wheel SKODA SUPERB 2011 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: SUPERB, Model: SKODA SUPERB 2011Pages: 252, PDF Size: 16.33 MB

Page 204 of 252

CAUTION■Only use the manual pressure and do not hit the full wheel trim – there is a

risk of damaging the trim.■

When using the anti-theft wheel bolt, ensure that it is in the hole in the

valve area.

■

If wheel trims are fitted, an adequate flow of air must be assured in order to

cool the brake system.

Note

We recommend that you use wheel trims from ŠKODA Original Accessories.

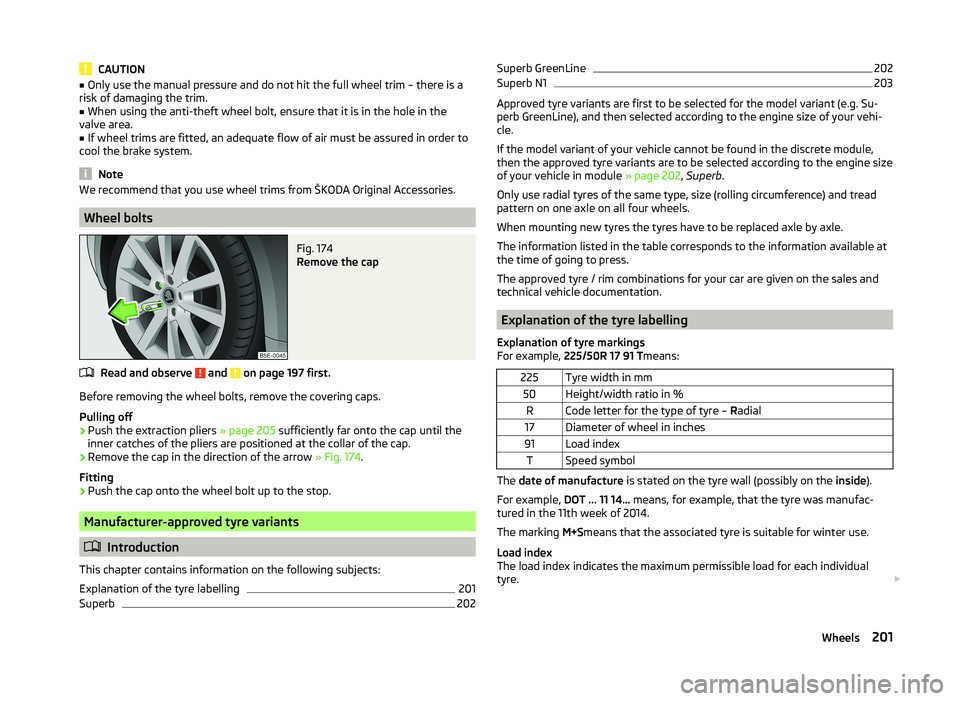

Wheel bolts

Fig. 174

Remove the cap

Read and observe and on page 197 first.

Before removing the wheel bolts, remove the covering caps.

Pulling off

›

Push the extraction pliers » page 205 sufficiently far onto the cap until the

inner catches of the pliers are positioned at the collar of the cap.

›

Remove the cap in the direction of the arrow » Fig. 174.

Fitting

›

Push the cap onto the wheel bolt up to the stop.

Manufacturer-approved tyre variants

Introduction

This chapter contains information on the following subjects:

Explanation of the tyre labelling

201

Superb

202Superb GreenLine202Superb N1203

Approved tyre variants are first to be selected for the model variant (e.g. Su-

perb GreenLine), and then selected according to the engine size of your vehi-

cle.

If the model variant of your vehicle cannot be found in the discrete module,

then the approved tyre variants are to be selected according to the engine size

of your vehicle in module » page 202, Superb .

Only use radial tyres of the same type, size (rolling circumference) and tread

pattern on one axle on all four wheels.

When mounting new tyres the tyres have to be replaced axle by axle.

The information listed in the table corresponds to the information available at the time of going to press.

