boot SKODA RAPID 2015 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: RAPID, Model: SKODA RAPID 2015 1.GPages: 204, PDF Size: 27.52 MB

Page 160 of 204

Remove the wheel / fix161Follow-up work161

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard warning lights system.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from the flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

Preliminary work

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear.

›

On vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Uncouple trailer, if attached.

Removing/stowing the wheel

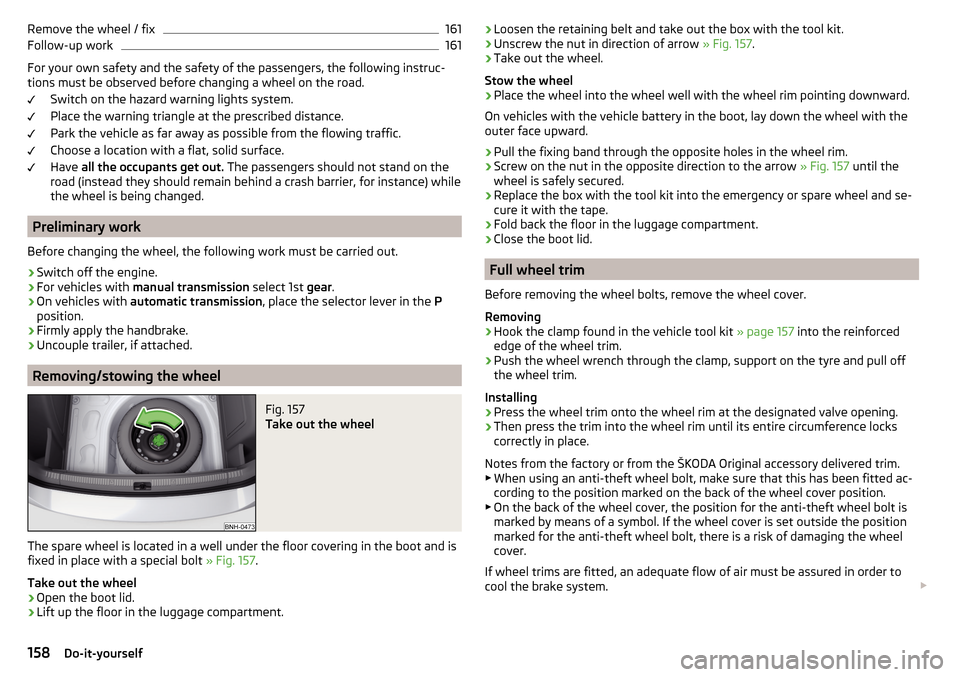

Fig. 157

Take out the wheel

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt » Fig. 157.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

› Loosen the retaining belt and take out the box with the tool kit.›Unscrew the nut in direction of arrow

» Fig. 157.›

Take out the wheel.

Stow the wheel

›

Place the wheel into the wheel well with the wheel rim pointing downward.

On vehicles with the vehicle battery in the boot, lay down the wheel with the

outer face upward.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw on the nut in the opposite direction to the arrow » Fig. 157 until the

wheel is safely secured.

›

Replace the box with the tool kit into the emergency or spare wheel and se-

cure it with the tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Full wheel trim

Before removing the wheel bolts, remove the wheel cover.

Removing

›

Hook the clamp found in the vehicle tool kit » page 157 into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

Notes from the factory or from the ŠKODA Original accessory delivered trim.

▶ When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.

▶ On the back of the wheel cover, the position for the anti-theft wheel bolt is

marked by means of a symbol. If the wheel cover is set outside the position

marked for the anti-theft wheel bolt, there is a risk of damaging the wheel

cover.

If wheel trims are fitted, an adequate flow of air must be assured in order to

cool the brake system.

158Do-it-yourself

Page 165 of 204

Preparations for using the breakdown kitRead and observe

on page 162 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear.

›

On vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 162,

General information .

›

Uncouple trailer, if attached.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 163 on page 162 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 162 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 163 on page 162 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

7

» Fig. 163 on page 162 of the air compressor

firmly onto the tyre valve.

›

For vehicles with manual transmission the lever into the neutral position.

›On vehicles with

automatic transmission , place the selector lever in the P

position.›

Start the engine and run it in idle.

