ECU SKODA YETI 2015 1.G / 5L Service Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: YETI, Model: SKODA YETI 2015 1.G / 5LPages: 232, PDF Size: 30.84 MB

Page 185 of 232

Remove the wheel / fix186Follow-up tasks186

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard warning lights system.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

Tyres with increased puncture resistance

Some vehicles may be fitted with tyres at the factory that have increased

puncture resistance (“SEAL” tyres).

These vehicles are delivered without a puncture repair kit, spare wheel and appropriate hand tools.

If tyres with increased puncture resistance are replaced with tyres that have

no increased puncture resistance, then the vehicle should be equipped with a

puncture repair kit, spare wheel and appropriate hand tools.

Preparation

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear.

›

On vehicles with automatic transmission place the selector lever in the P po-

sition.

›

Firmly apply the handbrake.

›

Uncouple any trailers.

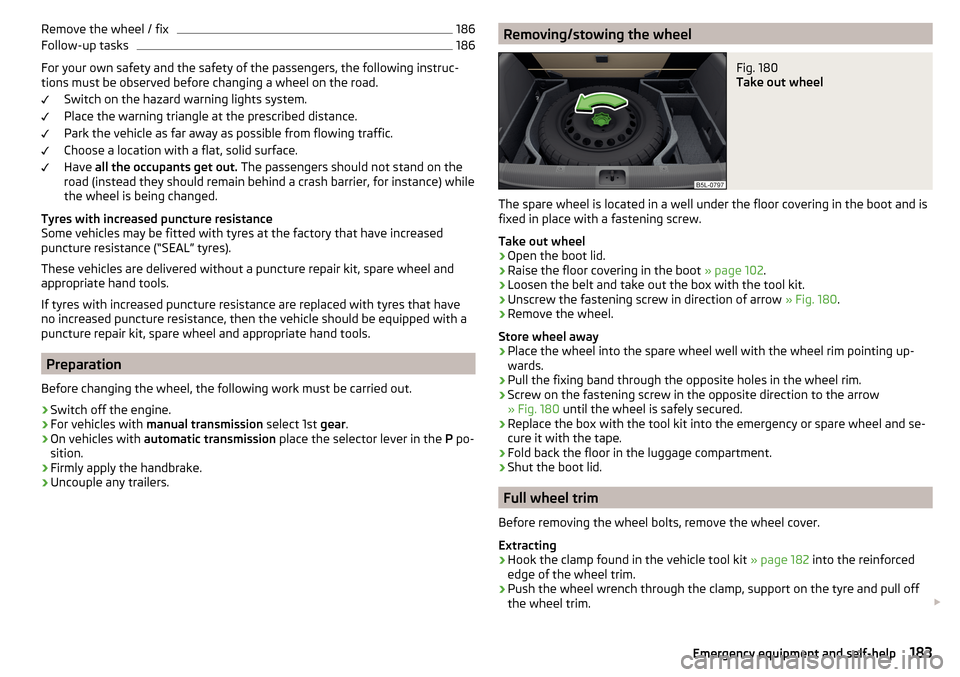

Removing/stowing the wheelFig. 180

Take out wheel

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a fastening screw.

Take out wheel

›

Open the boot lid.

›

Raise the floor covering in the boot » page 102.

›

Loosen the belt and take out the box with the tool kit.

›

Unscrew the fastening screw in direction of arrow » Fig. 180.

›

Remove the wheel.

Store wheel away

›

Place the wheel into the spare wheel well with the wheel rim pointing up-

wards.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw on the fastening screw in the opposite direction to the arrow

» Fig. 180 until the wheel is safely secured.

›

Replace the box with the tool kit into the emergency or spare wheel and se-

cure it with the tape.

›

Fold back the floor in the luggage compartment.

›

Shut the boot lid.

Full wheel trim

Before removing the wheel bolts, remove the wheel cover.

