SKODA SUPERB 2016 3.G / (B8/3V) Owner's Manual

Manufacturer: SKODA, Model Year: 2016, Model line: SUPERB, Model: SKODA SUPERB 2016 3.G / (B8/3V)Pages: 336, PDF Size: 53.89 MB

Page 281 of 336

Speed symbol

All-season or “winter” tyres (marked with M+S and a peak/snowflake symbol

) of a lower speed category than stated in the technical vehicle documenta-

tion can be used, provided the permissible maximum speed of these tyres is

not exceeded even if the possible maximum speed of the vehicle is higher.

The speed limit for all-season or “winter” tyres can be adjusted in Infotainment

in the

→

→

tire

menu.

If the vehicle has all-season or “winter” tyres of a lower speed category then

the specified maximum speed of the vehicle (referring to tyres that have not

been delivered by the factory, a warning label with the maximum value of the

speed category provided for the mounted tyres must be fixed in the interior of

the vehicle in a constantly visible place in the driver’s field of vision. The warn-

ing label (sticker) can be replaced by setting the maximum value of the speed

category supplied for the mounted tyres in Infotainment 1)

. This specification

defines the maximum vehicle speed with mounted all-season or “winter”tyres

that may not be exceeded.

Snow chains

The snow chains improve driving in wintry road conditions.

Remove the full wheel trims before installing the snow chains » page 283.

Only fit snow chains with links and locks no larger than 12 mm.

Snow chains must only be mounted on the front wheels and are applicable on-

ly for the following wheel / tyre combinations.

Applies for 2.0 l/162, 206 kW TSI

Rim sizeImpression depth DTyre size6.5J x 1741 mm215/55 R17

Applies to the other engines

Rim sizeImpression depth DTyre size6.5J x 1641 mm215/60 R166.5J x 1741 mm215/55 R17WARNINGDo not use chains on snow- and ice-free routes - the driving behaviour may

be affected and there is a risk of a puncture.1)

Applies to some countries.

279Wheels

Page 282 of 336

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

Placement of the first aid kit and warning triangle

280

Placement of reflective vest

280

Fire extinguisher

281

Vehicle tool kit

281

Placement of the first aid kit and warning triangle

Fig. 327

Placement of first aid kits and warning triangle: Variant 1 / Loos-

en warning triangle

Fig. 328

Placement of the first-aid kit and

the warning triangle: Variant 2

The following information applies for the first aid kit and warning triangle from

the ŠKODA Original Accessories.

Placing the first-aid kit

The first-aid kit can be attached by a strap to the right-hand side of the boot

» Fig. 327 or » Fig. 328 .

Depending on the equipment fitted, in the same place a storage compartment

may be located in which the first aid kit can be stowed.

Placing of the warning triangle - variant 1

The warning triangle can be inserted into the recess under the loading edge

and secured with the fastener tape » Fig. 327.›

To release , press the clasp on the tape in the direction of arrow

1

fold open

the belt

A

in the direction of arrow

2

» Fig. 327 .

›

To secure , fold up the belt

A

against the arrow direction

2

until it locks in-

to place.

Warning triangle – version 2

The warning triangle can be stored in the recess under the loading edge

» Fig. 328 . Before it is taken out, the floor covering of the luggage compart-

ment must be raised.

WARNINGProperly secure the first aid kit and the warning triangle, or there is a risk of

injury in the event of sudden braking or a vehicle collision.

Placement of reflective vest

Fig. 329

Stowage compartment for the

reflective vest in the front door

The reflective vest can be stowed in the storage compartment

A

inside the

storage compartment of the front door » Fig. 329.

280Do-it-yourself

Page 283 of 336

It is possible to store the reflective vests for the passengers on the rear seat in

the storage compartment in the rear doors.

