SKODA RAPID 2013 1.G Owner's Manual

Manufacturer: SKODA, Model Year: 2013, Model line: RAPID, Model: SKODA RAPID 2013 1.GPages: 226, PDF Size: 15.16 MB

Page 181 of 226

545 kg

615 kg

630 kg

650 kg

690 kg

Speed symbol

This indicates the maximum permissible vehicle speed with fitted tyres in each

category.

170 km/h

180 km/h

190 km/h

200 km/h

210 km/h

240 km/h

270 km/h

CAUTION

The information about the load index and the speed symbol is listed in your vehi-

cle documents.

Unidirectional tyres

First read and observe the introductory information and safety warn-

ings

on page 175.

The direction of rotation of the tyres is marked by arrows on the wall of the tyre.

The indicated direction of rotation must be adhered to in order to ensure the op- timal characteristics of these tyres.

These characteristics mainly relate to the following: › Increased driving stability.

› Reduced risk of aquaplaning.

› Reduced tyre noise and tyre wear.

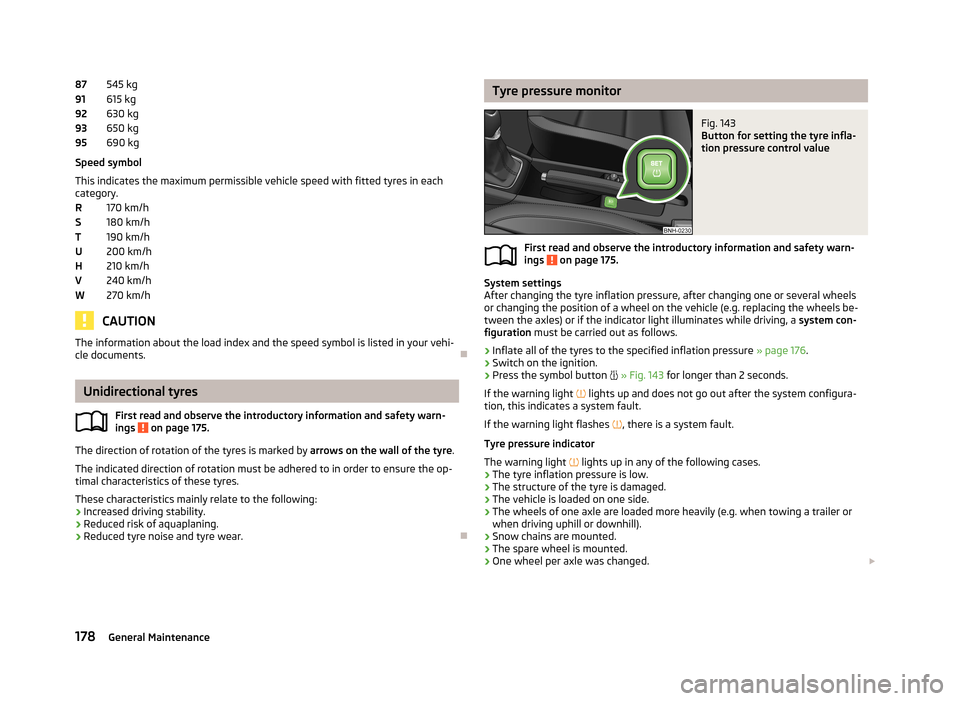

8791929395RSTUHVWTyre pressure monitorFig. 143

Button for setting the tyre infla-

tion pressure control value

First read and observe the introductory information and safety warn-

ings on page 175.

System settings

After changing the tyre inflation pressure, after changing one or several wheels or changing the position of a wheel on the vehicle (e.g. replacing the wheels be- tween the axles) or if the indicator light illuminates while driving, a system con-

figuration must be carried out as follows.

›

Inflate all of the tyres to the specified inflation pressure » page 176.

›

Switch on the ignition.

›

Press the symbol button

» Fig. 143 for longer than 2 seconds.

If the warning light

lights up and does not go out after the system configura-

tion, this indicates a system fault.

If the warning light flashes

, there is a system fault.

Tyre pressure indicator

The warning light

lights up in any of the following cases.

› The tyre inflation pressure is low.

› The structure of the tyre is damaged.

› The vehicle is loaded on one side.

› The wheels of one axle are loaded more heavily (e.g. when towing a trailer or

when driving uphill or downhill).

› Snow chains are mounted.

› The spare wheel is mounted.

› One wheel per axle was changed.

178General Maintenance

Page 182 of 226

WARNING■When the warning light illuminates, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Stop the vehicle as soon as

possible and inspect the tyres and their inflation pressure.■

Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light may light up after a delay, or not at all.

CAUTION

■

The tyre control display does therefore not replace the regular tyre inflation

pressure control, as the system cannot detect an even loss of pressure.■

The system cannot warn in case of very rapid tyre inflation pressure loss, e.g. in

case of sudden tyre damage. In this case carefully bring the vehicle to a standstill

without sudden steering movements or sharp braking.

