gearbox SKODA ROOMSTER 2011 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: ROOMSTER, Model: SKODA ROOMSTER 2011 1.GPages: 212, PDF Size: 3.3 MB

Page 93 of 212

the accelerator pedal fully into the kickdown range. The original programme will

be reactivated to match your particular style of driving once the gearbox has shif-

ted up again.

When driving in hilly regions, the gears are selected to match uphill and downhill

sections. This avoids the gearbox frequently shifting up and down when negotiat-

ing an uphill stretch. When driving downhill, it is possible to shift down into the

Tiptronic position, in order to exploit the engine brake torque.

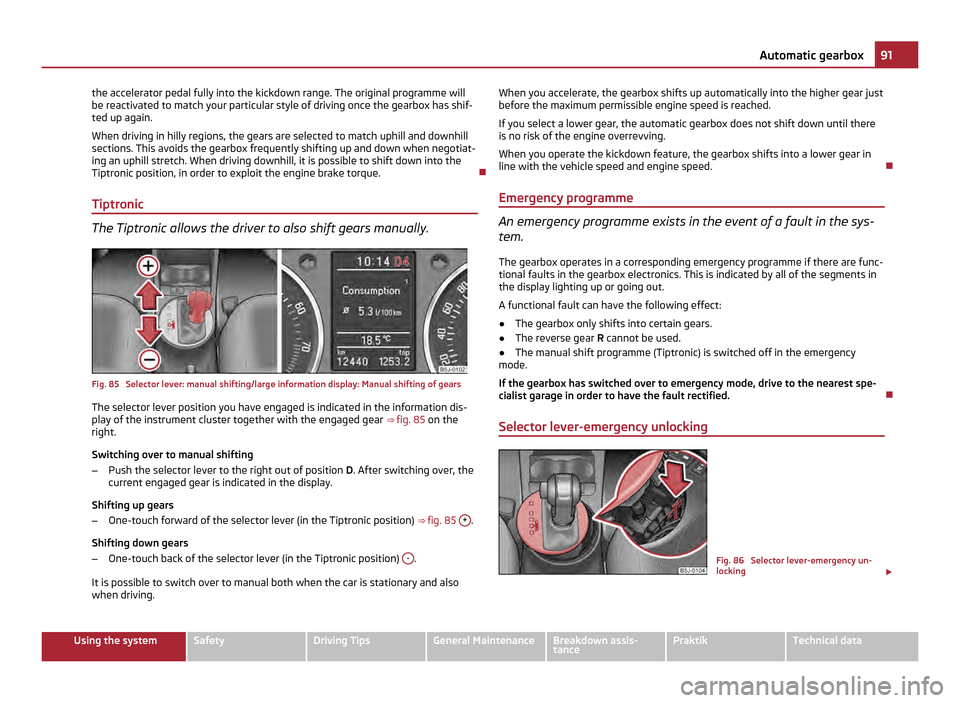

Tiptronic The Tiptronic allows the driver to also shift gears manually.

Fig. 85 Selector lever: manual shifting/large information display: Manual shifting of gears

The selector lever position you have engaged is indicated in the information dis-

play of the instrument cluster together with the engaged gear

⇒ fig. 85 on the

right.

Switching over to manual shifting

– Push the selector lever to the right out of position D. After switching over, the

current engaged gear is indicated in the display.

Shifting up gears

– One-touch forward of the selector lever (in the Tiptronic position) ⇒ fig. 85 + .

Shifting down gears

– One-touch back of the selector lever (in the Tiptronic position) - .

It is possible to switch over to manual both when the car is stationary and also

when driving. When you accelerate, the gearbox shifts up automatically into the higher gear just

before the maximum permissible engine speed is reached.

If you select a lower gear, the automatic gearbox does not shift down until there

is no risk of the engine overrevving.

When you operate the kickdown feature, the gearbox shifts into a lower gear in

line with the vehicle speed and engine speed.

Emergency programme An emergency programme exists in the event of a fault in the sys-

tem.

The gearbox operates in a corresponding emergency programme if there are func-

tional faults in the gearbox electronics. This is indicated by all of the segments in

the display lighting up or going out.

A functional fault can have the following effect:

● The gearbox only shifts into certain gears.

● The reverse gear R cannot be used.

● The manual shift programme (Tiptronic) is switched off in the emergency

mode.

If the gearbox has switched over to emergency mode, drive to the nearest spe-

cialist garage in order to have the fault rectified.

