lights SKODA SUPERB 2014 2.G / (B6/3T) Manual PDF

[x] Cancel search | Manufacturer: SKODA, Model Year: 2014, Model line: SUPERB, Model: SKODA SUPERB 2014 2.G / (B6/3T)Pages: 246, PDF Size: 17.16 MB

Page 192 of 246

Warning symbols on the vehicle batterySymbolImportanceAlways wear eye protection.Battery acid is severely caustic. Always wear gloves and eye pro-

tection.Keep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery.When charging the vehicle battery, a highly explosive gas mixture

is produced.Keep children away from the vehicle battery.WARNINGThere is risk of injuries, poisoning, chemical burns, explosions or fire when

working on the battery and on the electrical system. It is essential to com-

ply with the general applicable safety rules as well as the warning instruc-

tions outlined below.■

Keep the vehicle battery away from people who are not completely inde-

pendent, especially children.

■

Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings. Protect your eyes by wearing safety goggles or a

face shield – risk of blindness!

■

Always wear protective gloves, eye and skin protection when handling

the vehicle battery.

■

The battery acid is strongly corrosive and must, therefore, be handled

with the greatest of care.

■

Corrosive fumes in the air irritate the air passages and lead to conjunctivi-

tis and inflammation of the air passages in the lungs.

■

Battery acid corrodes dental enamel and, if it comes into contact with the

skin, causes deep wounds that take a long time to heal. Repeated contact

with diluted acids causes skin diseases (inflammations, ulcers, slin cracks).

■

If any battery acid comes into contact with your eyes, rinse the affected

eye immediately with clean water for several minutes and consult a doctor

immediately!

■

Splashes of acid on your skin or clothes should be neutralised as soon as

possible using soap suds and then rinsed with plenty of water. If you swal-

low battery acid, consult a doctor immediately!

WARNING■ It is prohibited to work with naked flames or lights.■It is prohibited to smoke or carry out any activities that produce sparks.■

Never use a damaged vehicle battery – risk of explosion!

■

Never charge a frozen or thawed vehicle battery – risk of explosion and

chemical burns!

■

Replace a frozen vehicle battery.

■

Never jump-start vehicle batteries with insufficient acid levels – risk of

explosion and chemical burns.

WARNING■ When you charge a battery, hydrogen is released, and a highly explosive

gas mixture is also produced. An explosion can be caused through sparkling

over during unclamping or loosening of the cable plug while the ignition is

on.■

Creating a bridge between the poles on the battery (e.g. with a metal ob-

ject or cable) creates a short circuit - risk of melting the lead bars, and risk

of explosion, battery fire and acid splashes.

■

Avoid creating sparks when working with cables and electrical devices.

Strong sparking represents a risk of injury.

■

Before carrying out any work on the electrical system, switch off the en-

gine, the ignition and all electrical components and disconnect the negative

terminal (-) on the battery.

CAUTION

Improper handling of the battery can lead to damage. We recommend having

all work on the vehicle battery carried out by a specialist garage.

CAUTION

■ The vehicle battery must only be disconnected if the ignition is switched off,

otherwise the vehicle's electrical system (electronic components) can be dam-

aged. When disconnecting the battery from the electrical system, first of all

disconnect the negative terminal (-) of the battery, and then the positive ter-

minal (+).■

When connecting the battery to the electrical system, first of all connect the

positive terminal (+) of the battery, and then the negative terminal (-). Under

no circumstances must the battery cables be connected incorrectly – risk of a

cable fire.

■

Ensure that battery acid does not come into contact with the bodywork – risk

of damage to the paintwork.

190General Maintenance

Page 195 of 246

OperationOperating measureSetting the clock» page 30Data in the multifunction display are de-

leted.» page 41

Note

We recommend having the vehicle checked by a specialist garage in order to

ensure full functionality of all electrical systems.

Automatic load deactivation

Read and observe

and on page 190 first.

The vehicle voltage control unit automatically prevents the battery from dis-

charging when the battery is put under high levels of strain. This manifests it-

self by the following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where necessary, large convenience consumers such as seat heaters and

rear window heaters have their power limited or are shut off completely in

the event of an emergency.

CAUTION

■ Despite such intervention by the vehicle electric system management, the

vehicle battery may be drained. For example, when the ignition is switched on

a long time with the engine turned off or the side or parking lights are turned

on during longer parking.■

Consumers that are supplied via a 12-V power socket can cause the vehicle

battery to discharge when the ignition is switched off.

Note

Driving comfort is not impaired by consumers being deactivated. The driver is

often not aware of it having taken place.Wheels

Tyres and wheel rims

Introduction

This chapter contains information on the following subjects:

Service life of tyres

194

New tyres

195

Unidirectional tyres

196

Tyre pressure monitor

196

Spare and temporary spare wheel

197

Full wheel trim

198

Wheel bolts

198

Wheel bolts

198WARNINGThe national legal regulations must be observed for the use of tyres.WARNINGInstructions for the use of tyres■For the first 500 km, new tyres do not yet provide optimum grip, and ap-

propriate care should therefore be taken when driving – risk of accident!■

Only use radial tyres of the same type, size (rolling circumference) and

tread pattern on all four wheels.