The approved tyre / rim combinations for your car are given on the sales and

technical vehicle documentation.

Explanation of the tyre labelling

Explanation of tyre markings

For example, 225/50R 17 91 T means:

225Tyre width in mm50Height/width ratio in %RCode letter for the type of tyre – Radial17Diameter of wheel in inches91Load indexTSpeed symbol

The date of manufacture is stated on the tyre wall (possibly on the inside).

For example, DOT ... 11 14... means, for example, that the tyre was manufac-

tured in the 11th week of 2014.

The marking M+Smeans that the associated tyre is suitable for winter use.

Load index

The load index indicates the maximum permissible load for each individual

tyre.

201Wheels

Page 206 of 252

Superb N1MotorisationTyresizeMinimal

Load indexMinimal Speed icon

3.6 l/191 kW FSI

205/50 R1793W225/45 R1794W225/40 R1892Y

Winter operation

Introduction

This chapter contains information on the following subjects:

Winter tyres

203

Snow chains

203

Winter tyres

Summer tyres have less grip on ice, snow and at temperatures below 7 °C. This

is especially true of low-profile tyres or high-speed tyres .

Fitting winter tyres will significantly improve the handling of your vehicle when

driving in wintry road conditions.

To get best possible handling, winter tyres must be fitted to all four wheels.

The minimum tread depth must be 4 mm.

Winter tyres (marked with M+S and a peak/snowflake symbol) of a lower speed

category can be used provided that the permissible maximum speed of these

tyres is not exceeded even if the possible maximum speed of the vehicle is

higher.

Only use those tyres or wheel rims which have been approved by ŠKODA for

your model of vehicle.

The speed limit for winter tyres can be set in the MAXI DOT display in the Win-

ter tyres menu item » page 47.

For the sake of the environmentRe-fit the summer tyres at an appropriate time as they provide better handling

properties, a shorter braking distance, less tyre noise, and reduced tyre wear

on roads which are free of snow and ice as well as at temperatures above 7 °C.

The fuel consumption is also lower.

Snow chains

When driving in wintry road conditions, snow chains improve not only traction,

but also the braking performance.

Snow chains must only be mounted on the front wheels.

Only fit snow chains with links and locks not larger than 9 mm.

For technical reasons, it is only permissible to fit snow chains with the follow-

ing wheel/tyre combinations.

Wheel sizeDepth DTyre size7J x 16 a)45 mm205/55 R166J x 16 a)50 mm205/55 R166J x 1745 mm205/50 R17a)

Not valid for vehicles with 3.6 l/191 kW FSI engine.

Remove the full wheel trims before installing the snow chains » page 200.

WARNINGObserve the national legal regulations relating to the use of snow chains.

CAUTION

The chains are to be removed when driving on snow-free paths. They would

otherwise cause loss of performance and damage the tyres.203Wheels

Page 208 of 252

The fire extinguisher must be checked by an authorised person once a year.

National legal requirements must be observed.WARNINGThe fire extinguisher must always be secured safely so that they do not