■

To ensure a proper functioning of the tyre control display, it is necessary to re-

peat the basic setting every 10,000 km or once a year.

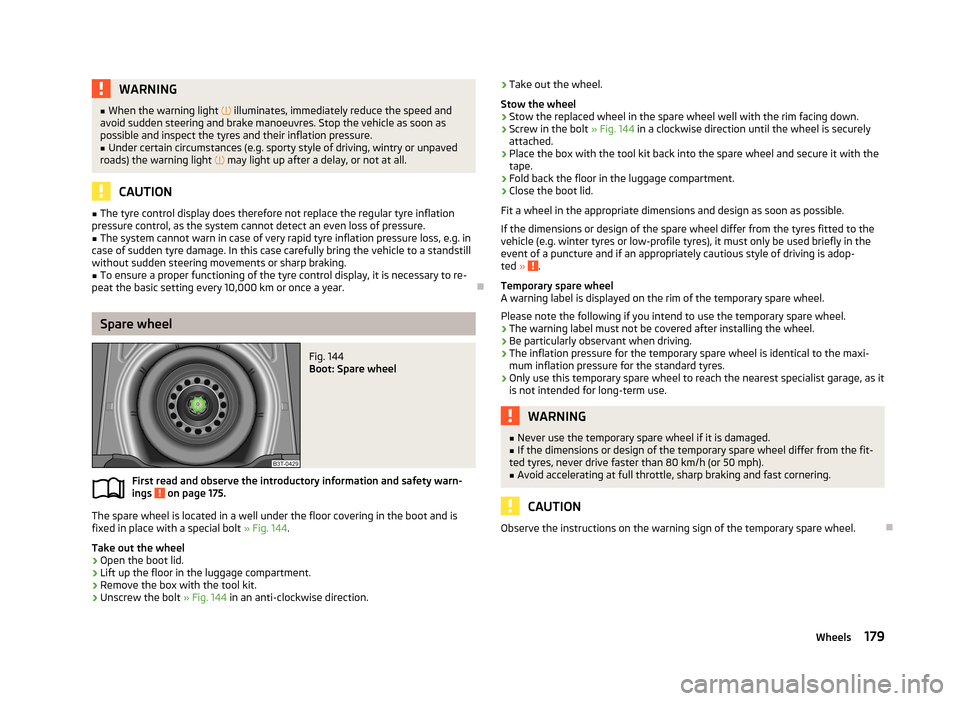

Spare wheel

Fig. 144

Boot: Spare wheel

First read and observe the introductory information and safety warn-

ings on page 175.

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt » Fig. 144.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

›

Remove the box with the tool kit.

›

Unscrew the bolt » Fig. 144 in an anti-clockwise direction.

›Take out the wheel.

Stow the wheel›

Stow the replaced wheel in the spare wheel well with the rim facing down.

›

Screw in the bolt » Fig. 144 in a clockwise direction until the wheel is securely

attached.

›

Place the box with the tool kit back into the spare wheel and secure it with the

tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Fit a wheel in the appropriate dimensions and design as soon as possible.

If the dimensions or design of the spare wheel differ from the tyres fitted to the

vehicle (e.g. winter tyres or low-profile tyres), it must only be used briefly in the

event of a puncture and if an appropriately cautious style of driving is adop-

ted »

.

Temporary spare wheel

A warning label is displayed on the rim of the temporary spare wheel.

Please note the following if you intend to use the temporary spare wheel. › The warning label must not be covered after installing the wheel.

› Be particularly observant when driving.

› The inflation pressure for the temporary spare wheel is identical to the maxi-

mum inflation pressure for the standard tyres.

› Only use this temporary spare wheel to reach the nearest specialist garage, as it

is not intended for long-term use.

WARNING■ Never use the temporary spare wheel if it is damaged.■If the dimensions or design of the temporary spare wheel differ from the fit-

ted tyres, never drive faster than 80 km/h (or 50 mph).■

Avoid accelerating at full throttle, sharp braking and fast cornering.

CAUTION

Observe the instructions on the warning sign of the temporary spare wheel.

179Wheels

Page 183 of 226

Full wheel trimFirst read and observe the introductory information and safety warn-

ings

on page 175.

Extracting

›

Hook the clamp found in the vehicle tool kit into the reinforced edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off the

wheel trim.

Installing

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks cor- rectly in place.

CAUTION

■ Use the pressure of your hand only, do not strike the full wheel trim. Avoid

heavy impacts when the trim has not yet been inserted into the wheel rim. This

could cause damage to the guide and centring elements of the trim.■

When using the anti-theft wheel bolt, ensure that it is in the hole in the valve

area » page 186 , Securing wheels against theft .

■

If wheel trims are retrofitted it must be ensured that an adequate flow of air is

assured to cool the brake system.