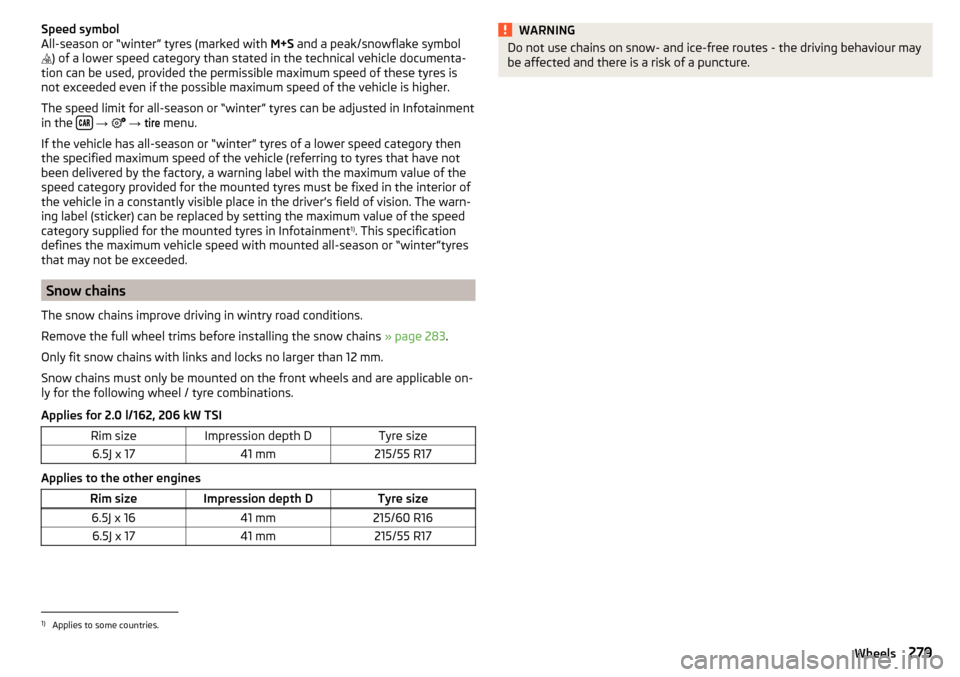

Fire extinguisher

Fig. 330

Release the fire extinguisher

The fire extinguisher is attached by two straps in a bracket under the front

passenger's seat.

›

To remove the fire extinguisher, release the safety catches on the two belts

in the direction of arrow » Fig. 330and remove the fire extinguisher.

›

To secure , place the fire extinguisher back in the mount and secure with the

belts.

The Owner´s Manual is fitted next to the fire extinguisher.

Pay attention to the expiration date of the fire extinguisher. After this date,

the correct function of the device is not guaranteed.

WARNINGAlways properly secure the fire extinguisher, there is a risk of injury in the

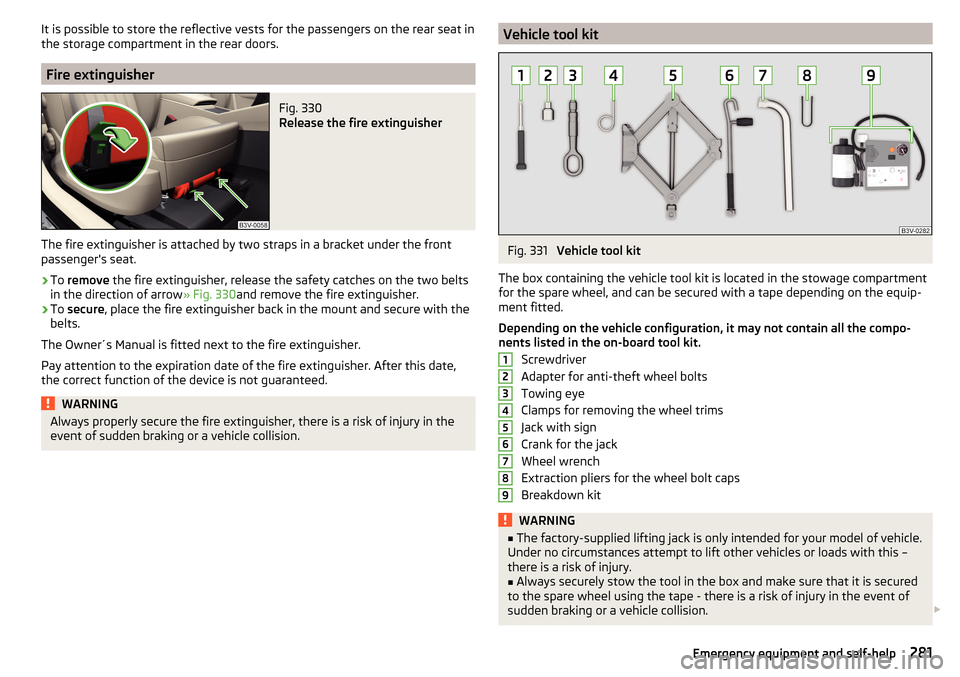

event of sudden braking or a vehicle collision.Vehicle tool kitFig. 331

Vehicle tool kit

The box containing the vehicle tool kit is located in the stowage compartment for the spare wheel, and can be secured with a tape depending on the equip-

ment fitted.

Depending on the vehicle configuration, it may not contain all the compo-

nents listed in the on-board tool kit.

Screwdriver

Adapter for anti-theft wheel bolts

Towing eye

Clamps for removing the wheel trims

Jack with sign

Crank for the jack

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kit

WARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with this –

there is a risk of injury.■

Always securely stow the tool in the box and make sure that it is secured

to the spare wheel using the tape - there is a risk of injury in the event of

sudden braking or a vehicle collision.

123456789281Emergency equipment and self-help

Page 284 of 336

CAUTIONScrew the jack back to its starting position prior to putting it back in its box -

Otherwise, there is a risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

As far as possible, park the vehicle far away from the traffic flow - find a

place with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1st gear.

