ECU SKODA RAPID SPACEBACK 2015 1.G User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2015 1.GPages: 208, PDF Size: 29.2 MB

Page 82 of 208

The maximum permissible load of each of the pockets is 150 g.WARNINGDo not exceed the maximum permissible load of the pockets. Heavy objects

are not secured sufficiently – risk of injury!

CAUTION

Never put large objects into the map pockets, e.g. bottles or objects with sharp

edges - risk of damaging the pockets and seat coverings.

AUX and MDI inputs (AUX and USB inputs)

Fig. 84

Installation locations of the inputs: AUX / MDI (AUX and USB)

Read and observe

on page 73 first.

The vehicle may have AUX or MDI inputs (AUX and USB) for connecting exter-

nal sources.

The USB input is above the storage compartment in the front centre console

» Fig. 84 -

and is identified by the symbol

.

The AUX input is marked with the lettering and is in one of the locations

listed below depending on equipment.

▶ Between the seats in the front centre console » Fig. 84 -

.

▶ Above the storage box of the front centre console » Fig. 84 –

.

Additional information » Owner´s Manual Infotainment .

Tablet holder

Introduction

This chapter contains information on the following subjects:

Installing/removing

80

Handling the holder

81

External devices (e.g. tablet, smartphone, etc.) measuring min. 122 mm and

max. 195 mm can be secured in the holder.

The maximum permissible load of the holder is 750 g.

CAUTION

Never exceed the maximum permissible load of the holder - there is a risk of

damage or functional impairment.

Installing/removing

Fig. 85

Positioning the adapter/installing the holder

80Using the system

Page 83 of 208

Fig. 86

Removing the holder/removing the adapter

Read and observe

on page 80 first.

Installing

›

Attach the opened adapter to the guide rods of the headrest » Fig. 85.

›

Clip in the adapter in the direction of arrow

1

» .

›

Clip the holder into the adapter in the direction of arrow

2

.

Removing

›

Pull on the locking strap

A

in the direction of arrow

3

» Fig. 86 .

›

Remove the holder from the bracket in the direction of arrow

4

.

›

Press the adapter and remove it from the guide rods of the head rest in the

direction of arrow

5

.

WARNINGClip in the adapter carefully - there is a risk of injuring your finger.

Handling the holder

Fig. 87

Tilting and rotating the holder

Fig. 88

Adjusting the holder size

Read and observe on page 80 first.

Tilting and rotating the holder

The holder may be tilted 30° in the direction of arrow

1

and rotated through

360° in the direction of arrow

2

» Fig. 87 .

Adjusting the holder size

›

Pull out the securing tab

A

in the direction of arrow

3

and move part

B

in

direction of arrow

4

to the desired position » Fig. 88.

Luggage compartment and transport of cargo

Introduction

This chapter contains information on the following subjects:

Fastening elements

82

Fixing nets

83

Multifunction pocket

83

Hooks

83

Luggage compartment cover

84

“Parking position” of the boot cover

84

Storage compartment in the boot

85

Storage net bag

85

Cargo elements

85

Floor covering on both sides

86

Class N1 vehicles

86

81Transporting and practical equipment

Page 84 of 208

When transporting cargo the following the instructions must be adhered to

▶ When transporting heavy objects, the driving characteristics change due to

the shift in centre-of-gravity. The speed and style of driving must be adjus-

ted accordingly.

▶ The cargo is stowed in the luggage compartment. To prevent this from mov-

ing it should be secured with suitable lashing straps to the lashing eyes or

secured with fixing nets.

▶ Distribute loads as evenly as possible.

▶ Place heavy objects as far forward as possible.

▶ The transported items must be stowed in such a way that no objects are able

to slip forward on sudden driving or braking manoeuvres – risk of injury!

▶ Tyre pressure is to match the load.

▶ When transporting loads in the luggage compartment that has been en-

larged by folding the rear seats forward, ensure the safety of the passengers

transported on the other rear seats .