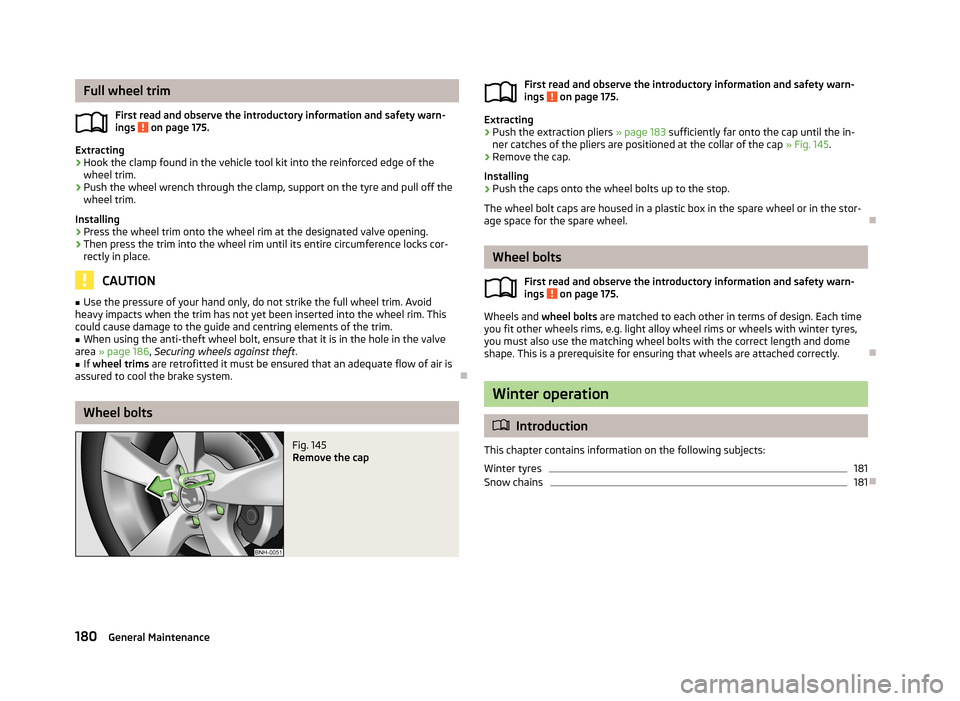

Wheel bolts

Fig. 145

Remove the capFirst read and observe the introductory information and safety warn-

ings on page 175.

Extracting

›

Push the extraction pliers » page 183 sufficiently far onto the cap until the in-

ner catches of the pliers are positioned at the collar of the cap » Fig. 145.

›

Remove the cap.

Installing

›

Push the caps onto the wheel bolts up to the stop.

The wheel bolt caps are housed in a plastic box in the spare wheel or in the stor-

age space for the spare wheel.

Wheel bolts

First read and observe the introductory information and safety warn-ings

on page 175.

Wheels and wheel bolts are matched to each other in terms of design. Each time

you fit other wheels rims, e.g. light alloy wheel rims or wheels with winter tyres,

you must also use the matching wheel bolts with the correct length and dome

shape. This is a prerequisite for ensuring that wheels are attached correctly.

Winter operation

Introduction

This chapter contains information on the following subjects:

Winter tyres

181

Snow chains

181

180General Maintenance

Page 184 of 226

Winter tyresFirst read and observe the introductory information given on page 180.

Fitting winter tyres will significantly improve the handling of your vehicle whendriving in wintry road conditions. Summer tyres have less grip on ice, snow and attemperatures below 7 °C. This is especially true of vehicles fitted with wide tyres

or high-speed tyres .

In order to achieve the best possible handling properties, winter tyres must be fit-

ted on all four wheels, the minimum tread depth must be 4 mm and tyres must be

no older than 4 years.

Winter tyres of a lower speed category can be used provided that the permissible

maximum speed of these tyres is not exceeded even if the possible maximum

speed of the vehicle is higher.

The speed limit for winter tyres can be set in the MAXI DOT display in the menu

item Winter tyres » page 28 .

For the sake of the environment

Fit the summer tyres on again in good time as they provide better handling prop-

erties, a shorter braking distance, less tyre noise, and reduced tyre wear on roadswhich are free of snow and ice as well as at temperatures above 7 °C. The fuel

consumption is also lower.