■

For reasons of driving safety, do not replace tyres individually.

■

Never exceed the maximum permissible load bearing capacity for fitted

tyres – risk of accident!

■

Never exceed the maximum permissible speed for fitted tyres – risk of ac-

cident!

■

Incorrect wheel alignment at the front or rear impairs handling – risk of

accident!

■

Unusual vibrations or pulling of the vehicle to one side could be a sign of

tyre damage. If there is any doubt that a wheel is damaged, immediately re-

duce your speed and stop! If no external damage is evident, drive slowly

and carefully to the nearest specialist garage to have the vehicle checked.

■

Only use tyres or wheel rims that have been approved by ŠKODA for your

model of vehicle. Failure to observe this instruction may impair the road

safety of your vehicle – risk of accident!

193Wheels

Page 198 of 246

Where possible, replace tyres by axle. Always fit the tyres with the deeper

tread depth to the front wheels.

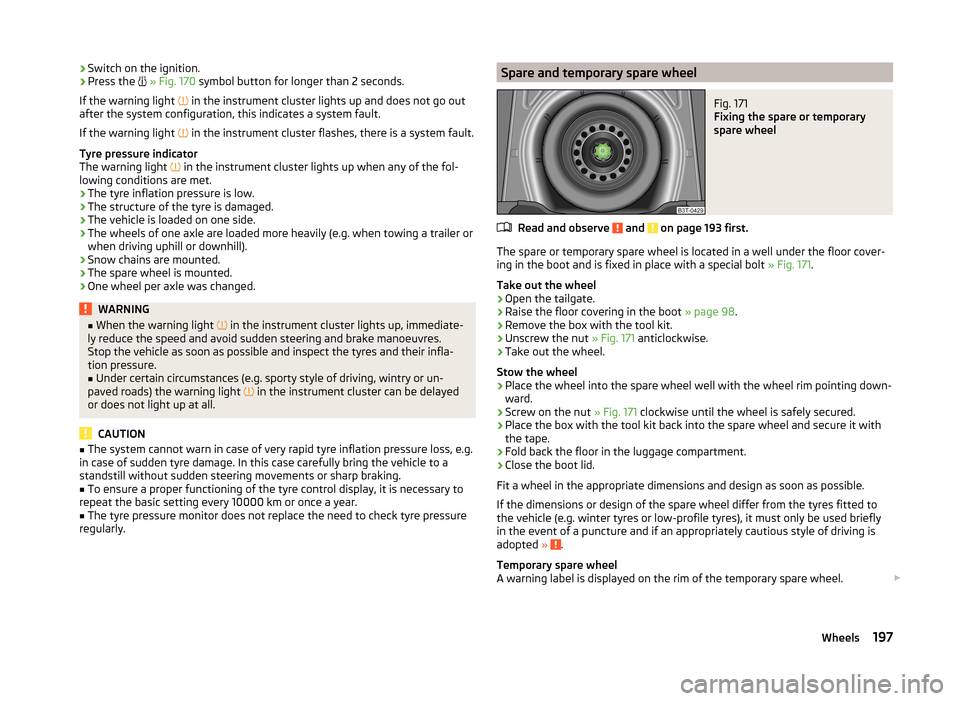

Explanation of tyre markings

205/55 R 16 94 V

What this means is:205Tyre width in mm » Fig. 168 on page 194 - 55Height/width ratio in % » Fig. 168 on page 194 - RCode letter for the type of tyre – Radial » Fig. 168 on page 194 -

16Diameter of wheel in inches » Fig. 168 on page 194 - 94Load index » VSpeed symbol »

The date of manufacture is stated on the tyre wall (possibly on the inside). e.g.

DOT ... 11 14...

means, for example, that the tyre was manufactured in the 11th week of 2014.

Load index

This indicates the maximum permissible load for each individual tyre.

615 kg

630 kg

650 kg

670 kg

690 kg

730 kg

775 kg

Speed symbol

This indicates the maximum permissible vehicle speed with fitted tyres in each

category.

130 km/h

160 km/h

170 km/h

180 km/h

190 km/h

200 km/h

210 km/h

91929394959799MQRSTUH240 km/h

270 km/h

300 km/h

CAUTION

The information about the load index and the speed symbol is listed in your

vehicle documents.

Unidirectional tyres

Read and observe

and on page 193 first.

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The indicated direction of rotation must be adhered to in order to ensure the

optimal characteristics of these tyres.

These characteristics mainly relate to the following: › Increased driving stability.

› Reduced risk of aquaplaning.

› Reduced tyre noise and tyre wear.