come loose when making an emergency braking or in a vehicle collision

which could cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper function-

ing of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

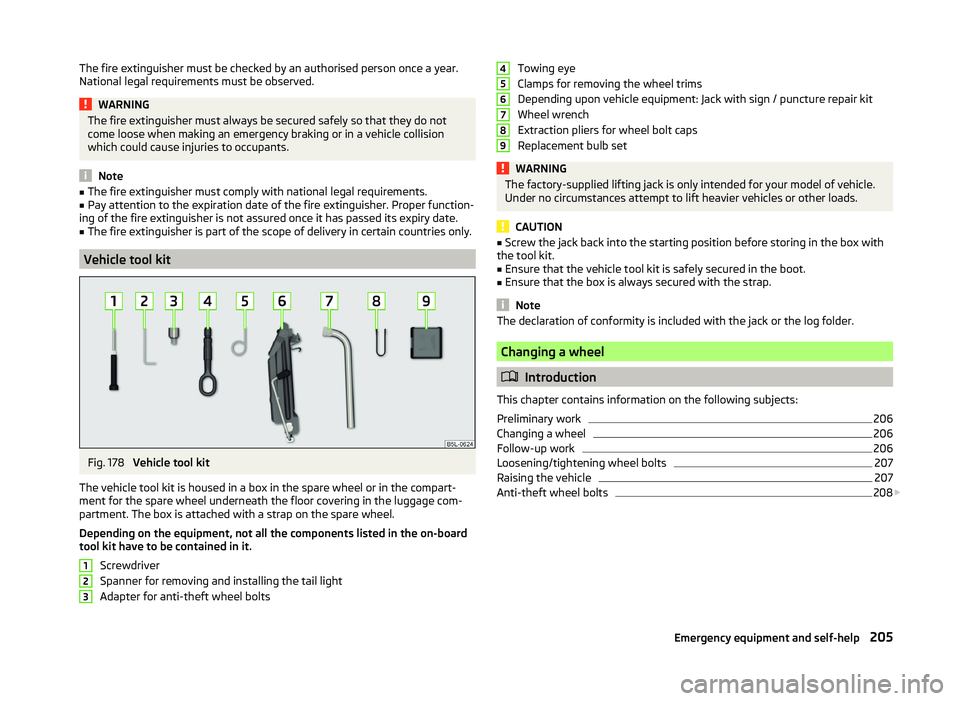

Vehicle tool kit

Fig. 178

Vehicle tool kit

The vehicle tool kit is housed in a box in the spare wheel or in the compart-

ment for the spare wheel underneath the floor covering in the luggage com-

partment. The box is attached with a strap on the spare wheel.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Screwdriver

Spanner for removing and installing the tail light

Adapter for anti-theft wheel bolts

123Towing eye

Clamps for removing the wheel trims

Depending upon vehicle equipment: Jack with sign / puncture repair kit

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb setWARNINGThe factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads.

CAUTION

■ Screw the jack back into the starting position before storing in the box with

the tool kit.■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

206

Changing a wheel

206

Follow-up work

206

Loosening/tightening wheel bolts

207

Raising the vehicle

207

Anti-theft wheel bolts

208

456789205Emergency equipment and self-help

Page 209 of 252

WARNING■If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory fitted ones » page 201,

Explanation of the tyre labelling .

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 206 first.

Before changing the wheel, the following work must be carried out.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Uncouple a trailer.

›Remove the

vehicle tool kit » page 205 and the spare wheel » page 200 from

the boot.

Changing a wheel

Read and observe

on page 206 first.

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the indication is cor-

rect » page 197 .

WARNINGIf it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

Follow-up work

Read and observe

on page 206 first.

After changing the wheel, the following work must be carried out.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 200 .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

206Do-it-yourself

Page 210 of 252

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, tyre pressure values are to be stor-

ed » page 166 .

Replace the damaged wheel or consult a specialist garage about repair op-

tions.WARNINGDrive cautiously and only at a moderate speed until the tightening torque

has been checked.

Loosening/tightening wheel bolts

Fig. 179

Changing a wheel: Loosening the

wheel bolts

Read and observe on page 206 first.

Before removing the wheel bolts, the caps for the wheel bolts must be pulled off.

Releasing

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt about one turn in the direction of

the arrow » Fig. 179.

Tightening

›

Push the wheel wrench onto the wheel bolt as far as the stop 1)

.

›

Grip the wrench at its end and turn the bolt against the direction of the ar-

row » Fig. 179 until it is tight.

After tightening the wheel bolts, the covering caps must be replaced.

WARNING■ Undo the wheel bolts only a little (about one turn) provided that the vehi-

cle has not yet been jacked up. Otherwise the wheel could become loose

and fall off.■

If it proves difficult to undo the bolts, carefully apply pressure to the end

of the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing.

Raising the vehicle

Fig. 180

Jacking points for positioning

lifting jack

Fig. 181

Attach lifting jack

Read and observe

on page 206 first.