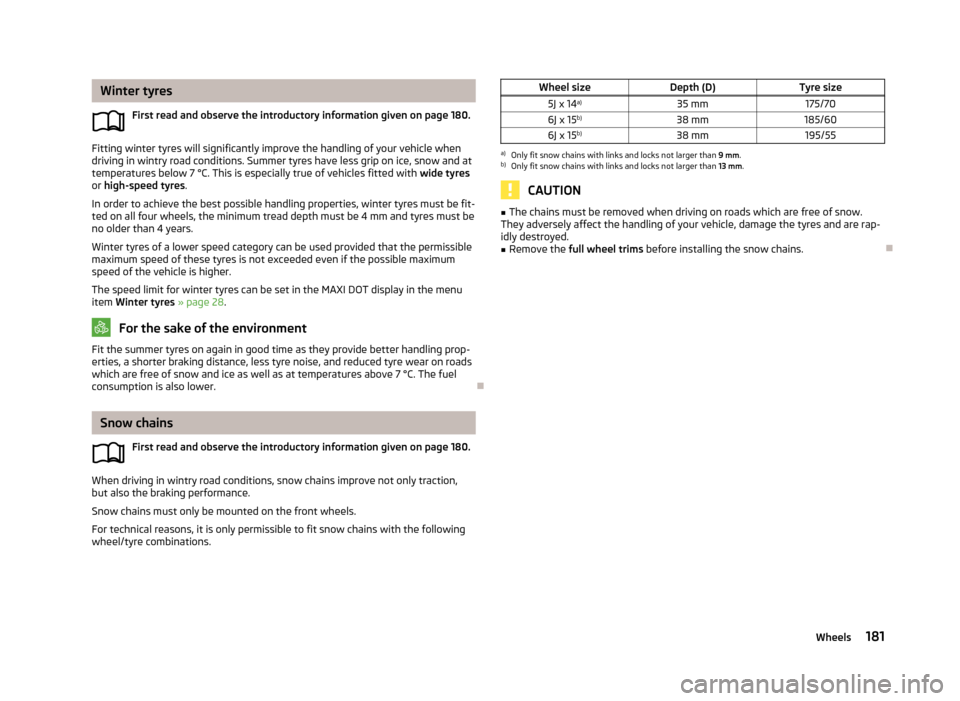

Snow chains

First read and observe the introductory information given on page 180.

When driving in wintry road conditions, snow chains improve not only traction,but also the braking performance.

Snow chains must only be mounted on the front wheels.

For technical reasons, it is only permissible to fit snow chains with the following wheel/tyre combinations.

Wheel sizeDepth (D)Tyre size5J x 14 a)35 mm175/706J x 15 b)38 mm185/606J x 15b)38 mm195/55a)

Only fit snow chains with links and locks not larger than

9 mm.

b)

Only fit snow chains with links and locks not larger than 13 mm.

CAUTION

■

The chains must be removed when driving on roads which are free of snow.

They adversely affect the handling of your vehicle, damage the tyres and are rap-

idly destroyed.■

Remove the full wheel trims before installing the snow chains.