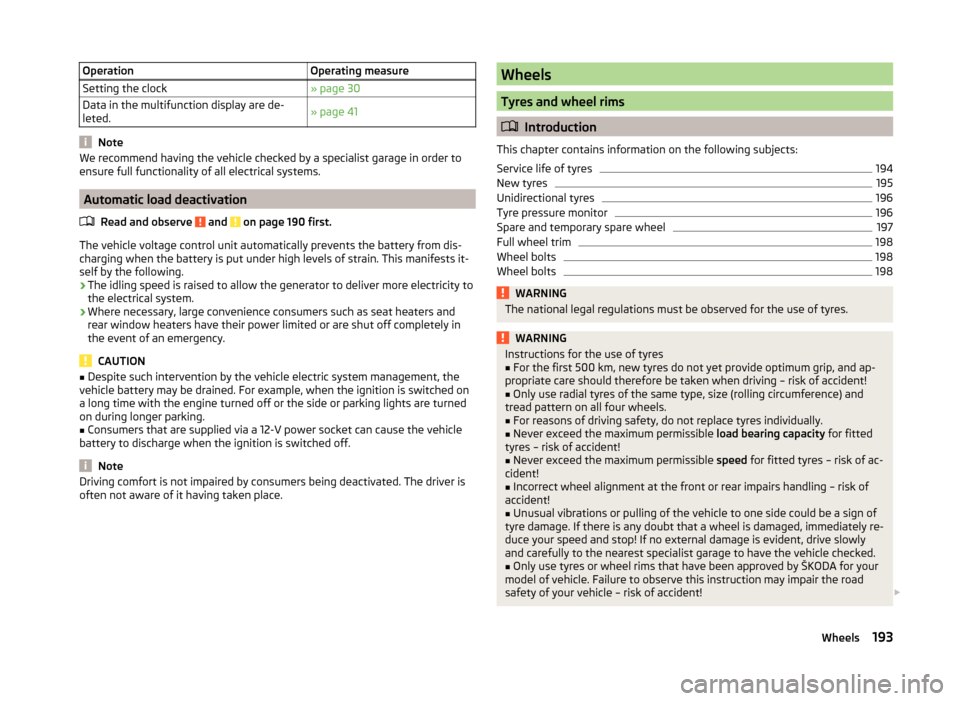

Tyre pressure monitor

Fig. 170

Button for setting the tyre infla-

tion pressure control value

Read and observe and on page 193 first.

System settings

After changing the tyre inflation pressure, after changing one or several

wheels, the position of a wheel on the vehicle (e.g. exchanging the wheels be-

tween the axles) or when the warning light lights up while driving, a system

configuration must be carried out as follows.

›

Inflate all of the tyres to the specified inflation pressure » page 195.

V

WY196General Maintenance

Page 199 of 246

›Switch on the ignition.›Press the

» Fig. 170 symbol button for longer than 2 seconds.

If the warning light

in the instrument cluster lights up and does not go out

after the system configuration, this indicates a system fault.

If the warning light

in the instrument cluster flashes, there is a system fault.

Tyre pressure indicator

The warning light

in the instrument cluster lights up when any of the fol-

lowing conditions are met.

› The tyre inflation pressure is low.

› The structure of the tyre is damaged.

› The vehicle is loaded on one side.

› The wheels of one axle are loaded more heavily (e.g. when towing a trailer or

when driving uphill or downhill).

› Snow chains are mounted.

› The spare wheel is mounted.

› One wheel per axle was changed.WARNING■

When the warning light in the instrument cluster lights up, immediate-

ly reduce the speed and avoid sudden steering and brake manoeuvres.

Stop the vehicle as soon as possible and inspect the tyres and their infla-

tion pressure.■

Under certain circumstances (e.g. sporty style of driving, wintry or un-

paved roads) the warning light

in the instrument cluster can be delayed

or does not light up at all.

CAUTION

■ The system cannot warn in case of very rapid tyre inflation pressure loss, e.g.

in case of sudden tyre damage. In this case carefully bring the vehicle to a

standstill without sudden steering movements or sharp braking.■

To ensure a proper functioning of the tyre control display, it is necessary to

repeat the basic setting every 10000 km or once a year.

■

The tyre pressure monitor does not replace the need to check tyre pressure

regularly.