Extracting

›

Hook the clamp found in the vehicle tool kit » page 182 into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

183Emergency equipment and self-help

Page 188 of 232

WARNING■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. If the surface is smooth, such as on cobbled stones, tiled floor, etc.,

use a non-slip base (e.g. a rubber foot mat).

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg - risk of damage to the vehicle.

Remove the wheel / fix

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (alter-

nating crosswise). Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 178 .

All bolts must be clean and must turn easily.

If it is established when changing a wheel that the wheel bolts are corroded and difficult to move, then these must be replaced.

Under no circumstances grease or oil the wheel bolts.WARNINGUndo the wheel bolts only a little (about one turn) as long as the vehicle

has not yet been jacked up. Otherwise the wheel could become loose and

fall off.

Follow-up tasks

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the wheel well and secure it with a special nut.

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the fitted wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, save tyre pressure values » page 141.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

The prescribed tightening torque of the wheel bolts is 120 Nm.

WARNING■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

Puncture repair kit

Introduction

This chapter contains information on the following subjects:

Components of the puncture repair kits

187

General information

187

186Do-it-yourself

Page 197 of 232

›Insert a screwdriver or similar tool into the opening in the trim

» Fig. 197 as

far as the stop.›

Unlock the lid by moving it in the direction of the arrow.

›

Open the boot lid.

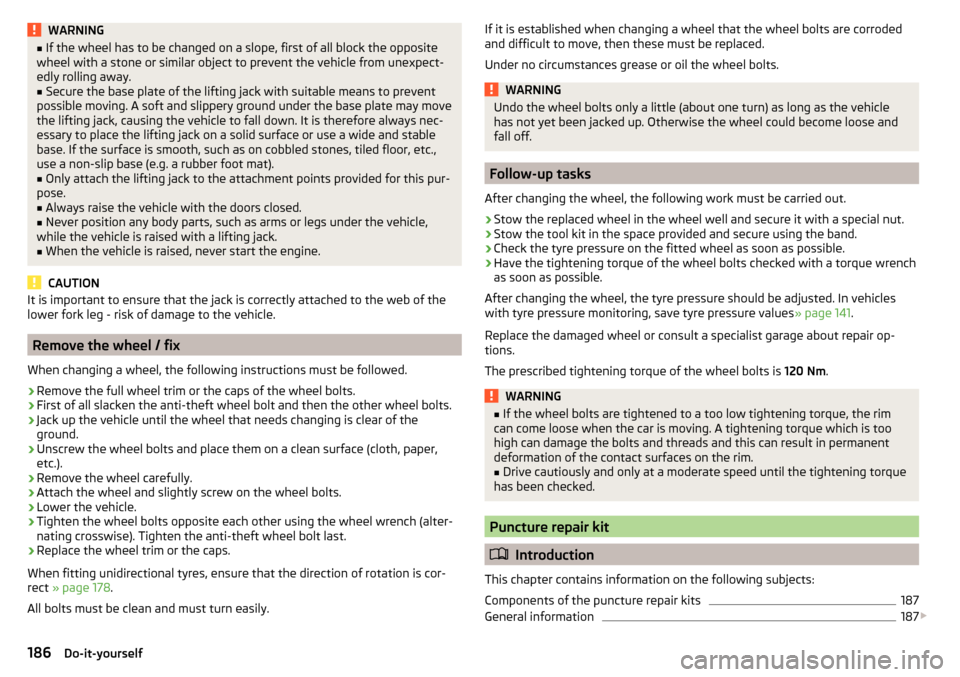

Selector lever-emergency unlocking

Fig. 198

Selector lever-emergency unlocking

›

Firmly apply the handbrake.

›

Insert a flat-head screwdriver into the gap in the arrow range

1

» Fig. 198

and lift the cover in arrow direction

2

.

›

Use a finger to press the yellow plastic part in the direction of the arrow

3

.

›

At the same time, press the locking button in the selector lever and move

the selector lever to position N.

If the selector lever is moved again to position P, it is once again blocked.

CAUTION

Make sure when lifting not to damage cover parts by the screwdriver in the

shift lever environment.