181Wheels

Page 185 of 226

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

First aid kit and warning triangle

182

fire extinguisher

183

Vehicle tool kit

183

First aid kit and warning triangle

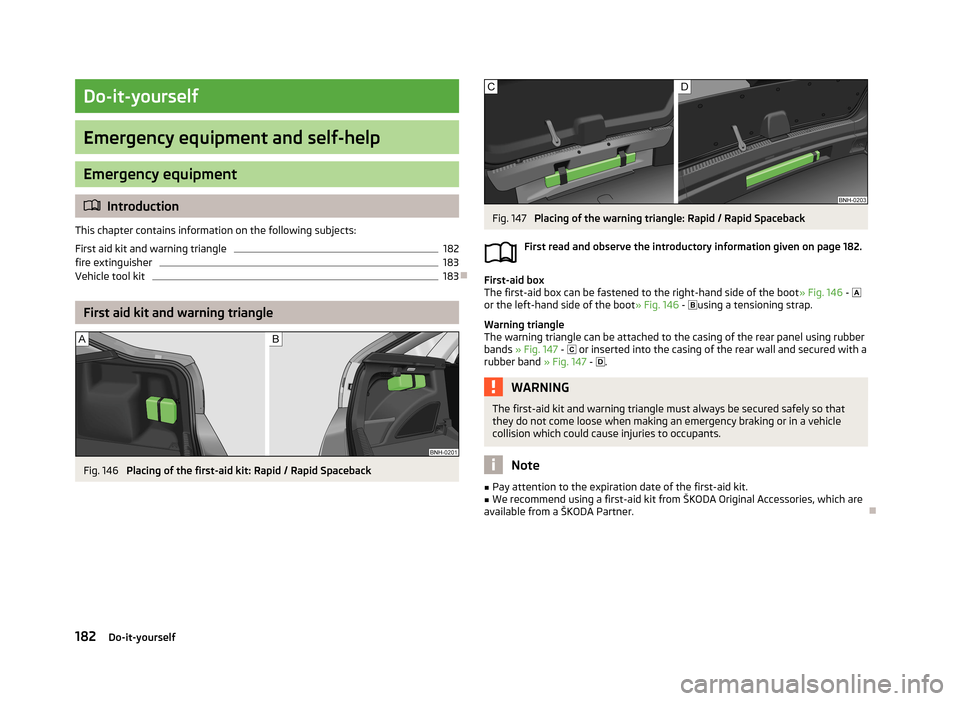

Fig. 146

Placing of the first-aid kit: Rapid / Rapid Spaceback

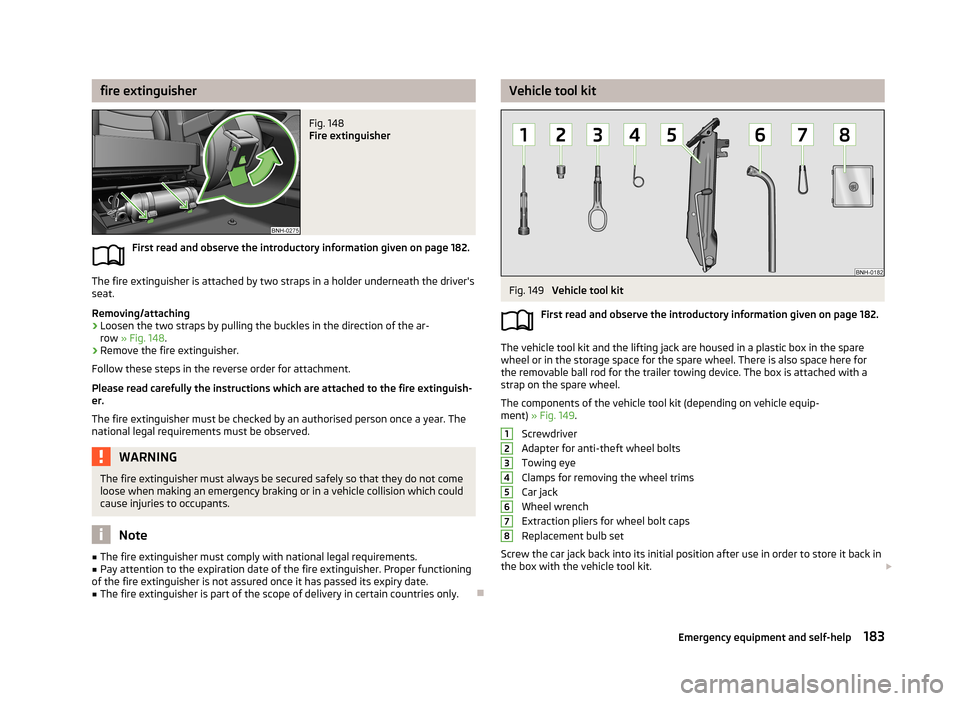

Fig. 147

Placing of the warning triangle: Rapid / Rapid Spaceback

First read and observe the introductory information given on page 182.

First-aid box

The first-aid box can be fastened to the right-hand side of the boot » Fig. 146 -

or the left-hand side of the boot » Fig. 146 -

using a tensioning strap.

Warning triangle

The warning triangle can be attached to the casing of the rear panel using rubber bands » Fig. 147 -

or inserted into the casing of the rear wall and secured with a

rubber band » Fig. 147 -

.

WARNINGThe first-aid kit and warning triangle must always be secured safely so that

they do not come loose when making an emergency braking or in a vehicle

collision which could cause injuries to occupants.

Note

■ Pay attention to the expiration date of the first-aid kit.■We recommend using a first-aid kit from ŠKODA Original Accessories, which are

available from a ŠKODA Partner.

182Do-it-yourself

Page 186 of 226

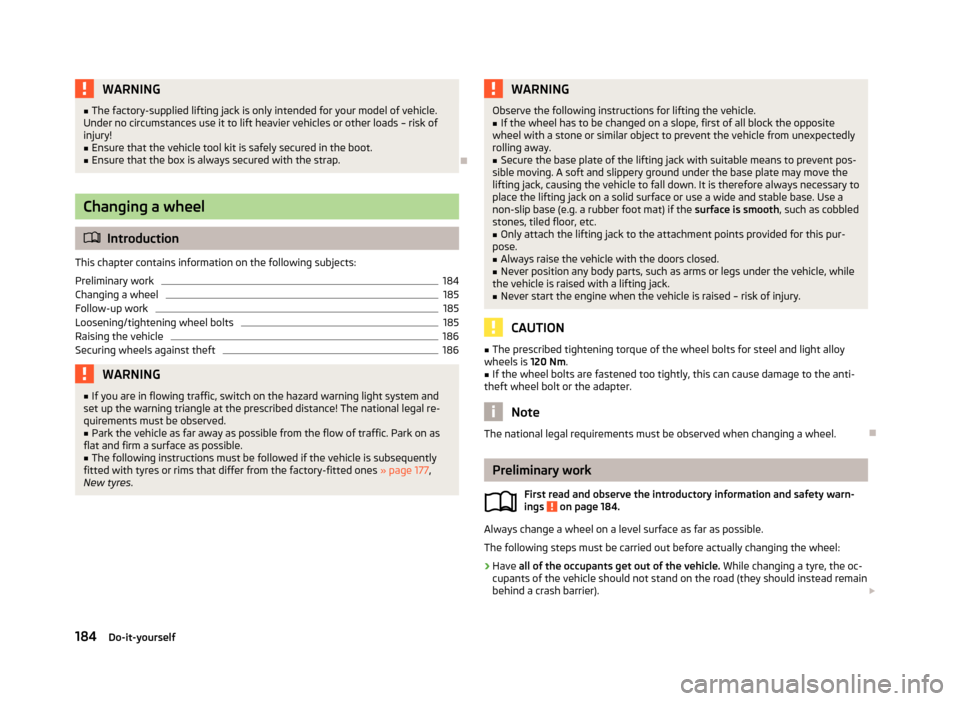

fire extinguisherFig. 148

Fire extinguisher

First read and observe the introductory information given on page 182.

