ECU SKODA RAPID 2013 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: RAPID, Model: SKODA RAPID 2013 1.GPages: 226, PDF Size: 15.16 MB

Page 147 of 226

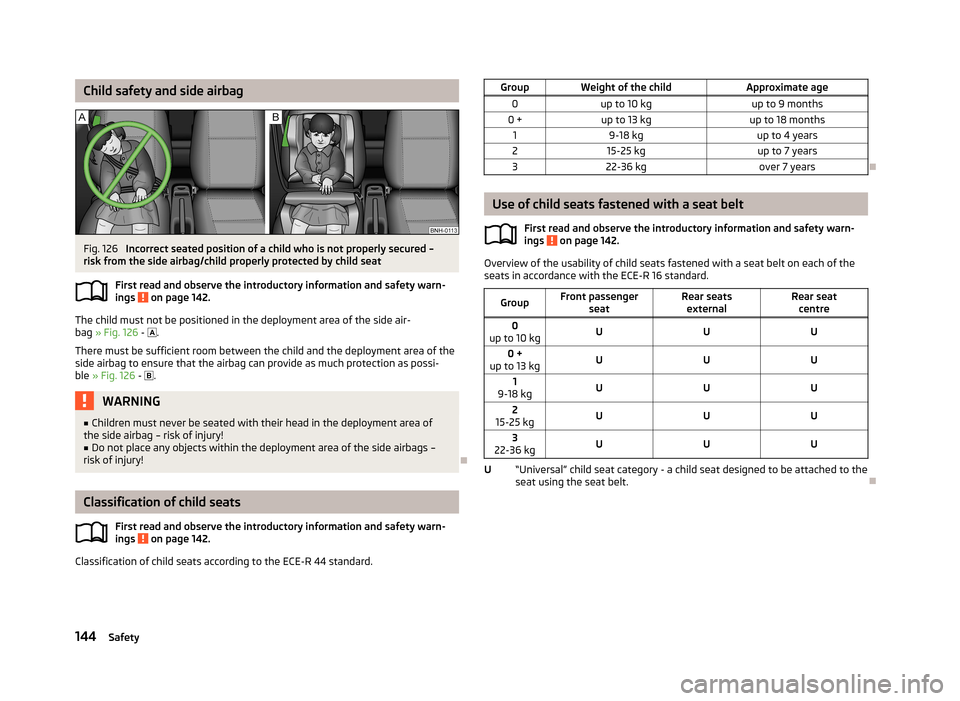

Child safety and side airbagFig. 126

Incorrect seated position of a child who is not properly secured –

risk from the side airbag/child properly protected by child seat

First read and observe the introductory information and safety warn-

ings

on page 142.

The child must not be positioned in the deployment area of the side air-

bag » Fig. 126 -

.

There must be sufficient room between the child and the deployment area of the

side airbag to ensure that the airbag can provide as much protection as possi-

ble » Fig. 126 -

.

WARNING■

Children must never be seated with their head in the deployment area of

the side airbag – risk of injury!■

Do not place any objects within the deployment area of the side airbags –

risk of injury!

Classification of child seats

First read and observe the introductory information and safety warn-

ings

on page 142.

Classification of child seats according to the ECE-R 44 standard.

GroupWeight of the childApproximate age0up to 10 kgup to 9 months0 +up to 13 kgup to 18 months19-18 kgup to 4 years215-25 kgup to 7 years322-36 kgover 7 years

Use of child seats fastened with a seat belt

First read and observe the introductory information and safety warn-ings

on page 142.

Overview of the usability of child seats fastened with a seat belt on each of the

seats in accordance with the ECE-R 16 standard.

GroupFront passenger seatRear seatsexternalRear seat centre0

up to 10 kgUUU0 +

up to 13 kgUUU1

9-18 kgUUU2

15-25 kgUUU3

22-36 kgUUU

“Universal” child seat category - a child seat designed to be attached to the

seat using the seat belt.

U144Safety

Page 164 of 226

›Insert the pump nozzle into the fuel filler neck as far as it will go.

The fuel tank is full just as soon as the pump nozzle switches off for the first time »

.

›

Remove the pump nozzle from the fuel filler neck and put it back in the pump.

›

Place the filler cap onto the fuel filler neck and turn it in the opposite direction

to the arrow until it securely engages » Fig. 131 - .

›

Close the fuel filler flap until it clicks into place.

Check that the fuel filler flap is closed properly.

CAUTION

The fuel tank is full just as soon as the pump nozzle switches off for the first time, provided the nozzle has been operated properly. Do not continue filling the

fuel tank otherwise the expansion volume is filled up.

Note

The fuel tank has a capacity of about 55 litres, containing a reserve of approx. 7

litres .