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing front windscreen wipers

195

Replacing the rear window wiper blade

196WARNINGReplace the windscreen wiper blades once or twice a year for safety rea-

sons. These can be purchased from a ŠKODA Partner.

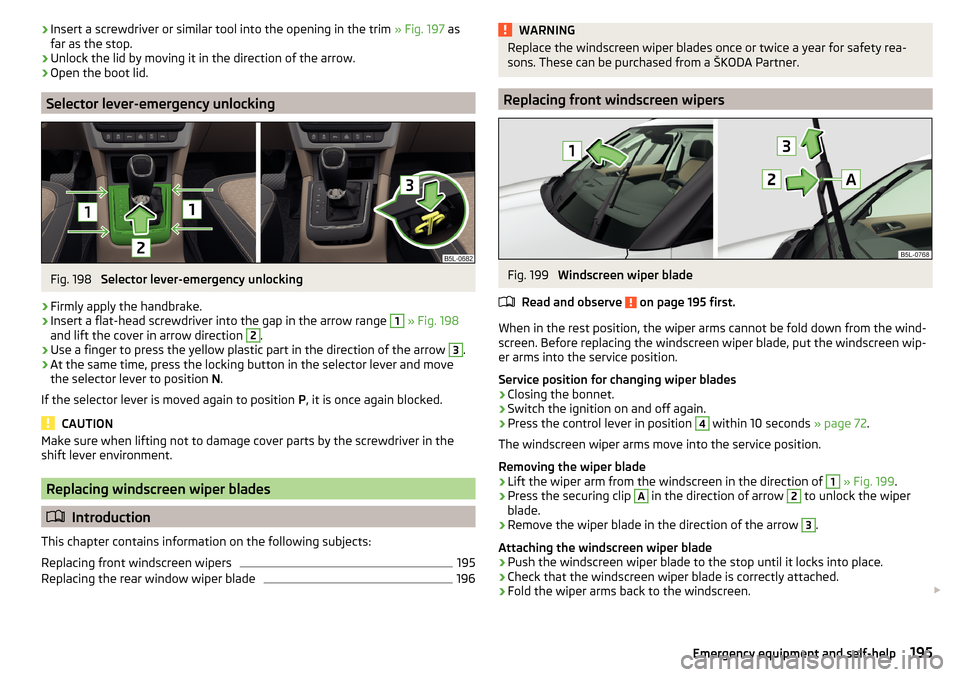

Replacing front windscreen wipers

Fig. 199

Windscreen wiper blade

Read and observe

on page 195 first.

When in the rest position, the wiper arms cannot be fold down from the wind-

screen. Before replacing the windscreen wiper blade, put the windscreen wip-

er arms into the service position.

Service position for changing wiper blades

›

Closing the bonnet.

›

Switch the ignition on and off again.

›

Press the control lever in position

4

within 10 seconds » page 72.

The windscreen wiper arms move into the service position.

Removing the wiper blade

›

Lift the wiper arm from the windscreen in the direction of

1

» Fig. 199 .

›

Press the securing clip

A

in the direction of arrow

2

to unlock the wiper

blade.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the wiper arms back to the windscreen.

195Emergency equipment and self-help

Page 198 of 232

The windscreen wiper arms move back into the rest position - after switching

on the ignition and changing the position of the window wiper lever or when

driving at a speed of more than 6°km/h.

CAUTION

If the windscreen wipers are handled carelessly, there is a risk of damage to

the windscreen.

Replacing the rear window wiper blade

Fig. 200

Rear window wiper blade

Read and observe

on page 195 first.

Removing the wiper blade

›

Lift the wiper arm from the windscreen in the direction of

1

» Fig. 200 .

›

Tilt the wiper blade to the stop in the same direction.

›

Hold the upper part of the wiper arm and press the securing mechanism

A

in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

Attaching the windscreen wiper blade

›

Push the windscreen wiper blade to the stop until it locks into place.

›

Check that the windscreen wiper blade is correctly attached.