In the event of an accident, even small and light objects gain so much kinetic energy that they can cause severe injuries.

The magnitude of the kinetic energy is dependent on the speed at which the

vehicle is travelling and the weight of the object.

Example: In the event of a frontal collision at a speed of 50 km/h, an object

with a weight of 4.5 kg produces an energy, which corresponds to 20 times its

own weight. This means that it results in a weight of approx. 90 kg “ ”.

Luggage compartment light

The warning light turns on when tailgate is opened.

The warning light turns off when the tailgate is closed.

If the boot lid is open and the ignition switched off, the light will extinguish

automatically after around 10 minutes.WARNING■ Never exceed the maximum permissible load of the respective fasteners,

nets, hooks etc. as heavy objects are not e sufficiently secured - there is a

risk of injury!■

If the cargo is tied down with unsuitable or damaged lashing straps, inju-

ries can occur in the event of braking manoeuvres or accidents.

WARNING (Continued)■ Loose cargo can be thrown forward during a sudden manoeuvre or in case

of an accident and can injure the occupants or other road users.■

Loose cargo could hit a deployed airbag and injure occupants – danger of

death!

CAUTION

■ Never exceed the maximum permissible load of the respective fasteners,

nets, hooks etc. - these could be damaged.■

Please ensure that the heating elements for the rear window heater are not

damaged as a result of abrasive objects.

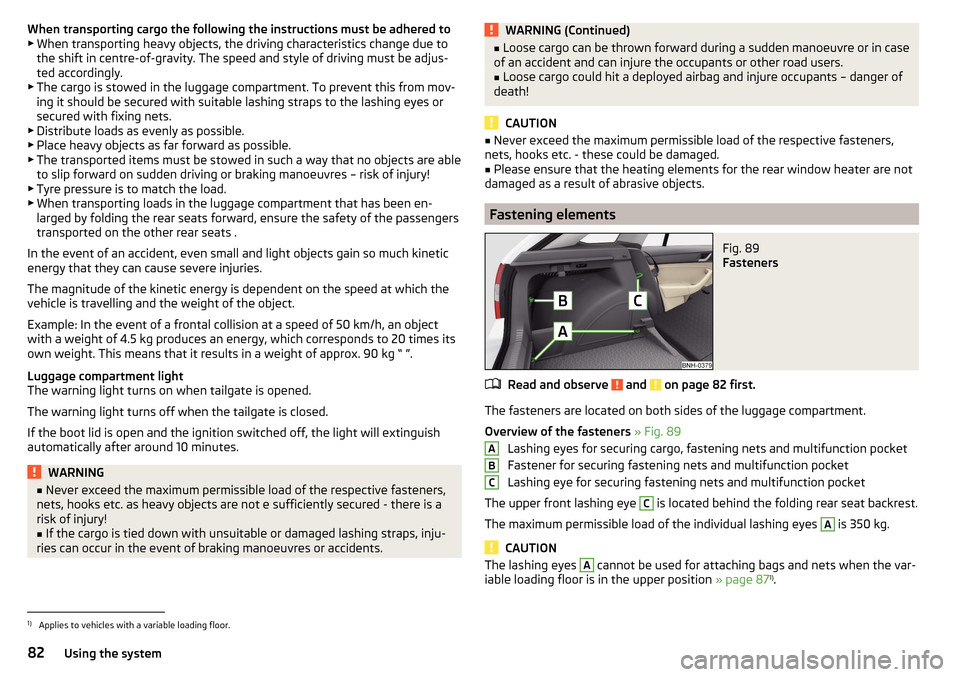

Fastening elements

Fig. 89

Fasteners

Read and observe and on page 82 first.

The fasteners are located on both sides of the luggage compartment.

Overview of the fasteners » Fig. 89

Lashing eyes for securing cargo, fastening nets and multifunction pocket

Fastener for securing fastening nets and multifunction pocket

Lashing eye for securing fastening nets and multifunction pocket

The upper front lashing eye

C

is located behind the folding rear seat backrest.