›

Plug the connector

6

into the 12-volt socket » page 75.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0 - 2.5 bar is achieved, you can continue the journey.

WARNING■ If the tyre does not inflate to at least. 2.0 bar, the damage is too great.

The sealing agent cannot be used to seal the tyre. Do not drive the vehi-

cle. Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – there is a risk of burning.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating. Allow the air compressor to cool a few minutes before

switching it on again.

Notes for driving with tyre repaired

Read and observe

on page 162 first.

The inflation pressure of the repaired tyre must be checked after driving for 10minutes.

If the tyre pressure is 1.3 bar or less

›

Do not continue to drive! You cannot properly seal with tyre with the

breakdown kit.

163Emergency equipment and self-help

Page 167 of 204

The jump-start cable must be connected to the engine earthing point C» Fig. 164 only on vehicles with the START-STOP system.

Starting engine›

Start the engine on the vehicle providing the power and allow it to idle.

›

Start the engine of the vehicle with the discharged battery.

›

If the engine does not start, halt the attempt to start the engine after 10 sec-

onds and wait for 30 seconds before repeating the process.

›

Remove the jump start cables in the reverse order as attachment.

Engines in vehicles with the vehicle battery in the boot

The positive terminal

A

is located under a cover in the engine compartment

» Fig. 165 .

›

Unlock the retainer tab on the cover in direction of arrow

1

.

›

Open the cover in the direction of the arrow

2

.

›

Clamp the positive terminal of the jumper cable to the position

A

» Fig. 165 .

›

Clamp the negative terminal of the jumper cable to the earthing point of the

engine

D

» Fig. 164 or on a metal part firmly connected to the engine block

or directly on the engine block.

›

Remove the jump start cables in the reverse order as attachment.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the bat-

tery supplying the power must not be significantly less than the capacity of

the discharged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and

insulated terminal clamps. Observe the instructions of the jumper lead manu-

facturer.

Positive cable – colour coding in the majority of cases is red.

Negative cable – colour coding in the majority of cases is black.

WARNING■

Do not clamp the jump-start cable to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being star-

ted.■

The non-insulated parts of the terminal clamps must never touch each

other – there is a risk of short circuit.

WARNING (Continued)■ The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– there is a risk of short circuit.■

Route the jump-start cables so that they cannot be caught by any rotat-

ing parts in the engine compartment.

Towing the vehicle

Introduction

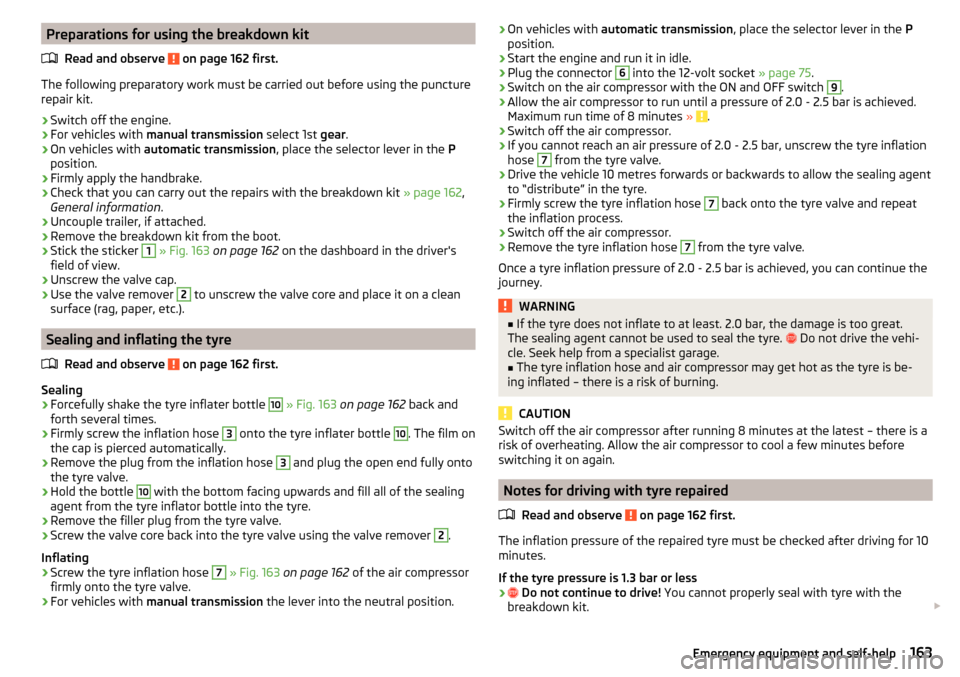

Fig. 166

Braided tow rope / Spiral tow rope

This chapter contains information on the following subjects:

Front towing eye

166

Rear towing eye

167

Vehicles with a tow hitch

167

For towing a braided tow rope is to be used » Fig. 166-

.