The fire extinguisher is attached by two straps in a holder underneath the driver's

seat.

Removing/attaching

›

Loosen the two straps by pulling the buckles in the direction of the ar- row » Fig. 148 .

›

Remove the fire extinguisher.

Follow these steps in the reverse order for attachment.

Please read carefully the instructions which are attached to the fire extinguish-

er.

The fire extinguisher must be checked by an authorised person once a year. The

national legal requirements must be observed.

WARNINGThe fire extinguisher must always be secured safely so that they do not come loose when making an emergency braking or in a vehicle collision which could

cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper functioning

of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

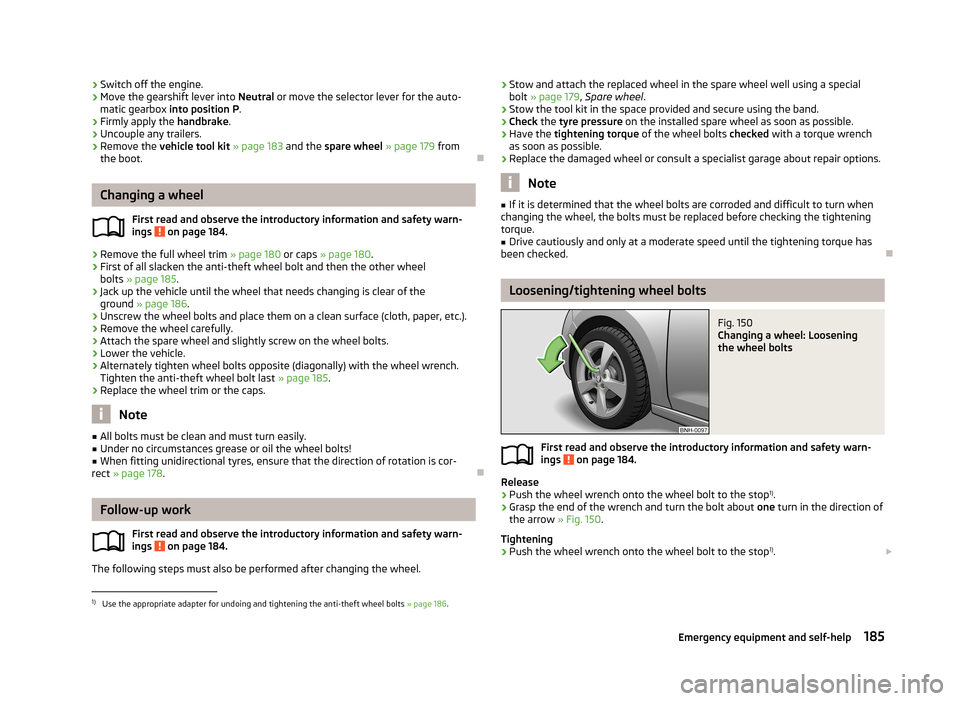

Vehicle tool kitFig. 149

Vehicle tool kit

First read and observe the introductory information given on page 182.

The vehicle tool kit and the lifting jack are housed in a plastic box in the spare

wheel or in the storage space for the spare wheel. There is also space here for

the removable ball rod for the trailer towing device. The box is attached with a

strap on the spare wheel.

The components of the vehicle tool kit (depending on vehicle equip-

ment) » Fig. 149 .

Screwdriver

Adapter for anti-theft wheel bolts

Towing eye

Clamps for removing the wheel trims

Car jack

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb set

Screw the car jack back into its initial position after use in order to store it back in the box with the vehicle tool kit.

12345678183Emergency equipment and self-help

Page 187 of 226

WARNING■The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances use it to lift heavier vehicles or other loads – risk of

injury!■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

184

Changing a wheel

185

Follow-up work

185

Loosening/tightening wheel bolts

185

Raising the vehicle

186

Securing wheels against theft

186WARNING■ If you are in flowing traffic, switch on the hazard warning light system and

set up the warning triangle at the prescribed distance! The national legal re-

quirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on as

flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory-fitted ones » page 177,

New tyres .

WARNINGObserve the following instructions for lifting the vehicle.■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack.

■

Never start the engine when the vehicle is raised – risk of injury.

CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.■

If the wheel bolts are fastened too tightly, this can cause damage to the anti-

theft wheel bolt or the adapter.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

First read and observe the introductory information and safety warn-ings

on page 184.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

›

Have all of the occupants get out of the vehicle. While changing a tyre, the oc-

cupants of the vehicle should not stand on the road (they should instead remain

behind a crash barrier).

