ECU SKODA RAPID 2016 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2016, Model line: RAPID, Model: SKODA RAPID 2016 1.GPages: 184, PDF Size: 27.06 MB

Page 113 of 184

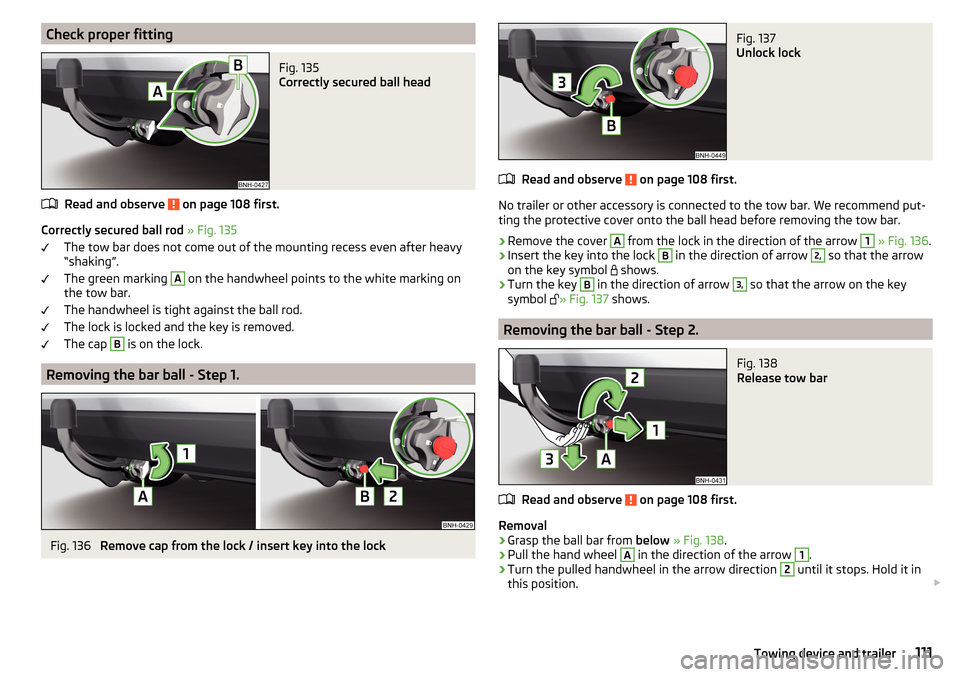

Check proper fittingFig. 135

Correctly secured ball head

Read and observe on page 108 first.

Correctly secured ball rod » Fig. 135

The tow bar does not come out of the mounting recess even after heavy

“shaking”.

The green marking

A

on the handwheel points to the white marking on

the tow bar.

The handwheel is tight against the ball rod.

The lock is locked and the key is removed.

The cap

B

is on the lock.

Removing the bar ball - Step 1.

Fig. 136

Remove cap from the lock / insert key into the lock

Fig. 137

Unlock lock

Read and observe on page 108 first.

No trailer or other accessory is connected to the tow bar. We recommend put-

ting the protective cover onto the ball head before removing the tow bar.

›

Remove the cover

A

from the lock in the direction of the arrow

1

» Fig. 136 .

›

Insert the key into the lock

B

in the direction of arrow

2,

so that the arrow

on the key symbol shows.

›

Turn the key

B

in the direction of arrow

3,

so that the arrow on the key

symbol » Fig. 137

shows.

Removing the bar ball - Step 2.

Fig. 138

Release tow bar

Read and observe on page 108 first.

Removal

›

Grasp the ball bar from below » Fig. 138 .

›

Pull the hand wheel

A

in the direction of the arrow

1

.

›

Turn the pulled handwheel in the arrow direction

2

until it stops. Hold it in

this position.

111Towing device and trailer

Page 114 of 184

›Remove the tow bar from the mounting recess downwards and in the direc-

tion of the arrow 3. At the same time, the ball rod latches into the ready po-

sition and is therefore ready to be re-fitted.

After removing the ball rod, insert the cap for the receiving shaft A

against

the direction of arrow

1

» Fig. 133 on page 110 .

If the hand wheel

A

is not turned all the way to the stop, then it will return to

its initial position when the tow bar is removed and will rest on the tow bar

and not engage into the ready position. The ball head then needs to be

brought into this position before the next time it is fitted » page 109, Adjusting

the ready position .

The ball rod must be cleaned before it is stored in the box with the tool kit.

WARNINGNever allow the tow bar to remain unsecured in the boot. This could cause

damage to the boot upon sudden braking, and could put the safety of the

occupants at risk.

