warning SKODA OCTAVIA TOUR 2010 1.G / (1U) Columbus Navigation System Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: OCTAVIA TOUR, Model: SKODA OCTAVIA TOUR 2010 1.G / (1U)Pages: 207, PDF Size: 12.63 MB

Page 164 of 207

Wheels and Tyres163

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

means, for example, that the tyre was ma

nufactured in the 50th week of the year 2008.

If the spare wheel* differs from the tyres fitted to the vehicle (e.g. winter tyres or low-

profile tyres), the spare wheel* should only be used for a short time in the event of a

puncture and when adopting an appropriately cautious style of driving. It should be

replaced as quickly as po ssible by a normal wheel.

WARNING

Only use those tyres or wheel rims which have been approved for your

model of Škoda Auto vehicle. Failure to observe this instruction will adversely

affect the road safety of your vehicle - risk of accident! Approval and licencing

of your vehicle on public roads may also become void as a result.

You must on no account drive at a high er speed than is permissible for your

tyres - risk of an accident resulting from tyre damage and loss of control over

your vehicle.

Tyres which are 6 years old or more should only be fitted in exceptional

cases and when adopting an approp riately cautious style of driving.

Never fit tyres which have already been used without having adequate

knowledge of their previous history. Tyre s age even if they have not been used

at all or only very little. A spare tyre must only be used in exceptional cases and

only then when adopting an appropriately cautious style of driving.

Do not, where possible, replace individu al tyres but at least replace them on

both wheels of a given axle at the same time. Always fit the tyres with the

deeper tread depth to the front wheels.For the sake of the environment

Old tyres must be disposed of in conf ormity with the appropriate regulations.

Note

It is not normally possible to fit wheels from other models of cars for technical reasons.

This may also apply in certain circumstan ces to the wheels of the same type of

vehicle.

Wheel boltsWheels and wheel bolts are matched to each other in terms of design. Each time you

fit other wheels - e.g. light alloy wheels or wheels with winter tyres - you must therefore

also use the matching wheel bolts of the corr ect length and shape of spherical cap. This

is essential to ensure that the wheels are tightly fitted and that the brake system oper-

ates properly.

If you retrofit wheel trims (or have this done), please also ensure that an adequate

flow of air remains assured for cooling the brake system.

The specialist garages are informed about the technical possibilities which exist

regarding converting or retrofitting wheels, tyres and wheel trims.

WARNING

In case of incorrect treatment of the wheel bolts, the wheel can loosen when

the car is moving - risk of accident!

The wheel bolts must be clean and must turn easily. However, they must

never be treated with grease or oil.

If the wheel bolts are tightened to a too low tightening torque, the rim can

lossen when the car is moving - risk of accident! A tightening torque which is

too high can damage the bolts and threads and this can result in permanent

deformation of the contac t surfaces on the rims.Caution

The prescribed tightening torque of the wh eel bolts for steel and light alloy wheels is

120 Nm.Winter tyresThe handling of your vehicle will be significantly improved when driving on wintry

roads if you fit winter tyres. Summer tyres do not offer the same grip on ice, snow and

at temperatures below 7 °C because of thei r construction (width, rubber blend, tread

pattern). This particularly applies to vehicles which are equipped with low-profile

tyres or high-speed tyres (code index H or V on wall of tyre).

s2rc.book Page 163 Thursday, April 22, 2010 10:58 AM

Page 165 of 207

Wheels and Tyres

164

Winter tyres must be mounted on all four wheels to obtain the best handling charac-

teristics.

You must only fit those types of winter tyre which are approved for your vehicle. The

permissible sizes of winter tyres are stated in your vehicle documents. Approvals

may differ because of national legislation.

Please remember that the tyres should be inflated to 20 kPa (0.2 bar) more than is the

case for summer tyres page 160, fig. 153.

Winter tyres no longer offer the same winter performance once the tyre tread has

worn down to a depth of about 4 mm.

Ageing also causes winter tyres to lose most of their winter performance properties -

even in cases where the remaining tread depth is still clearly more than 4 mm.