›

Fold the wiper arm back to the windscreen.

Fuses and light bulbs

Fuses

Introduction

This chapter contains information on the following subjects:

Fuses in the dash panel

197

Assignment of the fuses in the dash panel

197

Fuses in the engine compartment

198

Assignment of fuses in the engine compartment

198

Individual electrical circuits are protected by fuses.

Switch off the ignition and the corresponding power consuming device before

replacing a fuse.

Find out which fuse belongs to the component that is not operating

» page 197 , Fuses in the dash panel or » page 198 , Fuses in the engine com-

partment .

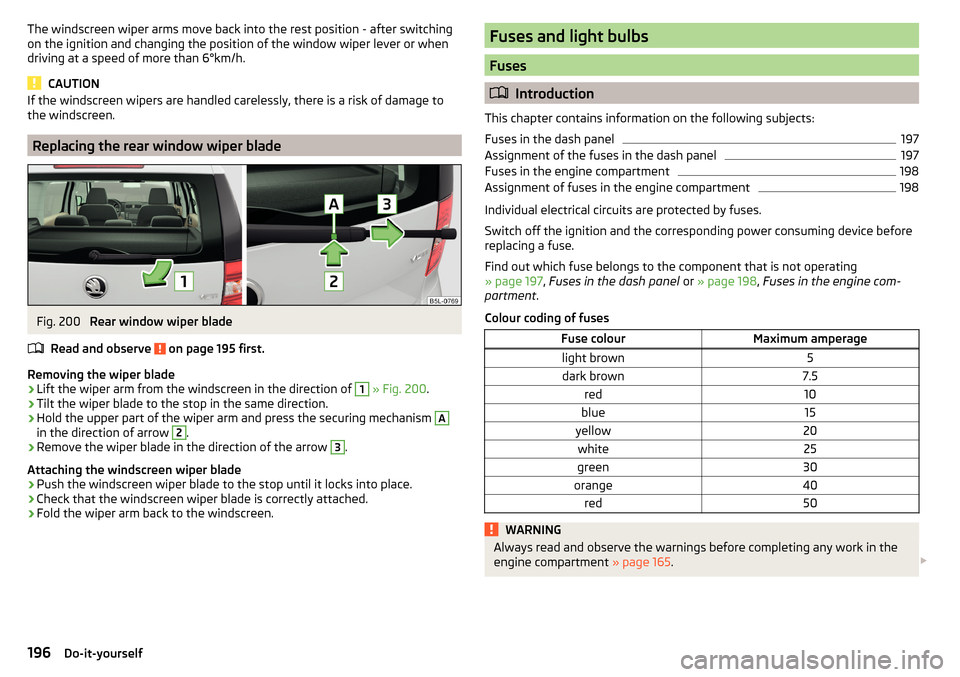

Colour coding of fuses

Fuse colourMaximum amperagelight brown5dark brown7.5red10blue15yellow20white25green30orange40red50WARNINGAlways read and observe the warnings before completing any work in the

engine compartment » page 165. 196Do-it-yourself

Page 200 of 232

No.Consumer19ABS, ESP, switch for tyre air pressure control, parking aid, switch for

OFF ROAD mode, START STOP button20Switch, airbag21WIV, tail lamp, dimming mirror, pressure sensor, telephone prepara-

tion, air mass sensor, headlight range control and headlight tilt22Instrument cluster, electromechanical power steering, databus23Central locking system and bonnet lid24Rear power window25Rear window heater, auxiliary heating and ventilation26Power socket in the boot27Panorama window - sliding / tilting roof, electric sunblind28Fuel pump, injectors, AdBlue ®

heating29Front power window30front and rear lighter31Headlight cleaning system32Front seat heating, regulator for seat heating33Heating, air conditioning, Climatronic, remote control for auxiliary

