warning lights SKODA SUPERB 2015 3.G / (B8/3V) Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: SUPERB, Model: SKODA SUPERB 2015 3.G / (B8/3V)Pages: 276, PDF Size: 42.14 MB

Page 188 of 276

Coupling / uncoupling trainerFig. 222

Housing of the 13 pin socket,

safety eyelet

Connect and disconnect

›

Swing out the tow bar » page 184.

›

Place the trailer onto the ball.

›

Plug the trailer cable into the 13-pin socket

A

» Fig. 222 .

If the trailer that is to be towed has a 7-pin connector, you can use a suitable

adapter from ŠKODA Original Accessories to establish a connection to the elec-

tricity.

›

Hook the breakaway cable of the trailer onto the safety eyelet

B

.

The breakaway cable of the trailer must sag in all trailer positions relative to

the vehicle (sharp curves, reverse driving and the like).

Uncoupling takes place in reverse order.

Exterior mirrors

You should have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors.

Headlights

The front of the vehicle may lift up when a trailer is being towed and the head-

lights may dazzle other road users.

Adjust the headlights using the headlight beam control » page 67, Operating

the lights 1)

.

Power to the trailer power grid

For the electrical connection between the vehicle and trailer, the power for the

trailer power grid is supplied by the vehicle.

The power supply works with ignition on or off.

With the ignition off, the battery of the towing vehicle is discharged by activa-

ted consumers.

At low charge state of the vehicle battery power to the trailer is interrupted.WARNING■ Improperly connected trailer electrical installations may cause accidents

or serious injury due to electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting up the power socket, check the

rear lights on the trailer to ensure they are working.

■

Never use the safety eyelet for towing!

CAUTION

Improperly connected trailer electrical installations may cause malfunction of

the entire vehicle electronics.

Note

■ The total power consumption of all the connected consumers on the trailer

must not exceed 350 watts.■

Coat the ball head of the towing device with a suitable grease whenever

necessary.

Loading a trailer

Distribution of the cargo

Distribute the cargo in the trailer in such a way that heavy items are located as

close to the trailer axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Maintain a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 217.

1)

Applies to vehicles with xenon headlights.

186Driving

Page 191 of 276

On downhill sections shift down a gear in good time to also use the engine as

a brake.WARNINGAlways drive particularly carefully with the trailer.

CAUTION

If you tow a trailer frequently, you should also have your vehicle inspected be-

tween service intervals.

Anti-theft alarm system

If the vehicle is locked, the alarm is activated when the electrical connection to

the trailer is interrupted.

Always switch off the anti-theft alarm system before a trailer is coupled or un-

coupled » page 57 .

Conditions for including a trailer in the anti-theft alarm system. The vehicle is factory-fitted with an anti-theft alarm system and towing

device.

The trailer is electrically connected to the towing vehicle via the trailer

socket.

The electrical system of the vehicle and trailer is functional.

The vehicle is locked and the anti-theft alarm system is activated.

CAUTION

For technical reasons, trailers with rear LED lights cannot be connected to the

anti-theft alarm system.189Hitch and trailer

Page 199 of 276

CAUTIONInformation for cleaning windows■Do not clean the inside of the windows with sharp-edged objects or corro-

sive and acidic cleaning agents – there is a risk of damaging the heating ele-

ments or window aerial.■

When drying the windows after washing the vehicle, do not use window

leathers that have been used to polish the bodywork. Residues of preserva-

tives in the window leather can make the window dirty and reduce visibility.

Headlight glasses

Read and observe

and on page 195 first.

Clean plastic front headlight lenses using clean, warm water and soap.

CAUTION

■The headlights are never to be wiped dry - there is a risk of damaging the

protective lacquer and the headlight glass subsequently developing cracks.■

Do not use sharp objects to clean the glasses - there is a risk of damaging

the protective lacquer and the headlight glasses subsequently developing

cracks.

■

Do not use any aggressive cleaning or chemical solvent products to clean the

headlights – risk of damaging the headlight lenses.

Camera lens

Read and observe

and on page 195 first.

Moisten the lens of the rear view camera first with clean water and then dry

with a dry cloth.

Remove the snow from the lens with a brush and the ice from the lens with

de-icing agents specifically developed for these purposes.

CAUTION

■ Remove snow or ice on the lens with warm or hot water - there is a risk of

damaging the lens.■

Never use cleaners containing abrasive effect to clean the lens.