Unleaded petrol

First read and observe the introductory information and safety warn-

ings

on page 160.

Your vehicle can only be operated with unleaded petrol in compliance with the

EN 228 1)

standard.

All petrol engines can be operated using petrol that contains at most 10% bioe-

thanol (E10).

Required fuel - unleaded petrol 95/91 or 92 or 93 RON

Use unleaded fuel with the octane rating 95 RON. Unleaded petrol with the oc-

tane ratings 91, 92 or 93 RON can also be used, but may result in a slight loss in

performance.

Prescribed fuel – unleaded petrol min. 95 RON Use unleaded fuel with the octane rating 95 RON or higher.

In case of necessity, you can refuel with petrol with the octane ratings 91, 92 or

93 RON, if petrol with the octane rating 95 RON is not available » .

Prescribed fuel – unleaded petrol 98/(95) RON Use unleaded fuel with the octane rating 98 RON or higher. Unleaded petrol

95 RON can also be used but results in a slight loss in performance.

In case of necessity, you can refuel with petrol with the octane ratings 91, 92 or

93 RON, if unleaded fuel with octane rating 98 RON or 95 RON is not availa-

ble »

.

Fuel additives

Unleaded petrol in accordance with the EN 228 standard 1 )

meets all the condi-

tions for a smooth-running engine. We therefore recommend that no fuel addi-

tives are used. This can result in considerable damage to parts of the engine or

the exhaust system.

CAUTION

■ Even filling the tank with leaded petrol that does not meet the standards once

can lead to serious damage to parts of the exhaust system!■

If a fuel other than unleaded fuel which complies to the above mentioned

standards (e.g. leaded petrol) is used by mistake, do not start the engine or

switch on the ignition! Extensive damage to engine parts can occur! We recom-

mend that you have the fuel system cleaned by a specialist garage.

CAUTION

■ If, in an emergency, the vehicle has to be refuelled with petrol of a lower octane

number than the one prescribed, the journey must only be continued at medium

engine speeds and a low engine load. Driving at high engine revs or a high engine

load can severely damage the engine! Refuel using petrol of the prescribed oc-

tane number as soon as possible.■

Engine parts can be damaged if petrol with a lower octane number than the one

prescribed is used.

■

Even in the event of an emergency, petrol of a lower octane number than 91

RON must not be used, otherwise the engine can be severely damaged!

1)

In Germany also DIN 51626-1 or E10 for unleaded petrol with octane number 91 or 95 or DIN 51626-2

or E5 for unleaded petrol with octane number 95 and 98.

161Inspecting and replenishing

Page 166 of 226

WARNINGInjuries or scolding or risks of accident or fire may occur when working in the

engine compartment. For this reason, it is essential to comply with the warn- ing instructions outlined below and with the general applicable safety rules.

The engine compartment of your car is a hazardous area!WARNINGThe following instructions must be followed before starting work in the en-

gine compartment.■

Turn off the engine and withdraw the ignition key.

■

Firmly apply the handbrake.

■

If the vehicle is fitted with a manual gearbox, move the gearshift lever into

Neutral, or if the vehicle is fitted with an automatic gearbox, move the selec-

tor lever into position P.

■

Allow the engine to cool.

■

Never open the bonnet if you can see steam or coolant escaping from the

engine compartment – risk of scalding! Wait until no more steam or coolant is escaping.

WARNINGThe following instructions must be followed when working in the engine com-

partment.■

Keep children clear of the engine compartment.

■

Never touch the radiator fan while the engine is still warm. The fan might

suddenly start running!

■

Do not touch any hot engine parts – risk of burns!

■

The coolant additive and thus all of the coolant is harmful to your health.

■

Avoid contact with the coolant.

■

Coolant vapours are harmful to health.

■

Never open the end cover of the coolant expansion reservoir while the en-

gine is still warm. The cooling system is pressurized!

■

When opening the end cover of the coolant expansion reservoir, cover it

with a cloth to protect your face, hands and arms from hot steam or hot cool-

ant.

■

If any coolant splashes into your eyes, immediately rinse out your eyes with

clear water and contact a doctor as soon as possible.

WARNING (Continued)■ Always store the coolant additive securely in its original container, and in

particular out of the reach of children – risk of poisoning!■

If coolant is swallowed, consult a doctor immediately.

■

Do not leave any items (e.g. cloths or tools) in the engine compartment.

■

Never spill fluids on the hot engine. Such fluids (e.g. the antifreeze con-

tained in the coolant) may ignite!

WARNINGThe following warning instructions must be observed at all times when work-

ing in the engine compartment while the engine is running.■

Pay particular attention to rotating engine parts (e.g. V-ribbed belt, genera-

tor, radiator fan) and the high-voltage ignition system – risk to life!