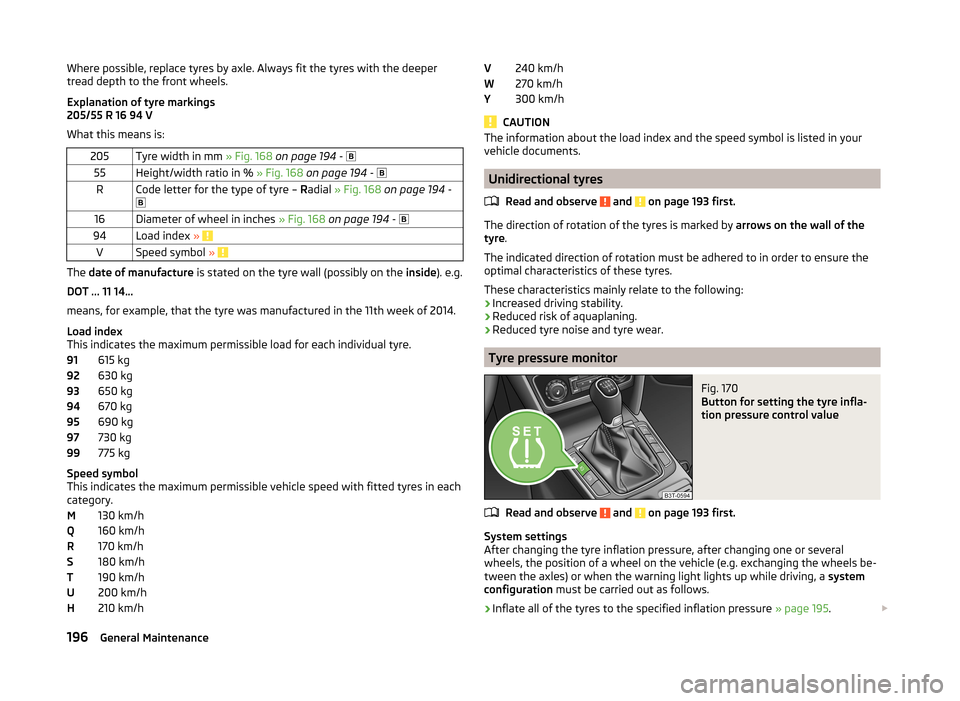

Spare and temporary spare wheelFig. 171

Fixing the spare or temporary

spare wheel

Read and observe and on page 193 first.

The spare or temporary spare wheel is located in a well under the floor cover-

ing in the boot and is fixed in place with a special bolt » Fig. 171.

Take out the wheel

›

Open the tailgate.

›

Raise the floor covering in the boot » page 98.

›

Remove the box with the tool kit.

›

Unscrew the nut » Fig. 171 anticlockwise.

›

Take out the wheel.

Stow the wheel

›

Place the wheel into the spare wheel well with the wheel rim pointing down-

ward.

›

Screw on the nut » Fig. 171 clockwise until the wheel is safely secured.

›

Place the box with the tool kit back into the spare wheel and secure it with

the tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Fit a wheel in the appropriate dimensions and design as soon as possible.

If the dimensions or design of the spare wheel differ from the tyres fitted to

the vehicle (e.g. winter tyres or low-profile tyres), it must only be used briefly

in the event of a puncture and if an appropriately cautious style of driving is

adopted »

.

Temporary spare wheel

A warning label is displayed on the rim of the temporary spare wheel.

197Wheels

Page 210 of 246

Negative cable - colour coding in the majority of cases is black.

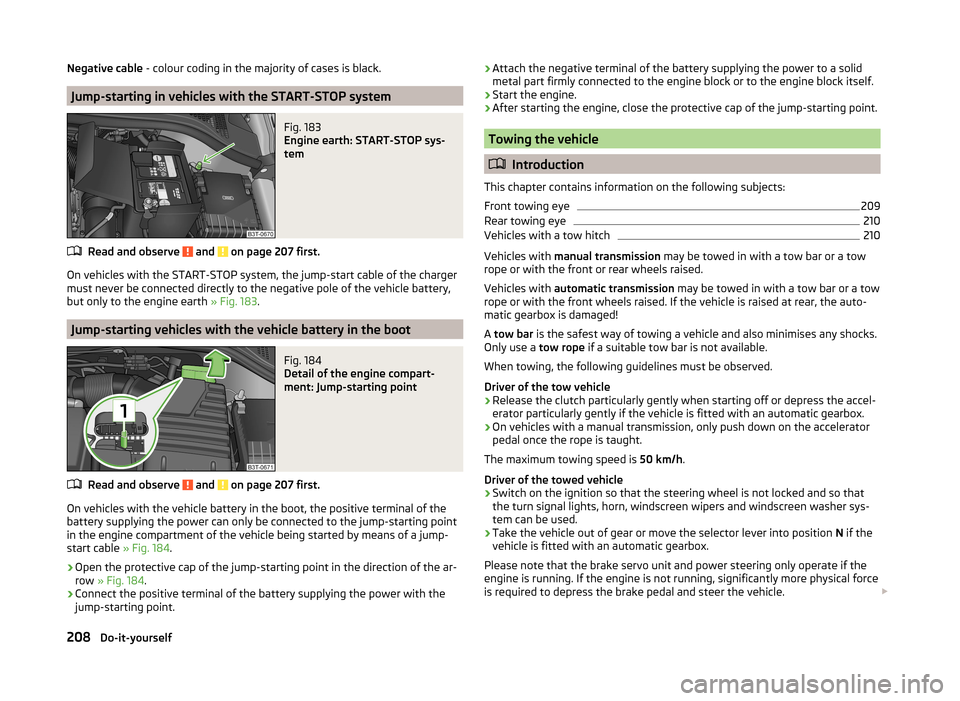

Jump-starting in vehicles with the START-STOP system

Fig. 183

Engine earth: START-STOP sys-

tem

Read and observe and on page 207 first.

On vehicles with the START-STOP system, the jump-start cable of the charger

must never be connected directly to the negative pole of the vehicle battery,

but only to the engine earth » Fig. 183.