184Do-it-yourself

Page 188 of 226

›Switch off the engine.›Move the gearshift lever into

Neutral or move the selector lever for the auto-

matic gearbox into position P .›

Firmly apply the handbrake.

›

Uncouple any trailers.

›

Remove the vehicle tool kit » page 183 and the spare wheel » page 179 from

the boot.

Changing a wheel

First read and observe the introductory information and safety warn-

ings

on page 184.

›

Remove the full wheel trim » page 180 or caps » page 180 .

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 185 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 186 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last » page 185.

›

Replace the wheel trim or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 178 .

Follow-up work

First read and observe the introductory information and safety warn-

ings

on page 184.

The following steps must also be performed after changing the wheel.

› Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 179 , Spare wheel .›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

›

Replace the damaged wheel or consult a specialist garage about repair options.

Note

■ If it is determined that the wheel bolts are corroded and difficult to turn when

changing the wheel, the bolts must be replaced before checking the tightening

torque.■

Drive cautiously and only at a moderate speed until the tightening torque has

been checked.

Loosening/tightening wheel bolts

Fig. 150

Changing a wheel: Loosening

the wheel bolts

First read and observe the introductory information and safety warn- ings on page 184.

Release

›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt about one turn in the direction of

the arrow » Fig. 150.

Tightening

›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 186.

185Emergency equipment and self-help

Page 189 of 226

›Grasp the end of the wrench and turn the bolt against the direction of the ar-

row » Fig. 150 until it is tight.WARNINGUndo the wheel bolts only a little (about one turn) provided that the vehicle

has not yet been jacked up. Otherwise the wheel could come off and fall down – risk of injury!

Note

If it proves difficult to undo the bolts, carefully apply pressure to the end of the

wrench with your foodt. Keep hold of the vehicle when doing so, and make sure

you keep your footing.

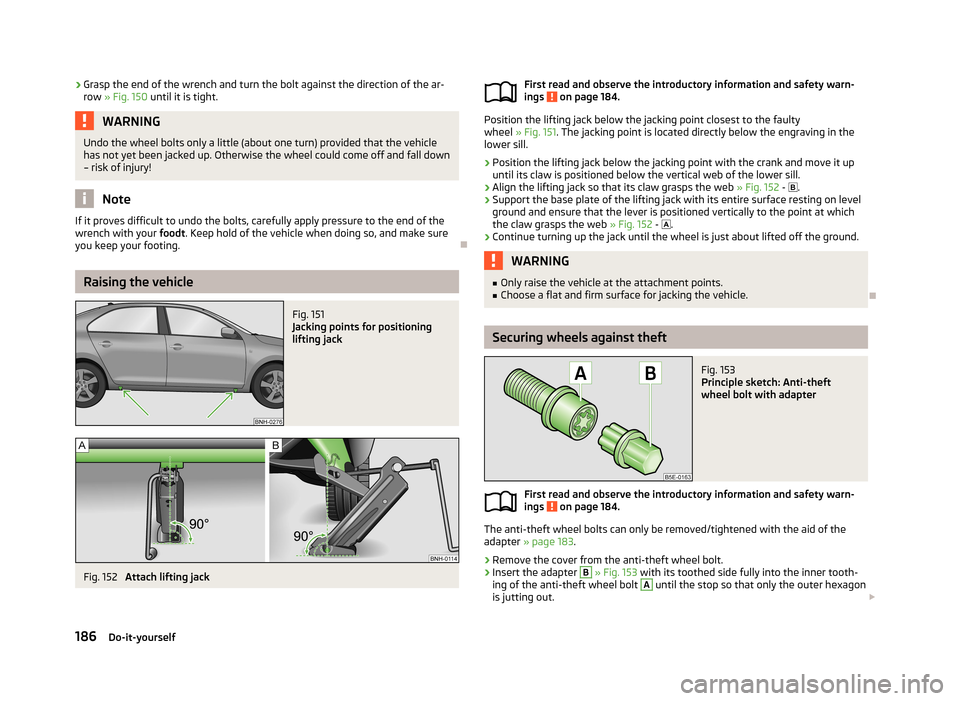

Raising the vehicle

Fig. 151

Jacking points for positioning

lifting jack

Fig. 152

Attach lifting jack

First read and observe the introductory information and safety warn-

ings on page 184.

Position the lifting jack below the jacking point closest to the faulty

wheel » Fig. 151 . The jacking point is located directly below the engraving in the

lower sill.

›

Position the lifting jack below the jacking point with the crank and move it up until its claw is positioned below the vertical web of the lower sill.

›

Align the lifting jack so that its claw grasps the web » Fig. 152 - .

›

Support the base plate of the lifting jack with its entire surface resting on level

ground and ensure that the lever is positioned vertically to the point at which the claw grasps the web » Fig. 152 - .

›

Continue turning up the jack until the wheel is just about lifted off the ground.

WARNING■

Only raise the vehicle at the attachment points.■Choose a flat and firm surface for jacking the vehicle.