■

Never touch the electric wiring on the ignition system.

■

Avoid short circuits in the electrical system – particularly on the vehicle's

battery.

■

Always make sure that no jewellery, loose clothing or long hair can get

caught in rotating engine parts – risk to life! Always remove any jewellery, tie

back long hair and wear tight fitting clothing before completing any work.

WARNINGThe following warning instructions must be observed if work has to be carried

out on the fuel or electrical systems.■

Always disconnect the vehicle battery from the electrical system.

■

Do not smoke.

■

Never work near open flames.

■

Always have a functioning fire extinguisher nearby.

WARNING■ Read and observe the information and warning instructions on the fluid con-

tainers.■

Keep fluids in their original containers and keep securely out of the reach of

children!

163Inspecting and replenishing

Page 167 of 226

WARNING (Continued)■If you intend to work underneath the vehicle, you must secure the vehicle

from rolling away and support it with suitable supporting blocks; the car jack

is not sufficient – risk of injury!■

Never cover the engine with additional insulation material (e.g. with a cover)

– risk of fire!

■

The bonnet must always be properly closed when driving. Therefore, the

lock must always be checked after closing the bonnet in order to ensure that

it has engaged properly.

■

If you notice that the lock is not properly engaged while driving, stop the ve-

hicle immediately and close the bonnet – risk of accident!

CAUTION

Always top up using the correct specification of fluids. This may result in major

operating problems and also vehicle damage!

For the sake of the environment

In view of the requirements for the environmentally friendly disposal of fluids and the special tools and knowledge required for such work, we recommend that flu-

ids be changed by a specialist garage.

Note

■ Please consult a specialist garage for any questions relating to fluids.■Fluids with the correct specifications can be purchased from ŠKODA Original Ac-

cessories.

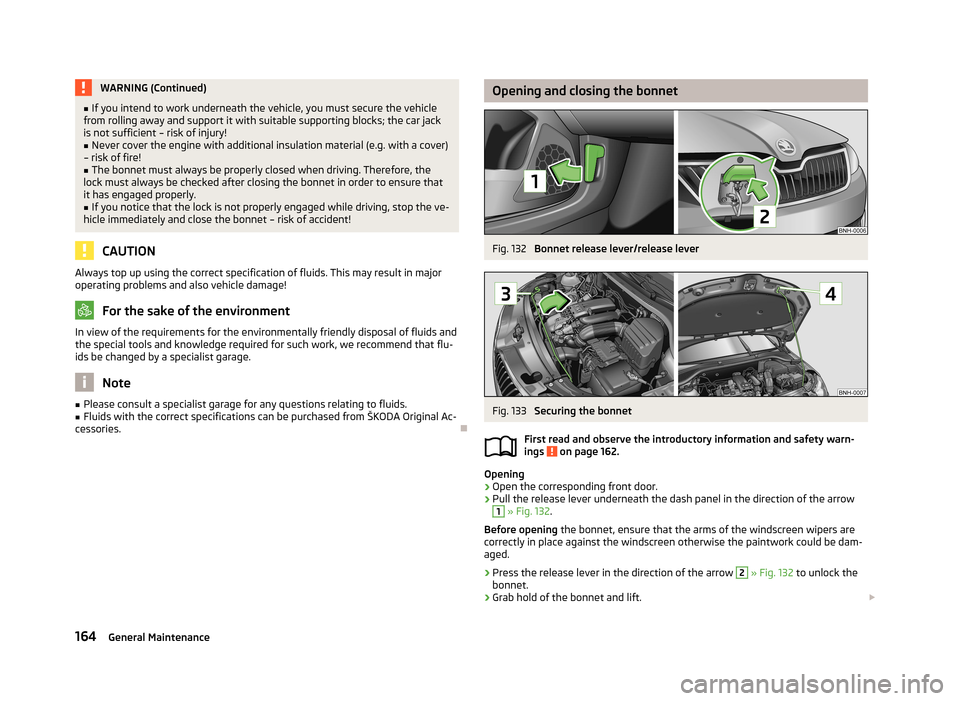

Opening and closing the bonnetFig. 132

Bonnet release lever/release lever

Fig. 133

Securing the bonnet

First read and observe the introductory information and safety warn-

ings

on page 162.

Opening

›

Open the corresponding front door.

›

Pull the release lever underneath the dash panel in the direction of the arrow

1

» Fig. 132 .

Before opening the bonnet, ensure that the arms of the windscreen wipers are

correctly in place against the windscreen otherwise the paintwork could be dam- aged.

›

Press the release lever in the direction of the arrow

2

» Fig. 132 to unlock the

bonnet.

›

Grab hold of the bonnet and lift.