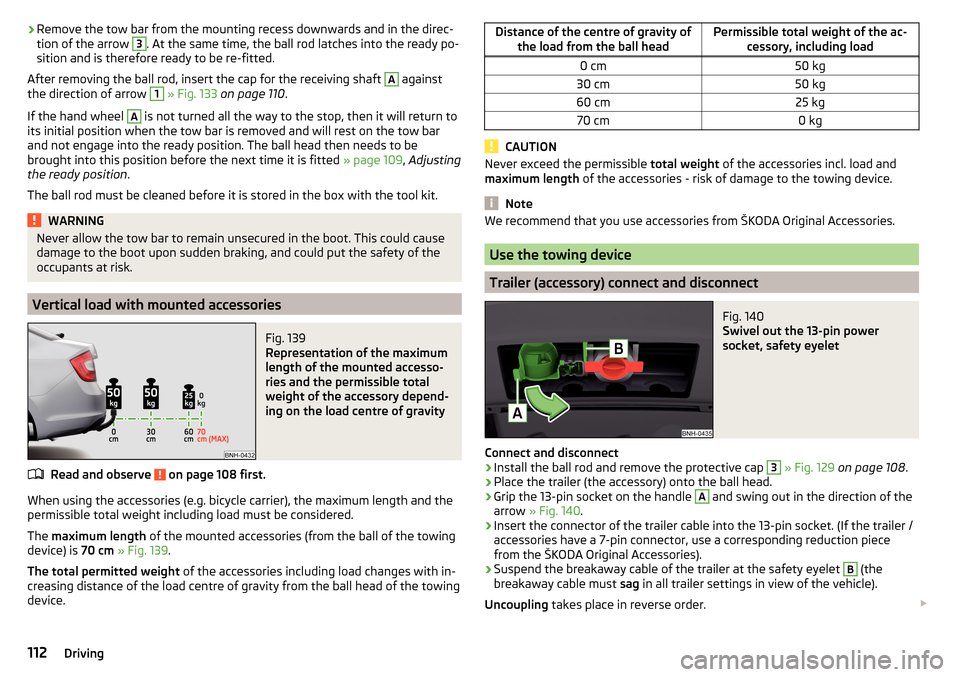

Vertical load with mounted accessories

Fig. 139

Representation of the maximum

length of the mounted accesso-

ries and the permissible total

weight of the accessory depend-

ing on the load centre of gravity

Read and observe on page 108 first.

When using the accessories (e.g. bicycle carrier), the maximum length and the

permissible total weight including load must be considered.

The maximum length of the mounted accessories (from the ball of the towing

device) is 70 cm » Fig. 139 .

The total permitted weight of the accessories including load changes with in-

creasing distance of the load centre of gravity from the ball head of the towing

device.

Distance of the centre of gravity of the load from the ball headPermissible total weight of the ac- cessory, including load0 cm50 kg30 cm50 kg60 cm25 kg70 cm0 kg

CAUTION

Never exceed the permissible total weight of the accessories incl. load and

maximum length of the accessories - risk of damage to the towing device.

Note

We recommend that you use accessories from ŠKODA Original Accessories.

Use the towing device

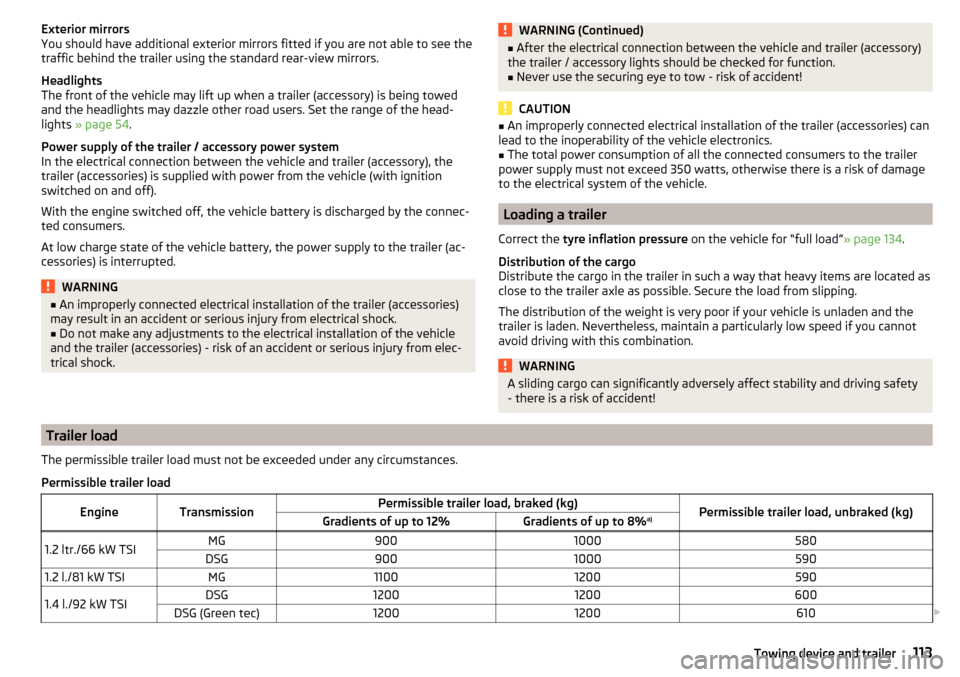

Trailer (accessory) connect and disconnect

Fig. 140

Swivel out the 13-pin power

socket, safety eyelet

Connect and disconnect

›

Install the ball rod and remove the protective cap

3

» Fig. 129 on page 108 .

›

Place the trailer (the accessory) onto the ball head.

›

Grip the 13-pin socket on the handle

A

and swing out in the direction of the

arrow » Fig. 140 .

›

Insert the connector of the trailer cable into the 13-pin socket. (If the trailer /

accessories have a 7-pin connector, use a corresponding reduction piece

from the ŠKODA Original Accessories).