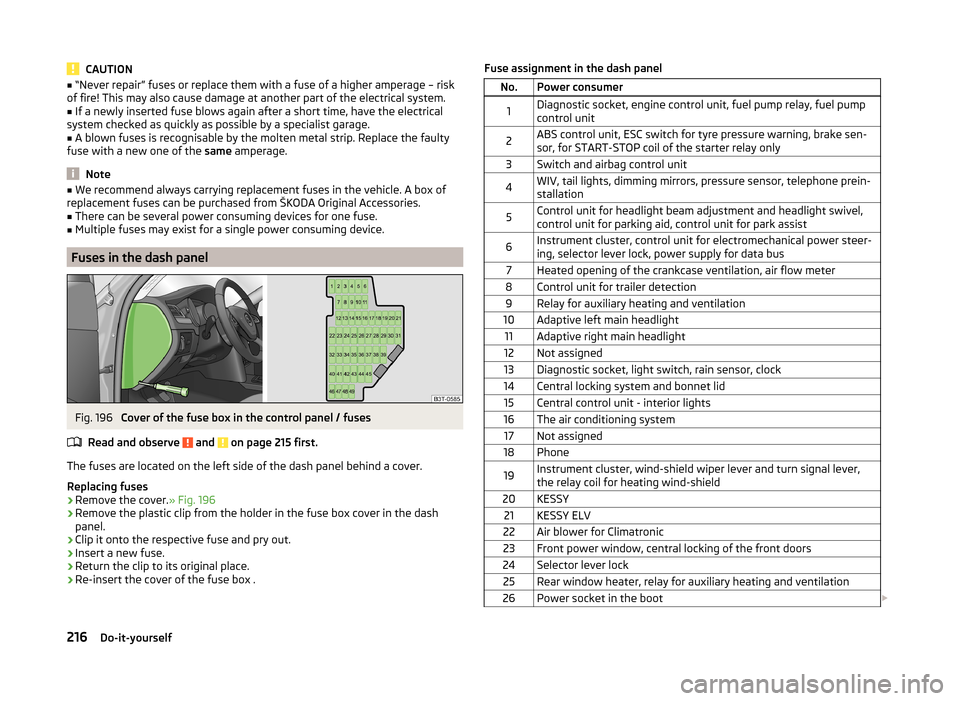

Jump-starting vehicles with the vehicle battery in the boot

Fig. 184

Detail of the engine compart-

ment: Jump-starting point

Read and observe and on page 207 first.

On vehicles with the vehicle battery in the boot, the positive terminal of the

battery supplying the power can only be connected to the jump-starting point

in the engine compartment of the vehicle being started by means of a jump-

start cable » Fig. 184.

›

Open the protective cap of the jump-starting point in the direction of the ar-

row » Fig. 184 .

›

Connect the positive terminal of the battery supplying the power with the

jump-starting point.

› Attach the negative terminal of the battery supplying the power to a solid

metal part firmly connected to the engine block or to the engine block itself.›

Start the engine.

›

After starting the engine, close the protective cap of the jump-starting point.

Towing the vehicle

Introduction

This chapter contains information on the following subjects:

Front towing eye

209

Rear towing eye

210

Vehicles with a tow hitch

210

Vehicles with manual transmission may be towed in with a tow bar or a tow

rope or with the front or rear wheels raised.

Vehicles with automatic transmission may be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the auto-

matic gearbox is damaged!

A tow bar is the safest way of towing a vehicle and also minimises any shocks.

Only use a tow rope if a suitable tow bar is not available.

When towing, the following guidelines must be observed.

Driver of the tow vehicle

›

Release the clutch particularly gently when starting off or depress the accel-

erator particularly gently if the vehicle is fitted with an automatic gearbox.

›

On vehicles with a manual transmission, only push down on the accelerator

pedal once the rope is taught.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

›

Switch on the ignition so that the steering wheel is not locked and so that

the turn signal lights, horn, windscreen wipers and windscreen washer sys-

tem can be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the

engine is running. If the engine is not running, significantly more physical force

is required to depress the brake pedal and steer the vehicle.

208Do-it-yourself

Page 218 of 246

CAUTION■“Never repair” fuses or replace them with a fuse of a higher amperage – risk

of fire! This may also cause damage at another part of the electrical system.■

If a newly inserted fuse blows again after a short time, have the electrical

system checked as quickly as possible by a specialist garage.

■

A blown fuses is recognisable by the molten metal strip. Replace the faulty

fuse with a new one of the same amperage.

Note

■

We recommend always carrying replacement fuses in the vehicle. A box of

replacement fuses can be purchased from ŠKODA Original Accessories.■

There can be several power consuming devices for one fuse.

■

Multiple fuses may exist for a single power consuming device.