164General Maintenance

Page 168 of 226

›Take the bonnet support out of its holder 3

» Fig. 133 in the direction of the

arrow and secure the opened bonnet by inserting the end of the support into the opening 4

.

Closing

›

Lift the bonnet slightly and unhook the bonnet support. Insert the bonnet sup-

port into the designated holder

3

» Fig. 133 .

›

Let the bonnet drop into the lock carrier lock from a height of around 20 cm – do

not push it in .

WARNINGCheck that the bonnet is closed properly.

CAUTION

Never open the bonnet using the release lever » Fig. 132.

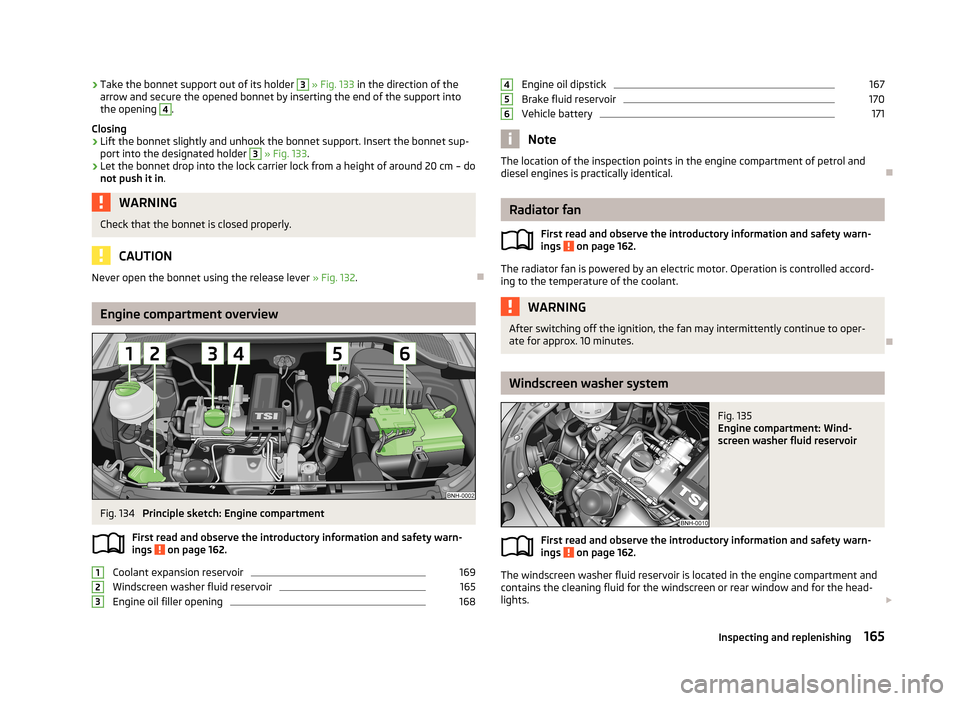

Engine compartment overview

Fig. 134

Principle sketch: Engine compartment

First read and observe the introductory information and safety warn- ings

on page 162.

Coolant expansion reservoir

169

Windscreen washer fluid reservoir

165

Engine oil filler opening

168123Engine oil dipstick167Brake fluid reservoir170

Vehicle battery

171

Note

The location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

First read and observe the introductory information and safety warn-

ings

on page 162.

The radiator fan is powered by an electric motor. Operation is controlled accord-

ing to the temperature of the coolant.

WARNINGAfter switching off the ignition, the fan may intermittently continue to oper-

ate for approx. 10 minutes.

Windscreen washer system

Fig. 135

Engine compartment: Wind-

screen washer fluid reservoir

First read and observe the introductory information and safety warn- ings on page 162.

The windscreen washer fluid reservoir is located in the engine compartment and

contains the cleaning fluid for the windscreen or rear window and for the head-

lights.