When towing, the following guidelines must be observed.

Vehicles with manual transmission may be towed in with a tow bar or a tow

rope or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at the rear, the au-

tomatic gearbox will be damaged! If possible, the vehicle should be towed with

the engine running or at least with the ignition on.

Driver of the tow vehicle

›

Engage the clutch gently when starting off or depress the accelerator partic-

ularly gently if the vehicle is fitted with an automatic gearbox.

165Emergency equipment and self-help

Page 170 of 204

›Insert the new battery.›Insert the battery cover A and press it down until it clicks audibly into place.

Synchronising the remote control

Read and observe

on page 167 first.

If the vehicle does not unlock when pressing the remote control, the key may

not be synchronised. This can occur when the buttons on the remote control

key are actuated a number of times outside of the operative range of the

equipment or the battery in the remote control key has been replaced.

Synchronise the key as follows.

›

Press any button on the remote control key.

›

Unlock the door with the key in the lock cylinder within 1 minute of pressing the button.

Emergency unlocking/locking

Introduction

This chapter contains information on the following subjects:

Locking the door without a locking cylinder

168

Unlock the boot lid

168

Selector lever-emergency unlocking

168

Locking the door without a locking cylinder

Fig. 170

Emergency locking: Left/right rear door

An emergency locking mechanism is located on the face side of the doors

which have no locking cylinder, it is only visible after opening the door.

› Remove the cover A

» Fig. 170 .›Insert the vehicle key into the slot and turn in the direction of the arrow

(sprung position).›

Replace the cover

A

.

Unlock the boot lid

Fig. 171

Unlocking the boot lid

The boot lid can be unlocked manually.

›

Fold the rear seat backrest forward » page 71.

›

Insert a screwdriver or similar tool into the recess in the trim » Fig. 171 as far

as the stop.

›

Unlock the lid by moving it in the direction of the arrow.

›

Open the boot lid.

Selector lever-emergency unlocking

Fig. 172

Selector lever-emergency unlocking

›

Firmly apply the handbrake.

›

With one hand on the edge of the cover, push in direction of arrow

1

» Fig. 172 .

168Do-it-yourself

Page 176 of 204

Replacing the bulb for the licence plate light177Rear Light177

Replacing bulbs in rear light

178

Some manual skills are required to change a bulb. For this reason, we recom-

mend having bulbs replaced by a specialist garage or seeking other expert help

in the event of any uncertainties.

▶ Switch off the ignition and the relevant lights before replacing a bulb.

▶ Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

A stowage compartment for replacement bulbs is located in a plastic box in

the spare wheel or underneath the floor covering in the boot.

We recommend having the headlight settings checked by a specialist garage

after replacing a bulb in the low, high or fog beam.

In case of failure of a xenon gas discharge lamp or an LED diode, visit a special- ist garage.

WARNING■ Always read and observe the warning notes before completing any work

in the engine compartment » page 139.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

H7 and H15 bulbs are pressurised and may burst when changing the bulb -

risk of injury! We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Do not carry out any work on the Xenon gas discharge lamps - risk of

death!

CAUTION

■ Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.■

The protective cap of the bulb must always be properly inserted into the

headlamp. Water and dirt may get into the headlamp if the cover is not re-

placed properly - there is a risk of damage to the headlamp!