›

Suspend the breakaway cable of the trailer at the safety eyelet

B

(the

breakaway cable must sag in all trailer settings in view of the vehicle).

Uncoupling takes place in reverse order.

112Driving

Page 115 of 184

Exterior mirrors

You should have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer using the standard rear-view mirrors.

Headlights

The front of the vehicle may lift up when a trailer (accessory) is being towed

and the headlights may dazzle other road users. Set the range of the head-

lights » page 54 .

Power supply of the trailer / accessory power system

In the electrical connection between the vehicle and trailer (accessory), the

trailer (accessories) is supplied with power from the vehicle (with ignition

switched on and off).

With the engine switched off, the vehicle battery is discharged by the connec-

ted consumers.

At low charge state of the vehicle battery, the power supply to the trailer (ac-

cessories) is interrupted.WARNING■ An improperly connected electrical installation of the trailer (accessories)

may result in an accident or serious injury from electrical shock.■

Do not make any adjustments to the electrical installation of the vehicle

and the trailer (accessories) - risk of an accident or serious injury from elec-

trical shock.

WARNING (Continued)■ After the electrical connection between the vehicle and trailer (accessory)

the trailer / accessory lights should be checked for function.■

Never use the securing eye to tow - risk of accident!

CAUTION

■ An improperly connected electrical installation of the trailer (accessories) can

lead to the inoperability of the vehicle electronics.■

The total power consumption of all the connected consumers to the trailer

power supply must not exceed 350 watts, otherwise there is a risk of damage

to the electrical system of the vehicle.

Loading a trailer

Correct the tyre inflation pressure on the vehicle for “full load” » page 134.

Distribution of the cargo

Distribute the cargo in the trailer in such a way that heavy items are located as

close to the trailer axle as possible. Secure the load from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Nevertheless, maintain a particularly low speed if you cannot

avoid driving with this combination.

WARNINGA sliding cargo can significantly adversely affect stability and driving safety

- there is a risk of accident!

Trailer load

The permissible trailer load must not be exceeded under any circumstances.Permissible trailer loadEngineTransmissionPermissible trailer load, braked (kg)Permissible trailer load, unbraked (kg)Gradients of up to 12%Gradients of up to 8% a)1.2 ltr./66 kW TSIMG9001000580DSG90010005901.2 l./81 kW TSIMG110012005901.4 l./92 kW TSIDSG12001200600DSG (Green tec)12001200610

113Towing device and trailer

Page 120 of 184

▶Fixed service interval QI4.

▶ Variable service interval QI6.

In order to operate a vehicle with a variable service interval, it must only be

filled and topped up with the prescribed engine oil.

If this engine oil is not available, the oil change is subject to a fixed service in-

terval. In this case, the vehicle must be changed to the fixed service interval.

Note

■

The corresponding motor oil specifications » page 128.■For vehicles with variable service interval QI6 you can initiate a change to the

fixed service interval or back to the variable service interval to be carried out

by a specialist garage.

Fixed service intervals QI1 - QI4

Oil change serv- ice

QI1Every 5,000 km or every 1 year a)

.QI2Every 7,500 km or every 1 year a)

.QI3Every 10,000 km or every 1 year a)

.QI4Every 15,000 km or every 1 year a)

.Inspection b)

Variant 1

QI1 - QI4

After the first 30,000 km or 2 years a)

, then every

30,000 km or every 1 year a)

.Inspection b)

Variant 2Every 15,000 km or every 1 year a)

.Inspection b)

Variant 3Every 10,000 km or every 1 year a)

.Brake fluid

changeQI1 - QI4First change after 3 years, then every 2 years.a)

Depending on which comes first.

b)

For information about the variant that applies to your vehicle, please contact a ŠKODA partner.

WARNINGThe brake fluid must always be changed after the first 3 years and then ev-

ery 2 years. Longer intervals between changing the brake fluid can cause

vapour bubbles to form in the brake system when braking sharply. This can

impair the efficiency of the brakes – risk of accident!NoteFor diesel operation with a high sulphur content, the oil must be changed ev-

ery 7,500 km. Ask your specialist garage for information on the countries

where diesel fuel has a high sulphur content.

Variable service interval QI6

The oil change service intervals depend on the intensity at which the vehicle is

driven and the local conditions in which the vehicle is used. For example, your

vehicle is subjected to different demands when driven over short distances

than when driven over long distances. The intervals are therefore variable.

Oil change serv-

iceIn accordance with the service interval display (after

30,000 km or 2 years a)

at the latest).Inspection b)

Variant 1After the first 30,000 km or 2 years a)

, then every 30,000

km or every 1 year a)

.Inspection b)

Variant 2Every 15 000 km or every 1 year a)

.Brake fluid

changeFirst change after 3 years, then every 2 years.a)

Depending on which comes first.

b)

For information about the variant that applies to your vehicle, please contact a ŠKODA partner.

WARNINGThe brake fluid must always be changed after the first 3 years and then ev-

ery 2 years. Longer intervals between changing the brake fluid can cause

vapour bubbles to form in the brake system when braking sharply. This can

impair the efficiency of the brakes – risk of accident!