The maximum permissible load of the individual lashing eyes

A

is 350 kg.

CAUTION

The lashing eyes A cannot be used for attaching bags and nets when the var-

iable loading floor is in the upper position » page 871)

.ABC1)

Applies to vehicles with a variable loading floor.

82Using the system

Page 85 of 208

Fixing netsFig. 90

Fastening examples for nets

Fig. 91

Fastening a vertical pocket

Read and observe and on page 82 first.

Fastening examples for nets » Fig. 90 and » Fig. 91

Horizontal pocket

Floor net

Vertical pocket

The maximum permissible load of each of the nets is 1.5 kg.

CAUTION

■ Do not place any sharp objects in the nets – risk of net damage.■The lashing eyelets A » Fig. 89 on page 82 cannot be used for attaching

nets, when the variable loading floor is in the upper position » page 871)

.ABCMultifunction pocketFig. 92

Securing the multifunction pock-

et

Read and observe and on page 82 first.

The pocket » Fig. 92 can be secured to the fastening elements

A

,

B

and

C

» Fig. 89 on page 82 .

The maximum permissible load for the pocket attached to the fastening ele-

ment is 3 kg.

CAUTION

In vehicles with a variable loading floor, it is not possible to secure the pocket

to the fastening elements.

Hooks

Fig. 93

Hooks

Read and observe and on page 82 first.

One hook for attaching small items of luggage, such as bags etc., is provided

on each side of the luggage compartment. » Fig. 93.

1)

Applies to vehicles with a variable loading floor.

83Transporting and practical equipment

Page 88 of 208

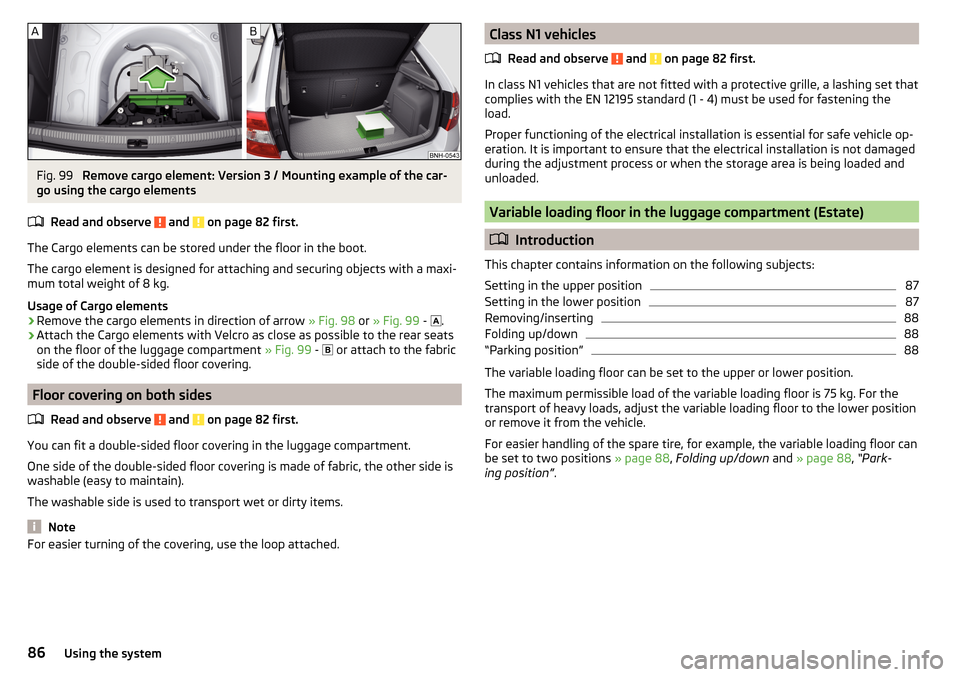

Fig. 99

Remove cargo element: Version 3 / Mounting example of the car-

go using the cargo elements

Read and observe

and on page 82 first.