In order to raise the vehicle, the jack from the tool kit is to be used.

Position the car jack at the jacking point closest to the flat tyre .

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 208.

207Emergency equipment and self-help

Page 211 of 252

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 181.›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking

point » Fig. 181 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 181 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNINGNotes for vehicle lifting■Choose a flat and firm surface for jacking the vehicle.■

If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.

■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

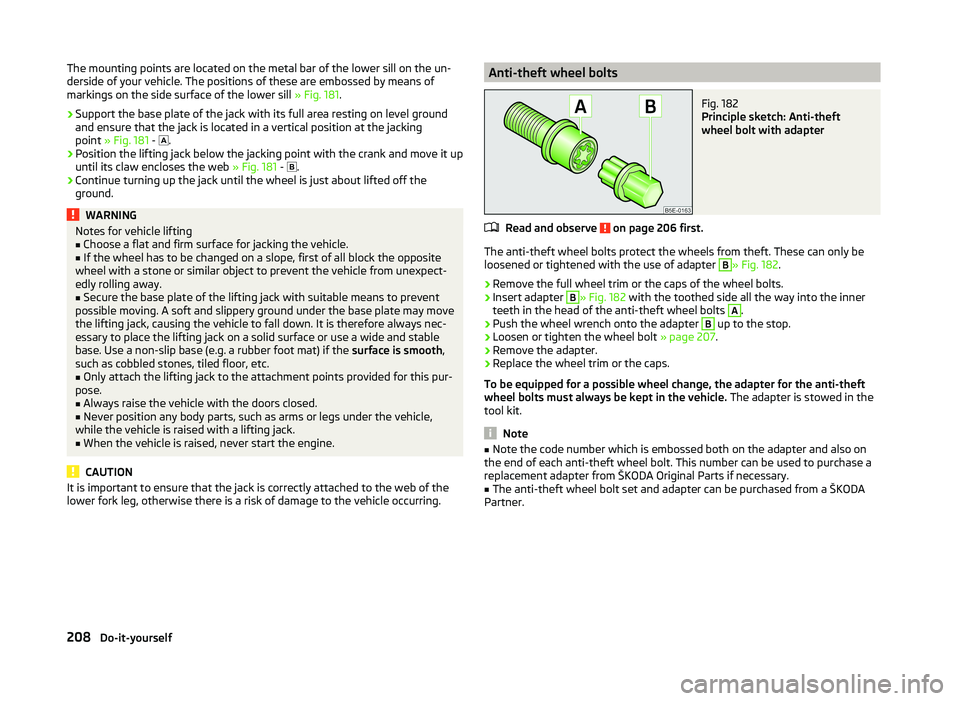

lower fork leg, otherwise there is a risk of damage to the vehicle occurring.Anti-theft wheel boltsFig. 182

Principle sketch: Anti-theft

wheel bolt with adapter

Read and observe on page 206 first.

The anti-theft wheel bolts protect the wheels from theft. These can only be loosened or tightened with the use of adapter

B

» Fig. 182 .

›

Remove the full wheel trim or the caps of the wheel bolts.

›

Insert adapter

B

» Fig. 182 with the toothed side all the way into the inner

teeth in the head of the anti-theft wheel bolts

A

.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 207.

›

Remove the adapter.

›

Replace the wheel trim or the caps.

To be equipped for a possible wheel change, the adapter for the anti-theft

wheel bolts must always be kept in the vehicle. The adapter is stowed in the

tool kit.

Note

■ Note the code number which is embossed both on the adapter and also on

the end of each anti-theft wheel bolt. This number can be used to purchase a

replacement adapter from ŠKODA Original Parts if necessary.■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

208Do-it-yourself

Page 212 of 252

Puncture set

Introduction

This chapter contains information on the following subjects:

Components of the puncture repair kits

209

Preparations for using the breakdown kit

210

Sealing and inflating the tyre

210

Notes for driving with tyre repaired

211

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a perma-

nent repair on the tyre. Its purpose is to get you to the nearest specialist ga-

rage.