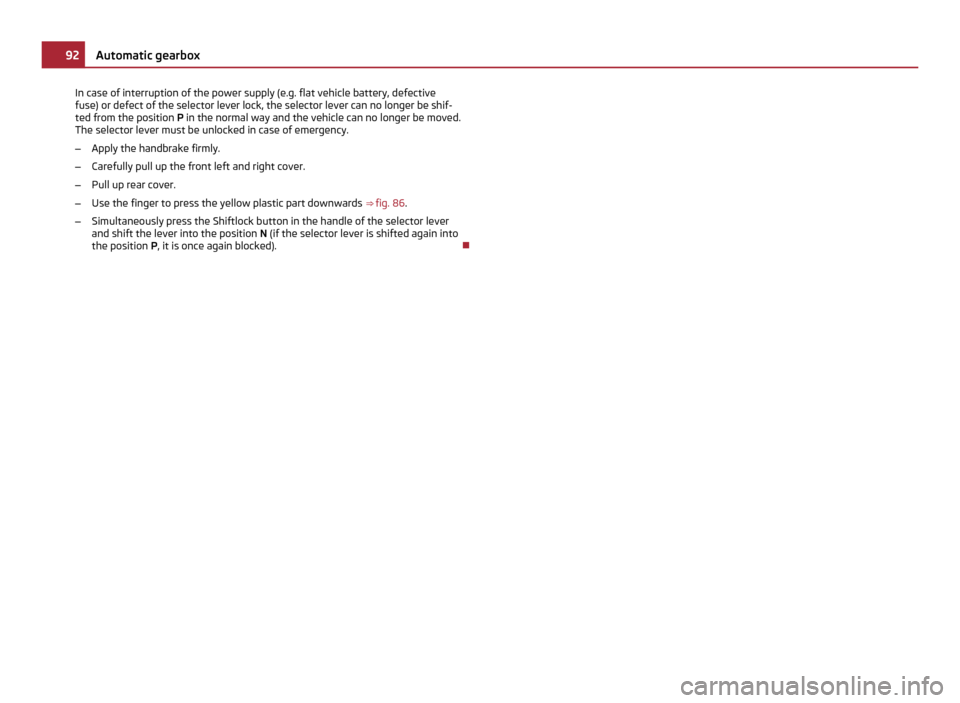

Selector lever-emergency unlocking Fig. 86 Selector lever-emergency un-

locking

£ 91

Automatic gearbox Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 94 of 212

In case of interruption of the power supply (e.g. flat vehicle battery, defective

fuse) or defect of the selector lever lock, the selector lever can no longer be shif-

ted from the position

P in the normal way and the vehicle can no longer be moved.

The selector lever must be unlocked in case of emergency.

– Apply the handbrake firmly.

– Carefully pull up the front left and right cover.

– Pull up rear cover.

– Use the finger to press the yellow plastic part downwards ⇒ fig. 86.

– Simultaneously press the Shiftlock button in the handle of the selector lever

and shift the lever into the position N (if the selector lever is shifted again into

the position P , it is once again blocked). 92

Automatic gearbox

Page 130 of 212

Low brake fluid level

An insufficient level of brake fluid may result in problems in the brake system. The

level of the brake fluid is monitored electronically

⇒ page 26, Brake system .WARNING

● Only apply the brakes for the purpose of drying and cleaning the brake

discs if the traffic conditions permit this. Do not place any other road users in

jeopardy.

● When retrospectively mounting a front spoiler, solid wheel hubs etc. one

must ensure that the air supply to the front wheel brakes is not reduced oth-

erwise the braking system could run too hot.

● Allow for the fact that new brake pads do not achieve their full braking ef-

ficiency until approximately 200 kilometres. New brake pads must be first

“run in

” before they develop their optimal friction force. You can, however,

compensate for this slightly reduced braking force by increasing the pressure

on the brake pedal. This guideline also applies to any new brake pads installed

at a future date. CAUTION

● Never allow the brakes to rub by applying slight pressure if you do not wish to

brake the vehicle. This causes the brakes to overheat and can also result in a lon-

ger braking distance and excessive wear.

● Before negotiating a steep downhill section, please reduce your speed, shift

down into the next lower gear (manual gearbox) or select a lower driving stage

(automatic gearbox). This enables you to make full use of the braking power of

the vehicle and reduces the strain on the brakes. Any additional braking should be

done intermittently, not continuously. Note

The brake light flashes automatically in case of an emergency braking at speeds

greater than 60 km/h or with the intervention of the ABS, which lasts longer than

1.5 seconds. After the speed was reduced below 10 km/h or the vehicle was stop-

ped, the brake light stops flashing and the hazard warning light system switches

on. The hazard warning light system is switched off automatically after accelerat-

ing or driving off again. Brake booster The brake booster boosts the pressure which you generate with the brake pedal.