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Switch on the parking brake.

›

Position the hazard warning system and the warning triangle at the prescri-

bed distance.

›

All the occupants should get out of the vehicle. The passengers should not

stand on the road (instead they should remain behind a crash barrier, for in-

stance) while the wheel is being changed.

›

Uncouple any trailers.

Changing a wheel

›

Remove the spare wheel » page 283.

›

Remove the full wheel trim » page 283 or caps » page 283 .

›

Loosen the wheel bolts » page 284 » .

›

Jack up the vehicle » page 284 until the wheel that needs changing is clear of

the ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“alter- nating crosswise”) » page 284.

›Replace the wheel trim

» page 283and the caps » page 283.

When fitting a wheel with a unidirectional tyre, ensure that the direction of ro-

tation is correct » page 276.

All bolts must be clean and must turn easily. If the screws are corroded and dif-

ficult to move, then these must be replaced.WARNING■ Undo the wheel bolts just a little (about one turn) while the vehicle is not

jacked up. Otherwise, the wheel could come off and fall down – there is a

risk of injury.■

Under no circumstances grease or oil the wheel bolts - risk of accident!

Subsequent steps

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure with a locking screw.

›

Stow the tool kit in the space provided and secure using the band.

›

Check and, if necessary, adjust the tyre pressure on the assembled wheel,

and, for vehicle with tyre pressure monitoring, save the tyre pressure values

in the system » page 249.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible. The prescribed tightening torque is 140 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

WARNINGA tightening torque which is too high can damage the bolts and threads

and this can result in permanent deformation of the contact surfaces on

the rim. Too low tightening torque, the wheels may fall off while driving -

risk of an accident. Drive cautiously and only at a moderate speed until the

tightening torque has been checked.282Do-it-yourself

Page 285 of 336

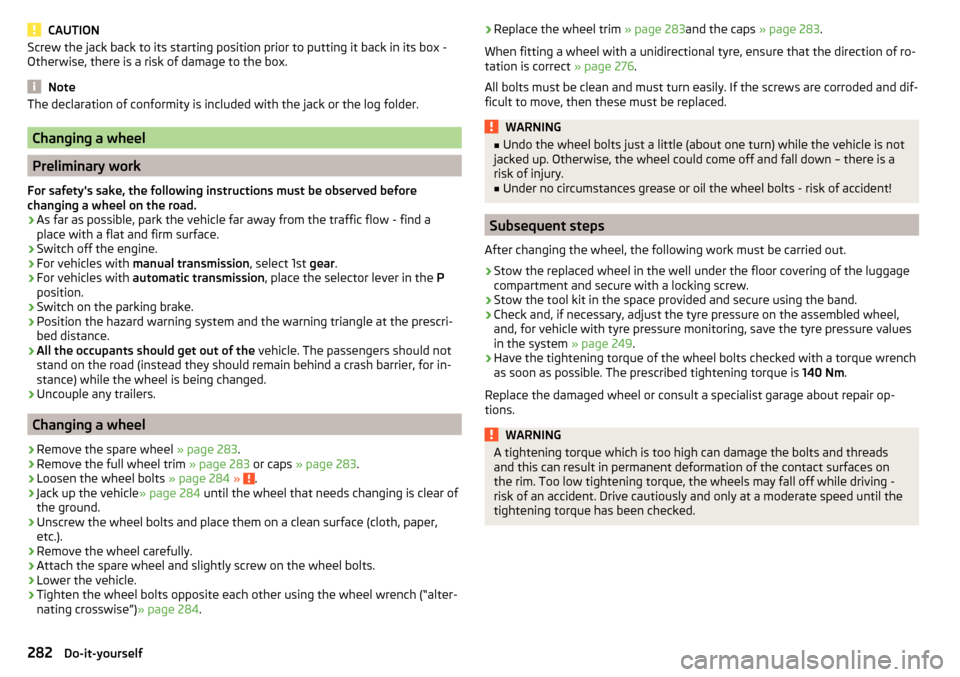

Removing /stowing the spare wheelFig. 332

Take out wheel

The spare wheel is located in a well under the floor covering in the luggage

compartment and is fixed in place with a fastening screw.

Take out wheel

›

Lift up the floor in the luggage compartment.

›

Loosen the retaining belt and take out the box with the tool kit.

›

Unscrew the locking screw in the direction of arrow » Fig. 332 and the re-

move the wheel.

Store wheel away

›

Place the wheel into the wheel well with the wheel rim pointing downward.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw the locking screw against the direction of arrow until it stops

» Fig. 332 .

›

Replace the box with the tool kit into the wheel and secure it with the tape.

›

Fold back the floor in the luggage compartment.