■

Never use pressurized water or steam jet to clean the lens.

Door closing cylinder

Read and observe

and on page 195 first.

Specific products must be used for de-icing door lock cylinders.

CAUTION

Make sure that as little water as possible gets into the locking cylinder when

washing the vehicle - there is a risk of freezing the lock cylinder!

Cavity protection

Read and observe

and on page 195 first.

All the cavities of your vehicle which are at risk from corrosion are protected

for life by a layer of protective wax applied in the factory.

This wax protection does not need to be inspected or re-applied.

If any small amount of wax flow out of the cavities at high temperatures, these

must be removed with a plastic scraper and the stains cleaned using a petrole-

um cleaner.

WARNINGSafety regulations should be observed when using petroleum cleaner to re-

move wax – risk of fire!

Jack

Read and observe

and on page 195 first.

The jack is maintenance-free.

If necessary, the moving parts of the jack should be lubricated with a suitable

lubricant.

Wheels

Read and observe

and on page 195 first.

Wheel rims

Also thoroughly wash the wheel rims when washing the vehicle on a regular

basis.

197Care and maintenance

Page 210 of 276

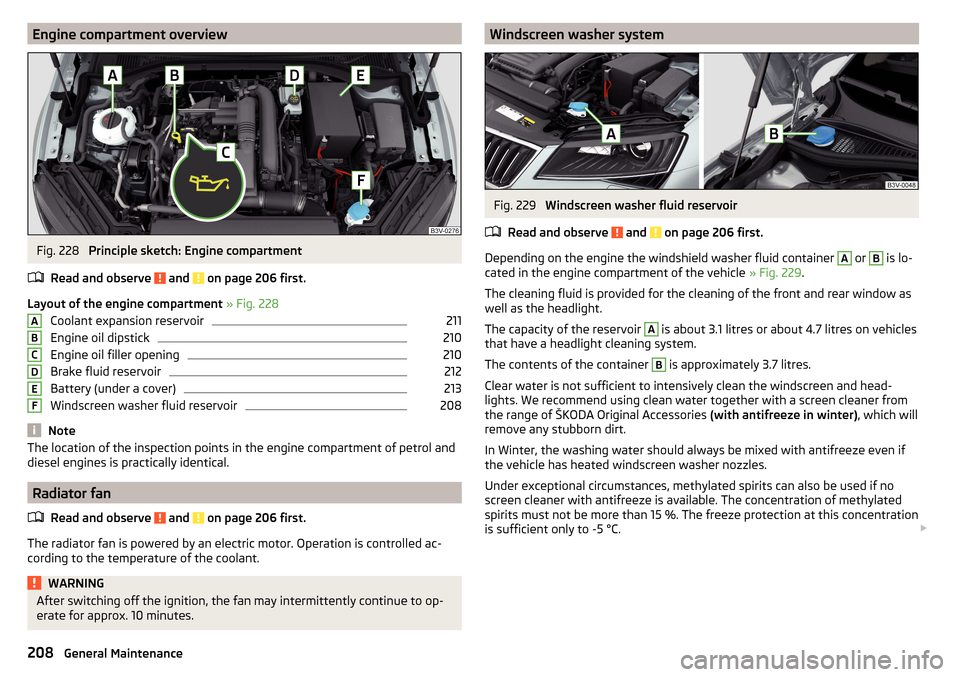

Engine compartment overviewFig. 228

Principle sketch: Engine compartment

Read and observe

and on page 206 first.

Layout of the engine compartment » Fig. 228

Coolant expansion reservoir

211

Engine oil dipstick

210

Engine oil filler opening

210

Brake fluid reservoir

212

Battery (under a cover)

213

Windscreen washer fluid reservoir

208

Note

The location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

Read and observe

and on page 206 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

WARNINGAfter switching off the ignition, the fan may intermittently continue to op-