heating34Alarm, spare horn35Automatic gearbox DSG36Tow hitch

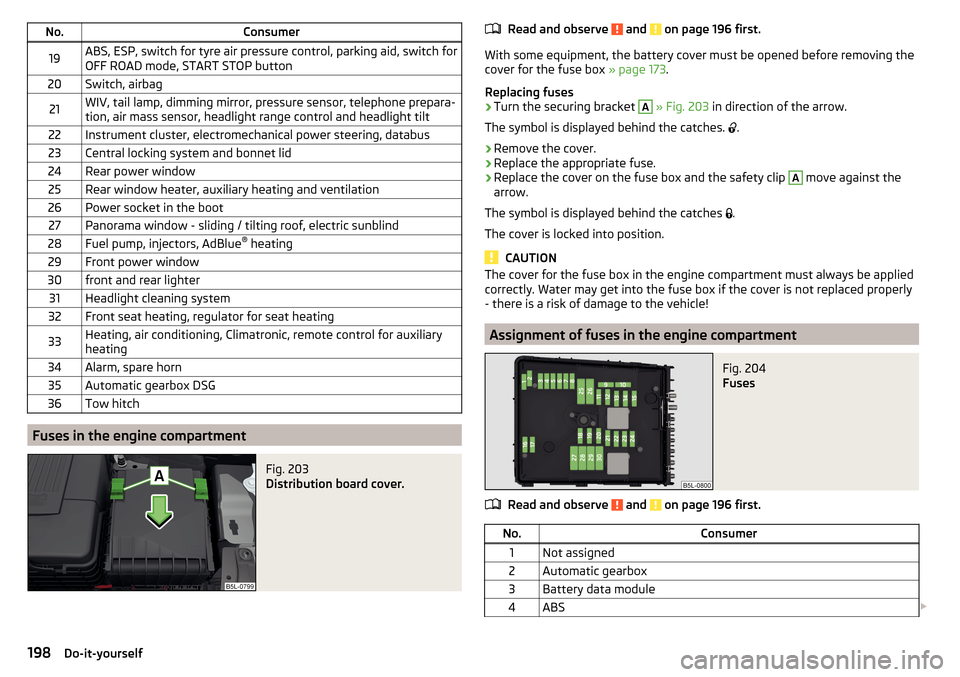

Fuses in the engine compartment

Fig. 203

Distribution board cover.

Read and observe and on page 196 first.

With some equipment, the battery cover must be opened before removing the

cover for the fuse box » page 173.

Replacing fuses

›

Turn the securing bracket

A

» Fig. 203 in direction of the arrow.

The symbol is displayed behind the catches.

.

›

Remove the cover.

›

Replace the appropriate fuse.

›

Replace the cover on the fuse box and the safety clip

A

move against the

arrow.

The symbol is displayed behind the catches .

The cover is locked into position.

CAUTION

The cover for the fuse box in the engine compartment must always be applied

correctly. Water may get into the fuse box if the cover is not replaced properly

- there is a risk of damage to the vehicle!