Digital Service Plan

A specialist garage will not record the work carried out in a service evidence in

this Owner's Manual, but in the service information system called Digital Serv-

ice Plan.

We therefore recommend that you always have the record of work carried out

in a service printed out for you.

Benefits of the Digital Service Plan

▶ High level of security preventing manipulation of the entries.

▶ Transparent documentation of service work carried out.

118General Maintenance

Page 123 of 184

The towing device is maintenance-free. Coat the ball head of the towing de-

vice with a suitable grease whenever necessary.

Protection of cavities

All the cavities of your vehicle which are at risk from corrosion are protected by

a layer of long-lasting protective wax applied in the factory.

If any small amount of wax flow out of the cavities at high temperatures, these

must be removed with a plastic scraper and the stains cleaned using a petrole-

um cleaner.

Underbody

The underside of your vehicle is already permanently protected by the factory

against chemical and mechanical influences.

We recommend having the protective coating — preferably before the begin-

ning of winter and at the end of winter.

Product life of the films

Environmental influences (e.g. sunlight, humidity, air pollution, rockfall) affect

the life of the films. Films will age and become brittle – this is entirely normal;

this is not a fault.

Sunlight may also affect the strength of the film colour.

When transporting a load on the roof rack (e.g. roof box or similar), there is an

increased risk of film damage (e.g. of chipping from the secured load).

CAUTION

■ Vehicle paint

■ Repair damaged areas as soon as possible.

■ Matt-painted parts should not be treated with polishes or hard waxes.

■ Do not polish in a dusty environment - risk of paint scratches.

■ Do not apply any paint care products to door seals or window guides.■

Plastic parts

■ Do not use paint polish.

■

Chromed and anodised parts

■ Do not polish in a dusty environment - risk of surface scratches.

■

Films

The following instructions must be observed, otherwise there is a risk of film

damage. ■ Do not use dirty cloths or sponges for cleaning.

■ Do not use a scraper or other means to remove ice and snow.

■ Do not polish the films

■ Do not use a high pressure cleaner on the films.

■

Rubber seals

■ Do not treat the door seals and window guides deal with anything - the

protective varnish coating could be damaged.■

Windows and door mirrors ■ Do not clean the insides of the windows/mirrors with sharp objects - risk of

damage to the filaments or the antenna. ■ Do not use a cloth which has been used to polish the body - this could dirty

the window and impair visibility.

■

Head lights / lights

■ Do not wipe headlight/lights dry, do not use any sharp objects - risk of

damage to the protective coating and cracks forming on the headlight glass

covers.

■

Reversing camera

The following instructions must be observed, otherwise there is a risk of

camera damage. ■ Do not remove snow / ice with warm / hot water.

■ To wash, never use a pressure washer or steam jet.

■ For cleaning, do not use abrasive cleaners.

■

Door lock cylinders

■ Make sure that as little water as possible gets into the locking cylinder

when washing the vehicle - there is a risk of freezing the lock cylinder!

■

Wheels ■ Heavy soiling of the wheels can affect the balance of the wheels - the re-

sult can be a vibration, which can cause premature wear of the steering.

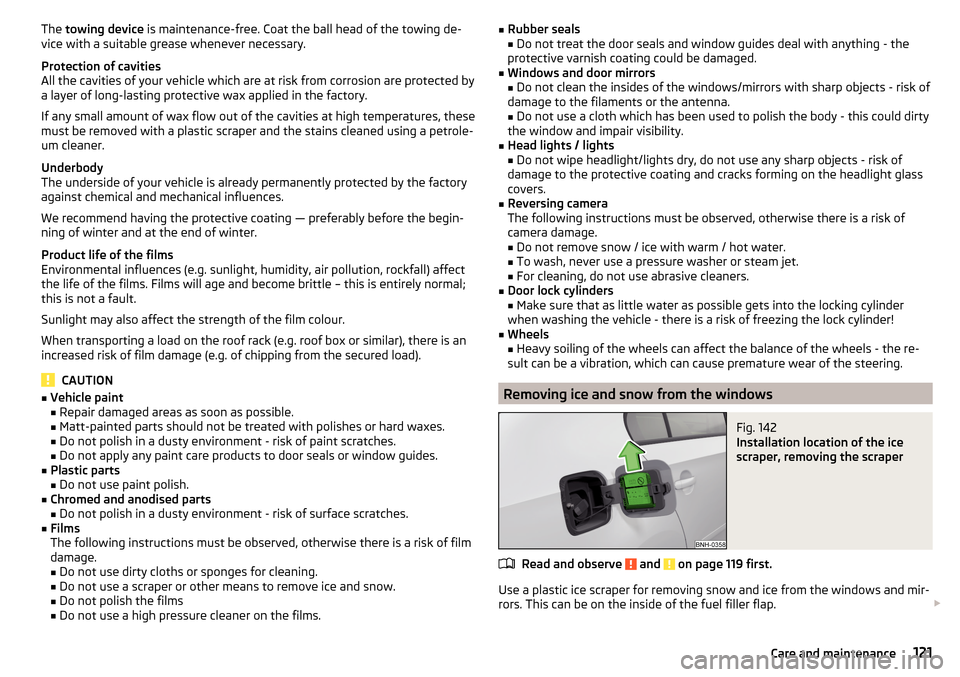

Removing ice and snow from the windows

Fig. 142

Installation location of the ice

scraper, removing the scraper

Read and observe and on page 119 first.