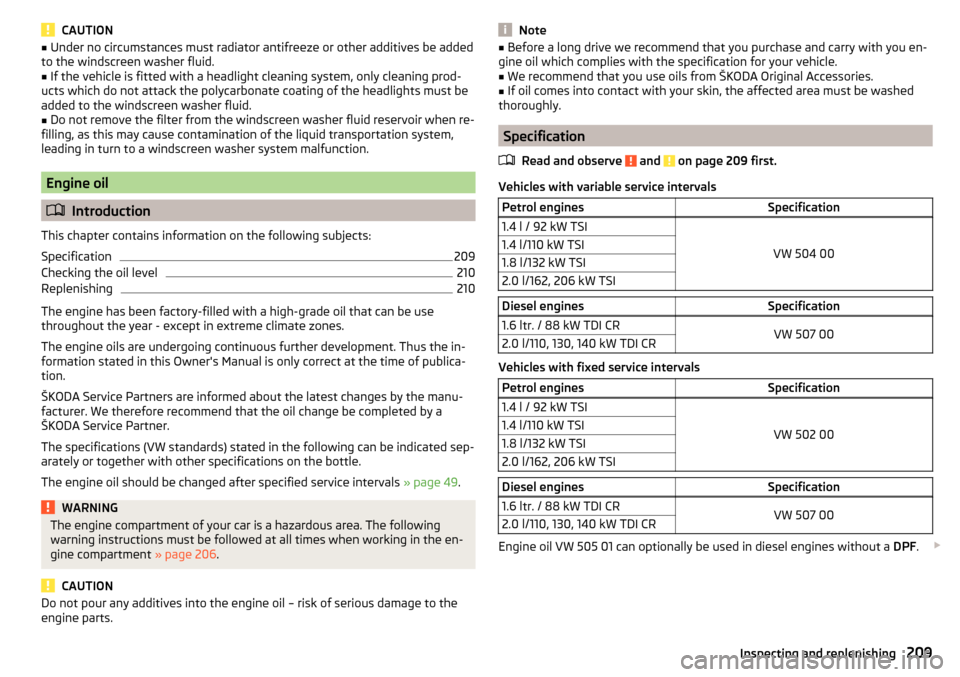

erate for approx. 10 minutes.ABCDEFWindscreen washer systemFig. 229

Windscreen washer fluid reservoir

Read and observe

and on page 206 first.

Depending on the engine the windshield washer fluid container

A

or

B

is lo-

cated in the engine compartment of the vehicle » Fig. 229.

The cleaning fluid is provided for the cleaning of the front and rear window as

well as the headlight.

The capacity of the reservoir

A

is about 3.1 litres or about 4.7 litres on vehicles

that have a headlight cleaning system.

The contents of the container

B

is approximately 3.7 litres.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We recommend using clean water together with a screen cleaner from

the range of ŠKODA Original Accessories (with antifreeze in winter), which will

remove any stubborn dirt.

In Winter, the washing water should always be mixed with antifreeze even if

the vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no

screen cleaner with antifreeze is available. The concentration of methylated

spirits must not be more than 15 %. The freeze protection at this concentration

is sufficient only to -5 °C.

208General Maintenance

Page 211 of 276

CAUTION■Under no circumstances must radiator antifreeze or other additives be added

to the windscreen washer fluid.■

If the vehicle is fitted with a headlight cleaning system, only cleaning prod-

ucts which do not attack the polycarbonate coating of the headlights must be

added to the windscreen washer fluid.

■

Do not remove the filter from the windscreen washer fluid reservoir when re-

filling, as this may cause contamination of the liquid transportation system,

leading in turn to a windscreen washer system malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specification

209

Checking the oil level

210

Replenishing

210

The engine has been factory-filled with a high-grade oil that can be use

throughout the year - except in extreme climate zones.

The engine oils are undergoing continuous further development. Thus the in- formation stated in this Owner's Manual is only correct at the time of publica-

tion.

ŠKODA Service Partners are informed about the latest changes by the manu-

facturer. We therefore recommend that the oil change be completed by a

ŠKODA Service Partner.

The specifications (VW standards) stated in the following can be indicated sep-

arately or together with other specifications on the bottle.

The engine oil should be changed after specified service intervals » page 49.

WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 206.

CAUTION

Do not pour any additives into the engine oil – risk of serious damage to the

engine parts.Note■ Before a long drive we recommend that you purchase and carry with you en-

gine oil which complies with the specification for your vehicle.■

We recommend that you use oils from ŠKODA Original Accessories.

■

If oil comes into contact with your skin, the affected area must be washed

thoroughly.

Specification

Read and observe

and on page 209 first.