456165Inspecting and replenishing

Page 176 of 226

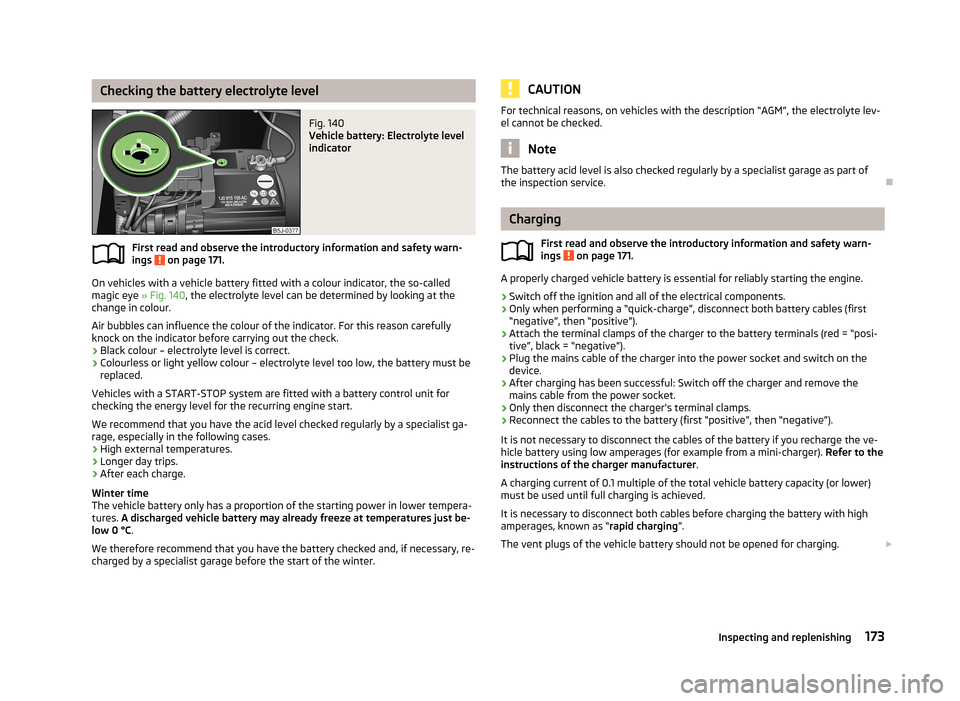

Checking the battery electrolyte levelFig. 140

Vehicle battery: Electrolyte level

indicator

First read and observe the introductory information and safety warn-

ings on page 171.

On vehicles with a vehicle battery fitted with a colour indicator, the so-called

magic eye » Fig. 140, the electrolyte level can be determined by looking at the

change in colour.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

› Black colour – electrolyte level is correct.

› Colourless or light yellow colour – electrolyte level too low, the battery must be

replaced.

Vehicles with a START-STOP system are fitted with a battery control unit for checking the energy level for the recurring engine start.

We recommend that you have the acid level checked regularly by a specialist ga-

rage, especially in the following cases.

› High external temperatures.

› Longer day trips.

› After each charge.

Winter time

The vehicle battery only has a proportion of the starting power in lower tempera-

tures. A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C .

We therefore recommend that you have the battery checked and, if necessary, re-

charged by a specialist garage before the start of the winter.

CAUTIONFor technical reasons, on vehicles with the description “AGM”, the electrolyte lev- el cannot be checked.

Note

The battery acid level is also checked regularly by a specialist garage as part of

the inspection service.

Charging

First read and observe the introductory information and safety warn-ings

on page 171.

A properly charged vehicle battery is essential for reliably starting the engine.

›

Switch off the ignition and all of the electrical components.

›

Only when performing a “quick-charge”, disconnect both battery cables (first

“negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red = “posi- tive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch on the

device.

›

After charging has been successful: Switch off the charger and remove themains cable from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

It is not necessary to disconnect the cables of the battery if you recharge the ve-

hicle battery using low amperages (for example from a mini-charger). Refer to the

instructions of the charger manufacturer .

A charging current of 0.1 multiple of the total vehicle battery capacity (or lower) must be used until full charging is achieved.

It is necessary to disconnect both cables before charging the battery with high

amperages, known as “ rapid charging”.

The vent plugs of the vehicle battery should not be opened for charging.

173Inspecting and replenishing

Page 182 of 226

WARNING■When the warning light illuminates, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Stop the vehicle as soon as

possible and inspect the tyres and their inflation pressure.■

Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light may light up after a delay, or not at all.

CAUTION

■

The tyre control display does therefore not replace the regular tyre inflation

pressure control, as the system cannot detect an even loss of pressure.■

The system cannot warn in case of very rapid tyre inflation pressure loss, e.g. in

case of sudden tyre damage. In this case carefully bring the vehicle to a standstill

without sudden steering movements or sharp braking.

■

To ensure a proper functioning of the tyre control display, it is necessary to re-

peat the basic setting every 10,000 km or once a year.