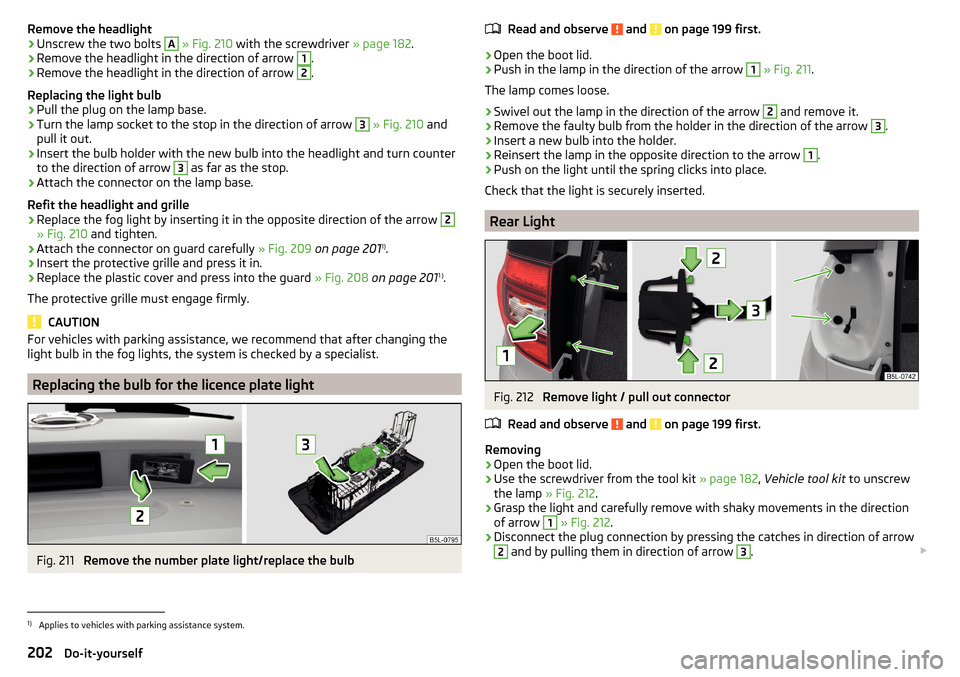

Assignment of fuses in the engine compartment

Fig. 204

Fuses

Read and observe and on page 196 first.

No.Consumer1Not assigned2Automatic gearbox3Battery data module4ABS 198Do-it-yourself

Page 204 of 232

Remove the headlight›Unscrew the two bolts A » Fig. 210 with the screwdriver » page 182.›

Remove the headlight in the direction of arrow

1

.

›

Remove the headlight in the direction of arrow

2

.

Replacing the light bulb

›

Pull the plug on the lamp base.

›

Turn the lamp socket to the stop in the direction of arrow

3

» Fig. 210 and

pull it out.

›

Insert the bulb holder with the new bulb into the headlight and turn counter

to the direction of arrow

3

as far as the stop.

›

Attach the connector on the lamp base.

Refit the headlight and grille

›

Replace the fog light by inserting it in the opposite direction of the arrow

2

» Fig. 210 and tighten.

›

Attach the connector on guard carefully » Fig. 209 on page 201 1)

.

›

Insert the protective grille and press it in.

›

Replace the plastic cover and press into the guard » Fig. 208 on page 201 1 )

.

The protective grille must engage firmly.

CAUTION

For vehicles with parking assistance, we recommend that after changing the

light bulb in the fog lights, the system is checked by a specialist.