Full wheel trim

Removing the trim

›

The clamps for removing the full wheel trims hang on the edge of the full

wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing the trim

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

The back of the wheel trim supplied by the factory or from the ŠKODA Original

Accessories shows the position for the anti-theft wheel bolt. When using the

anti-theft wheel bolt, this is to be fitted in this point »

.

WARNINGWe recommend that you use hub caps from ŠKODA Original Accessories.

With other hub caps, a sufficient air supply for cooling the brake system

may not be guaranteed - There is risk of an accident.

CAUTION

■ If the wheel trim is set outside the position marked for the anti-theft wheel

bolt, there is a risk of damaging the wheel trim.■

Use only manual pressure and do not hit the full wheel trim – there is a risk

of damaging the trim.

Note

We recommend that you use hub caps from ŠKODA Original Accessories.

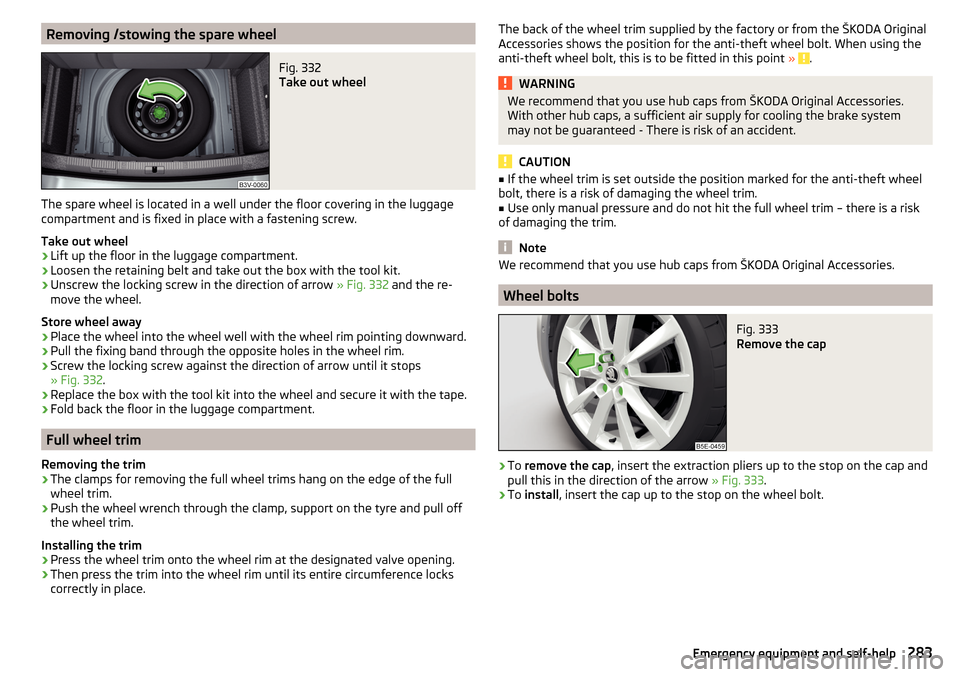

Wheel bolts

Fig. 333

Remove the cap

›

To remove the cap , insert the extraction pliers up to the stop on the cap and

pull this in the direction of the arrow » Fig. 333.

›

To install , insert the cap up to the stop on the wheel bolt.