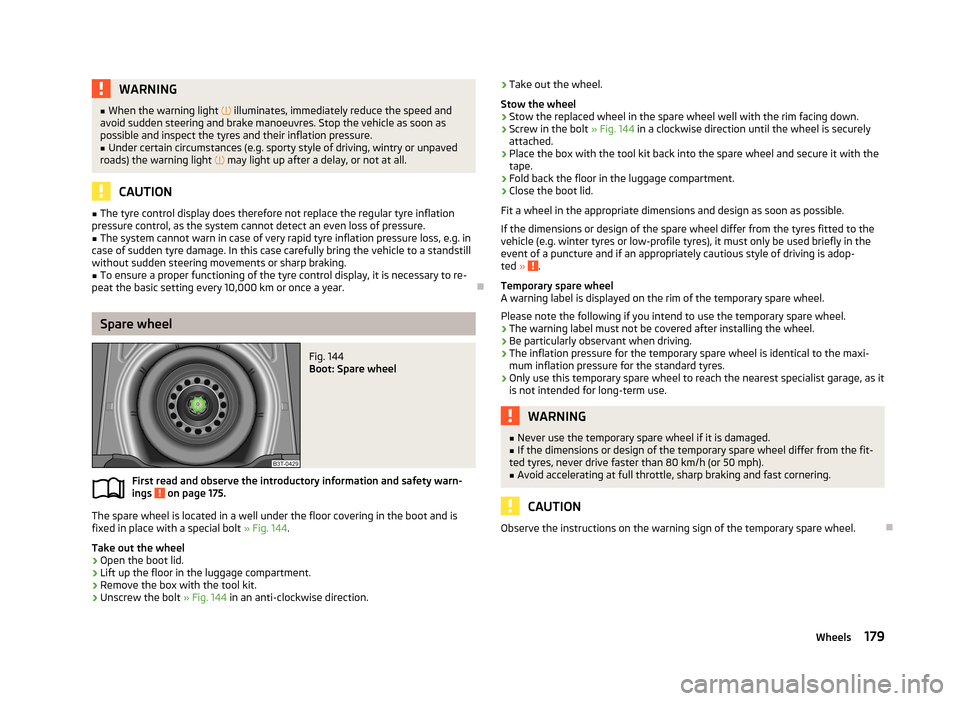

Spare wheel

Fig. 144

Boot: Spare wheel

First read and observe the introductory information and safety warn-

ings on page 175.

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt » Fig. 144.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

›

Remove the box with the tool kit.

›

Unscrew the bolt » Fig. 144 in an anti-clockwise direction.

›Take out the wheel.

Stow the wheel›

Stow the replaced wheel in the spare wheel well with the rim facing down.

›

Screw in the bolt » Fig. 144 in a clockwise direction until the wheel is securely

attached.

›

Place the box with the tool kit back into the spare wheel and secure it with the

tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Fit a wheel in the appropriate dimensions and design as soon as possible.

If the dimensions or design of the spare wheel differ from the tyres fitted to the

vehicle (e.g. winter tyres or low-profile tyres), it must only be used briefly in the

event of a puncture and if an appropriately cautious style of driving is adop-

ted »

.

Temporary spare wheel

A warning label is displayed on the rim of the temporary spare wheel.

Please note the following if you intend to use the temporary spare wheel. › The warning label must not be covered after installing the wheel.

› Be particularly observant when driving.

› The inflation pressure for the temporary spare wheel is identical to the maxi-

mum inflation pressure for the standard tyres.

› Only use this temporary spare wheel to reach the nearest specialist garage, as it

is not intended for long-term use.

WARNING■ Never use the temporary spare wheel if it is damaged.■If the dimensions or design of the temporary spare wheel differ from the fit-

ted tyres, never drive faster than 80 km/h (or 50 mph).■

Avoid accelerating at full throttle, sharp braking and fast cornering.

CAUTION

Observe the instructions on the warning sign of the temporary spare wheel.

179Wheels

Page 183 of 226

Full wheel trimFirst read and observe the introductory information and safety warn-

ings

on page 175.

Extracting

›

Hook the clamp found in the vehicle tool kit into the reinforced edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off the

wheel trim.

Installing

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks cor- rectly in place.

CAUTION

■ Use the pressure of your hand only, do not strike the full wheel trim. Avoid

heavy impacts when the trim has not yet been inserted into the wheel rim. This

could cause damage to the guide and centring elements of the trim.■

When using the anti-theft wheel bolt, ensure that it is in the hole in the valve

area » page 186 , Securing wheels against theft .

■

If wheel trims are retrofitted it must be ensured that an adequate flow of air is

assured to cool the brake system.