Use a plastic ice scraper for removing snow and ice from the windows and mir-

rors. This can be on the inside of the fuel filler flap.

121Care and maintenance

Page 126 of 184

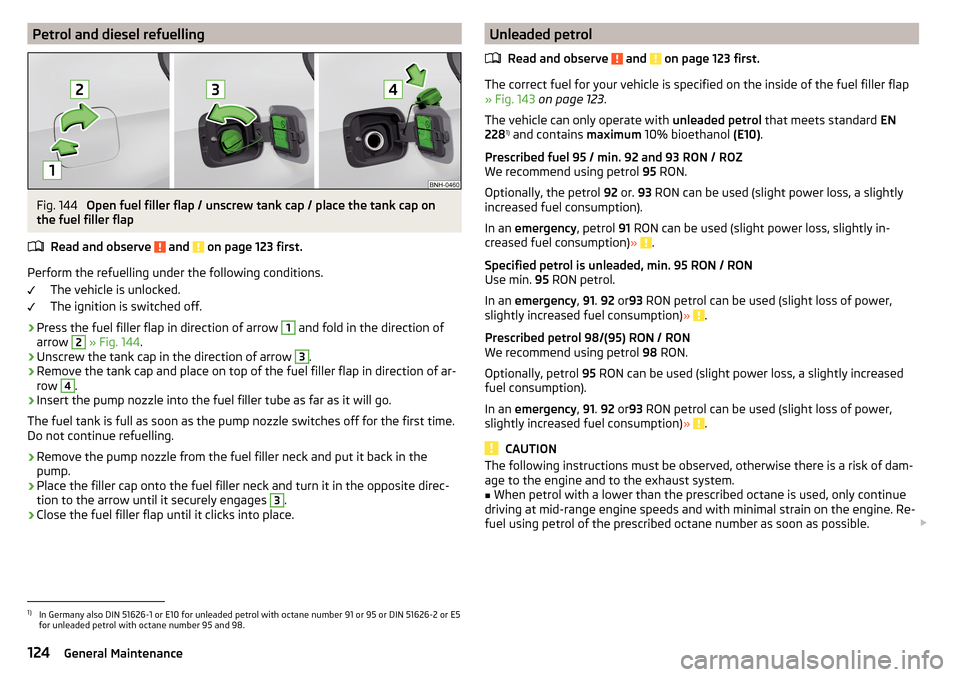

Petrol and diesel refuellingFig. 144

Open fuel filler flap / unscrew tank cap / place the tank cap on

the fuel filler flap

Read and observe

and on page 123 first.

Perform the refuelling under the following conditions. The vehicle is unlocked.

The ignition is switched off.

›

Press the fuel filler flap in direction of arrow

1

and fold in the direction of

arrow

2

» Fig. 144 .

›

Unscrew the tank cap in the direction of arrow

3

.

›

Remove the tank cap and place on top of the fuel filler flap in direction of ar-

row

4

.

›

Insert the pump nozzle into the fuel filler tube as far as it will go.

The fuel tank is full as soon as the pump nozzle switches off for the first time.

Do not continue refuelling.

›

Remove the pump nozzle from the fuel filler neck and put it back in the

pump.

›

Place the filler cap onto the fuel filler neck and turn it in the opposite direc-

tion to the arrow until it securely engages

3

.

›

Close the fuel filler flap until it clicks into place.

Unleaded petrol

Read and observe

and on page 123 first.

The correct fuel for your vehicle is specified on the inside of the fuel filler flap

» Fig. 143 on page 123 .

The vehicle can only operate with unleaded petrol that meets standard EN

228 1)

and contains maximum 10% bioethanol (E10).

Prescribed fuel 95 / min. 92 and 93 RON / ROZ

We recommend using petrol 95 RON.

Optionally, the petrol 92 or. 93 RON can be used (slight power loss, a slightly

increased fuel consumption).

In an emergency , petrol 91 RON can be used (slight power loss, slightly in-

creased fuel consumption) »

.

Specified petrol is unleaded, min. 95 RON / RON

Use min. 95 RON petrol.

In an emergency , 91 . 92 or 93 RON petrol can be used (slight loss of power,

slightly increased fuel consumption) »

.

Prescribed petrol 98/(95) RON / RON

We recommend using petrol 98 RON.

Optionally, petrol 95 RON can be used (slight power loss, a slightly increased

fuel consumption).

In an emergency , 91 . 92 or 93 RON petrol can be used (slight loss of power,

slightly increased fuel consumption) »

.

CAUTION

The following instructions must be observed, otherwise there is a risk of dam-

age to the engine and to the exhaust system.■

When petrol with a lower than the prescribed octane is used, only continue

driving at mid-range engine speeds and with minimal strain on the engine. Re-

fuel using petrol of the prescribed octane number as soon as possible.

1)

In Germany also DIN 51626-1 or E10 for unleaded petrol with octane number 91 or 95 or DIN 51626-2 or E5

for unleaded petrol with octane number 95 and 98.