The necessary pressure is only generated when the engine is running. WARNING

● Never switch off the engine before the vehicle is stationary.

● The brake booster only operates when the engine is running. Greater

physical effort for braking is required when engine is switched off. Because if

you do not stop as normal, this can cause an accident and severe injuries.

● While stopping or braking with a vehicle with a petrol engine and manual

transmission in the low rev range, press down on the clutch pedal. If you fail

to do so, the result may be an impairment of the function of the power brake.

You will apply a greater force to the brake pedal which you are used to - dan-

ger of accident!

Antilock brake system (ABS) ABS prevents the wheels locking when braking.

General

The ABS contributes significantly to enhancing the active safety of your vehicle.

Compared to a car not fitted with the ABS brake system, you are able to retain op-

timal steering ability even during a full brake application on a slippery road surface

because the wheels do not lock up.

You must not expect, however, that the braking distance will be shorter under all

circumstances as a result of the ABS. The braking distance for example on gravel

and fresh snow, when you should anyway be driving slowly and cautiously, will be

longer.

Operating principle

The brake pressure will be reduced on a wheel which is rotating at a speed which

is too low for the speed of the vehicle and tending to lock. This control cycle is

noticeable from a pulsating movement of the brake pedal which is accompanied

by noises. This is consciously intended to provide the driver with the information

that the wheels are tending to lock (ABS control range). You must always keep the

brake pedal depressed to enable the ABS to optimally control the brake applica-

tion in this braking range. Never interrupt the application of the brakes! £128

Intelligent Technology

Page 134 of 212

Driving and the Environment

The first 1 500 kilometres and afterwards

New engine The engine has to be run in during the first 1 500 kilometres.

Up to 1 000 kilometres

– Do not drive faster than 3/4 of the maximum speed of the gear in use, that is

3/4 of the maximum permissible engine speed.

– Do not use full throttle.

– Avoid high engine revolutions.

– Do not tow a trailer.

From 1 000 up to 1 500 kilometres

– Increase the power output of the engine gradually up to the full speed of the

gear engaged, that is up to the maximum permissible engine revolutions.

During the first operating hours the engine has higher internal friction than later

until all of the moving parts have harmonized. The driving style which you adopt

during the first approx.1 500 kilometres plays a decisive part in the success of run-

ning in your car.

You should not drive at unnecessarily high engine revolutions even after the run-

ning-in period is complete. The maximum permissible engine speed is marked by

the beginning of the red zone on the scale of the revolutions counter. Shift up in-

to the next higher gear on a vehicle fitted with manual gearbox before the red

zone is reached. During acceleration (depressing the accelerator) exceptionally

high engine speeds are automatically reduced, yet the engine is not protected

against too high engine speeds which are caused by incorrectly shifting down the

gears resulting in a sudden increase of the engine speeds above the permitted

maximum revolutions which can lead to engine damage.

For a vehicle fitted with a manual gearbox the converse situation also applies: Do

not drive at engine revolutions which are too low. Shift down as soon as the en-

gine is no longer running smoothly. CAUTION

All the speed and engine revolution figures apply only when the engine is at its

normal operating temperature. Never rev up an engine which is cold, neither when

the vehicle is stationary nor when driving in individual gears. For the sake of the environment

Not driving at unnecessarily high engine revolutions and shifting to a higher gear

as early as possible are ways to minimise fuel consumption and operating noise

levels and protects the environment.

New tyres New tyres have to be “run in” since they do not offer optimal grip at first. You

should take account of this fact for the first 500 kilometres and drive particularly

carefully.

New brake pads Allow for the fact that new brake pads do not achieve their full braking efficiency

until approximately 200 kilometres. New brake pads must be first “run in” before

they develop their optimal friction force. You can, however, compensate for this

slightly reduced braking force by increasing the pressure on the brake pedal.

This guideline also applies to any new brake pads installed at a future date.

During the running-in period, you should avoid excessive stresses on the brakes.

This includes, for example, violent braking, particularly from very high speeds, and

also when crossing mountain passes.

Catalytic converter Proper operation of the emission control system (catalytic convert-

er) is of major significance for driving your vehicle in an environ-

mentally conscious way.

Please refer to the following guidelines: £132

Driving and the Environment

Page 136 of 212

Shifting gears and saving energy

Shifting up early saves on fuel.