Note■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

Bulb arrangement in the headlights

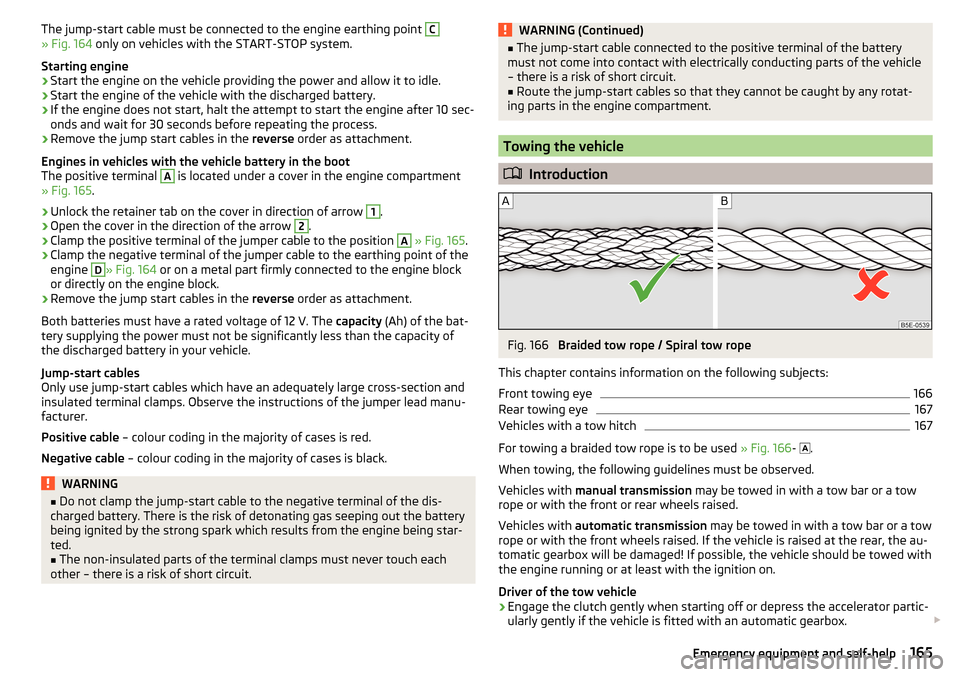

Fig. 180

Principle sketch: Headlights

Read and observe and on page 174 first.

Bulb arrangement » Fig. 180

Low beam or low beam with xenon gas discharge lamp

Main beam, separate daytime running lights, and parking light

Turn signal light (at the front)

ABC174Do-it-yourself

Page 179 of 204

›Attach the connector.

Refit the headlight and grille›

Replace the fog light by inserting it in the opposite direction of the arrow

4

» Fig. 185 and tightening.

›

Insert the protective grille and carefully press it in.

The protective grille must engage firmly.

Replacing the bulb for the licence plate light

Fig. 186

Remove the number plate light/replace the bulb

Read and observe

and on page 174 first.

›

Open the boot lid.

›

Push in the lamp in the direction of the arrow

1

» Fig. 186 .

The lamp comes loose.

›

Swivel out the lamp in the direction of the arrow

2

and remove it.

›

Remove the faulty bulb from the holder in the direction of the arrow

3

.

›

Insert a new bulb into the holder.

›

Reinsert the lamp in the opposite direction to the arrow

1

.

›

Push on the light until the spring clicks into place.

Check that the light is securely inserted.

Rear LightFig. 187

Remove light / pull out connector

Read and observe

and on page 174 first.

Removing

›

Open the boot lid.

›

Insert the clamps for removing the full wheel covers » page 157, Vehicle tool

kit into opening

A

» Fig. 187 .

›

Remove the cover by pulling the hook in the direction of arrow

1

.

›

Unscrew the screws

B

with the key from the tool kit.

›

Grasp the lamp and carefully remove in the direction of arrow

2

.

›

Press the latch on the connector in the direction of arrow

3

.

›

Carefully remove the connector from the tail lamp assembly in the direction

of the arrow

4

.

Fitting

›

Insert the bulb holder into the lamp.

The lock on the plug must be inserted securely.

›

Insert the lamp with the pin

B

» Fig. 188 on page 178 into the recesses

C

» Fig. 187 in the body.