124General Maintenance

Page 129 of 184

›Raise the bonnet in the direction of the arrow 3.›Remove the lid prop in the direction of arrow 4 from the holder.›

Secure the open flap inserting the end of the post into the opening in the di-

rection of arrow

5

.

Close the flap

›

Lift the bonnet.

›

Decouple the bonnet support and press into the holder designed to hold it.

›

Drop down the bonnet lid from a height of about 20 cm applying light pres-

sure until it clicks safely into place.

WARNING■ Never drive with the bonnet lid not properly closed - risk of accident!■Make sure that when closing the bonnet, no body parts are crushed -

there is danger of injury!

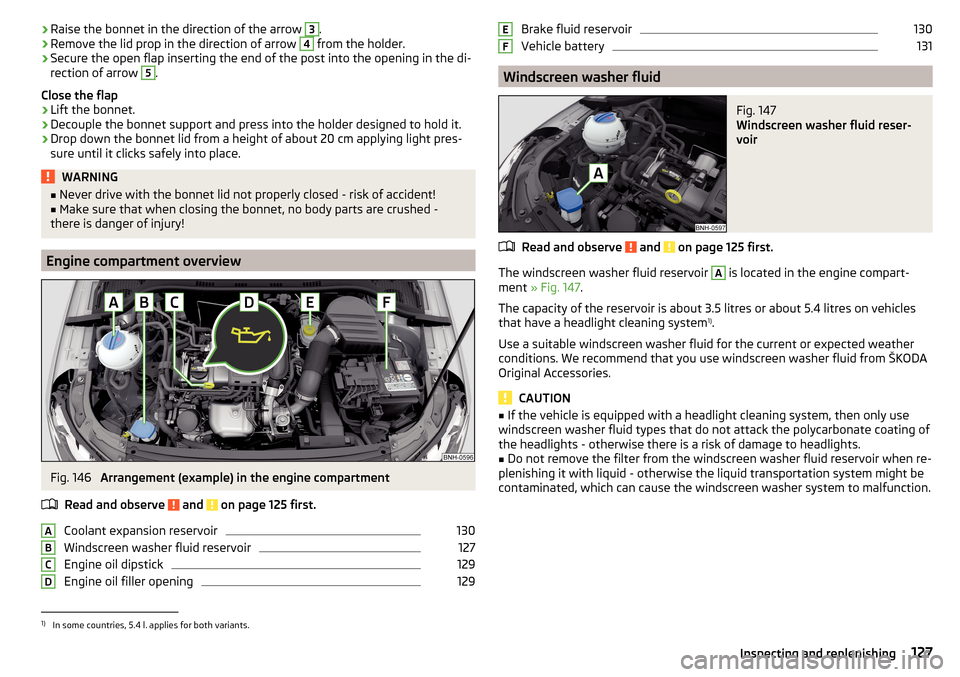

Engine compartment overview

Fig. 146

Arrangement (example) in the engine compartment

Read and observe

and on page 125 first.

Coolant expansion reservoir

130

Windscreen washer fluid reservoir

127

Engine oil dipstick

129

Engine oil filler opening

129ABCDBrake fluid reservoir130

Vehicle battery

131

Windscreen washer fluid

Fig. 147

Windscreen washer fluid reser-

voir

Read and observe and on page 125 first.

The windscreen washer fluid reservoir

A

is located in the engine compart-

ment » Fig. 147 .

The capacity of the reservoir is about 3.5 litres or about 5.4 litres on vehicles

that have a headlight cleaning system 1)

.

Use a suitable windscreen washer fluid for the current or expected weather

conditions. We recommend that you use windscreen washer fluid from ŠKODA

Original Accessories.

CAUTION

■ If the vehicle is equipped with a headlight cleaning system, then only use

windscreen washer fluid types that do not attack the polycarbonate coating of

the headlights - otherwise there is a risk of damage to headlights.■

Do not remove the filter from the windscreen washer fluid reservoir when re-

plenishing it with liquid - otherwise the liquid transportation system might be

contaminated, which can cause the windscreen washer system to malfunction.

EF1)

In some countries, 5.4 l. applies for both variants.