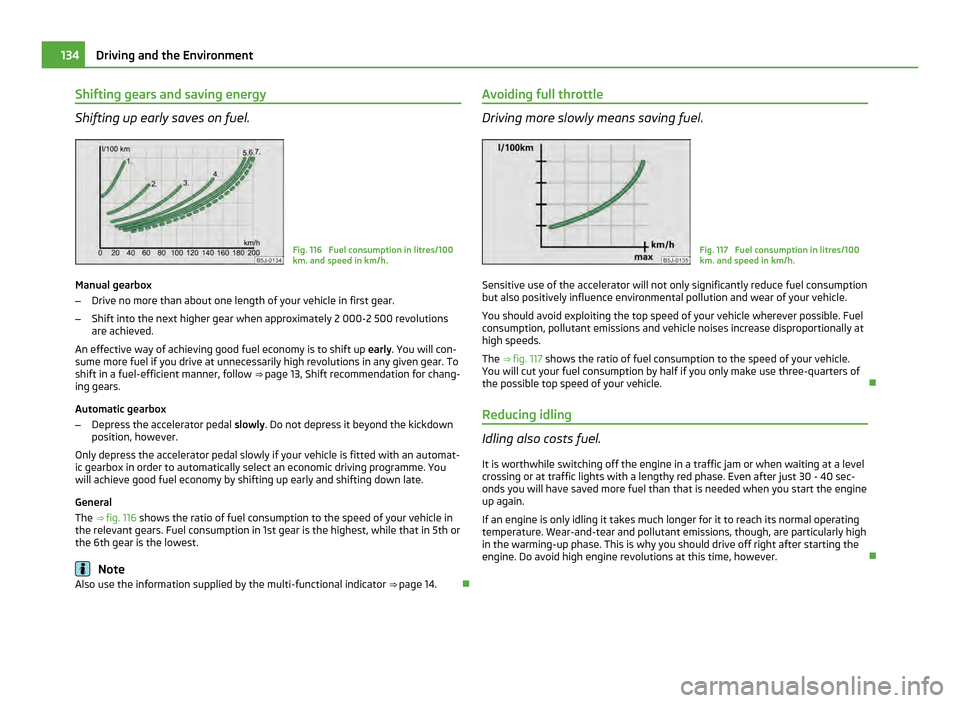

Fig. 116 Fuel consumption in litres/100

km. and speed in km/h.

Manual gearbox

– Drive no more than about one length of your vehicle in first gear.

– Shift into the next higher gear when approximately 2 000-2 500 revolutions

are achieved.

An effective way of achieving good fuel economy is to shift up early . You will con-

sume more fuel if you drive at unnecessarily high revolutions in any given gear. To

shift in a fuel-efficient manner, follow ⇒

page 13, Shift recommendation for chang-

ing gears.

Automatic gearbox

– Depress the accelerator pedal slowly. Do not depress it beyond the kickdown

position, however.

Only depress the accelerator pedal slowly if your vehicle is fitted with an automat-

ic gearbox in order to automatically select an economic driving programme. You

will achieve good fuel economy by shifting up early and shifting down late.

General

The ⇒ fig. 116 shows the ratio of fuel consumption to the speed of your vehicle in

the relevant gears. Fuel consumption in 1st

gear is the highest, while that in 5th or

the 6th gear is the lowest. Note

Also use the information supplied by the multi-functional indicator ⇒ page 14.Avoiding full throttle Driving more slowly means saving fuel.