Speed restrictions apply to winter tyres as well as to summer tyres page 162,

.

You can fit winter tyres of a lower speed ca tegory to your vehicle provided that you

also do not drive faster than the permissible maximum speed for such tyres, even if the

possible maximum speed of your vehicle is higher. The corresponding tyre category

can damage the tyres when exceeding the permissible maximum speed.

Please pay attention to the notes if you decide to fit winter tyres page 160.

You can also fit so-called “all-year tyres” instead of winter tyres.

Please contact your specialist garage if there are any points which are not clear who

will be able to provide you with inform ation regarding the maximum speed for your

tyres.

WARNING

You must on no account drive your car at more than the permissible maximum

speed for your winter tyres - risk of an accident resulting from tyre damage and

loss of control over your car.

For the sake of the environment

Fit your summer tyres on again in good time since summer tyres offer you better grip

and handling on roads which are free of snow and ice as well as ar temperatures below 7 °C - the braking distance is shorter, there is less tyre noise, tyre wear is reduced and

fuel consumption is reduced.

Note

Please observe the various differing legal requirements regarding tyres.Snow chainsSnow chains must only be mounted on the front wheels.

When driving on wintry roads, snow chains

improve not only traction, but also the

braking performance.

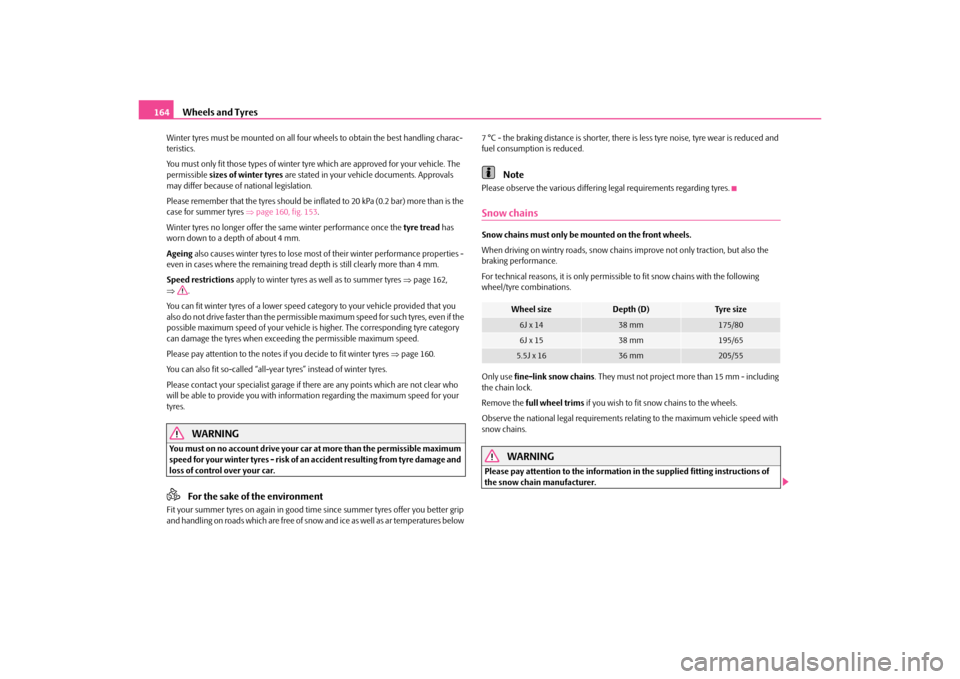

For technical reasons, it is only permissi ble to fit snow chains with the following

wheel/tyre combinations.

Only use fine-link snow chains . They must not project more than 15 mm - including

the chain lock.

Remove the full wheel trims if you wish to fit snow chains to the wheels.

Observe the national legal requirements re lating to the maximum vehicle speed with

snow chains.

WARNING

Please pay attention to the information in the supplied fitting instructions of

the snow chain manufacturer.