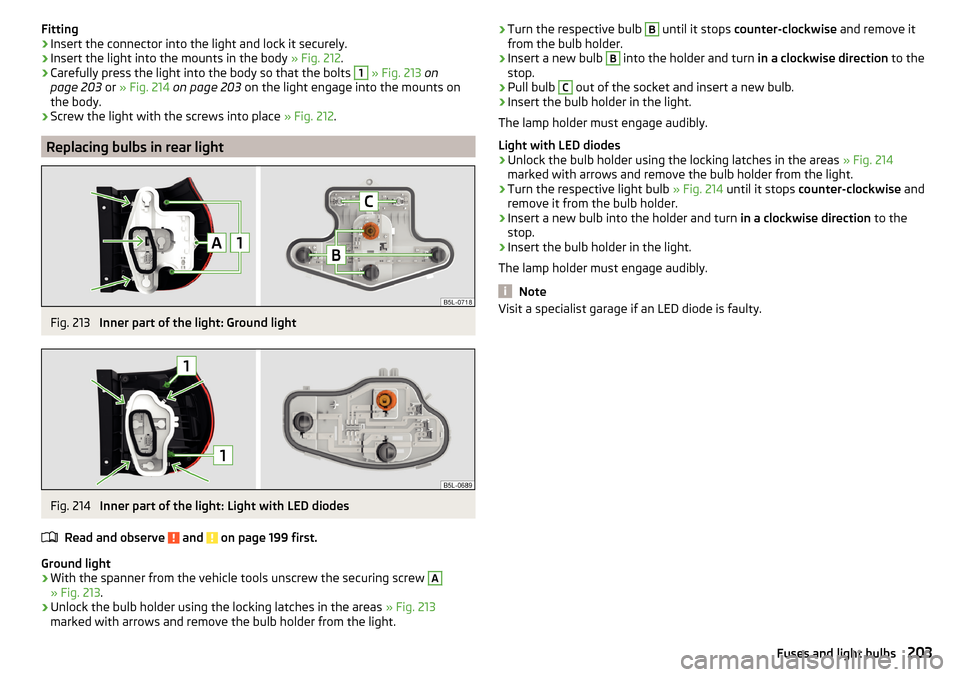

Replacing the bulb for the licence plate light

Fig. 211

Remove the number plate light/replace the bulb

Read and observe and on page 199 first.›

Open the boot lid.

›

Push in the lamp in the direction of the arrow

1

» Fig. 211 .

The lamp comes loose.

›

Swivel out the lamp in the direction of the arrow

2

and remove it.

›

Remove the faulty bulb from the holder in the direction of the arrow

3

.

›

Insert a new bulb into the holder.

›

Reinsert the lamp in the opposite direction to the arrow

1

.

›

Push on the light until the spring clicks into place.

Check that the light is securely inserted.

Rear Light

Fig. 212

Remove light / pull out connector

Read and observe

and on page 199 first.

Removing

›

Open the boot lid.

›

Use the screwdriver from the tool kit » page 182, Vehicle tool kit to unscrew

the lamp » Fig. 212.

›

Grasp the light and carefully remove with shaky movements in the direction

of arrow

1

» Fig. 212 .

›

Disconnect the plug connection by pressing the catches in direction of arrow

2

and by pulling them in direction of arrow

3

.

1)

Applies to vehicles with parking assistance system.

202Do-it-yourself

Page 205 of 232

Fitting›Insert the connector into the light and lock it securely.›

Insert the light into the mounts in the body » Fig. 212.

›

Carefully press the light into the body so that the bolts

1

» Fig. 213 on

page 203 or » Fig. 214 on page 203 on the light engage into the mounts on

the body.

›

Screw the light with the screws into place » Fig. 212.

Replacing bulbs in rear light

Fig. 213

Inner part of the light: Ground light

Fig. 214

Inner part of the light: Light with LED diodes

Read and observe

and on page 199 first.

Ground light

›

With the spanner from the vehicle tools unscrew the securing screw

A

» Fig. 213 .

›

Unlock the bulb holder using the locking latches in the areas » Fig. 213

marked with arrows and remove the bulb holder from the light.

› Turn the respective bulb B until it stops

counter-clockwise and remove it

from the bulb holder.›

Insert a new bulb

B

into the holder and turn in a clockwise direction to the

stop.

›

Pull bulb

C

out of the socket and insert a new bulb.

›

Insert the bulb holder in the light.

The lamp holder must engage audibly.

Light with LED diodes

›

Unlock the bulb holder using the locking latches in the areas » Fig. 214

marked with arrows and remove the bulb holder from the light.

›

Turn the respective light bulb » Fig. 214 until it stops counter-clockwise and

remove it from the bulb holder.

›

Insert a new bulb into the holder and turn in a clockwise direction to the

stop.

›

Insert the bulb holder in the light.

The lamp holder must engage audibly.