The wheel need not be removed during the repair.

Do not remove foreign bodies , e.g. screws or nails, from the tyre.

The breakdown kit must not be used under the following circumstances. › There is damage to the rim.

› The outside temperature is less than -20 °C.

› The tears or punctures are greater than 4 mm in size.

› There is damage to the tyre wall.

› Driving with very low tyre pressure or with a completely flat tyre.

› If the use-by-date (see inflation bottle) has passed.

WARNING■

If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

WARNING■ A tyre filled with sealant has the same driving characteristics as a stand-

ard tyre.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

WARNING (Continued)■ The sealant is hazardous to heath. Remove immediately if it comes into

contact with the skin.■

Observe the manufacturer's usage instructions for the breakdown kit.

For the sake of the environment

Used sealant or sealant whose expiry date has passed must be disposed of in

accordance with environmental protection regulations.

Note

■ A new bottle of sealant can be purchased from ŠKODA Original Parts.■Immediately replace the tyre that was repaired using the breakdown kit, or

consult a specialist garage about repair options.■

The national legal requirements must be observed when repairing a tyre.

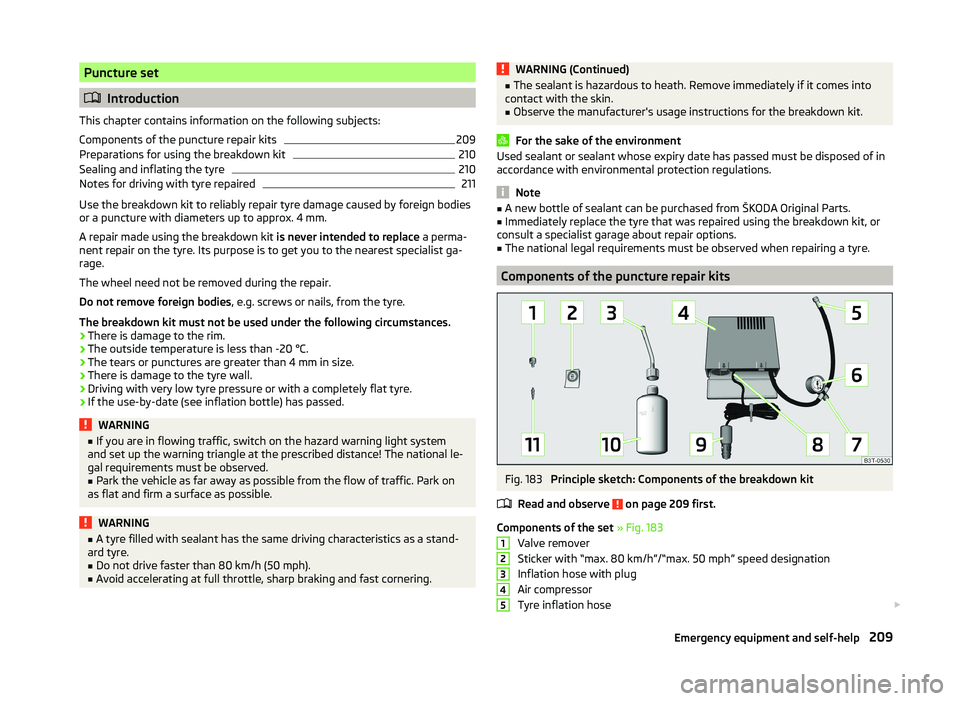

Components of the puncture repair kits

Fig. 183

Principle sketch: Components of the breakdown kit

Read and observe

on page 209 first.

Components of the set » Fig. 183

Valve remover

Sticker with “max. 80 km/h”/“max. 50 mph” speed designation

Inflation hose with plug

Air compressor

Tyre inflation hose

12345209Emergency equipment and self-help

Page 213 of 252

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.

Preparations for using the breakdown kit

Read and observe

on page 209 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit

» page 209.

›

Uncouple a trailer.

›

Remove the breakdown kit from the boot.