Wheel size

Depth (D)

Ty re s i z e

6J x 14

38 mm

175/80

6J x 15

38 mm

195/65

5.5J x 16

36 mm

205/55

s2rc.book Page 164 Thursday, April 22, 2010 10:58 AM

Page 167 of 207

Accessories, changes and replacement of parts

166

Accessories, changes and replacement of partsAccessories and re placement partsŠkoda vehicles have been built according to the latest discoveries in safety engi-

neering. Thus one should not change the co ndition in which the vehicle was delivered

from the manufacturer without some thought.

The following guidelines should be observed when a vehicle is to be retrofitted with

accessories, have technical ch anges made to it or a part has to be replaced at some

time in the future.

Advise should always be obtained from a specialist garage before buying any

accessories and before making any technical changes .

This is particularly the case when acce ssories are bought in a foreign country.

Škoda Genuine Accessories which have been released for use and Skoda original

parts can be bought from specialist ga rages that professionally undertake the

assembly of parts which were purchased there.

All Škoda original accessories which are listed in the catalogue of original accesso-

ries such as sliding/tilting roofs, sp oilers, wheel rims etc. are homologized.

Radios, aerials and other electrical acce ssories should only be installed by a

specialist garage.

The guidelines issued by Škoda Auto mu st be observed when making technical

changes.

This is to ensure that no technical damage occurs to the vehicle, that travelling and

operating safety are maintained and that the chnages are permissible. The specialist

garages also undertake this work professionally or refer it to another specialist garage

in special cases.

Any damage which is done caused by tech nical changes made without consulting

a Skoda dealer is exclud ed from the guarantee.

WARNING

We advise you, in your own interest, to only use Škoda Genuine Accessories

and Škoda original parts which have been expressly approved for use on your Škoda. Reliability, safety and suitabilii

ty have been established for these Škoda

original parts.

We cannot guarantee suitability of installation into your vehicle of other

products despite keeping a constant eye on market developments (also not in

the case where there is an attestation or permission can be produced).

Technical changesInterference on the electronic components and their software can lead to operational

faults. This interference can also impair no t directly affected systems because of the

networking of the electronic components. This means that the operating safety of your

vehicle can be considerably jeopardized, a greater wear of vehicle parts can occur and

finally the vehicle registration documents expire.

We trust that you will understand that Šk oda Auto cannot be liable for damage

resulting from unprofessional work.

We therefore recommend that you have all wo rk carried out with Škoda original parts

at specialist garages.

WARNING

Work or modifications on your vehicle, which have been carried out unprofes-

sionally, can cause operational faults - risk of accident!Vehicles of category N1The vehicle of category N1 is a vehicle wh ich is designed and manufactured for trans-

porting loads with a maximum weight of 3.5 tonnes.

WARNING (continued)

s2rc.book Page 166 Thursday, April 22, 2010 10:58 AM

Page 168 of 207

Breakdown assistance167

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Breakdown assistanceBreakdown assistanceFirst-aid box*, Warning triangle* and bulb set*A space for stowing the first-aid box and the bu lb set is located in a well of the plastic

part under the floor covering of the lu ggage compartment behind the spare wheel.

A space for the warning triangle is located in the luggage compartment.

Note

Pay attention to the use-by-date of the contents of the first-aid box.

If you equip your vehicle additionally with a warning triangle or with a first-aid box,

you can purchase these from the ra nge of Škoda Original Accessories.

Fire extinguisher*The fire extinguisher is attached with st raps in a holder under the driver seat.

Please read carefully the instructions whic h are attached to the fire extinguisher.

The fire extinguisher must be checked by an authorised person or company annually

(please observe the differing legal requirements).

WARNING

If the fire extinguisher is not correctly attached, in case of sudden manoeuvres

or an accident it can be “thrown” through the interior compartment and cause

injuries.

Note

The fire extinguisher must comply with the relevant and valid legal requirements.

Pay attention to the expiration date of the fire extinguisher. If the fire extinguisher

is used after the expiration date, its proper function is no longer assured.

The fire extinguisher is only supplied in certain countries within the scope of

delivery.