Vehicles with variable service intervals

Petrol enginesSpecification1.4 l / 92 kW TSI

VW 504 00

1.4 l/110 kW TSI1.8 l/132 kW TSI2.0 l/162, 206 kW TSIDiesel enginesSpecification1.6 ltr. / 88 kW TDI CRVW 507 002.0 l/110, 130, 140 kW TDI CR

Vehicles with fixed service intervals

Petrol enginesSpecification1.4 l / 92 kW TSI

VW 502 00

1.4 l/110 kW TSI1.8 l/132 kW TSI2.0 l/162, 206 kW TSIDiesel enginesSpecification1.6 ltr. / 88 kW TDI CRVW 507 002.0 l/110, 130, 140 kW TDI CR

Engine oil VW 505 01 can optionally be used in diesel engines without a DPF.

209Inspecting and replenishing

Page 212 of 276

CAUTION■In an emergency, another engine oil to be refilled. To prevent damage to the

engine, a maximum of 0.5 litres only of the following engine oils may be used:

■ For petrol engine models: ACEA A3/ACEA B4 or API SN, (API SM);

■ For diesel engine models: ACEA C3 or API CJ-4.

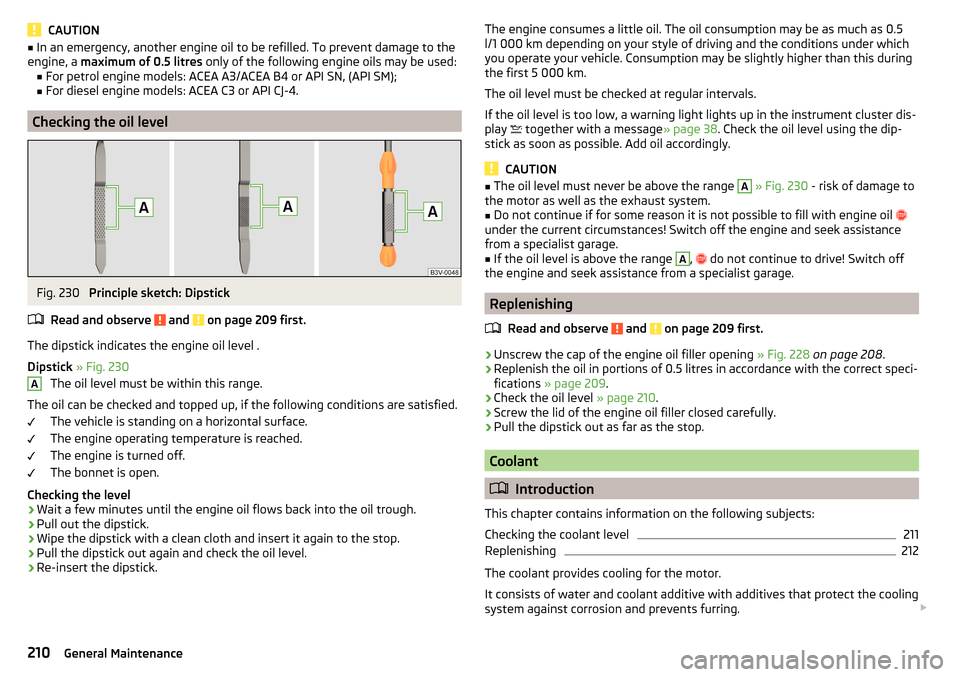

Checking the oil level

Fig. 230

Principle sketch: Dipstick

Read and observe

and on page 209 first.

The dipstick indicates the engine oil level .

Dipstick » Fig. 230

The oil level must be within this range.

The oil can be checked and topped up, if the following conditions are satisfied. The vehicle is standing on a horizontal surface.

The engine operating temperature is reached.

The engine is turned off.

The bonnet is open.

Checking the level

›

Wait a few minutes until the engine oil flows back into the oil trough.

›

Pull out the dipstick.

›

Wipe the dipstick with a clean cloth and insert it again to the stop.

›

Pull the dipstick out again and check the oil level.

›

Re-insert the dipstick.

AThe engine consumes a little oil. The oil consumption may be as much as 0.5

l/1 000 km depending on your style of driving and the conditions under which

you operate your vehicle. Consumption may be slightly higher than this during

the first 5 000 km.

The oil level must be checked at regular intervals.

If the oil level is too low, a warning light lights up in the instrument cluster dis-

play

together with a message » page 38. Check the oil level using the dip-

stick as soon as possible. Add oil accordingly.