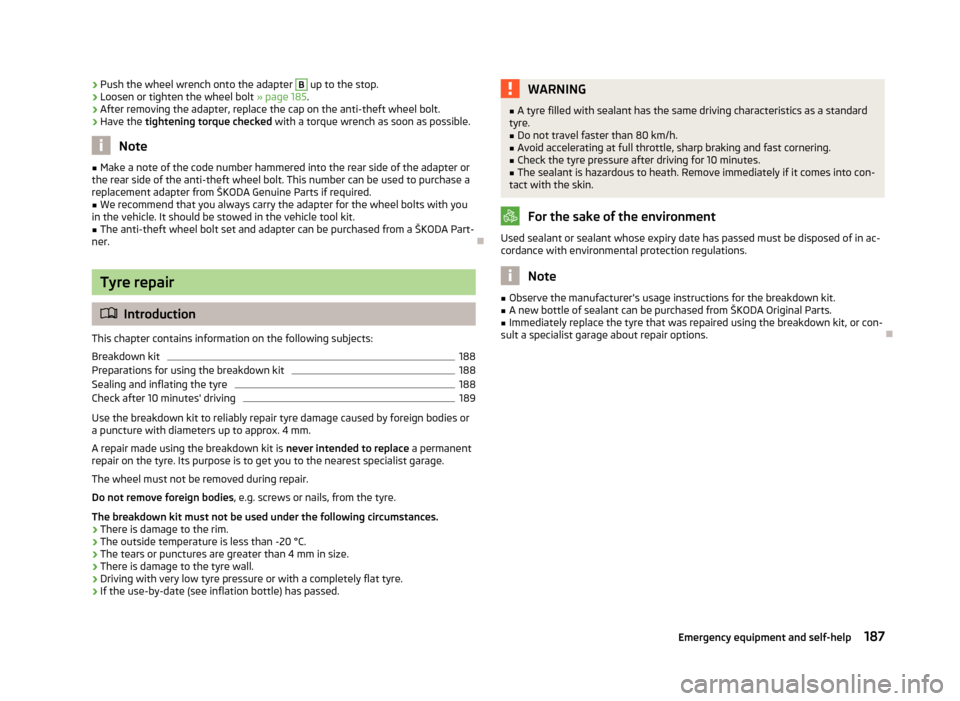

Securing wheels against theft

Fig. 153

Principle sketch: Anti-theft

wheel bolt with adapter

First read and observe the introductory information and safety warn-

ings on page 184.

The anti-theft wheel bolts can only be removed/tightened with the aid of the

adapter » page 183 .

›

Remove the cover from the anti-theft wheel bolt.

›

Insert the adapter

B

» Fig. 153 with its toothed side fully into the inner tooth-

ing of the anti-theft wheel bolt

A

until the stop so that only the outer hexagon

is jutting out.

186Do-it-yourself

Page 190 of 226

›Push the wheel wrench onto the adapter B up to the stop.›Loosen or tighten the wheel bolt

» page 185.›

After removing the adapter, replace the cap on the anti-theft wheel bolt.

›

Have the tightening torque checked with a torque wrench as soon as possible.

Note

■

Make a note of the code number hammered into the rear side of the adapter or

the rear side of the anti-theft wheel bolt. This number can be used to purchase a

replacement adapter from ŠKODA Genuine Parts if required.■

We recommend that you always carry the adapter for the wheel bolts with you

in the vehicle. It should be stowed in the vehicle tool kit.

■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA Part-

ner.

Tyre repair

Introduction

This chapter contains information on the following subjects:

Breakdown kit

188

Preparations for using the breakdown kit

188

Sealing and inflating the tyre

188

Check after 10 minutes' driving

189

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies or

a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a permanent

repair on the tyre. Its purpose is to get you to the nearest specialist garage.

The wheel must not be removed during repair.Do not remove foreign bodies , e.g. screws or nails, from the tyre.

The breakdown kit must not be used under the following circumstances. › There is damage to the rim.

› The outside temperature is less than -20 °C.

› The tears or punctures are greater than 4 mm in size.

› There is damage to the tyre wall.

› Driving with very low tyre pressure or with a completely flat tyre.

› If the use-by-date (see inflation bottle) has passed.

WARNING■

A tyre filled with sealant has the same driving characteristics as a standard

tyre.■

Do not travel faster than 80 km/h.

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

■

Check the tyre pressure after driving for 10 minutes.

■

The sealant is hazardous to heath. Remove immediately if it comes into con-

tact with the skin.

For the sake of the environment

Used sealant or sealant whose expiry date has passed must be disposed of in ac- cordance with environmental protection regulations.

Note

■ Observe the manufacturer's usage instructions for the breakdown kit.■A new bottle of sealant can be purchased from ŠKODA Original Parts.■

Immediately replace the tyre that was repaired using the breakdown kit, or con-

sult a specialist garage about repair options.

187Emergency equipment and self-help