driver SKODA YETI 2017 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2017, Model line: YETI, Model: SKODA YETI 2017Pages: 200, PDF Size: 28.93 MB

Page 155 of 200

The speed limit for all-season or “winter”Tires can be adjusted in MAXI

DOTDisplay in the menu item winter tires

» page 43 .

If the vehicle has all-season or “winter”tires of a lower speed category then

the specified maximum speed of the vehicle (referring to tyres that have not

been delivered by the factory, a warning label with the maximum value of the

speed category provided for the mounted tyres must be fixed in the interior of

the vehicle in a constantly visible place in the driver’s field of vision. The warn-

ing label (sticker) can be replaced by setting maximum value of the mounted

tire speed rating in the MAXI DOTDisplay in the

winter tires

menu item 1)

. This

specification defines the maximum vehicle speed with mounted all-season or

“winter”tyres that may not be exceeded.

Snow chains

The snow chains improve handling in wintry road conditions.

Remove the full wheel trims before installing the snow chains » page 156.

Only fit snow chains with links and locks not larger than 12 mm.

The use of snow chains on vehicles with front-wheel drive and on vehicles

with four-wheel drive differs.

Front-wheel drive

Snow chains must only be fitted on the front wheels and are applicable only to

the following wheel / tyre combinations.

Rim sizePress depth DTyre size6J x 1650 mm205/55 R167J x 1645 mm205/55 R166J x 1745 mm205/50 R17

All-wheel drive

Snow chains can be mounted on the wheels on the front and rear axles.

It is only permissible to fit snow chains on the front wheels with the following

wheel/tyre combinations.

Rim sizePress depth DTyre size6J x 1650 mm205/55 R167J x 1645 mm205/55 R166J x 1745 mm205/50 R17

It is only permissible to fit snow chains on the rear wheels with the following

wheel/tyre combinations.

Rim sizePress depth DTyre size7J x 1645 mm215/60 R167J x 1745 mm225/50 R17WARNINGDo not use chains on snow and ice-free routes - the handling would be im-

paired and there is a risk of damage to the tyres.1)

Valid in certain countries.

153Wheels

Page 156 of 200

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

Placement of the first aid kit and warning triangle

154

Location of reflective vest

154

Fire extinguisher

154

Vehicle tool kit

155

Placement of the first aid kit and warning triangle

Fig. 167

Location of the first-aid kit and the warning triangle

The following information applies for the first aid kit and warning triangle from the ŠKODA Original Accessories.

Placing the first-aid kit

The first-aid box can be attached by a strap to the right-hand side of the boot

» Fig. 167 -

.

Placing of the warning triangle

The warning triangle can be attached using the tensioning straps in the recess

of the loading edge » Fig. 167 -

.

The warning triangle, which is included in the equipment with the spare wheel,

can be stowed in a removable box on the right next to the spare wheel

» page 91 .

WARNINGProperly secure the first aid kit and the warning triangle - there is a risk of

injury in the event of sudden braking or a vehicle collision.

Location of reflective vest

Fig. 168

Storage compartment for the re-

flective vest

The reflective vest can be stowed in a holder under the driver's seat » Fig. 168.

Fire extinguisher

Fig. 169

Release the fire extinguisher

The fire extinguisher is attached by two straps in a holder underneath the driv-

er's seat.

›

To remove the fire extinguisher, release the safety catches on the two belts

in the direction of arrow » Fig. 169 and remove the fire extinguisher.

›

To secure , place the fire extinguisher back in the mount and secure with the

belts.

The Owner's Manual is fitted next to the fire extinguisher.

Pay attention to the expiration date of the fire extinguisher. After this date,

the correct function of the device is not guaranteed.

154Do-it-yourself

Page 157 of 200

WARNINGAlways properly secure the fire extinguisher - there is a risk of injury in the

event of sudden braking or a vehicle collision.