CAUTION

■ The oil level must never be above the range A » Fig. 230 - risk of damage to

the motor as well as the exhaust system.■

Do not continue if for some reason it is not possible to fill with engine oil

under the current circumstances! Switch off the engine and seek assistance

from a specialist garage.

■

If the oil level is above the range

A

,

do not continue to drive! Switch off

the engine and seek assistance from a specialist garage.

Replenishing

Read and observe

and on page 209 first.

›

Unscrew the cap of the engine oil filler opening » Fig. 228 on page 208 .

›

Replenish the oil in portions of 0.5 litres in accordance with the correct speci-

fications » page 209 .

›

Check the oil level » page 210.

›

Screw the lid of the engine oil filler closed carefully.

›

Pull the dipstick out as far as the stop.

Coolant

Introduction

This chapter contains information on the following subjects:

Checking the coolant level

211

Replenishing

212

The coolant provides cooling for the motor.

It consists of water and coolant additive with additives that protect the cooling

system against corrosion and prevents furring.

210General Maintenance

Page 213 of 276

The proportion of coolant additive in the mixture must be at least 40%.

The coolant additive may be increased to a maximum of 60%.

The correct mixing ratio of water and coolant additive is to be checked if nec-

essary by a specialist garage or is to be restored if necessary.

The description of the coolant is shown in the coolant expansion reservoir

» Fig. 231 on page 211 .WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en- gine compartment » page 206.■

The coolant is harmful to health.

■

Avoid contact with the coolant.

■

Coolant vapours are harmful to health.

■

Never open the end cover of the coolant expansion reservoir while the

engine is still warm. The cooling system is pressurized!

■

When opening the end cover of the coolant expansion reservoir, cover it

with a cloth to protect your face, hands and arms from hot steam or hot

coolant.

■

If any coolant splashes into your eyes, immediately rinse out your eyes

with clear water and contact a doctor as soon as possible.

■

Always keep the coolant in the original container, safe from people who

are not completely independent, especially children - there is a danger of

poisoning!

■

If coolant is swallowed, consult a doctor immediately.

■

Never spill operating fluids over the hot engine - risk of fire.

CAUTION

■ Do not continue if for some reason it is not possible to fill with coolant un-

der the current circumstances! Switch off the engine and seek assistance from

a specialist garage.■

If the expansion tank is empty, do not top up with coolant. The system could

ventilate - there is a risk of engine damage,

not continue! Switch off the en-

gine and seek assistance from a specialist garage.

■

The concentration of coolant additive in the coolant must never be under

40%.

■

Over 60% of coolant additive in the coolant reduces the antifreeze protec-

tion and cooling effect.

■

A coolant additive that does not comply with the correct specification can

significantly reduce the corrosion protection of the cooling system.

■ Any faults resulting from corrosion may cause a loss of coolant and can con-

sequently result in major engine damage.■

Do not fill the coolant above the mark

A

» Fig. 231 on page 211 .

■

If an error occurs, leading to the engine overheating, the help of a professio-

nal garage is to be sought - there is a risk of serious engine damage occurring.

■

Additional headlights and other attached components in front of the air inlet

impair the cooling efficiency of the coolant.

■

Never cover the radiator - there is a risk of the engine overheating.

Note

The coolant capacity is approximately 1 l greater on vehicles that are fitted

with an auxiliary heater (auxiliary heating and ventilation).

Checking the coolant level

Fig. 231

Coolant expansion reservoir

Read and observe and on page 211 first.

The coolant expansion bottle is located in the engine compartment.

Coolant expansion reservoir » Fig. 231

Mark for the maximum permissible coolant level

Mark for the lowest permissible coolant level

The coolant level should be kept between the marks

A

and

B

.

The coolant can be checked and topped up, if the following conditions are sat-

isfied.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The engine is not heated.

The bonnet is open.

AB211Inspecting and replenishing

Page 214 of 276

Checking the level›Check the coolant level in the coolant expansion tank » Fig. 231.

If the engine is warm, the test result may be inaccurate. The level can also be

above the mark A

» Fig. 231 .

If the oil level is too low, a warning light lights up in the instrument cluster dis-

play

together with a message » page 38. We still recommend inspecting the

coolant level directly at the reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the cooling sys-

tem. Do not merely top up the coolant. Have the cooling system checked by a

specialist garage.