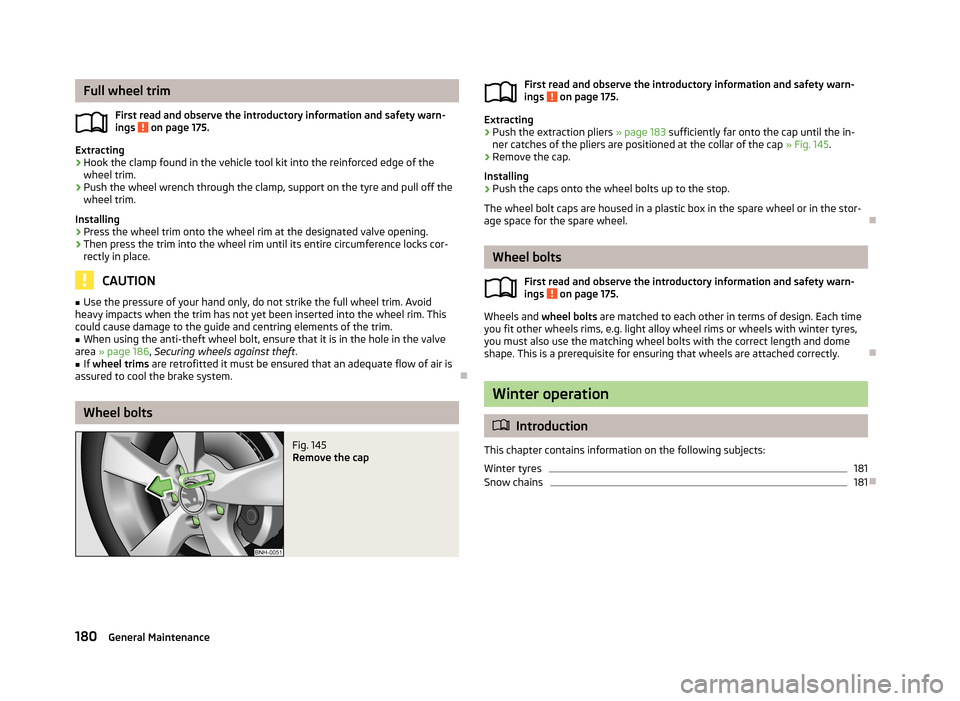

Wheel bolts

Fig. 145

Remove the capFirst read and observe the introductory information and safety warn-

ings on page 175.

Extracting

›

Push the extraction pliers » page 183 sufficiently far onto the cap until the in-

ner catches of the pliers are positioned at the collar of the cap » Fig. 145.

›

Remove the cap.

Installing

›

Push the caps onto the wheel bolts up to the stop.

The wheel bolt caps are housed in a plastic box in the spare wheel or in the stor-

age space for the spare wheel.

Wheel bolts

First read and observe the introductory information and safety warn-ings

on page 175.

Wheels and wheel bolts are matched to each other in terms of design. Each time

you fit other wheels rims, e.g. light alloy wheel rims or wheels with winter tyres,

you must also use the matching wheel bolts with the correct length and dome

shape. This is a prerequisite for ensuring that wheels are attached correctly.

Winter operation

Introduction

This chapter contains information on the following subjects:

Winter tyres

181

Snow chains

181

180General Maintenance

Page 185 of 226

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

First aid kit and warning triangle

182

fire extinguisher

183

Vehicle tool kit

183

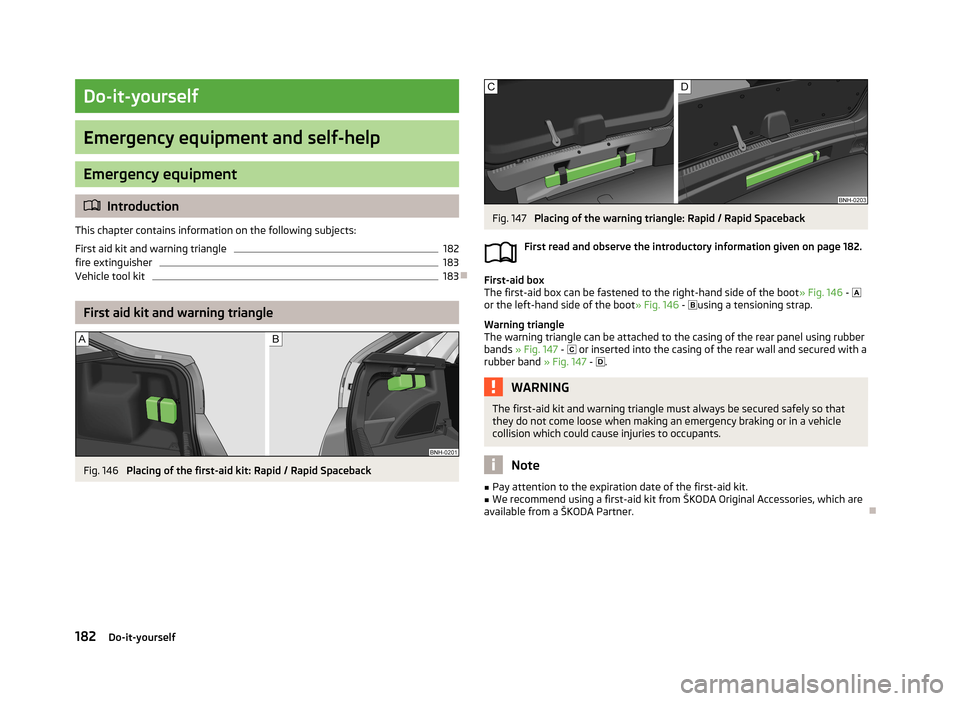

First aid kit and warning triangle

Fig. 146

Placing of the first-aid kit: Rapid / Rapid Spaceback

Fig. 147

Placing of the warning triangle: Rapid / Rapid Spaceback

First read and observe the introductory information given on page 182.