Note

Visit a specialist garage if an LED diode is faulty.203Fuses and light bulbs

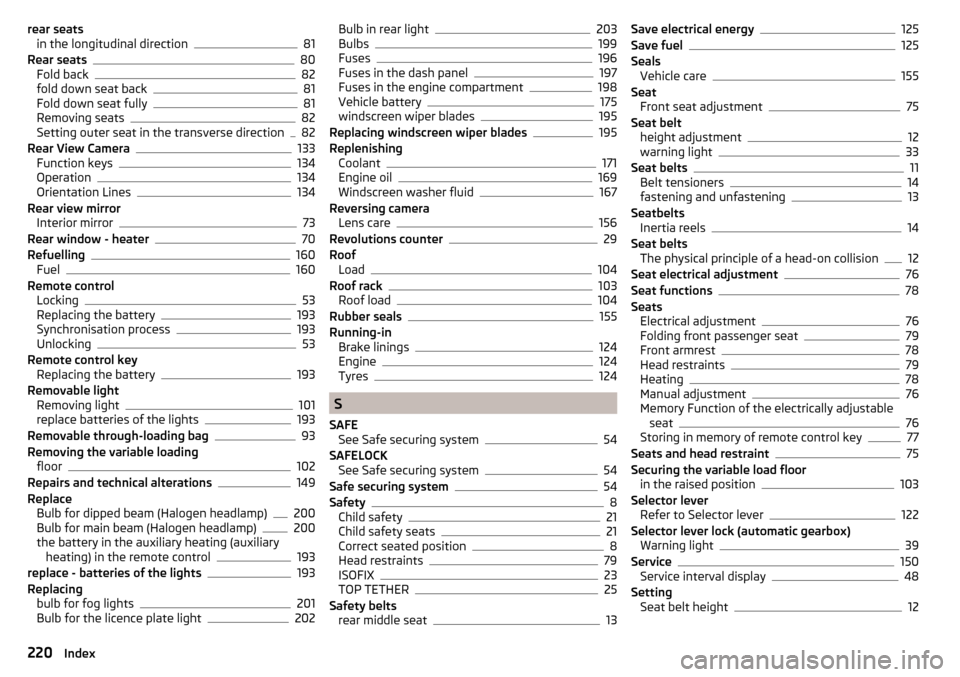

Page 222 of 232

rear seatsin the longitudinal direction81

Rear seats80

Fold back82

fold down seat back81

Fold down seat fully81

Removing seats82

Setting outer seat in the transverse direction82

Rear View Camera133

Function keys134

Operation134

Orientation Lines134

Rear view mirror Interior mirror

73

Rear window - heater70

Refuelling160

Fuel160

Remote control Locking

53

Replacing the battery193

Synchronisation process193

Unlocking53

Remote control key Replacing the battery

193

Removable light Removing light

101

replace batteries of the lights193

Removable through-loading bag93

Removing the variable loading floor

102

Repairs and technical alterations149

Replace Bulb for dipped beam (Halogen headlamp)

200

Bulb for main beam (Halogen headlamp)200

the battery in the auxiliary heating (auxiliary heating) in the remote control

193

replace - batteries of the lights193

Replacing bulb for fog lights

201

Bulb for the licence plate light202

Bulb in rear light203

Bulbs199

Fuses196

Fuses in the dash panel197

Fuses in the engine compartment198

Vehicle battery175

windscreen wiper blades195

Replacing windscreen wiper blades195

Replenishing Coolant

171

Engine oil169

Windscreen washer fluid167

Reversing camera Lens care

156

Revolutions counter29

Roof Load

104

Roof rack103

Roof load104

Rubber seals155

Running-in Brake linings

124

Engine124

Tyres124

S

SAFE See Safe securing system

54

SAFELOCK See Safe securing system

54

Safe securing system54

Safety8

Child safety21

Child safety seats21

Correct seated position8

Head restraints79

ISOFIX23

TOP TETHER25

Safety belts rear middle seat

13

Save electrical energy125

Save fuel125

Seals Vehicle care

155

Seat Front seat adjustment

75

Seat belt height adjustment

12

warning light33

Seat belts11

Belt tensioners14

fastening and unfastening13

Seatbelts Inertia reels

14

Seat belts The physical principle of a head-on collision

12

Seat electrical adjustment76

Seat functions78

Seats Electrical adjustment

76

Folding front passenger seat79

Front armrest78

Head restraints79

Heating78

Manual adjustment76

Memory Function of the electrically adjustable seat

76

Storing in memory of remote control key77

Seats and head restraint75

Securing the variable load floor in the raised position

103

Selector lever Refer to Selector lever

122

Selector lever lock (automatic gearbox) Warning light

39

Service150

Service interval display48

Setting Seat belt height

12

220Index