Vehicle tool kitThe vehicle tool kit and the lifting jack* are stowed in a box in the spare wheel*

fig. 157 ; there is also space here for the detachable ball head of the towing device*.

The box is attached with a strap on the spare wheel*.

Fig. 156 Placement of fire extin-

guisher

Fig. 157 Luggage compartment:

storage compartment for vehicle

tool kit

s2rc.book Page 167 Thursday, April 22, 2010 10:58 AM

Page 169 of 207

Breakdown assistance

168

The vehicle tool kit contains the following parts (depending on equipment fitted):

Wire clamps for removing the full wheel trims,

Screwdriver,

Plastic clip for a wheel bolt cover,

Wheel wrench*,

To w i n g e y e ,

Adapter for the safety wheel bolts*.

Before placing the lifting jack* back in its storage area, screw in the arm of the lifting

jack fully.

WARNING

The factory-supplied lifting jack* is only intended for your model of vehicle.

On no account attempt to lift a heavier vehicle or other loads - risk of injury!

Ensure that the vehicle tool kit is safely attached in the luggage compart-

ment.Note

Ensure that the box is always secured with the strap.Spray for repairing a tyre*

The spray for repairing a tyre is intended for rapid repair of small defects in a tyre

consisting of a damage up to a size of up to 5 mm. The spray is not at all intended to

replace a permanent repair on the tyre ; this repair serves to reach the workshop.

The repair can be undertaken on the vehicl e immediately. Please read the attached

instructions carefully before the repair.

The spray for repairing a tyre is located in th e right front well of the plastic part behind

the spare wheel.Tyre repair kit*The tyre repair kit is intended for the repair of minor tyre defects. The tyre repair kit

contains a compressor, inflation bottle, operating instructions and accessories.

The repair with the tyre repair kit is not at all intended to replace a permanent repair

on the tyre, this repair only serves to reach the next specialist garage. The repair can be

undertaken on the vehicle immediately. Please read the attached instructions care-

fully before the repair.

The spray for repairing a tyre is located in th e right front well of the plastic part behind

the spare wheel.Spare wheel*

Fig. 158 Vehicle tool kit: Spray

for repairing a tyre

Fig. 159 Luggage compartment:

Spare wheel

s2rc.book Page 168 Thursday, April 22, 2010 10:58 AM

Page 170 of 207

Breakdown assistance169

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

The spare wheel lies in a well under the floor covering of the luggage compartment

and is fixed in place using special screws

page 168, fig. 159 .

Before removing the spare wheel, you must take out the box with the vehicle tool kit

box page 167, fig. 157.

One should check the inflation pressure in the spare wheel (at best when generally

checking the tyre air pressures - see sign on the fuel filler flap page 160) to ensure

that the spare wheel is always ready to use.

Temporary spare wheel

A warning label displayed on the rim of the temporary spare wheel indicates that your

vehicle is equippe d with a temporary spare wheel.

Please observe the following notes when driving with a temporary spare wheel:

The warning label must not be covered after installing the wheel.

Do not drive faster than 80 km/h with this spare wheel and pay particular attention

while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.

The inflation pressure for this spare wheel is identical to the inflation pressure of

the standard tyres.

Use this spare wheel only to reach the nearest specialist garage as it is not intended

for continuous use.

Changing a wheelPreliminary workThe following steps should be carried ou t before actually changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible from

the traffic flow. The place you choose should be level.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the road (e.g. behind a crash barrier).

– Apply the handbrake firmly.

– Shift up into the 1st gear . – If a trailer is coupled, uncouple it.

–Take the

vehicle tool kit page 167 and the spare wheel* page 168 out of the

luggage compartment.

WARNING

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescribed

distance from your vehicle while observin g all national legal provisions. In this

way you are protecting not only yourself but also other road users.

Never start the engine with the vehicle si tting on the raised jack - danger of

suffering injury.Caution

If you have to change a wheel on a slope fi rst block the opposite wheel with a stone or

similar object in order to secure the vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.Changing a wheelAlways change a wheel on a level surface as far as possible.

– Take off the full wheel trim* page 170 or the caps page 171.