The Cargo elements can be stored under the floor in the boot.

The cargo element is designed for attaching and securing objects with a maxi-

mum total weight of 8 kg.

Usage of Cargo elements

›

Remove the cargo elements in direction of arrow » Fig. 98 or » Fig. 99 -

.

›

Attach the Cargo elements with Velcro as close as possible to the rear seats

on the floor of the luggage compartment » Fig. 99 -

or attach to the fabric

side of the double-sided floor covering.

Floor covering on both sides

Read and observe

and on page 82 first.

You can fit a double-sided floor covering in the luggage compartment.

One side of the double-sided floor covering is made of fabric, the other side is washable (easy to maintain).

The washable side is used to transport wet or dirty items.

Note

For easier turning of the covering, use the loop attached.Class N1 vehicles

Read and observe

and on page 82 first.

In class N1 vehicles that are not fitted with a protective grille, a lashing set that

complies with the EN 12195 standard (1 - 4) must be used for fastening the

load.

Proper functioning of the electrical installation is essential for safe vehicle op-

eration. It is important to ensure that the electrical installation is not damaged

during the adjustment process or when the storage area is being loaded and

unloaded.

Variable loading floor in the luggage compartment (Estate)

Introduction

This chapter contains information on the following subjects:

Setting in the upper position

87

Setting in the lower position

87

Removing/inserting

88

Folding up/down

88

“Parking position”

88

The variable loading floor can be set to the upper or lower position.

The maximum permissible load of the variable loading floor is 75 kg. For the

transport of heavy loads, adjust the variable loading floor to the lower position

or remove it from the vehicle.

For easier handling of the spare tire, for example, the variable loading floor can

be set to two positions » page 88, Folding up/down and » page 88 , “Park-

ing position” .

86Using the system

Page 91 of 208

Folding up›Remove the luggage compartment cover from the vehicle » page 84.›

Grasp the variable loading floor at handle

A

» Fig. 104 .

›

Lift the variable loading floor in the direction of the arrow

1

until the folding

corners

B

lock into place in area

C

.

Folding down

›

Push the folding corners

B

» Fig. 104 on both sides of the variable loading

floor in the direction of the arrow

2

and release these from positions

C

.

›

Grasp the variable loading floor in the middle or at handle

A

.

›

Fold down the variable loading floor in the direction of arrow

3

.

WARNINGThe variable loading floor in the “parking position” restricts the driver's

view at the back.

CAUTION

■ The variable loading floor can only be in set to the “parking position” when it

is in the lower position and the luggage compartment cover has been taken

out.■

If the variable loading floor is in the “parking position”, the “parking position”

on the luggage compartment cover cannot be set » page 84.

Roof rack

Introduction

This chapter contains information on the following subjects:

fixing points for base support

89

Roof load

90WARNINGWhen transporting cargo the following the instructions must be adhered

to.■

The items being transported on the roof rack must always be securely at-

tached – risk of accident!

■

Always secure the load with appropriate and undamaged lashing straps

or tensioning straps.

■

Distribute the load evenly over the roof rack system.

WARNING (Continued)■ When transporting heavy objects or objects which take up a large area on

the roof rack system, handling of the car may change as a result of the dis-

placement of the centre of gravity. The style of driving and speed must

therefore be adapted to the current circumstances.■

Avoid abrupt and sudden driving/braking manoeuvres.

■

The permissible roof load, permissible axle loads and permissible total ve-

hicle weight must not be exceeded under any circumstance – risk of acci-

dent!

CAUTION

■ On models fitted with an electrical sliding/tilting roof, ensure that the slid-

ing/tilting roof does not strike any items of luggage transported on the roof

when tilting.■

Ensure that the boot lid does not hit the roof load when opened.

■

The height of the vehicle changes after mounting a roof luggage rack system

including the load that is being transported. Compare the vehicle height with

available clearances, such as underpasses and garage doors.

■

Ensure the roof aerial is not impaired by the load being transported.