127Inspecting and replenishing

Page 140 of 184

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

Placement of the first aid kit and warning triangle

138

Location of reflective vest

138

fire extinguisher

138

Vehicle tool kit

139

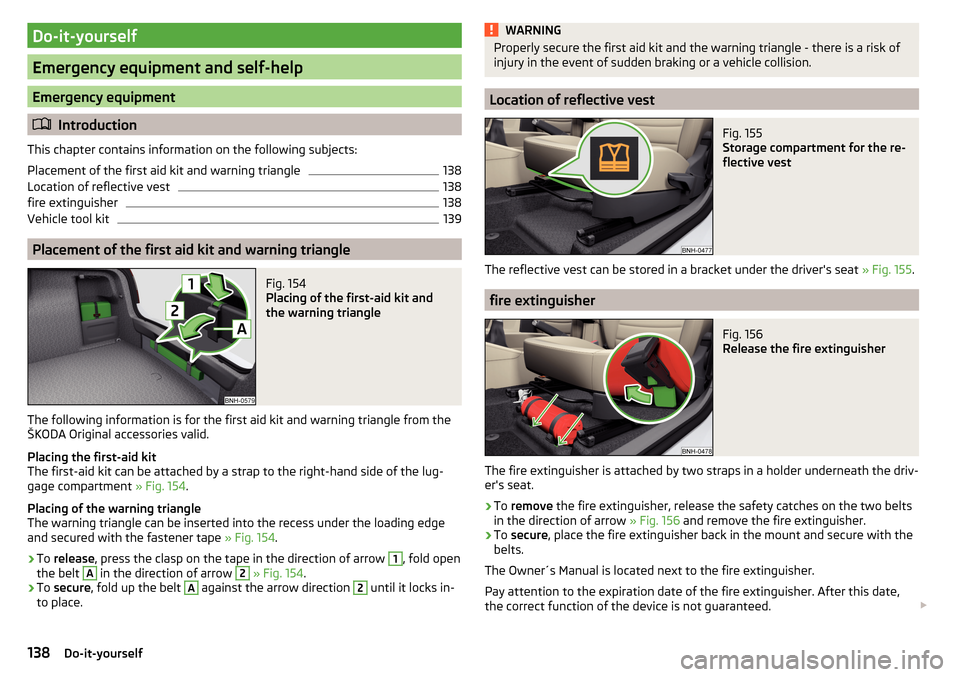

Placement of the first aid kit and warning triangle

Fig. 154

Placing of the first-aid kit and

the warning triangle

The following information is for the first aid kit and warning triangle from the

ŠKODA Original accessories valid.

Placing the first-aid kit

The first-aid kit can be attached by a strap to the right-hand side of the lug- gage compartment » Fig. 154.

Placing of the warning triangle

The warning triangle can be inserted into the recess under the loading edge

and secured with the fastener tape » Fig. 154.

›

To release , press the clasp on the tape in the direction of arrow

1

, fold open

the belt

A

in the direction of arrow

2

» Fig. 154 .

›

To secure , fold up the belt

A

against the arrow direction

2

until it locks in-

to place.

WARNINGProperly secure the first aid kit and the warning triangle - there is a risk of

injury in the event of sudden braking or a vehicle collision.

Location of reflective vest

Fig. 155

Storage compartment for the re-

flective vest

The reflective vest can be stored in a bracket under the driver's seat » Fig. 155.

fire extinguisher

Fig. 156

Release the fire extinguisher

The fire extinguisher is attached by two straps in a holder underneath the driv-

er's seat.

›

To remove the fire extinguisher, release the safety catches on the two belts

in the direction of arrow » Fig. 156 and remove the fire extinguisher.

›

To secure , place the fire extinguisher back in the mount and secure with the

belts.

The Owner´s Manual is located next to the fire extinguisher.

Pay attention to the expiration date of the fire extinguisher. After this date, the correct function of the device is not guaranteed.

138Do-it-yourself

Page 141 of 184

WARNINGAlways properly secure the fire extinguisher - there is a risk of injury in the

event of sudden braking or a vehicle collision.

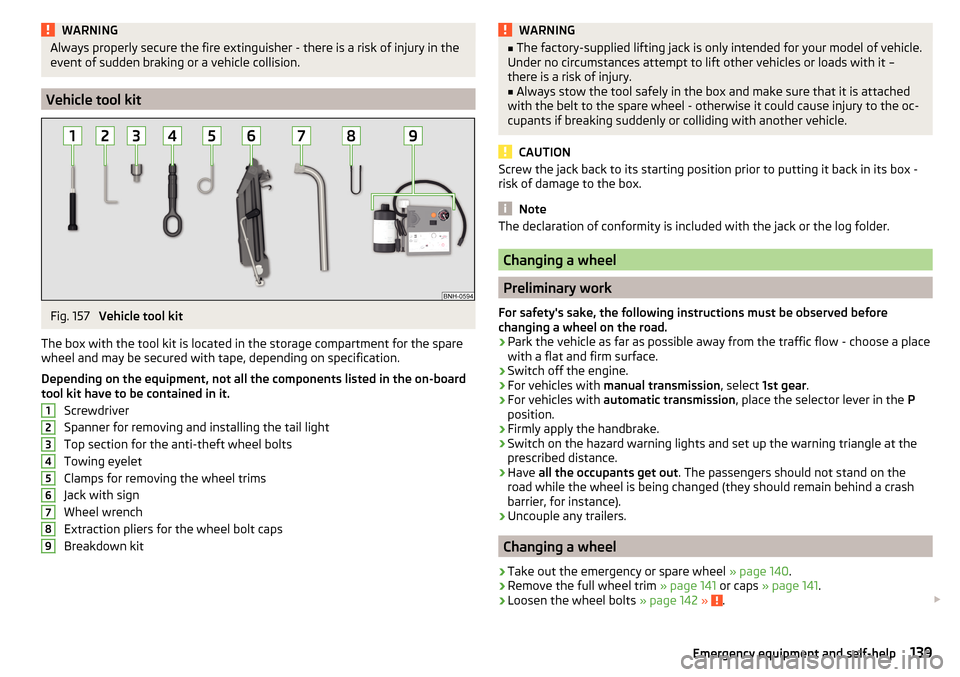

Vehicle tool kit

Fig. 157

Vehicle tool kit

The box with the tool kit is located in the storage compartment for the spare

wheel and may be secured with tape, depending on specification.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Screwdriver

Spanner for removing and installing the tail light

Top section for the anti-theft wheel bolts

Towing eyelet

Clamps for removing the wheel trims

Jack with sign

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kit

123456789WARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with it –

there is a risk of injury.■

Always stow the tool safely in the box and make sure that it is attached

with the belt to the spare wheel - otherwise it could cause injury to the oc-

cupants if breaking suddenly or colliding with another vehicle.