283Emergency equipment and self-help

Page 286 of 336

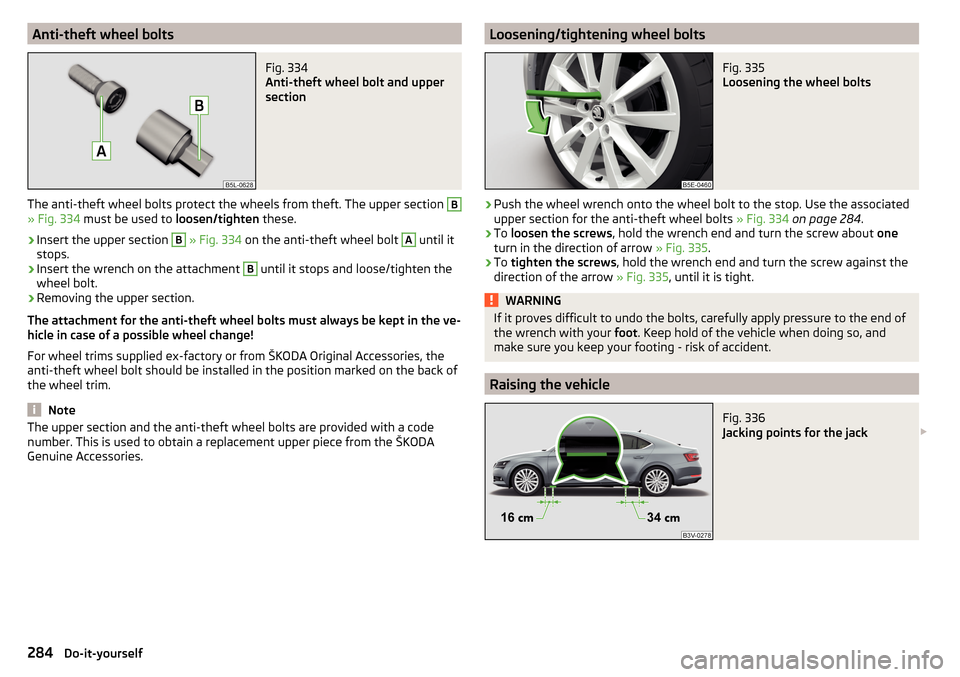

Anti-theft wheel boltsFig. 334

Anti-theft wheel bolt and upper

section

The anti-theft wheel bolts protect the wheels from theft. The upper section

B

» Fig. 334 must be used to loosen/tighten these.

›

Insert the upper section

B

» Fig. 334 on the anti-theft wheel bolt

A

until it

stops.

›

Insert the wrench on the attachment

B

until it stops and loose/tighten the

wheel bolt.

›

Removing the upper section.

The attachment for the anti-theft wheel bolts must always be kept in the ve-

hicle in case of a possible wheel change!

For wheel trims supplied ex-factory or from ŠKODA Original Accessories, the

anti-theft wheel bolt should be installed in the position marked on the back of

the wheel trim.

Note

The upper section and the anti-theft wheel bolts are provided with a code

number. This is used to obtain a replacement upper piece from the ŠKODA

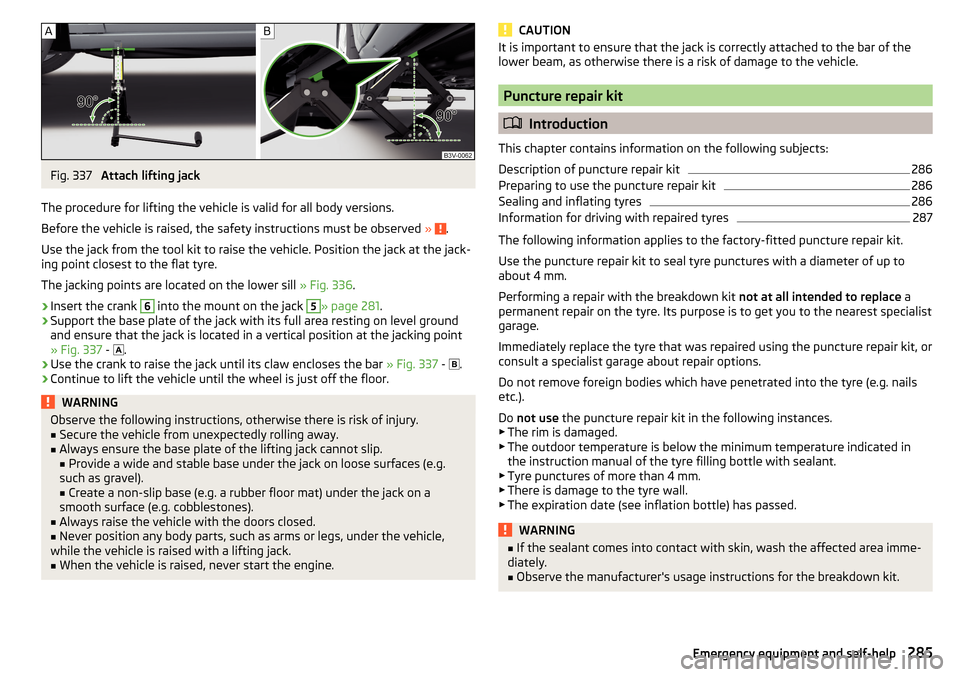

Genuine Accessories.Loosening/tightening wheel boltsFig. 335

Loosening the wheel bolts

›

Push the wheel wrench onto the wheel bolt to the stop. Use the associated

upper section for the anti-theft wheel bolts » Fig. 334 on page 284 .

›

To loosen the screws , hold the wrench end and turn the screw about one

turn in the direction of arrow » Fig. 335.

›

To tighten the screws , hold the wrench end and turn the screw against the

direction of the arrow » Fig. 335, until it is tight.

WARNINGIf it proves difficult to undo the bolts, carefully apply pressure to the end of

the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing - risk of accident.