›

Stick the appropriate sticker

2

» Fig. 183 on page 209 onto the dashboard in

the driver's field of view.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

67891011Sealing and inflating the tyre

Read and observe

on page 209 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 183 on page 209 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

1

.

Inflating

›

Screw the air compressor tyre inflation hose

5

» Fig. 183 on page 209 firmly

onto the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 91, Cigarette lighter .

›

Switch on the air compressor with the ON and OFF switch

8

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre pressure of 2.0 - 2.5 bar is reached, the journey may be continued

at a maximum speed of 80 km/h (50 mph).

210Do-it-yourself

Page 216 of 252

›After starting the engine, close the protective cap of the jump-starting point.

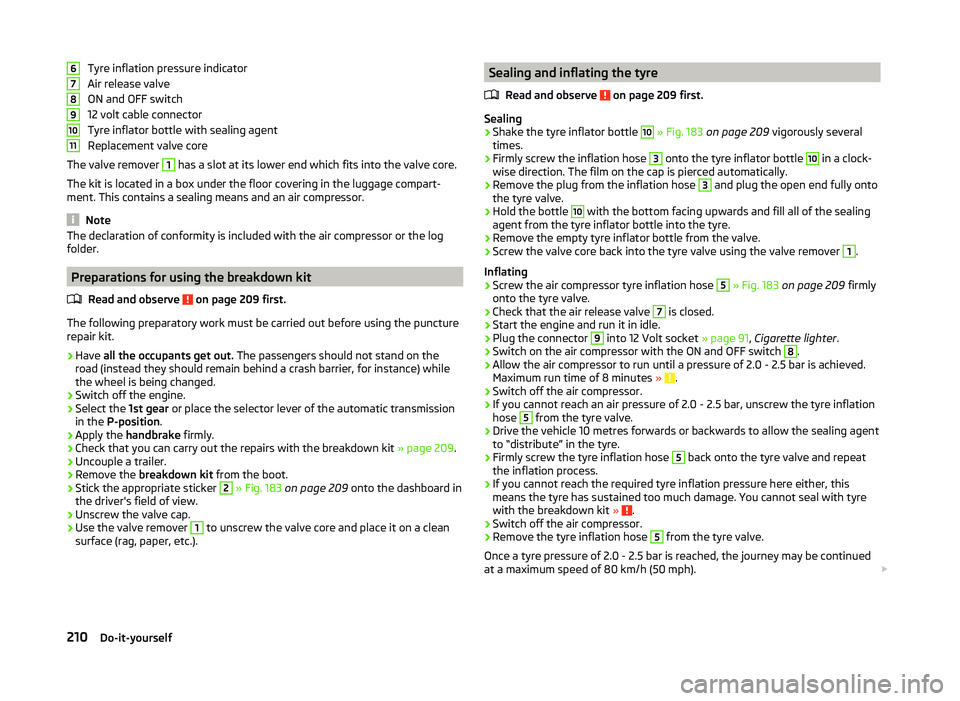

Towing the vehicle

Introduction

Fig. 187

Braided tow rope / Spiral tow rope

This chapter contains information on the following subjects:

Front towing eye

214

Rear towing eye

214

Vehicles with a tow hitch

214

For towing a braided tow rope is to be used » Fig. 187-

.

The following guidelines must be observed when towing.

Vehicles with manual transmission may be towed in with a tow bar or a tow

rope or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the auto-

matic gearbox is damaged!

Driver of the tow vehicle

›

Engage the clutch gently when starting off or depress the accelerator partic-

ularly gently if the vehicle is fitted with an automatic gearbox.

›

Only then, approach correctly when the rope is taut.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle›Switch on the ignition so that the steering wheel is not locked and so that

the turn signal lights, windscreen wipers and windscreen washer system can

be used.›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the

engine is running. If the engine is not running, significantly more physical force

is required to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

Both drivers should be familiar with the problems which might possibly occur while a vehicle is being towed. Unskilled drivers should not attempt to tow in

another vehicle or to be towed in.