Note

We recommend that you use a roof rack from ŠKODA Original Accessories.

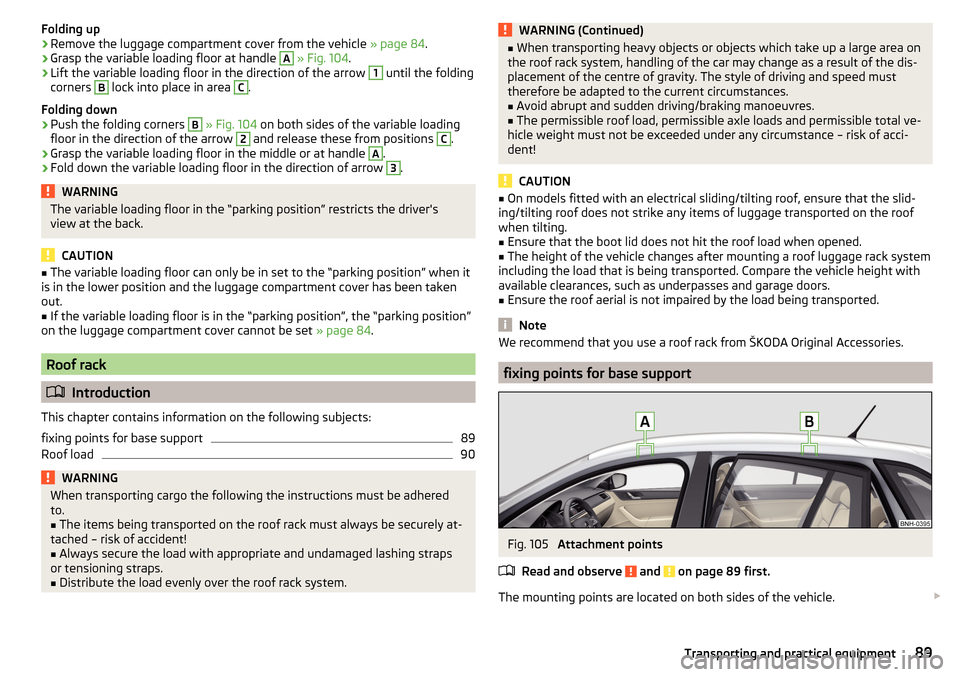

fixing points for base support

Fig. 105

Attachment points

Read and observe

and on page 89 first.

The mounting points are located on both sides of the vehicle.

89Transporting and practical equipment

Page 104 of 208

Wet roads or road salt

The performance of the brakes can be delayed as the brake discs and brake

pads may be moist or have a coating of ice or layer of salt on them in winter.

The brakes are cleaned and dried by applying the brakes several times »

.

Corrosion

Corrosion on the brake discs and dirt on the bake pads occur if the vehicle has

been parked for a long period and if you do not make much use of the braking

system. The brakes are cleaned by applying the brakes several times »

.

Long or steep slopes

Before travelling a long distance with a steep gradient, reduce speed and shift

into the next lowest gear. As a result, the braking effect of the engine will be

used, reducing the load on the brakes. Any additional braking should be com-

pleted intermittently, not continuously.

Emergency brake display

If the brakes are applied in full and the vehicle systems evaluate the situation

as dangerous for the traffic following behind, the brake light flashes automati-

cally.

After the speed was reduced below around 10 km/h or the vehicle was stop-

ped, the brake light stops flashing and the hazard warning light system

switches on. The hazard warning light system is switched off automatically af-

ter accelerating or driving off again.

Faults in the brake surface

If it is found that the braking distance has suddenly become longer and that

the brake pedal can be depressed further, the brake system may be faulty.

Visit a specialist garage immediately and adjust your style of driving appropri-

ately, as you will not know the exact extent of the damage.

Low brake fluid level

An insufficient level of brake fluid may result in problems in the brake system.

The level of the brake fluid is monitored electronically » page 32,

Brake sys-

tem .