Raising the vehicle

Fig. 336

Jacking points for the jack

284Do-it-yourself

Page 287 of 336

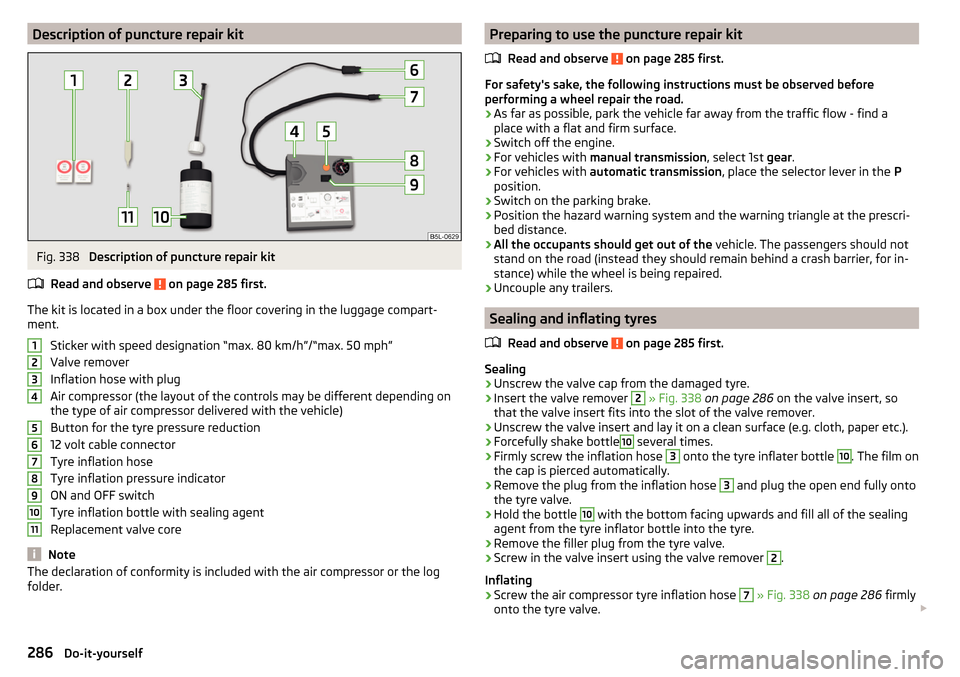

Fig. 337

Attach lifting jack

The procedure for lifting the vehicle is valid for all body versions.

Before the vehicle is raised, the safety instructions must be observed »

.

Use the jack from the tool kit to raise the vehicle. Position the jack at the jack-

ing point closest to the flat tyre.

The jacking points are located on the lower sill » Fig. 336.

›

Insert the crank

6

into the mount on the jack

5

» page 281 .

›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking point

» Fig. 337 -

.

›

Use the crank to raise the jack until its claw encloses the bar

» Fig. 337 -

.

›

Continue to lift the vehicle until the wheel is just off the floor.

WARNINGObserve the following instructions, otherwise there is risk of injury.■Secure the vehicle from unexpectedly rolling away.■

Always ensure the base plate of the lifting jack cannot slip.

■ Provide a wide and stable base under the jack on loose surfaces (e.g.

such as gravel). ■ Create a non-slip base (e.g. a rubber floor mat) under the jack on a

smooth surface (e.g. cobblestones).

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs, under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTIONIt is important to ensure that the jack is correctly attached to the bar of the

lower beam, as otherwise there is a risk of damage to the vehicle.

Puncture repair kit

Introduction

This chapter contains information on the following subjects:

Description of puncture repair kit

286

Preparing to use the puncture repair kit

286

Sealing and inflating tyres

286

Information for driving with repaired tyres

287

The following information applies to the factory-fitted puncture repair kit.

Use the puncture repair kit to seal tyre punctures with a diameter of up to

about 4 mm.

Performing a repair with the breakdown kit not at all intended to replace a

permanent repair on the tyre. Its purpose is to get you to the nearest specialist

garage.

Immediately replace the tyre that was repaired using the puncture repair kit, or

consult a specialist garage about repair options.

Do not remove foreign bodies which have penetrated into the tyre (e.g. nails etc.).

Do not use the puncture repair kit in the following instances.

▶ The rim is damaged.

▶ The outdoor temperature is below the minimum temperature indicated in

the instruction manual of the tyre filling bottle with sealant.

▶ Tyre punctures of more than 4 mm.

▶ There is damage to the tyre wall.

▶ The expiration date (see inflation bottle) has passed.

WARNING■ If the sealant comes into contact with skin, wash the affected area imme-

diately.■

Observe the manufacturer's usage instructions for the breakdown kit.