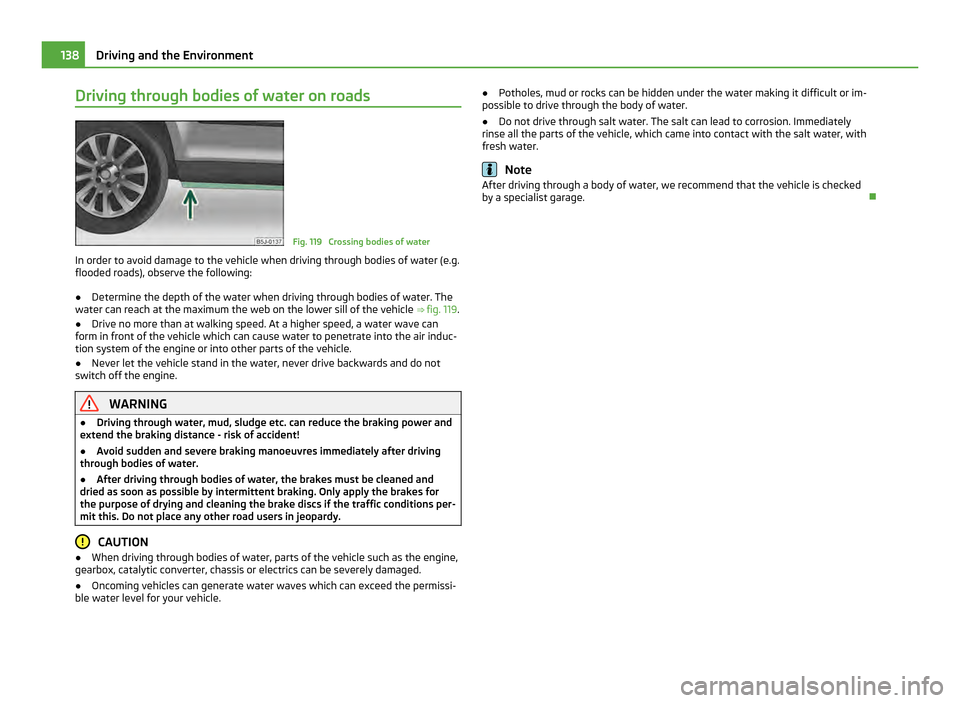

Fig. 117 Fuel consumption in litres/100

km. and speed in km/h.

Sensitive use of the accelerator will not only significantly reduce fuel consumption

but also positively influence environmental pollution and wear of your vehicle.

You should avoid exploiting the top speed of your vehicle wherever possible. Fuel

consumption, pollutant emissions and vehicle noises increase disproportionally at

high speeds.

The ⇒ fig. 117 shows the ratio of fuel consumption to the speed of your vehicle.

You will cut your fuel consumption by half if you only make use three-quarters of

the possible top speed of your vehicle.

Reducing idling Idling also costs fuel.

It is worthwhile switching off the engine in a traffic jam or when waiting at a level

crossing or at traffic lights with a lengthy red phase. Even after just 30 - 40 sec-

onds you will have saved more fuel than that is needed when you start the engine

up again.

If an engine is only idling it takes much longer for it to reach its normal operating

temperature. Wear-and-tear and pollutant emissions, though, are particularly high

in the warming-up phase. This is why you should drive off right after starting the

engine. Do avoid high engine revolutions at this time, however. 134

Driving and the Environment

Page 140 of 212

Driving through bodies of water on roads

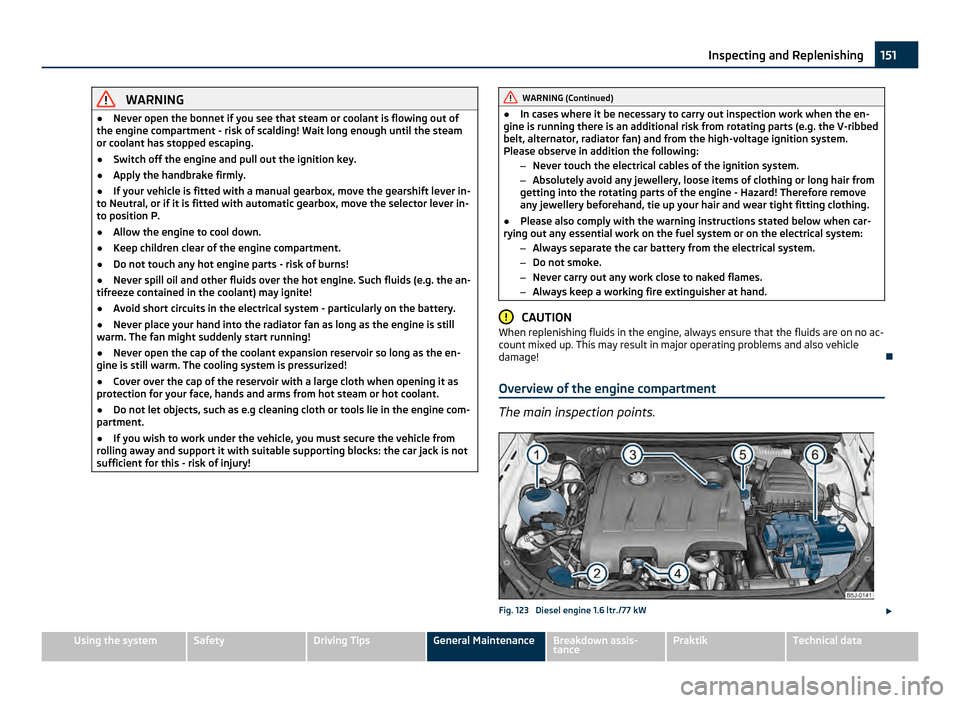

Fig. 119 Crossing bodies of water

In order to avoid damage to the vehicle when driving through bodies of water (e.g.

flooded roads), observe the following:

● Determine the depth of the water when driving through bodies of water. The

water can reach at the maximum the web on the lower sill of the vehicle ⇒

fig. 119 .

