torque SKODA SUPERB 2015 3.G / (B8/3V) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: SUPERB, Model: SKODA SUPERB 2015 3.G / (B8/3V)Pages: 276, PDF Size: 42.14 MB

Page 9 of 276

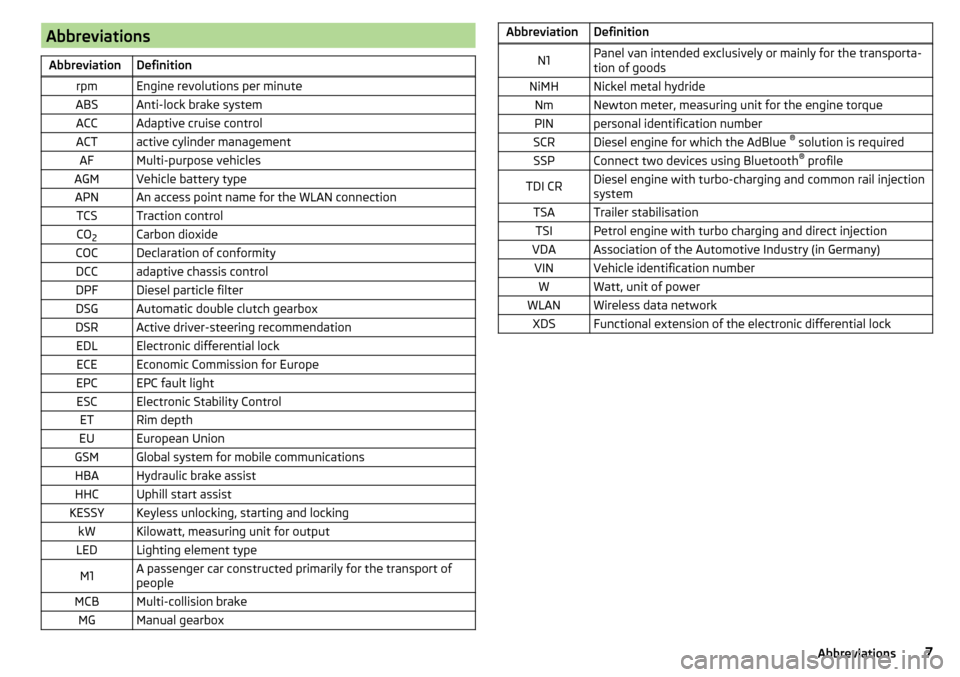

AbbreviationsAbbreviationDefinitionrpmEngine revolutions per minuteABSAnti-lock brake systemACCAdaptive cruise controlACTactive cylinder managementAFMulti-purpose vehiclesAGMVehicle battery typeAPNAn access point name for the WLAN connectionTCSTraction controlCO2Carbon dioxideCOCDeclaration of conformityDCCadaptive chassis controlDPFDiesel particle filterDSGAutomatic double clutch gearboxDSRActive driver-steering recommendationEDLElectronic differential lockECEEconomic Commission for EuropeEPCEPC fault lightESCElectronic Stability ControlETRim depthEUEuropean UnionGSMGlobal system for mobile communicationsHBAHydraulic brake assistHHCUphill start assistKESSYKeyless unlocking, starting and lockingkWKilowatt, measuring unit for outputLEDLighting element typeM1A passenger car constructed primarily for the transport of

peopleMCBMulti-collision brakeMGManual gearboxAbbreviationDefinitionN1Panel van intended exclusively or mainly for the transporta-

tion of goodsNiMHNickel metal hydrideNmNewton meter, measuring unit for the engine torquePINpersonal identification numberSCRDiesel engine for which the AdBlue ®

solution is requiredSSPConnect two devices using Bluetooth ®

profileTDI CRDiesel engine with turbo-charging and common rail injection

systemTSATrailer stabilisationTSIPetrol engine with turbo charging and direct injectionVDAAssociation of the Automotive Industry (in Germany)VINVehicle identification numberWWatt, unit of powerWLANWireless data networkXDSFunctional extension of the electronic differential lock7Abbreviations

Page 229 of 276

The mounting points are located on the metal bar » Fig. 246.›

Insert the crank

6

into the mount on the jack

5

» page 223 .

›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking point

» Fig. 247 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 247 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg - risk of damage to the vehicle.