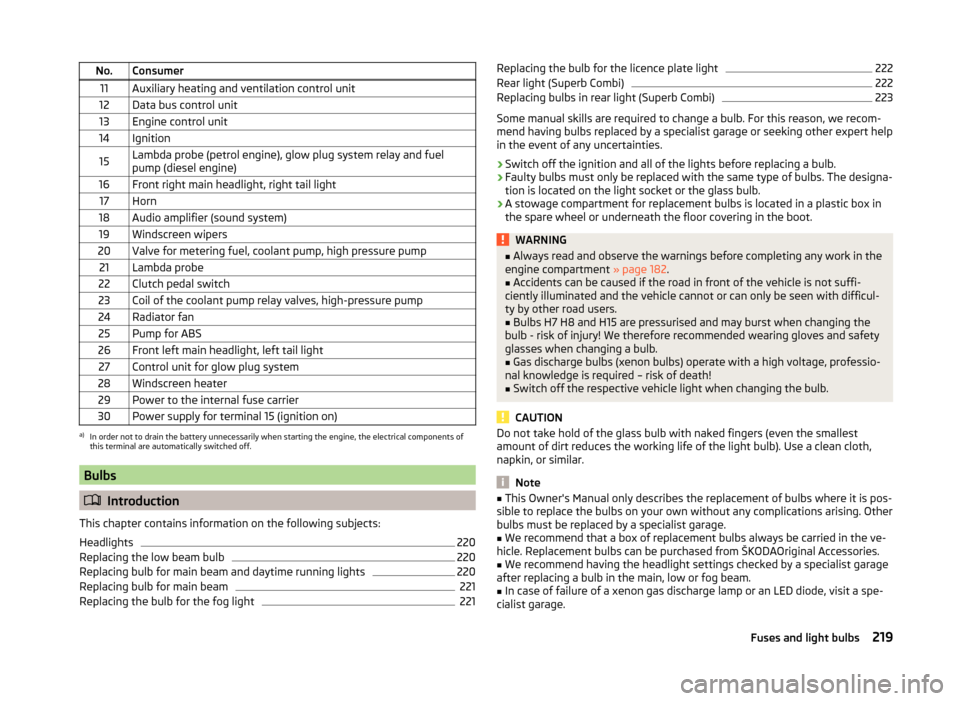

Fuses in the dash panel

Fig. 196

Cover of the fuse box in the control panel / fuses

Read and observe

and on page 215 first.

The fuses are located on the left side of the dash panel behind a cover.

Replacing fuses

›

Remove the cover. » Fig. 196

›

Remove the plastic clip from the holder in the fuse box cover in the dash

panel.

›

Clip it onto the respective fuse and pry out.

›

Insert a new fuse.

›

Return the clip to its original place.

›

Re-insert the cover of the fuse box .

Fuse assignment in the dash panelNo.Power consumer1Diagnostic socket, engine control unit, fuel pump relay, fuel pump

control unit2ABS control unit, ESC switch for tyre pressure warning, brake sen-

sor, for START-STOP coil of the starter relay only3Switch and airbag control unit4WIV, tail lights, dimming mirrors, pressure sensor, telephone prein-

stallation5Control unit for headlight beam adjustment and headlight swivel,

control unit for parking aid, control unit for park assist6Instrument cluster, control unit for electromechanical power steer-

ing, selector lever lock, power supply for data bus7Heated opening of the crankcase ventilation, air flow meter8Control unit for trailer detection9Relay for auxiliary heating and ventilation10Adaptive left main headlight11Adaptive right main headlight12Not assigned13Diagnostic socket, light switch, rain sensor, clock14Central locking system and bonnet lid15Central control unit - interior lights16The air conditioning system17Not assigned18Phone19Instrument cluster, wind-shield wiper lever and turn signal lever,

the relay coil for heating wind-shield20KESSY21KESSY ELV22Air blower for Climatronic23Front power window, central locking of the front doors24Selector lever lock25Rear window heater, relay for auxiliary heating and ventilation26Power socket in the boot 216Do-it-yourself

Page 221 of 246

No.Consumer11Auxiliary heating and ventilation control unit12Data bus control unit13Engine control unit14Ignition15Lambda probe (petrol engine), glow plug system relay and fuel

pump (diesel engine)16Front right main headlight, right tail light17Horn18Audio amplifier (sound system)19Windscreen wipers20Valve for metering fuel, coolant pump, high pressure pump21Lambda probe22Clutch pedal switch23Coil of the coolant pump relay valves, high-pressure pump24Radiator fan25Pump for ABS26Front left main headlight, left tail light27Control unit for glow plug system28Windscreen heater29Power to the internal fuse carrier30Power supply for terminal 15 (ignition on)a)

In order not to drain the battery unnecessarily when starting the engine, the electrical components of

this terminal are automatically switched off.

Bulbs

Introduction

This chapter contains information on the following subjects:

Headlights

220

Replacing the low beam bulb

220

Replacing bulb for main beam and daytime running lights

220

Replacing bulb for main beam

221

Replacing the bulb for the fog light

221Replacing the bulb for the licence plate light222Rear light (Superb Combi)222

Replacing bulbs in rear light (Superb Combi)

223

Some manual skills are required to change a bulb. For this reason, we recom-

mend having bulbs replaced by a specialist garage or seeking other expert help

in the event of any uncertainties.

› Switch off the ignition and all of the lights before replacing a bulb.

› Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

› A stowage compartment for replacement bulbs is located in a plastic box in

the spare wheel or underneath the floor covering in the boot.

WARNING■ Always read and observe the warnings before completing any work in the

engine compartment » page 182.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

Bulbs H7 H8 and H15 are pressurised and may burst when changing the

bulb - risk of injury! We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Gas discharge bulbs (xenon bulbs) operate with a high voltage, professio-

nal knowledge is required – risk of death!