177Fuses and light bulbs

Page 189 of 204

Index

A

abroad lead-free petrol

137

Abroad Headlights

63

ABS Operation

106

Warning light33

Acceptance and recycling of used vehicles129

Accessories126

Adjusting Exterior mirror

67

head restraints69

Seat68

Steering wheel9

Adjusting the seats8

Adjustment Beam range

59

Advance warning/emergency braking Warning light

38

Air-conditioning system Air outlet vents

90

Airbag14

Deactivating18

Deactivating the front passenger airbag18

Deployment15

Front airbag15

Head airbag17

Modifications and damage to the airbag system 128

Side airbag

16

Warning light34

Airbag system14

Air conditioning86

Air distribution control89

Climatronic88

Manual air conditioning87

Air distribution control89

Air outlet vents90

Alarm Enable/disable

54

Switch off54

Trailer124

Triggering54

Alcantara cleaning

135

Anodized parts Refer to vehicle maintenance

132

Anti-lock braking system (ABS)106

Anti-theft alarm system Enable/disable

54

Trailer124

Anti-theft wheel bolts159

Armrest Front

71

Rear71

artificial leather135

Ashtray75

Assembling the bar ball, Step 1

119

bar ball, Step 2120

Assist systems105

Auto-check control39

Automatic driving lamp control61

Automatic gearbox100

Selector lever-emergency unlocking168

Selector lever lock101

Starting-off and driving102

Tiptronic101

Using the selector lever100

Automatic gearbox modes100

Automatic load deactivation149

automatic transmission selector lever lock defect

101

Automatic transmission Kick-down

102

Malfunction36

Selector lever lock101

Warning light36

Warning messages36

AUX79

Avoiding damage to your vehicle104

B

Bags on the backs of the front seats

78

on the inner sides of the front seats79

Ball head Check fitting

120

Ready position118, 119

Battery In the remote control key

167

Belts11

Belt tensioners13

Bonnet Closing

140

Opening140

Boot Cargo element

84

Class N1 vehicles85

Hooks82

See Boot lid55

Storage compartments84

Boot cover Parking position

83

Boot lid automatic locking

55

Closing55

Opening55

Brake Assist (HBA)107

Brake booster98

brake fluid specification

146

Brake fluid145

Checking146

Information messages32

187Index

Page 191 of 204

Cockpit12-Volt power outlet75

Ashtray75

Cigarette lighter74

General view27

Lights63

storage compartments72

useful equipment72

COMING HOME62

compartments72

Component protection128

Components of the puncture repair kits162

Computer see multifunction display

40

convenience turn signal61

Coolant144

Checking144

Messages36

Replenishing145

Temperature gauge29

Warning light36

CORNER see Headlights with CORNER function

62

Correct routing of seat belt

12

Correct seated position8

Front passenger10

Rear seats10

Correct seat position Driver

9

Counter for distance driven30

cruise control operation

110

operation Description111

Cruise control system Warning light

35

Cup holders73

D

DAY LIGHT See Daytime running lights

60

Daytime running lights60

De-icing windows

132

Deactivating an airbag18

Decorative films131

Defrosting rear window64

Delayed locking of the boot lid see boot lid

55

Departure angle183

Diesel refer to Fuel

138

Diesel fuel Operation in winter

138

Diesel particulate filter37

information messages37

Digital Clock31

Dipstick143

Disconnecting and reconnecting vehicle battery

149

Display29

Compass points45

Coolant temperature29

Fuel supply30

Gear changes39

Service intervals46

Disposal Acceptance and recycling of used vehicles

129

Distance driven30

Distance warning Warning light

38

Door Child safety lock

53

Closing53

Emergency locking168

Opening53

Door warning39

Drive Driving through water

104

DriveGreen103

Driving Emissions

180

Fuel consumption180

Maximum speed184

through water104

driving data operation

40

E

Economical driving Tips

102

EDL107

Electrical power windows Button in the rear doors

57

Electric power windows Operational faults

58

Electric Windows56

Button in driver's door56

Electronic Differential Lock (EDL)107

Electronic immobilizer91

Emergency Changing a wheel

157

Hazard warning light system62

Jump-starting164

Locking the door without a locking cylinder168

Selector lever-unlocking168

Switch off the engine by pressing a button94

Towing the vehicle165

Towing the vehicle using the tow hitch167

tyre repair161

emergency equipment reflective vest

156

Emergency equipment Fire extinguisher