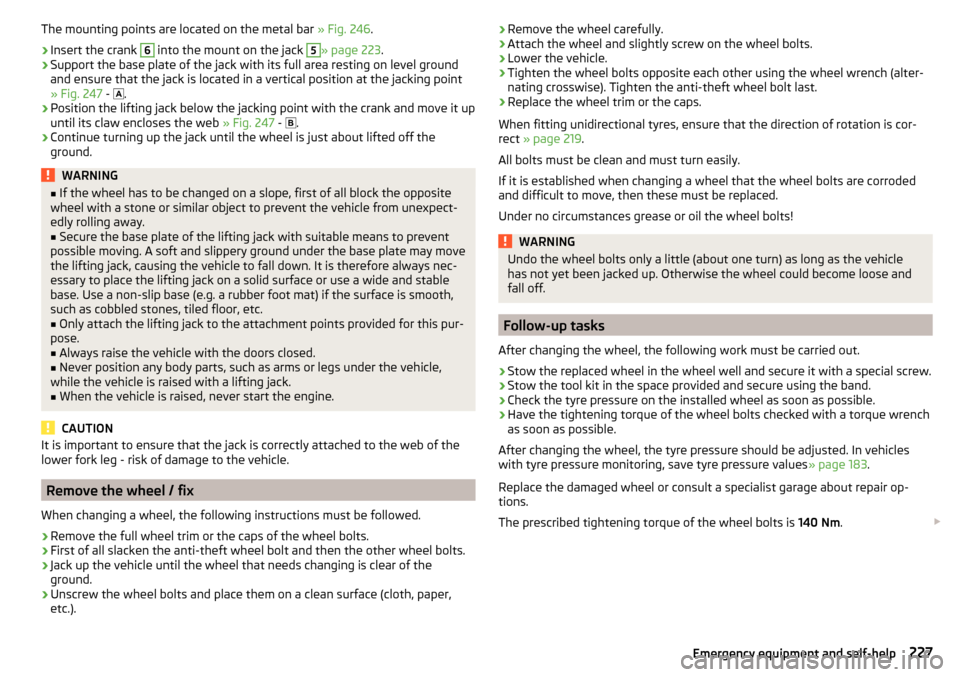

Remove the wheel / fix

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

› Remove the wheel carefully.›Attach the wheel and slightly screw on the wheel bolts.›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (alter-

nating crosswise). Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 219 .

All bolts must be clean and must turn easily.

If it is established when changing a wheel that the wheel bolts are corroded and difficult to move, then these must be replaced.

Under no circumstances grease or oil the wheel bolts!

WARNINGUndo the wheel bolts only a little (about one turn) as long as the vehicle

has not yet been jacked up. Otherwise the wheel could become loose and

fall off.

Follow-up tasks

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the wheel well and secure it with a special screw.

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, save tyre pressure values » page 183.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

The prescribed tightening torque of the wheel bolts is 140 Nm.

227Emergency equipment and self-help

Page 230 of 276

WARNING■If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

Puncture repair kit

Introduction

This chapter contains information on the following subjects:

Components of the puncture repair kits

228

General information

229

Preparations for using the breakdown kit

229

Sealing and inflating the tyre

229

Notes for driving with repaired tyres

230

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

Performing a repair with the breakdown kit not at all intended to replace a

permanent repair on the tyre. Its purpose is to get you to the nearest specialist

garage.

The wheel must not be removed during repair.

Do not remove foreign bodies , which have penetrated the wheel profile from

the tyre (e.g. screws or nails).

Immediately replace the tyre that was repaired using the breakdown kit, or

consult a specialist garage about repair options.

WARNING■ The sealant is hazardous to heath. Remove immediately if it comes into

contact with the skin.■

Observe the manufacturer's usage instructions for the breakdown kit.

Note

A new bottle of sealant can be purchased from ŠKODA Original Parts.Components of the puncture repair kitsFig. 248

Principle sketch: Components of the breakdown kit

Read and observe

on page 228 first.

Kit components » Fig. 248

Sticker with speed designation “max. 80 km/h”/“max. 50 mph” Valve remover

Inflation hose with plug

Air compressor

Button for releasing the tyre pressure

12 volt cable connector

Tyre inflation hose

Tyre inflation pressure indicator

ON and OFF switch

Tyre inflation bottle with sealing agent

Replacement valve core

The valve remover

2

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. The kit contains a sealant and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.1234567891011228Do-it-yourself

Page 254 of 276

Vehicle-specific information depending on engine type

Introduction

This chapter contains information on the following subjects:

1.4 l/92 kW TSI engine252

1.4 l/110 kW TSI ACT engine

252

1.4 l/110 kW TSI engine

253

1.8 l/132 kW TSI engine

253

2.0 l/162 kW TSI engine

2532.0 l/206 kW TSI engine2541.6 l/88 kW TDI CR engine254

2.0 l/110 kW TDI CR engine

254

2.0 l/130 kW TDI CR engine

255

2.0 l/140 kW TDI CR engine

255The values given have been determined in accordance with the rules and conditions specified in statutory or technical regulations for determining operational

and technical data for motor vehicles.The emissions standard is detailed in the technical vehicle documentation as well as in the certificate of conformity (COC document), which can be obtained from a ŠKODA partner a)

.a)

Only valid for some countries and some models.