First-aid box

The first-aid box can be fastened to the right-hand side of the boot » Fig. 146 -

or the left-hand side of the boot » Fig. 146 -

using a tensioning strap.

Warning triangle

The warning triangle can be attached to the casing of the rear panel using rubber bands » Fig. 147 -

or inserted into the casing of the rear wall and secured with a

rubber band » Fig. 147 -

.

WARNINGThe first-aid kit and warning triangle must always be secured safely so that

they do not come loose when making an emergency braking or in a vehicle

collision which could cause injuries to occupants.

Note

■ Pay attention to the expiration date of the first-aid kit.■We recommend using a first-aid kit from ŠKODA Original Accessories, which are

available from a ŠKODA Partner.

182Do-it-yourself

Page 186 of 226

fire extinguisherFig. 148

Fire extinguisher

First read and observe the introductory information given on page 182.

The fire extinguisher is attached by two straps in a holder underneath the driver's

seat.

Removing/attaching

›

Loosen the two straps by pulling the buckles in the direction of the ar- row » Fig. 148 .

›

Remove the fire extinguisher.

Follow these steps in the reverse order for attachment.

Please read carefully the instructions which are attached to the fire extinguish-

er.

The fire extinguisher must be checked by an authorised person once a year. The

national legal requirements must be observed.

WARNINGThe fire extinguisher must always be secured safely so that they do not come loose when making an emergency braking or in a vehicle collision which could

cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper functioning

of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

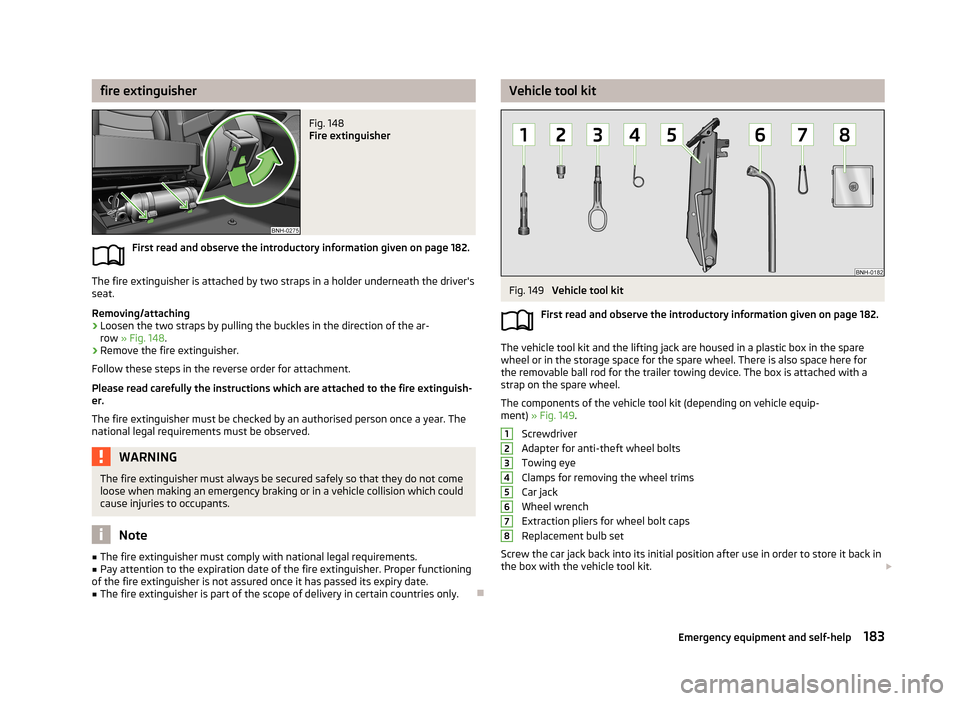

Vehicle tool kitFig. 149

Vehicle tool kit

First read and observe the introductory information given on page 182.

The vehicle tool kit and the lifting jack are housed in a plastic box in the spare

wheel or in the storage space for the spare wheel. There is also space here for

the removable ball rod for the trailer towing device. The box is attached with a

strap on the spare wheel.

The components of the vehicle tool kit (depending on vehicle equip-

ment) » Fig. 149 .

Screwdriver

Adapter for anti-theft wheel bolts

Towing eye

Clamps for removing the wheel trims

Car jack

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb set

Screw the car jack back into its initial position after use in order to store it back in the box with the vehicle tool kit.

12345678183Emergency equipment and self-help