The vehicle must be transported on a special breakdown vehicle or trailer if it

is not possible to tow in the vehicle in the way described or if the towing dis-

tance is greater than 50 km.

WARNING■ When towing, respect the national legal provisions, especially those

which relate to the identification of the towing vehicle and the vehicle be-

ing towed.■

When towing, exercise increased caution.

■

For towing no spiral tow rope is to be used » Fig. 187-

, the towing eye

may unscrew out of the vehicle - there is a risk of accidents.

■

The tow rope should not be twisted - there is a risk of accidents.

CAUTION

■ Do not tow start the engine – there is a risk of damaging the engine and the

catalytic converter. The battery from another vehicle can be used as a jump-

start aid » page 211 , Jump-starting .■

If the gearbox no longer contains any oil, your vehicle must only be towed

with the front axle raised clear of the ground or on a breakdown vehicle or

trailer.

■

To protect both vehicles when tow-starting or towing, the tow rope should

be elastic. Thus one should only use plastic fibre rope or a rope made out of a

similarly elastic material.

213Emergency equipment and self-help

Page 217 of 252

■There is always a risk of excessive stresses and damage resulting at the

points to which you attach the tow rope or tow bar when you attempt to tow a

vehicle which is not standing on a paved road.■

Attach the tow rope or the tow bar to the towing eyes » page 214 , Front

towing eye or » page 214 , Rear towing eye to the detachable ball head of the

towing equipment » page 166 .

Note

We recommend using a tow rope from ŠKODA Original Accessories, which is

available from a ŠKODA Partner.

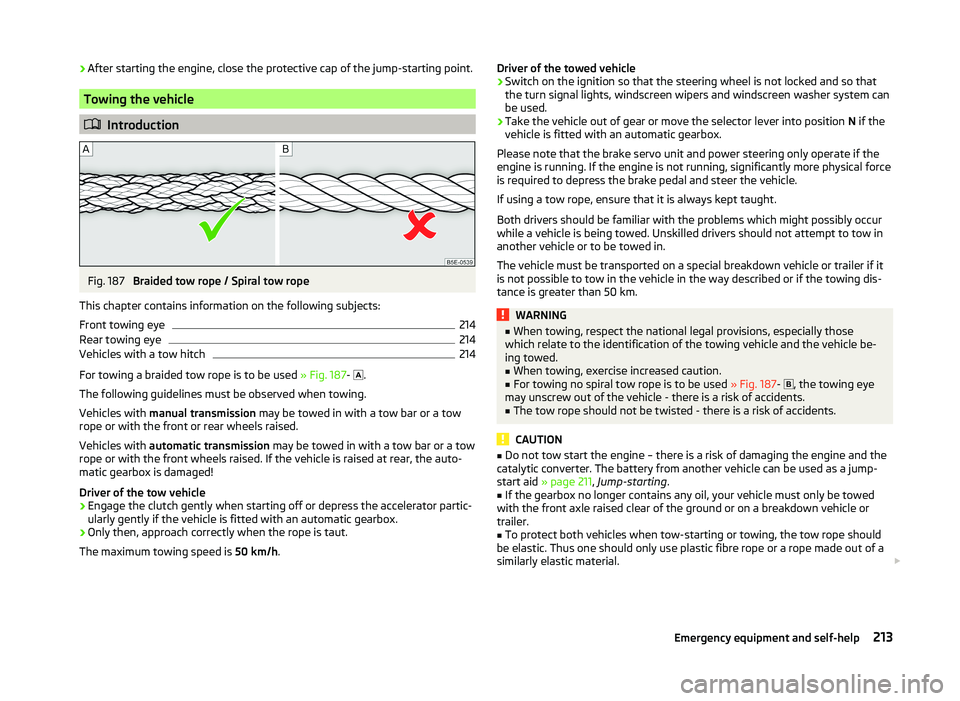

Front towing eye

Fig. 188

Removing the cap / installing the towing eye

Read and observe

and on page 213 first.