1.4 l/92 kW TSI engine

Output (kW/rpm)92/5000-6000Maximum torque (Nm/rpm)200/1400-4000Number of cylinders/displacement (cm 3

)4/1395BodySuperbSuperb EstateTransmissionMGMGTop speed (km/h)208206Acceleration 0-100 km/h (s)9.910.0

1.4 l/110 kW TSI ACT engine

Output (kW/rpm)110/5000-6000Maximum torque (Nm/rpm)250/1500-3500Number of cylinders/displacement (cm 3

)4/1395BodySuperbSuperb EstateTransmissionMGMG 4x4DSGMGMG 4x4DSGTop speed (km/h)220215220218213218Acceleration 0-100 km/h (s)8.69.08.88.79.18.9252Technical data

Page 255 of 276

1.4 l/110 kW TSI engineOutput (kW/rpm)110/5000-6000Maximum torque (Nm/rpm)250/1500-3500Number of cylinders/displacement (cm3

)4/1395BodySuperbSuperb EstateTransmissionMGDSGMGDSGTop speed (km/h)220220218218Acceleration 0-100 km/h (s)8.68.88.78.9

1.8 l/132 kW TSI engine

Output (kW/rpm)MG132/4000-6200DSG132/5100-6200Maximum torque (Nm/rpm)MG320/1450-3900DSG250/1250-5000Number of cylinders/displacement (cm 3

)4/1798BodySuperbSuperb EstateTransmissionMGDSGMGDSGTop speed (km/h)232232230230Acceleration 0-100 km/h (s)8.08.18.18.2

2.0 l/162 kW TSI engine

Output (kW/rpm)162/4500-6200Maximum torque (Nm/rpm)350/1500-4400Number of cylinders/displacement (cm 3

)4/1984BodySuperbSuperb EstateTransmissionDSGDSGTop speed (km/h)245243Acceleration 0-100 km/h (s)7.07.1253Technical data

Page 256 of 276

2.0 l/206 kW TSI engineOutput (kW/rpm)206/5600-6500Maximum torque (Nm/rpm)350/1700-5600Number of cylinders/displacement (cm3

)4/1984BodySuperbSuperb EstateTransmissionDSG 4x4DSG 4x4Top speed (km/h)250250Acceleration 0-100 km/h (s)5.85.8

1.6 l/88 kW TDI CR engine

Output (kW/rpm)88/3600-4000Maximum torque (Nm/rpm)250/1600-3250Number of cylinders/displacement (cm 3

)4/1598BodySuperbSuperb EstateTransmissionMGMG (Green Line)DSGMGMG (Green Line)DSGTop speed (km/h)206209206204206204Acceleration 0-100 km/h (s)10.911.011.011.011.111.1

2.0 l/110 kW TDI CR engine

Output (kW/rpm)110/3500-4000Maximum torque (Nm/rpm)340/1750-3000Number of cylinders/displacement (cm 3

)4/1968BodySuperbSuperb EstateTransmissionMGMG 4x4DSGMGMG 4x4DSGTop speed (km/h)220215218218213216Acceleration 0-100 km/h (s)8.89.08.98.99.19.0254Technical data

Page 257 of 276

2.0 l/130 kW TDI CR engineOutput (kW/rpm)130/3700-4000Maximum torque (Nm/rpm)380/1750-3400Number of cylinders/displacement (cm3

)4/1968BodySuperbSuperb EstateTransmissionDSGDSGTop speed (km/h)222220Acceleration 0-100 km/h (s)8.48.5

2.0 l/140 kW TDI CR engine

Output (kW/rpm)140/3500-4000Maximum torque (Nm/rpm)400/1750-3250Number of cylinders/displacement (cm 3

)4/1968BodySuperbSuperb EstateTransmissionMGDSGDSG 4x4MGDSGDSG 4x4Top speed (km/h)237235230235233228Acceleration 0-100 km/h (s)8.07.77.68.17.87.7255Technical data