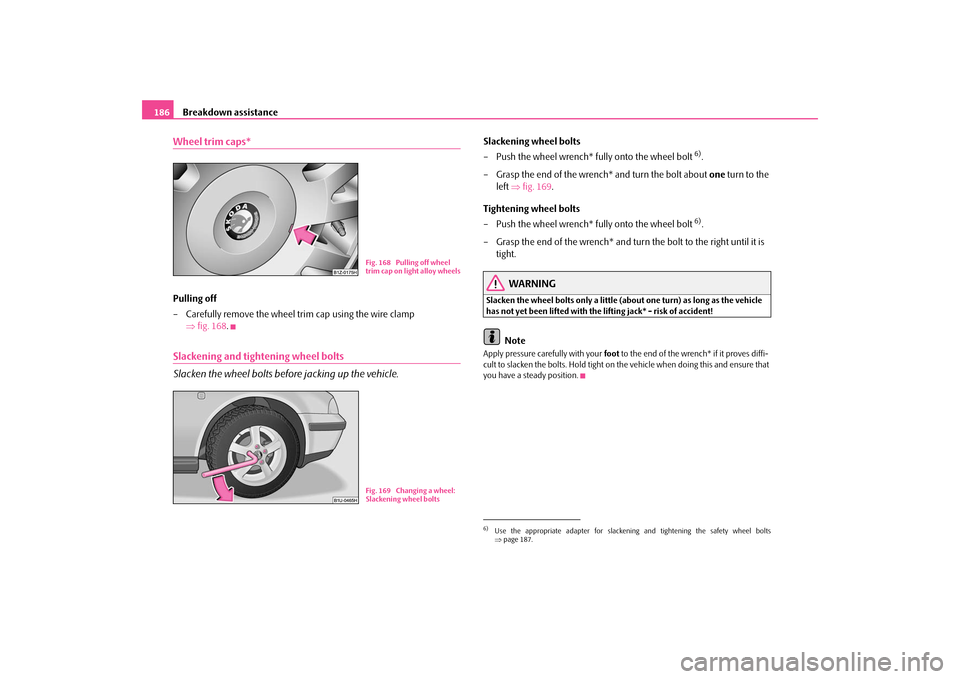

Slackening and tightening wheel bolts Slacken the wheel bolts before jacking up the vehicle.

Slackening wheel bolts – Push the wheel wrench* fully onto the wheel bolt

6).

– Grasp the end of the wrench* and turn the bolt about

one

turn to the

left

⇒

fig. 169

.

Tightening wheel bolts – Push the wheel wrench* fully onto the wheel bolt

6).

– Grasp the end of the wrench* and turn the bolt to the right until it is

tight.

WARNING

Slacken the wheel bolts only a little (a

bout one turn) as long as the vehicle

has not yet been lifted with the lifting jack* - risk of accident!

Note

Apply pressure carefully with your

foot

to the end of the wrench* if it proves diffi-

cult to slacken the bolts. Hold tight on th

e vehicle when doing this and ensure that

you have a steady position.

Fig. 168 Pulling off wheel trim cap on light alloy wheelsFig. 169 Changing a wheel: Slackening wheel bolts

6)Use the appropriate adapter for slackening

and tightening the safety wheel bolts

⇒ page 187.

s2g8.b.book Page 186 Tuesday, April 7, 2009 8:53 AM