›

Remove the cap from the front bumper » Fig. 188 -

.

›

Screw-in the towing eye by turning to the left up to the stop

» Fig. 188 -

and tighten as much as possible. For tightening purposes, we recommend,

for example, using the wheel wrench, towing eye from another vehicle or a

similar object that can be pushed through the eye.

›

After unscrewing the towing eye, put the cap on and press into place.

The cap must engage firmly.

WARNINGThe towing eye must always be screwed in fully and firmly tightened, oth-

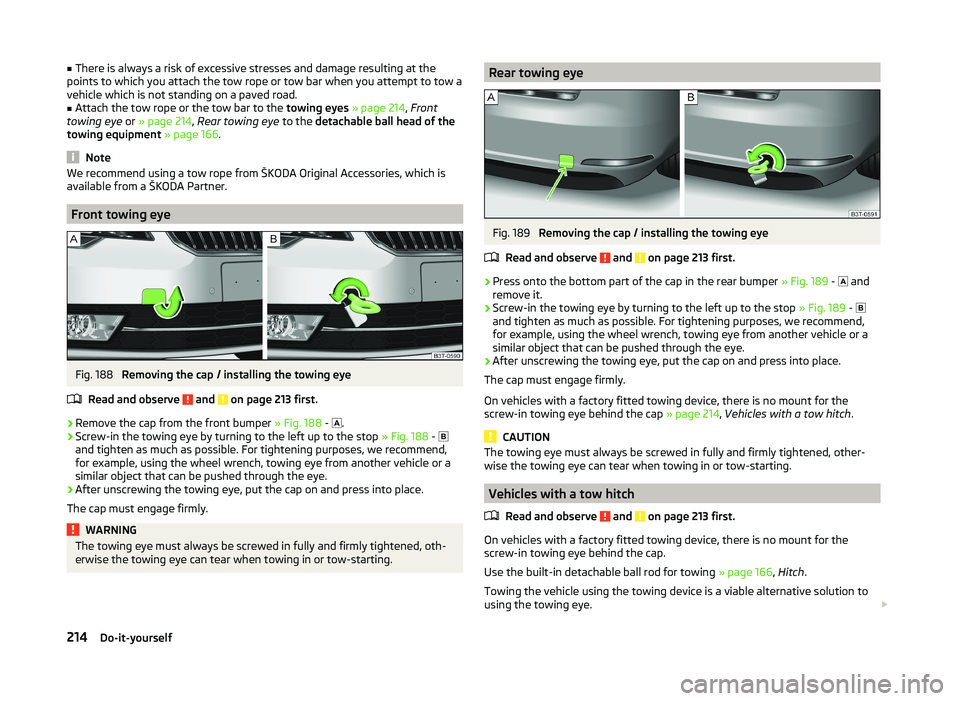

erwise the towing eye can tear when towing in or tow-starting.Rear towing eyeFig. 189

Removing the cap / installing the towing eye

Read and observe

and on page 213 first.

›

Press onto the bottom part of the cap in the rear bumper » Fig. 189 -

and

remove it.

›

Screw-in the towing eye by turning to the left up to the stop » Fig. 189 -

and tighten as much as possible. For tightening purposes, we recommend,

for example, using the wheel wrench, towing eye from another vehicle or a

similar object that can be pushed through the eye.

›

After unscrewing the towing eye, put the cap on and press into place.

The cap must engage firmly.

On vehicles with a factory fitted towing device, there is no mount for the

screw-in towing eye behind the cap » page 214, Vehicles with a tow hitch .

CAUTION

The towing eye must always be screwed in fully and firmly tightened, other-

wise the towing eye can tear when towing in or tow-starting.

Vehicles with a tow hitch

Read and observe

and on page 213 first.

On vehicles with a factory fitted towing device, there is no mount for the

screw-in towing eye behind the cap.

Use the built-in detachable ball rod for towing » page 166, Hitch .

Towing the vehicle using the towing device is a viable alternative solution to using the towing eye.

214Do-it-yourself