– In the case of light alloy wheels remove the wheel trim cap page 171.

– Slacken the wheel bolts page 171.

– Jack up the vehicle until the wheel to be changed is clear of the ground

page 172.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel.

– Fit on the new spare wheel* and tighten the wheel bolts slightly.

– Lower the car.

s2rc.book Page 169 Thursday, April 22, 2010 10:58 AM

Page 171 of 207

Breakdown assistance

170

– Tighten the wheel bolts firmly, alternately and diagonally using the wrench* (cross-

wise) page 171.

– Mount the full wheel trim/wheel trim cap or the caps.

Note

All bolts must be clean and must turn easily.

You must never grease or oil the wheel bolts!

When fitting on unidirectional tyres, ensu re that the tyres rotate in the correct

direction page 160.

Subsequent stepsAfter changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well.

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel* just mounted as soon as possible.

– Have the tightening torque of the wheel bolts checked with a torque wrench as

soon as possible. Steel and light alloy wh eels must be tightened to a tightening

torque of 120 Nm .

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on page 162, “New tyres and

wheels” if the vehicle is subsequently fitted with tyres which are different to

those it was fitted with at the works.

Note

If you find, when changing the wheel, that the wheel bolts are corroded and diffi-

cult to turn, the bolts must be replaced before checking the tightening torque.

Drive cautiously and only at a moderate speed to a workshop where the tightening

torque can be checked.

Full wheel trim*Pulling off– Hook the clamp found in the vehicle tool ki t into the reinforced edge of the full

wheel trim.

– Push the wheel wrench* through the clamp, support the wheel wrench at the tyre and pull off the wheel trim fig. 160 .Installing– First press the full wheel trim onto the wheel at the valve opening provided. Then

press the full wheel trim into the wheel in such a way that its entire circumference

locks correctly in place.

Caution

Use the pressure of your hand, do not knock on the full wheel trim! Heavy knocks

mainly on the points where the full wheel trim has not been inserted into the wheel,

can result in damage to the guide and centering elements of the full wheel trim.

Check for yourself that the safety wheel bolt * is located in the hole in the area of

the valve before fitting the full wheel trim onto a steel wheel which is attached with a

safety wheel bolt* page 172, “Securing wheels against being stolen*”.

Fig. 160 Removing the full

wheel trim

s2rc.book Page 170 Thursday, April 22, 2010 10:58 AM

Page 172 of 207

Breakdown assistance171

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Wheel bolts with caps*Pulling off– Push the plastic clip sufficiently far onto the cap until the inner catches of the clip

are positioned at the collar of the cap and detach the cap.Installing– Push the caps fully onto the wheel bolts.

The caps are located in the well of the luggage compartment.Wheel trim caps*

Pulling off– Carefully remove the wheel trim cap using the wire clamp fig. 162 .Slackening and tightening wheel bolts

Slacken the wheel bolts before jacking up the vehicle.Slackening wheel bolts– Push the wheel wrench* fully onto the wheel bolt

6).

– Grasp the end of the wrench* and turn the bolt about one turn to the left

fig. 163 .

Tightening wheel bolts– Push the wheel wrench* fully onto the wheel bolt

6).

– Grasp the end of the wrench* and turn the bolt to the right until it is tight.

WARNING

Slacken the wheel bolts only a little (about one turn) as long as the vehicle has

not yet been lifted with the li fting jack* - risk of accident!

Fig. 161 Removing the cap.Fig. 162 Pulling off wheel trim

cap on light alloy wheels

6)Use the appropriate adapter for slackening and tightening the safety wheel bolts page 172.

Fig. 163 Changing a wheel:

Slackening wheel bolts

s2rc.book Page 171 Thursday, April 22, 2010 10:58 AM

Page 173 of 207

Breakdown assistance

172Note

Apply pressure carefully with your foot to the end of the wrench* if it proves difficult

to slacken the bolts. Hold tight on the vehicl e when doing this and ensure that you have

a steady position.Raise vehicle

You have to raise the vehicle with the lifting jack* in order to be able to

take off the wheel.Place the jack* under the vehicle. Recesses are located at the lower sill (front and rear)

fig. 164 . There is a point under the recess wher e the lifting jack* can be positioned,

see arrows fig. 164 .