Replenishing

Read and observe

and on page 211 first.

The coolant expansion tank must always contain a small amount of coolant» page 211, in section Introduction .

›

Place a cloth over the cap of the coolant expansion tank and unscrew the

cap carefully .

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

Do not use an alternative additive if the specified coolant is not available. In

this case, use just water and have the correct mixing ratio of water and cool-

ant additive restored by a specialist garage as soon as possible.

Only top up with new coolant.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Checking the brake fluid level

212

Specification

213

The brake fluid reservoir is located in the engine compartment » Fig. 232 on

page 212 .

WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 206.■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

CAUTION

■ Do not continue your journey if the fluid level has dropped below the “MIN”

marking » Fig. 232 on page 212 , - there is a risk of an accident! Seek help

from a specialist garage.■

Brake fluid damages the paintwork of the vehicle.

Note

■ The brake fluid is changed as part of a compulsory inspection service.■We recommend using oils from the ŠKODA Original Accessories range.

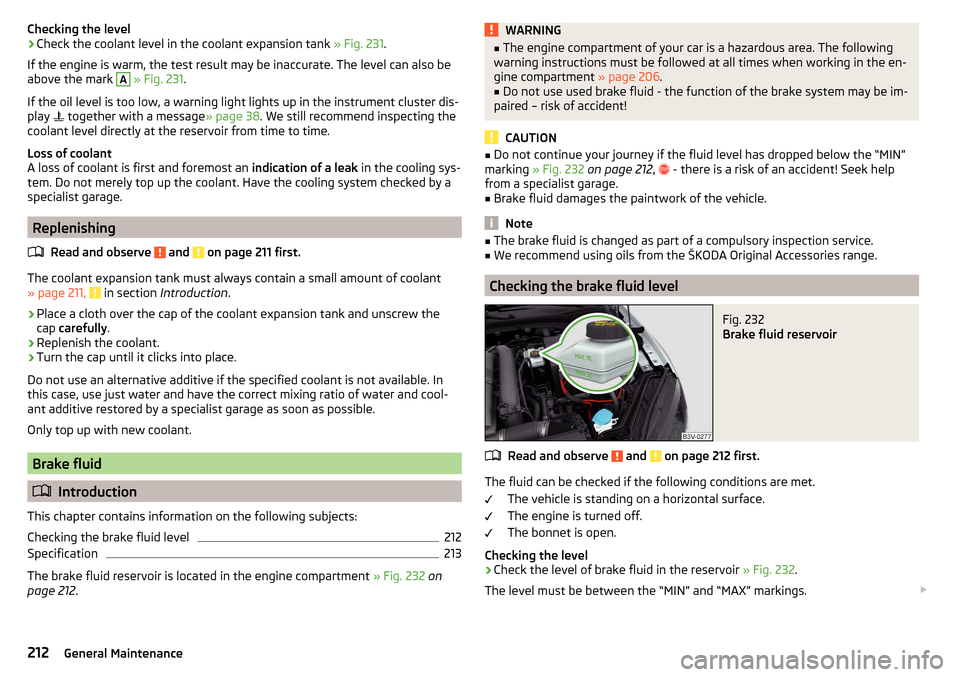

Checking the brake fluid level

Fig. 232

Brake fluid reservoir

Read and observe and on page 212 first.

The fluid can be checked if the following conditions are met.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The bonnet is open.

Checking the level

›

Check the level of brake fluid in the reservoir » Fig. 232.

The level must be between the “MIN” and “MAX” markings.

212General Maintenance

Page 226 of 276

WARNINGThe factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads.

CAUTION

■ Screw the jack back into the starting position before storing in the box with

the tool kit.■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preparation

224

Removing/stowing the wheel

224

Full wheel trim

225

Wheel bolts

225

Anti-theft wheel bolts

225

Loosening/tightening wheel bolts

226

Raising the vehicle

226

Remove the wheel / fix

227

Follow-up tasks

227

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard warning lights system.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from the flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

Tyres with increased puncture resistance

Some vehicles may be fitted with tyres at the factory that have increased

puncture resistance (so-called “SEAL” tyres).

These vehicles are delivered without a puncture repair kit, spare wheel and

appropriate hand tools.