● Drive no more than at walking speed. At a higher speed, a water wave can

form in front of the vehicle which can cause water to penetrate into the air induc-

tion system of the engine or into other parts of the vehicle.

● Never let the vehicle stand in the water, never drive backwards and do not

switch off the engine. WARNING

● Driving through water, mud, sludge etc. can reduce the braking power and

extend the braking distance - risk of accident!

● Avoid sudden and severe braking manoeuvres immediately after driving

through bodies of water.

● After driving through bodies of water, the brakes must be cleaned and

dried as soon as possible by intermittent braking. Only apply the brakes for

the purpose of drying and cleaning the brake discs if the traffic conditions per-

mit this. Do not place any other road users in jeopardy. CAUTION

● When driving through bodies of water, parts of the vehicle such as the engine,

gearbox, catalytic converter, chassis or electrics can be severely damaged.

● Oncoming vehicles can generate water waves which can exceed the permissi-

ble water level for your vehicle. ●

Potholes, mud or rocks can be hidden under the water making it difficult or im-

possible to drive through the body of water.

● Do not drive through salt water. The salt can lead to corrosion. Immediately

rinse all the parts of the vehicle, which came into contact with the salt water, with

fresh water. Note

After driving through a body of water, we recommend that the vehicle is checked

by a specialist garage. 138

Driving and the Environment

Page 153 of 212

WARNING

● Never open the bonnet if you see that steam or coolant is flowing out of

the engine compartment - risk of scalding! Wait long enough until the steam

or coolant has stopped escaping.

● Switch off the engine and pull out the ignition key.

● Apply the handbrake firmly.

● If your vehicle is fitted with a manual gearbox, move the gearshift lever in-

to Neutral, or if it is fitted with automatic gearbox, move the selector lever in-

to position

P.

● Allow the engine to cool down.

● Keep children clear of the engine compartment.

● Do not touch any hot engine parts - risk of burns!

● Never spill oil and other fluids over the hot engine. Such fluids (e.g. the an-

tifreeze contained in the coolant) may ignite!

● Avoid short circuits in the electrical system - particularly on the battery.

● Never place your hand into the radiator fan as long as the engine is still

warm. The fan might suddenly start running!

● Never open the cap of the coolant expansion reservoir so long as the en-

gine is still warm. The cooling system is pressurized!

● Cover over the cap of the reservoir with a large cloth when opening it as

protection for your face, hands and arms from hot steam or hot coolant.

● Do not let objects, such as e.g cleaning cloth or tools lie in the engine com-

partment.

● If you wish to work under the vehicle, you must secure the vehicle from

rolling away and support it with suitable supporting blocks: the car jack is not

sufficient for this - risk of injury! WARNING (Continued)

● In cases where it be necessary to carry out inspection work when the en-

gine is running there is an additional risk from rotating parts (e.g. the V-ribbed

belt, alternator, radiator fan) and from the high-voltage ignition system.

Please observe in addition the following:

–Never touch the electrical cables of the ignition system.

– Absolutely avoid any jewellery, loose items of clothing or long hair from

getting into the rotating parts of the engine - Hazard! Therefore remove

any jewellery beforehand, tie up your hair and wear tight fitting clothing.

● Please also comply with the warning instructions stated below when car-

rying out any essential work on the fuel system or on the electrical system:

–Always separate the car battery from the electrical system.

– Do not smoke.

– Never carry out any work close to naked flames.

– Always keep a working fire extinguisher at hand. CAUTION

When replenishing fluids in the engine, always ensure that the fluids are on no ac-

count mixed up. This may result in major operating problems and also vehicle

damage!