■

Switch off the respective vehicle light when changing the bulb.

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

■

We recommend having the headlight settings checked by a specialist garage

after replacing a bulb in the main, low or fog beam.

■

In case of failure of a xenon gas discharge lamp or an LED diode, visit a spe-

cialist garage.

219Fuses and light bulbs

Page 222 of 246

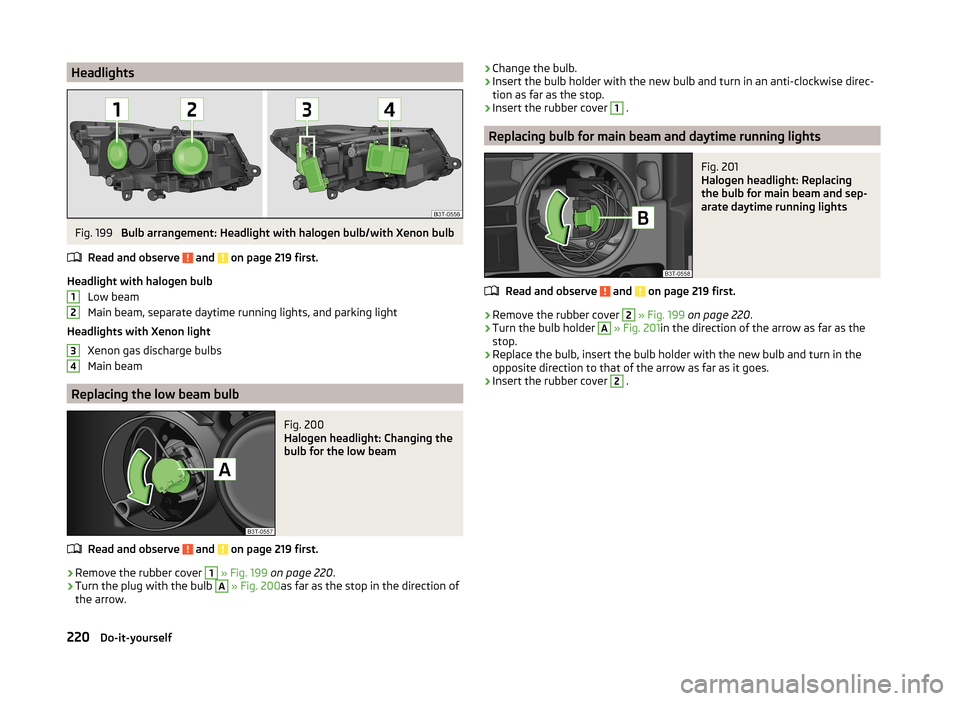

HeadlightsFig. 199

Bulb arrangement: Headlight with halogen bulb/with Xenon bulb

Read and observe

and on page 219 first.

Headlight with halogen bulb Low beam

Main beam, separate daytime running lights, and parking light

Headlights with Xenon light Xenon gas discharge bulbs

Main beam

Replacing the low beam bulb

Fig. 200

Halogen headlight: Changing the

bulb for the low beam

Read and observe and on page 219 first.

›

Remove the rubber cover

1

» Fig. 199 on page 220 .

›

Turn the plug with the bulb

A

» Fig. 200 as far as the stop in the direction of

the arrow.

1234› Change the bulb.›Insert the bulb holder with the new bulb and turn in an anti-clockwise direc-

tion as far as the stop.›

Insert the rubber cover

1

.

Replacing bulb for main beam and daytime running lights

Fig. 201

Halogen headlight: Replacing

the bulb for main beam and sep-

arate daytime running lights

Read and observe and on page 219 first.

›

Remove the rubber cover

2

» Fig. 199 on page 220 .

›

Turn the bulb holder

A

» Fig. 201 in the direction of the arrow as far as the

stop.

›

Replace the bulb, insert the bulb holder with the new bulb and turn in the

opposite direction to that of the arrow as far as it goes.

›

Insert the rubber cover

2

.