If the tyres with increased puncture resistance are replaced with tyres that

have no increased puncture resistance then the vehicle should be equipped

with a puncture repair kit, spare wheel and appropriate hand tools.

Preparation

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

›

For vehicles with manual transmission engage 1st gear.

›

On vehicles with

automatic transmission place the selector lever in the P po-

sition.

›

The parking brake switch.

›

Uncouple any trailers.

Removing/stowing the wheel

Fig. 242

Take out wheel

The wheel is located in a well under the floor covering in the boot and is fixed

in place with a special screw.

Take out wheel

›

Open the tailgate.

›

Lift up the floor in the luggage compartment.

›

Loosen the retaining belt and take out the box with the tool kit.

›

Unscrew the special screws in the direction of arrow » Fig. 242.

›

Remove the wheel.

224Do-it-yourself

Page 231 of 276

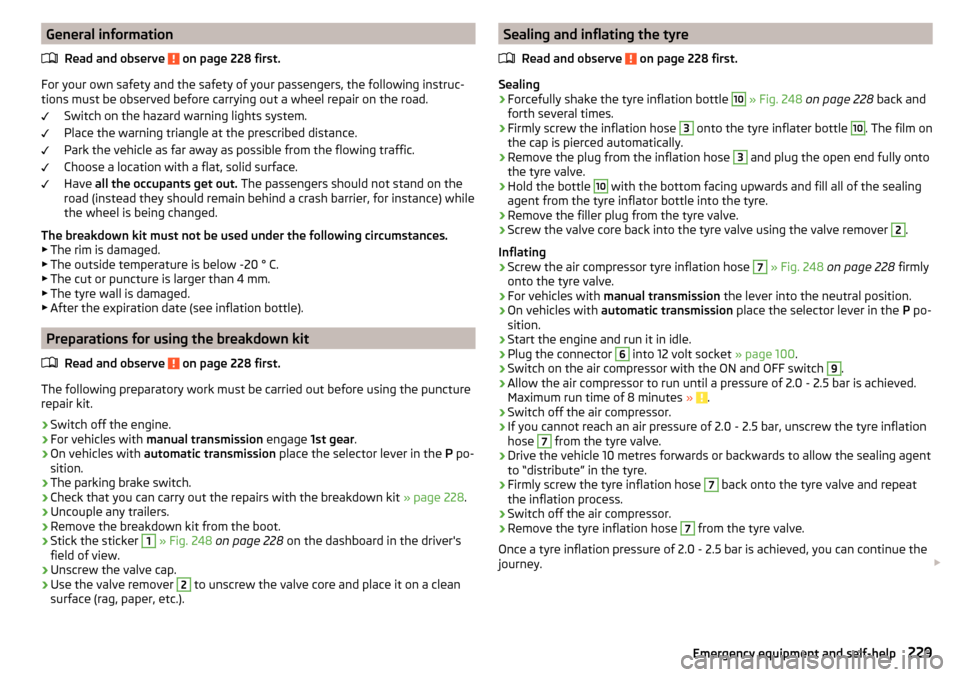

General informationRead and observe

on page 228 first.

For your own safety and the safety of your passengers, the following instruc-

tions must be observed before carrying out a wheel repair on the road.

Switch on the hazard warning lights system.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from the flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

The breakdown kit must not be used under the following circumstances. ▶ The rim is damaged.

▶ The outside temperature is below -20 ° C.

▶ The cut or puncture is larger than 4 mm.

▶ The tyre wall is damaged.

▶ After the expiration date (see inflation bottle).

Preparations for using the breakdown kit

Read and observe

on page 228 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Switch off the engine.

›

For vehicles with manual transmission engage 1st gear.

›

On vehicles with

automatic transmission place the selector lever in the P po-

sition.

›

The parking brake switch.

›

Check that you can carry out the repairs with the breakdown kit » page 228.

›

Uncouple any trailers.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 248 on page 228 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 228 first.

Sealing

›

Forcefully shake the tyre inflation bottle

10

» Fig. 248 on page 228 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the air compressor tyre inflation hose

7

» Fig. 248 on page 228 firmly

onto the tyre valve.

›

For vehicles with manual transmission the lever into the neutral position.

›

On vehicles with automatic transmission place the selector lever in the P po-

sition.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 volt socket » page 100.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0 - 2.5 bar is achieved, you can continue the journey.

229Emergency equipment and self-help