285Emergency equipment and self-help

Page 288 of 336

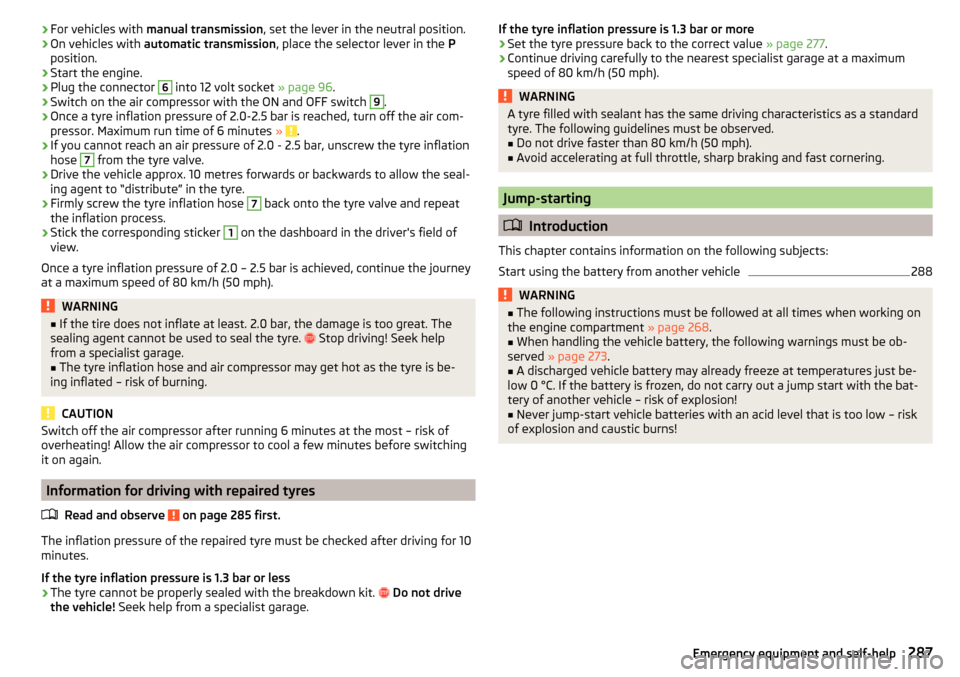

Description of puncture repair kitFig. 338

Description of puncture repair kit

Read and observe

on page 285 first.

The kit is located in a box under the floor covering in the luggage compart-

ment.

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”Valve remover

Inflation hose with plug

Air compressor (the layout of the controls may be different depending on

the type of air compressor delivered with the vehicle)

Button for the tyre pressure reduction

12 volt cable connector

Tyre inflation hose

Tyre inflation pressure indicator

ON and OFF switch

Tyre inflation bottle with sealing agent

Replacement valve core

Note

The declaration of conformity is included with the air compressor or the log

folder.1234567891011Preparing to use the puncture repair kit

Read and observe

on page 285 first.

For safety's sake, the following instructions must be observed before

performing a wheel repair the road.

›

As far as possible, park the vehicle far away from the traffic flow - find a

place with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1st gear.

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Switch on the parking brake.

›

Position the hazard warning system and the warning triangle at the prescri-

bed distance.

›

All the occupants should get out of the vehicle. The passengers should not

stand on the road (instead they should remain behind a crash barrier, for in-

stance) while the wheel is being repaired.

›

Uncouple any trailers.

Sealing and inflating tyres

Read and observe

on page 285 first.

Sealing

›

Unscrew the valve cap from the damaged tyre.

›

Insert the valve remover

2

» Fig. 338 on page 286 on the valve insert, so

that the valve insert fits into the slot of the valve remover.

›

Unscrew the valve insert and lay it on a clean surface (e.g. cloth, paper etc.).

›

Forcefully shake bottle

10

several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw in the valve insert using the valve remover

2

.

Inflating

›

Screw the air compressor tyre inflation hose

7

» Fig. 338 on page 286 firmly

onto the tyre valve.

286Do-it-yourself

Page 289 of 336

›For vehicles with

manual transmission , set the lever in the neutral position.›On vehicles with automatic transmission , place the selector lever in the P

position.›

Start the engine.

›

Plug the connector

6

into 12 volt socket » page 96.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Once a tyre inflation pressure of 2.0-2.5 bar is reached, turn off the air com-

pressor. Maximum run time of 6 minutes » .

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle approx. 10 metres forwards or backwards to allow the seal-

ing agent to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

Stick the corresponding sticker

1

on the dashboard in the driver's field of

view.

Once a tyre inflation pressure of 2.0 – 2.5 bar is achieved, continue the journey

at a maximum speed of 80 km/h (50 mph).

WARNING■ If the tire does not inflate at least. 2.0 bar, the damage is too great. The

sealing agent cannot be used to seal the tyre. Stop driving! Seek help

from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – risk of burning.

CAUTION

Switch off the air compressor after running 6 minutes at the most – risk of

overheating! Allow the air compressor to cool a few minutes before switching

it on again.

Information for driving with repaired tyres

Read and observe

on page 285 first.

The inflation pressure of the repaired tyre must be checked after driving for 10

minutes.

If the tyre inflation pressure is 1.3 bar or less

›

The tyre cannot be properly sealed with the breakdown kit.

Do not drive

the vehicle! Seek help from a specialist garage.

If the tyre inflation pressure is 1.3 bar or more›Set the tyre pressure back to the correct value » page 277.›

Continue driving carefully to the nearest specialist garage at a maximum

speed of 80 km/h (50 mph).