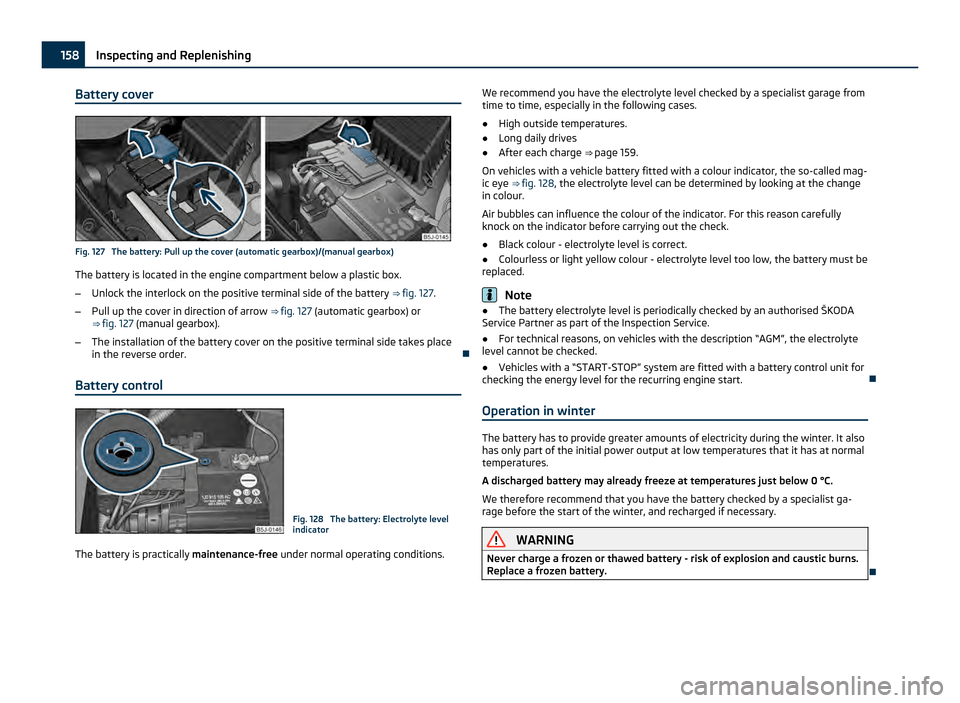

Overview of the engine compartment The main inspection points.

Fig. 123 Diesel engine 1.6 ltr./77 kW

£ 151

Inspecting and Replenishing Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 160 of 212

Battery cover

Fig. 127 The battery: Pull up the cover (automatic gearbox)/(manual gearbox)

The battery is located in the engine compartment below a plastic box.

– Unlock the interlock on the positive terminal side of the battery ⇒ fig. 127.

– Pull up the cover in direction of arrow ⇒ fig. 127 (automatic gearbox) or

⇒ fig. 127 (manual gearbox).

– The installation of the battery cover on the positive terminal side takes place

in the reverse order.

Battery control Fig. 128 The battery: Electrolyte level

indicator

The battery is practically maintenance-free under normal operating conditions. We recommend you have the electrolyte level checked by a specialist garage from

time to time, especially in the following cases.

● High outside temperatures.

● Long daily drives

● After each charge ⇒

page 159.

On vehicles with a vehicle battery fitted with a colour indicator, the so-called mag-

ic eye ⇒ fig. 128 , the electrolyte level can be determined by looking at the change

in colour.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

● Black colour - electrolyte level is correct.

● Colourless or light yellow colour - electrolyte level too low, the battery must be

replaced. Note

● The battery electrolyte level is periodically checked by an authorised

ŠKODA

Service Partner as part of the Inspection Service.

● For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

● Vehicles with a “START-STOP” system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

Operation in winter The battery has to provide greater amounts of electricity during the winter. It also

has only part of the initial power output at low temperatures that it has at normal

temperatures.

A discharged battery may already freeze at temperatures just below 0 °C.

We therefore recommend that you have the battery checked by a specialist ga-

rage before the start of the winter, and recharged if necessary. WARNING

Never charge a frozen or thawed battery - risk of explosion and caustic burns.

Replace a frozen battery. 158

Inspecting and Replenishing

Page 170 of 212

The vehicle tool kit contains the following parts (depending on equipment fitted):

●

Wheel wrench,

● Wire clamps for removing the full wheel trims,

● Towing eye,

● Adapter for the wheel bolts lock,

● Extraction pliers for wheel bolt caps,

● Replacement lamp,

● Screwdriver.

Before placing the lifting jack back in its storage area, screw in the arm of the lift-

ing jack fully. WARNING

● The factory-supplied lifting jack is only intended for your model of vehicle.

On no account attempt to lift a heavier vehicle or other loads - risk of injury!

● Ensure that the vehicle tool kit is safely attached in the luggage compart-

ment.

Spare wheel The spare wheel is stowed in the spare wheel well in the luggage

compartment below the floor covering.