– Position the lifting jack* below the jacking point and move it up until its claw is positioned directly below the vertical web of the lower sill.

– Position the lifting jack* so that the claw grasps the web of the lower sill and the

moving base plate of the lifting jack is resting flat against the floor.

– Turn the lifting jack* up further until the wheel is just clear of the ground.

Ground below the lifting jack which is soft and slippery can cause the vehicle to slip

off the jack. It is therefore always necessary to place the lifting jack* on a solid surface

or use a wide and stable base. Use a non-sl ip base (e.g. a rubber foot mat) if the

surface is smooth , such as cobbled stones, a tiled floor, etc.

WARNING

Always raise the vehicle with the doors closed - risk of injury!

Take suitable measures to prevent the ba se of the lifting jack from slipping

off - risk of injury!

Not positioning the lifting jack* at the specified points can result in damage

to the vehicle. The jack can al so slip off if it does not have sufficient grip - risk of

injury!

It is important to support the vehicle with suitable supporting blocks if you

wish to work under the lifted vehicle - risk of injury!

Securing wheels against being stolen*

You need a special adapter for sl ackening the safety wheel bolts.– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel

bolt.

– Insert the adapter with its toothed side fu lly into the inner toothing of the safety

wheel bolt right down in such a way that only the outer hexagon is jutting out

fig. 165 .

– Insert the wheel wrench fully onto the adapter .

– Slacken the wheel bolt, or tighten it firmly page 171.

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the cap onto the safety wheel bolt.

Fig. 164 Changing a wheel:

Jacking points for positioning

lifting jack

AA

AB

Fig. 165 Safety wheel bolt with

adapter

AB

AA

AB

s2rc.book Page 172 Thursday, April 22, 2010 10:58 AM

Page 174 of 207

Breakdown assistance173

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

– Have the

tightening torque checked with a torque wrench as soon as possible.

Steel and light alloy wheels must be tightened to a tightening torque of 120 Nm .

The safety wheel bolts on vehicles fitted wi th them (one safety wheel bolt per wheel)

can only be loosened or tighten up by using the adapter provided.

It is meaningful to note the code number hammered into the rear side of the adapter

or the rear side of the safety wheel bolts. You can obtain a replacement adapter from

a specialist garage, if necess ary, by quoting this number.

We recommend that you always carry the adapter for the wheel bolts with you in the

vehicle. It should be stow ed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety wh eel bolt if the safety wheel bolt is tight-

ened up too much.

Note

The set of safety wheel bolts can be obtained from a specialist garage.Jump-startingInitial stepsYou can use the battery of another vehicle for jump-starting yours if the engine does

not start because the battery on your vehicle is flat. You will require jump-start cables

for this purpose.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the battery

supplying the power must not be significantly less than the capacity of the discharged

battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and insu-

lated terminal clamps. Plea se pay attention to the manufacturer's instructions.

Positive cable - colour coding in the majority of cases red. Negative cable -

colour coding in the majority of cases black.

WARNING

A discharged battery may already freeze at temperatures just below 0°C. In

case of frozen battery carry out no jump-starting - risk of explosion!

Please pay attention to the warning instructions relating to working in the

engine compartment page 148.Note

There must not be any contact between the two vehicles otherwise current may

flow as soon as the negati ve terminals are connected.

The discharged battery must be properly connected to the system of the vehicle.

Switch off any mobile phone, pay attention to the instructions for use of the mobile

phone in such a situation.

We recommend purchasing jump-start cabl es from Škoda Service Partners as a

Škoda original accessory or from retailers who sell branded batteries.

Start engineIt is important to connect the jump-start cables in the correct order.

Fig. 166 Jump-starting using

the battery from another vehicle:

A - flat vehicle battery, B -

battery providing current

s2rc.book Page 173 Thursday, April 22, 2010 10:58 AM