CAUTION

Screw the jack back to its starting position prior to putting it back in its box -

risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1st gear .

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

›

Uncouple any trailers.

Changing a wheel

›

Take out the emergency or spare wheel » page 140.

›

Remove the full wheel trim » page 141 or caps » page 141 .

›

Loosen the wheel bolts » page 142 » .

139Emergency equipment and self-help

Page 142 of 184

›Jack up the vehicle

» page 142 until the wheel that needs changing is clear of

the ground.›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“pull- ing crossways”) » page 142.

›

Replace the wheel trim » page 141 and caps » page 141 .

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 134 .

All bolts must be clean and must turn easily. If screws are corroded and diffi-

cult to move, these must be replaced.

WARNING■ Undo the wheel bolts just a little (about one turn), provided the vehicle

has not yet been jacked up. Otherwise the wheel could come loose and fall

off – risk of injury.■

Under no circumstances must the bolts be greased or oiled - could cause

an accident.

Subsequent steps

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure it with a nut.

›

Stow the tool kit in the space provided and secure using the band.

›

Check tyre pressure on the fitted wheel and adjust if necessary and, with ve-

hicles with tyre pressure monitoring, save the tyre pressure values in the

system » page 106 .

›

Have the tightening torque of the wheel bolts checked as soon as possible.

The prescribed tightening torque is 120 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

WARNINGTightening torque which is too high can damage the threads and this can

result in permanent deformation of the contact surfaces on the rim. Where

tightening torque is too low, the wheels may become loose while driving -

risk of accident. Therefore drive cautiously and only at a moderate speed

until the tightening torque has been checked.

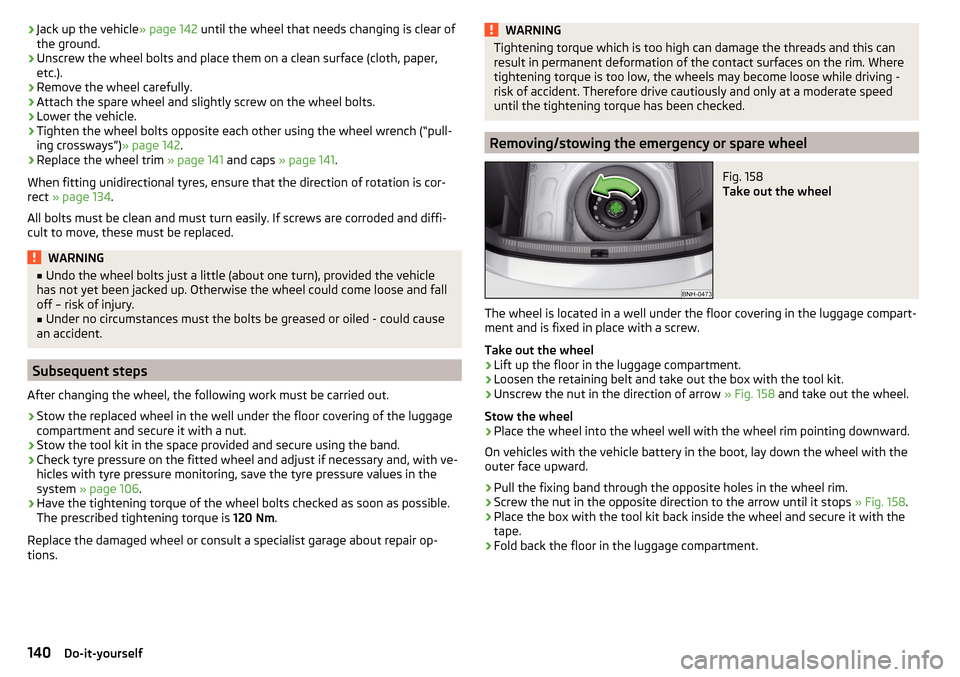

Removing/stowing the emergency or spare wheel

Fig. 158

Take out the wheel

The wheel is located in a well under the floor covering in the luggage compart-

ment and is fixed in place with a screw.

Take out the wheel

›

Lift up the floor in the luggage compartment.

›

Loosen the retaining belt and take out the box with the tool kit.

›

Unscrew the nut in the direction of arrow » Fig. 158 and take out the wheel.

Stow the wheel

›

Place the wheel into the wheel well with the wheel rim pointing downward.

On vehicles with the vehicle battery in the boot, lay down the wheel with the

outer face upward.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw the nut in the opposite direction to the arrow until it stops » Fig. 158.

›

Place the box with the tool kit back inside the wheel and secure it with the

tape.

›

Fold back the floor in the luggage compartment.

140Do-it-yourself