Fig. 134 Luggage compartment: Spare

wheel

The spare wheel lies in a well under the floor covering of the luggage compart-

ment and is fixed in place along with a vehicle tool kit box using a special screw

⇒ fig. 134. One should check the inflation pressure in the spare wheel (at best when general-

ly checking the tyre air pressures - see sign on the fuel filler flap

⇒ page 148

) to

ensure that the spare wheel is always ready to use.

Unidirectional tyres

If you have such tyres on your vehicle, please refer to the notes below:

● The spare wheel provided with a car fitted with unidirectional tyres has differ-

ent dimensions. The wheel is provided with a warning sticker.

● The warning label must not be covered after installing the wheel.

● Do not drive faster than 80 km/h with this spare wheel and pay particular at-

tention while driving. Avoid accelerating at full throttle, sharp braking and fast

cornering.

● The inflation pressure for this spare wheel is identical to the inflation pressure

of the standard tyres.

● Use this spare wheel only to reach the nearest specialist garage as it is not in-

tended for continuous use.

Changing a wheel Preliminary work The following steps should be carried out before actually changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible

from the traffic flow. The place you choose should be level.

– Have all the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a

crash barrier, for example).

– Apply the handbrake firmly.

– Engage 1st gear or if your vehicle is fitted with an automatic gearbox, position

the selector lever into position P .

– If a trailer is coupled, uncouple it.

– Take the vehicle tool kit and the spare wheel ⇒

page 167 out of the luggage

compartment. £168

Breakdown assistance

Page 176 of 212

–

Have all the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a

crash barrier, for example).

– Switch off the engine and engage 1st gear or if your vehicle is fitted with an

automatic gearbox, position the selector lever into position P .

– Apply the handbrake firmly.

– Check whether you can carry out the repairs with the tyre repair kit

⇒ page 172, General information.

– If a trailer is coupled, uncouple it.

– Remove the tyre repair kit from the luggage compartment.

– Stick the sticker 2

⇒

fig. 141 on the dash panel in view of the driver.

– Do not remove the foreign body, e.g. screw or nail, from the tyre.

– Unscrew the valve cap.

– Use the valve remover 1 to remove the valve core and place it down on a

clean surface.

Seal and inflate tyres Sealing tyres

–

Forcefully shake the tyre inflator bottle 10

⇒ fig. 141 several times.

– Firmly screw inflation hose 3 onto the tyre inflator bottle in a clockwise direc-

tion 10 . The film on the cap is pierced automatically.

– Remove the plug from the inflation hose 3 and plug the open end fully into

the tyre valve.

– Hold the bottle 10 with the floor facing upwards and fill the whole sealing

agent in the tyre inflator bottle into the tyres.

– Remove the empty tyre inflator bottle from the valve.

– Screw the valve core back into the tyre valve using the valve remover 1 .

Pumping up the tyres

– Screw the tyre inflation hose 5

⇒

fig. 141 of the air compressor firmly onto the

tyre valve.

– Check whether the air release valve 7 is closed.–

On vehicles fitted with a manual gearbox, move the gearshift lever into Neu-

tral.

– Start the engine and run it in idle.

– Plug the connector 9 into 12 Volt socket ⇒

page 64.

– Switch on the air compressor with the ON and OFF switch 8 .

– Allow the air compressor to run until reaching a pressure of 2.0 - 2.5 bar. Maxi-

mum run time of 8 minutes ⇒ !

– Switch off the air compressor with the ON and OFF switch.

– If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose 5 from the tyre valve.

– Drive the vehicle approx. 10 metres forwards or backwards to allow the sealing

agent to distribute in the tyre.

– Screw the tyre inflation hose of the air compressor 5 firmly back onto the

tyre valve and repeat the inflation procedure.

– If you cannot reach the required tyre inflation pressure here either, this means

the tyre has sustained too much damage. You cannot seal with tyre with the

breakdown kit ⇒ .

– Switch off the air compressor with the ON and OFF switch.

– Remove the tyre inflation hose 5 from the tyre valve.

After reaching a tyre inflation pressure of 2.0 – 2.5 bar, drive at a maximum speed

of 80 km/h (50

mph).

Check the tyre inflation pressure after driving 10 minutes ⇒ page 175, Check after

driving for 10 minutes. WARNING

● During inflation, the tyre inflation hose and air compressor may get hot-

risk of injury!

● Do not place hot tyre inflation hoses or hot air compressors on flammable

materials - risk of fire!

● If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the tyre.

Do not drive the vehicle. Get professional assistance. £174

Breakdown assistance