220Do-it-yourself

Page 223 of 246

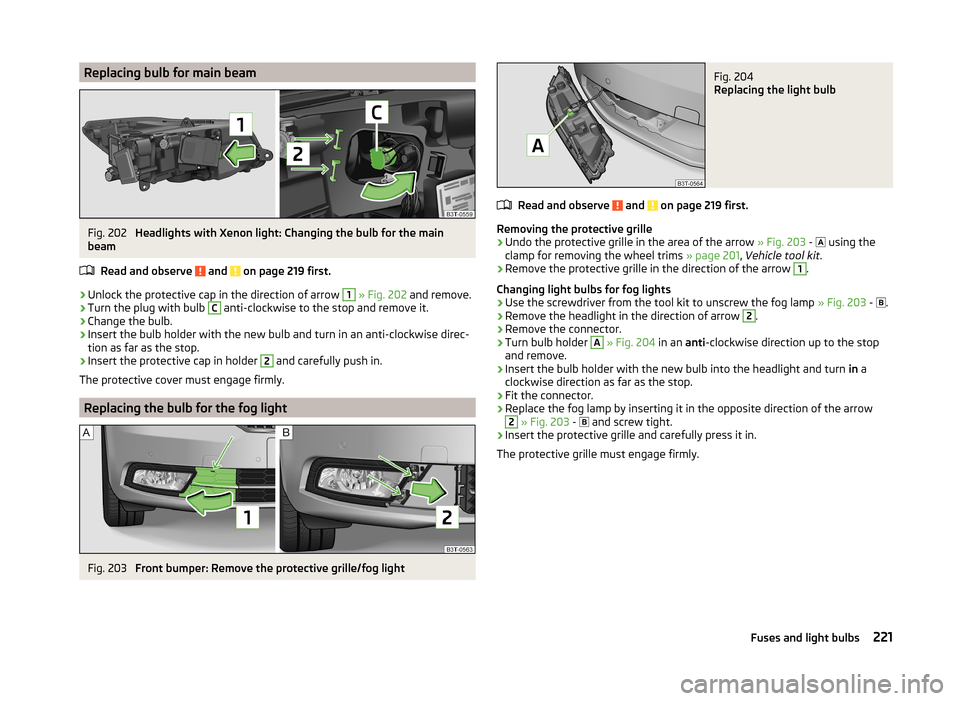

Replacing bulb for main beamFig. 202

Headlights with Xenon light: Changing the bulb for the main

beam

Read and observe

and on page 219 first.

›

Unlock the protective cap in the direction of arrow

1

» Fig. 202 and remove.

›

Turn the plug with bulb

C

anti-clockwise to the stop and remove it.

›

Change the bulb.

›

Insert the bulb holder with the new bulb and turn in an anti-clockwise direc-

tion as far as the stop.

›

Insert the protective cap in holder

2

and carefully push in.

The protective cover must engage firmly.

Replacing the bulb for the fog light

Fig. 203

Front bumper: Remove the protective grille/fog light

Fig. 204

Replacing the light bulb

Read and observe and on page 219 first.

Removing the protective grille

›

Undo the protective grille in the area of the arrow » Fig. 203 -

using the

clamp for removing the wheel trims » page 201, Vehicle tool kit .

›

Remove the protective grille in the direction of the arrow

1

.

Changing light bulbs for fog lights

›

Use the screwdriver from the tool kit to unscrew the fog lamp » Fig. 203 -

.

›

Remove the headlight in the direction of arrow

2

.

›

Remove the connector.

›

Turn bulb holder

A

» Fig. 204 in an anti-clockwise direction up to the stop

and remove.

›

Insert the bulb holder with the new bulb into the headlight and turn in a

clockwise direction as far as the stop.

›

Fit the connector.

›

Replace the fog lamp by inserting it in the opposite direction of the arrow

2

» Fig. 203 -

and screw tight.

›

Insert the protective grille and carefully press it in.

The protective grille must engage firmly.

221Fuses and light bulbs

Page 234 of 246

Index

A

Abroad Driving abroad

150

Unleaded petrol150

ABS Operation

152

Warning light36

Accessories169

Adaptive headlights (AFS)68

Adjust Auxiliary heating (auxiliary heating and ventila-tion)

117

Adjusting Belt height

13

Exterior mirrors78

Head restraints81

Interior mirror77

Manual air conditioning112

Seats79, 80

Steering wheel8

Adjusting the seats7, 79

Adjustment Headlight beam

66

Aerial173

See windows175

AFS68

Warning light36

Airbag14

Deactivating19

Deactivating the front passenger airbag20

Deployment14

Front airbag15

Head airbag18

Indicator light38

Knee airbag16

Modifications and damage to the airbag system 171 Side airbag

17

Airbag system14

Air conditioning system108

Air outlets108

Climatronic113

Manual air conditioning system110

Air outlets108

Air recirculation Climatronic

115

Alarm Switching off

54

Triggering54

Anti-theft alarm system Activating/deactivating

54

Trailer168

Antilock brake system (ABS)152

Armrest front

85

rear85, 94

Artificial leather178

Ashtray89

ASR Warning light

35

Assist systems151

ABS36, 152

ASR35

Cruise Control System158

DSR152

EDL152

ESC35, 151

HBA152

HHC153

Park assist154

Parking aid153

START-STOP159

TCS152

Auto Check Control31

Automatic driving lamp control68

Automatic gearbox142

Selector lever-emergency unlocking213

Starting-off and driving144

Tiptronic143

Using the selector lever142

Automatic gearbox modes142

Automatic load deactivation193

Automatic retractable cargo cover (Superb Combi))

99

Automatic transmission Kickdown

144

Malfunction144

Selector lever lock143

AUX Installation in the storage compartment

90

Auxiliary heating (auxiliary heating and ventila- tion)

116

Adjust117

Radio remote control118

Switching on/off117

Avoiding damage to the vehicle Driving through water

149

Avoiding damage to your vehicle149

B

Ball head Check fitting

165

Fitting164

Ready position164

Removing165

Battery In the remote control key

211

iReplace the remote control of the auxiliary heater (parking heater)

211

Belts10

Belt tensioners13

Bonnet Closing

183

Opening183

Warning light34

Boot Automatic retraction (Superb Combi)

99

Extending variable loading floor103

232Index