Brake booster

The brake booster increases the pressure generated with the brake pedal. The

brake booster only operates when the engine is running.

WARNINGOnly apply the brakes for the purpose of drying and cleaning the brake

discs if the traffic conditions permit this. Do not place any other road users

in jeopardy.

Handbrake

Fig. 115

Handbrake

Read and observe and on page 101 first.

The hand brake is used when stopping and parking for securing the vehicle

against unwanted movement.

Apply

›

Pull the handbrake lever firmly upwards.

Releasing

›

Pull the handbrake lever up slightly and at the same time push in the locking

button » Fig. 115 .

›

Move the lever right down while pressing the lock button.

The handbrake warning light

illuminates when the handbrake is applied,

provided the ignition is on.

A warning signal sounds if the vehicle is inadvertently driven off with the

handbrake applied.

The following message is shown in the information cluster display.

Release the handbrake!RELEASE HANDBRAKE

The handbrake warning is activated if the vehicle is driven at a speed of more

than around 5 km/h for more than 3 seconds.

102Driving

Page 123 of 208

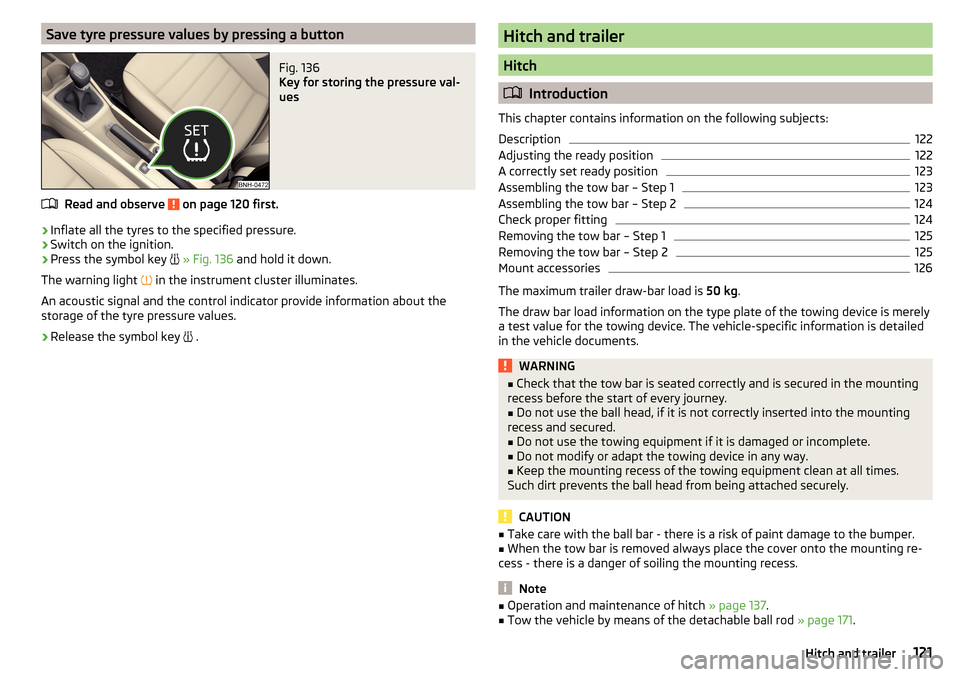

Save tyre pressure values by pressing a buttonFig. 136

Key for storing the pressure val-

ues

Read and observe on page 120 first.

›

Inflate all the tyres to the specified pressure.

›

Switch on the ignition.

›

Press the symbol key

» Fig. 136 and hold it down.

The warning light in the instrument cluster illuminates.

An acoustic signal and the control indicator provide information about the

storage of the tyre pressure values.

›

Release the symbol key .

Hitch and trailer

Hitch

Introduction

This chapter contains information on the following subjects:

Description

122

Adjusting the ready position

122

A correctly set ready position

123

Assembling the tow bar – Step 1

123

Assembling the tow bar – Step 2

124

Check proper fitting

124

Removing the tow bar – Step 1

125

Removing the tow bar – Step 2

125

Mount accessories

126

The maximum trailer draw-bar load is 50 kg.