WARNINGA tyre filled with sealant has the same driving characteristics as a standard

tyre. The following guidelines must be observed.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

Jump-starting

Introduction

This chapter contains information on the following subjects:

Start using the battery from another vehicle

288WARNING■ The following instructions must be followed at all times when working on

the engine compartment » page 268.■

When handling the vehicle battery, the following warnings must be ob-

served » page 273 .

■

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not carry out a jump start with the bat-

tery of another vehicle – risk of explosion!

■

Never jump-start vehicle batteries with an acid level that is too low – risk

of explosion and caustic burns!

287Emergency equipment and self-help

Page 290 of 336

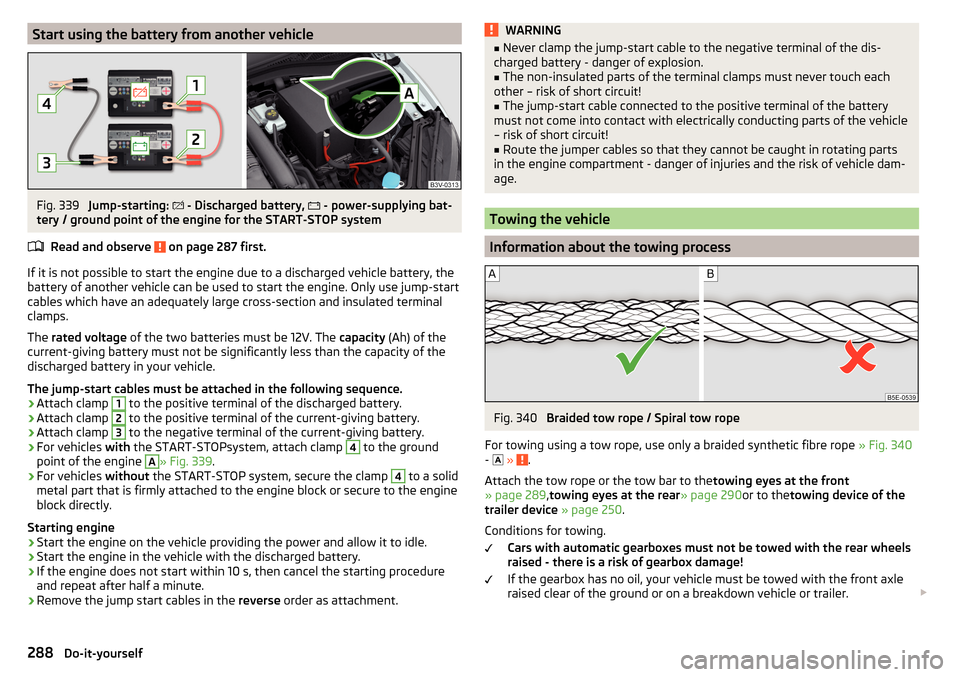

Start using the battery from another vehicleFig. 339

Jump-starting:

- Discharged battery,

- power-supplying bat-

tery / ground point of the engine for the START-STOP system

Read and observe

on page 287 first.

If it is not possible to start the engine due to a discharged vehicle battery, the

battery of another vehicle can be used to start the engine. Only use jump-start

cables which have an adequately large cross-section and insulated terminal

clamps.

The rated voltage of the two batteries must be 12V. The capacity (Ah) of the

current-giving battery must not be significantly less than the capacity of the

discharged battery in your vehicle.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery.

›

Attach clamp

2

to the positive terminal of the current-giving battery.

›

Attach clamp

3

to the negative terminal of the current-giving battery.

›

For vehicles with the START-STOPsystem, attach clamp

4

to the ground

point of the engine

A

» Fig. 339 .

›

For vehicles without the START-STOP system, secure the clamp

4

to a solid

metal part that is firmly attached to the engine block or secure to the engine

block directly.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Start the engine in the vehicle with the discharged battery.

›

If the engine does not start within 10 s, then cancel the starting procedure

and repeat after half a minute.

›

Remove the jump start cables in the reverse order as attachment.

WARNING■

Never clamp the jump-start cable to the negative terminal of the dis-

charged battery - danger of explosion.■

The non-insulated parts of the terminal clamps must never touch each

other – risk of short circuit!

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– risk of short circuit!

■

Route the jumper cables so that they cannot be caught in rotating parts

in the engine compartment - danger of injuries and the risk of vehicle dam-

age.

Towing the vehicle

Information about the towing process

Fig. 340

Braided tow rope / Spiral tow rope

For towing using a tow rope, use only a braided synthetic fibre rope » Fig. 340

-

»

.

Attach the tow rope or the tow bar to the towing eyes at the front

» page 289 ,towing eyes at the rear » page 290or to thetowing device of the

trailer device » page 250 .

Conditions for towing. Cars with automatic gearboxes must not be towed with the rear wheels

raised - there is a risk of gearbox damage!

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

288Do-it-yourself