156

First aid kit156

Jack157

189Index

Page 193 of 204

I

Ice scrapers

132

Ignition lock92

Immobilizer91

Indicator lights31

Individual settings Locking

52

Unlocking52

Inertia reels13

Information system39

Compass point display45

Door warning39

Gear recommendation39

MAXI DOT display42

Multifunction display40

operation40

Service interval display46

Information system operation40

Infotainment4

Instrument cluster28

Auto-check control39

Counter for distance driven30

Display29

Fuel gauge30

Indicator lights31

Overview28

Revolution counter29

see instrument cluster28

Temperature gauge29

Interior care134

Natural leather134

interior light Front

63

Interior monitor54

iPad holder Behind the headrests

80

Handling79

ISOFIX22

J

Jack

157

Maintenance133

Jacking points Raise vehicle

160

Jump-starting164

K

KESSY Locking

51

Unlocking51

Key Lock

50

Start the engine92

Stopping the engine92

Switch off the ignition92

Switch on the ignition92

Unlock50

L

Lamp failure Warning light

37

Lamps Warning light

37

Leather Natural leather care

134

LEAVING HOME

62

Lever Main beam

60

Turn signal60

Windscreen wipers66

Light COMING HOME / LEAVING HOME

62

Daytime running lights60

Fog Lights61

Headlights with CORNER function62

Parking light63

Rear fog light61

Lighting Luggage compartment80

Lights59

Automatic driving lamp control61

Beam range adjustment59

Cockpit63

Hazard warning light system62

Headlight flasher60

Indicator lights31

Low beam59

Main beam60

Parking light59

Replacing bulbs173

switching on/off59

Turn signal60

Load180

Lock Key

50

Locking Individual settings

52

KESSY51

Remote control50

Locking and unlocking the vehicle from the in- side

51

Locking the door without a locking cylinder Emergency

168

Low beam59

Low tyre pressure warning refer to the tyre pressure monitoring

115

Luggage compartment80

Cover83

Fastening elements81

Fixing nets82

floor covering on both sides84

Lighting80

unlock manually168

Unlock the boot lid168

Luggage compartment cover83

Luggage compartment lid55

191Index

Page 196 of 204

SmartGateConnection by searching for a Wi-Fi network47

introductory information47

Password/PIN code change48

Setting48

Wi-Fi Direct48

SmartLink see Infotainment

4

Snow chains155

Spare wheel153

Remove158

stow158

Speed control system110

Speed symbol See Wheels

154

Spoiler128

Stabilisation system105

Stability Control (ESC)106

Staring engine Jump-starting

164

START-STOP95

Jump-starting164

Manually deactivating/activating the system97

operation96

Warning light38

START-STOP system95

Starter button Problems with the engine start

95

Steering column lock locking93

Steering column lock unlocking93

Switching off the engine94

Switch off the ignition94

Switch on the ignition94

Starting and stopping the engine at the push of the button

93

Starting and stopping the engine using the key 91

Starting engine Jump-starting

164

Starting the engine Starter button

94

START STOPInformation messages97

Start the engine Key

92

Steering column lock locking Starter button

93

Steering column lock unlocking Starter button

93

Steering lock locking Key

92

Steering lock unlocking Key

92

Steering wheel correct posture

9

setting9

Stop see Parking

99

Stopping the engine Key

92

Storage72

Storage compartment Glasses compartment

77

in the boot84

in the centre console73

in the front arm rest77

on the front passenger side77

Storage compartments72

Stowage compartments in the doors

73

Sun visors65

Switching off the engine Starter button

94

Switch light on/off59

Switch off the ignition Key

92

Starter button94

Switch on the ignition Key

92

Starter button94

T

Tablet holder Behind the headrests

80

Taking care of your vehicle Automatic car wash system

130

High-pressure cleaner130

Washing by hand129

Wash system130

TCS Operation

106

Warning light33

Technical data179

Time31

Tiptronic101

Tools157

TOP TETHER24

Towing165

Towing a trailer124

Towing device Accessories

122

Description118

Operation and maintenance133

Towing eye Front

166

Rear167

Towing protection54

Towing the vehicle165

Traction control (TCS)106

Trailer122

13-pin socket123

connection and disconnection123

Load124

Loading123

Safety eye123

Towing a trailer124

Trailer operation117

Trailer stabilization system (TSA)107

Transmission Warning messages

36

194Index