The draw bar load information on the type plate of the towing device is merely

a test value for the towing device. The vehicle-specific information is detailed

in the vehicle documents.

WARNING■ Check that the tow bar is seated correctly and is secured in the mounting

recess before the start of every journey.■

Do not use the ball head, if it is not correctly inserted into the mounting

recess and secured.

■

Do not use the towing equipment if it is damaged or incomplete.

■

Do not modify or adapt the towing device in any way.

■

Keep the mounting recess of the towing equipment clean at all times.

Such dirt prevents the ball head from being attached securely.

CAUTION

■ Take care with the ball bar - there is a risk of paint damage to the bumper.■When the tow bar is removed always place the cover onto the mounting re-

cess - there is a danger of soiling the mounting recess.

Note

■ Operation and maintenance of hitch » page 137.■Tow the vehicle by means of the detachable ball rod » page 171.121Hitch and trailer

Page 126 of 208

Assembling the tow bar – Step 2Fig. 142

Secure the lock and remove key / place cap on lock

Read and observe

and on page 121 first.

›

First perform step 1 of the tow bar assembly » page 123.

›

Turn the key

A

in the direction of arrow

1,

so that the arrow on the key

symbol

» Fig. 142 shows.

›

Remove the key in the direction of the arrow

2

.

›

Fit the cap

B

on the lock in the direction of the arrow

3

.

›

Check that the tow bar is securely attached » page 124.

WARNING■

After fitting the tow bar, always secure the lock and remove the key.■The tow bar must not be operated with the key inserted.

CAUTION

After removing the key, always replace the cover on the lock – there is a risk of

the lock getting dirty.Check proper fittingFig. 143

Correctly secured ball head

Read and observe and on page 121 first.

Check that the tow bar is fitted properly before each use.

Correctly secured tow bar » Fig. 143

The tow bar does not come out of the mounting recess even after heavy

“shaking”.

The green marking

A

on the hand wheel points to the white marking on

the tow bar.

The hand wheel lies flush with the tow bar - there is no gap.

The lock is locked and the key is removed.

The cap

B

is on the lock.

WARNINGDo not use the towing hitch unless the tow ball has been properly locked –

risk of accident.124Driving

Page 127 of 208

Removing the tow bar – Step 1Fig. 144

Remove cap from the lock / insert key into the lock

Fig. 145

Unlock lock

Read and observe and on page 121 first.

›

Remove the cover

A

from the lock in the direction of the arrow

1

» Fig. 144 .

›

Insert the key into the lock

B

in the direction of arrow

2,

so that the arrow

on the key symbol shows.

›

Turn the key

B

in the direction of arrow

3,

so that the arrow on the key

symbol

» Fig. 145 shows.

WARNINGNever remove the tow bar while the trailer is still coupled.

Note

We recommend putting the protective cover onto the ball head before remov-

ing the tow bar.Removing the tow bar – Step 2Fig. 146

Release tow bar

Read and observe and on page 121 first.

Removing

›

To begin with, follow the first step for the ball rod assembly » page 125.

›

Grasp the ball bar from below » Fig. 146 .

›

Pull the hand wheel

A

in the direction of the arrow

1

.

›

Turn the hand wheel in the direction of the arrow

2

to the stop, and hold in

this position.

›

Remove the tow bar from the mounting recess downwards and in the direc-

tion of the arrow

3

.

At the same time, the ball head latches into the ready position and is thus

ready to be re-inserted into the mounting recess »

.

Subsequent steps

After removing the tow bar the following work must be carried out.

›

Fit the cover for the mounting recess

A

in the opposite direction to arrow

1

» Fig. 141 on page 123 .

WARNINGNever allow the tow bar to remain unsecured in the boot. This could cause

damage on sudden braking and could put the safety of the occupants at

risk! 125Hitch and trailer