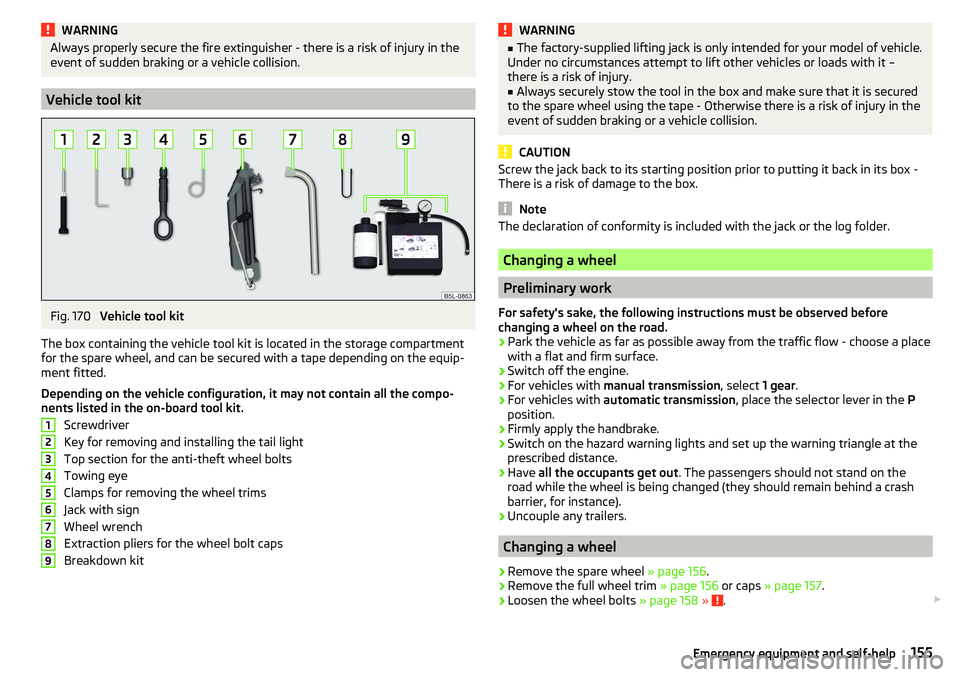

Vehicle tool kit

Fig. 170

Vehicle tool kit

The box containing the vehicle tool kit is located in the storage compartment

for the spare wheel, and can be secured with a tape depending on the equip-

ment fitted.

Depending on the vehicle configuration, it may not contain all the compo-

nents listed in the on-board tool kit.

Screwdriver

Key for removing and installing the tail light

Top section for the anti-theft wheel bolts

Towing eye

Clamps for removing the wheel trims

Jack with sign

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kit

123456789WARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with it –

there is a risk of injury.■

Always securely stow the tool in the box and make sure that it is secured

to the spare wheel using the tape - Otherwise there is a risk of injury in the

event of sudden braking or a vehicle collision.

CAUTION

Screw the jack back to its starting position prior to putting it back in its box -

There is a risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1 gear.

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

›

Uncouple any trailers.

Changing a wheel

›

Remove the spare wheel » page 156.

›

Remove the full wheel trim » page 156 or caps » page 157 .

›

Loosen the wheel bolts » page 158 » .

155Emergency equipment and self-help

Page 162 of 200

Preparing to use the breakdown kitRead and observe

on page 159 first.

For safety's sake, the following instructions must be observed before

undertaking a wheel repair on a road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1. gear.

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . While the repair is being carried out, the pas-

sengers should not stand on the road (instead they should remain behind a

crash barrier, for instance).

›

Uncouple any trailers.

Sealing and inflating tyres

Read and observe

on page 159 first.

Sealing

›

Unscrew the valve cap from the damaged tyre.

›

Insert the valve remover

2

» Fig. 177 on page 159 on the valve insert, so that

the valve insert fits into the slot of the valve remover.

›

Unscrew the valve insert and place it on a clean base (rag, paper etc.).

›

Forcefully shake bottle

10

» Fig. 177 on page 159 several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the bottle cap is pierced.

›

Remove the plug from the inflation hose

3

and insert the bottle onto the

tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw in the valve insert with the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

8

» Fig. 177 on page 159 firmly onto the tyre

valve.

› For vehicles with

manual transmission , set the lever in the neutral position.›On vehicles with automatic transmission , place the selector lever in the P

position.›

Check that the screw for the tire pressure reduction

6

is closed.

›

Start the engine.

›

Plug the connector

4

into 12 volt socket » page 79.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Once tyre inflation pressure of 2.0-2.5 bar has been reached, turn off the air

compressor. Maximum run time of 6 minutes » .

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

8

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

8

back onto the tyre valve and repeat

the inflation process.

›

Stick the sticker

1

» Fig. 177 on page 159 on the dashboard in the driver's

field of view.

At a tyre inflation pressure of 2.0–2.5 bar, the journey can be continued at a

maximum speed of 80 km/h or 50 mph.

WARNING■ If the tire does not inflate at least. 2.0 bar, the damage is too great. The

sealing agent cannot be used to seal the tyre. Stop driving! Seek help

from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – risk of burning.

CAUTION

Switch off the air compressor if it has been running for as much as 6 minutes –

There is a risk of damage to the compressor! Allow the air compressor to cool a

few minutes before switching it on again.

Information on driving with repaired tyres

Read and observe

on page 159 first.

The inflation pressure of the repaired tyre must be checked after driving for 10

minutes.

If the tyre inflation pressure is 1.3 bar or less

›

The tyre cannot be properly sealed with the breakdown kit.

Stop driving!

Seek help from a specialist garage.

160Do-it-yourself

Page 164 of 200

WARNING■Never clamp the jump cable to the negative terminal of the discharged

battery -There is a risk of an explosion.■

The non-insulated parts of the terminal clamps must never touch each

other – risk of short circuit!

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– risk of short circuit!

■

Position the jump cables so that they cannot be caught in rotating parts

in the engine compartment - danger of injuries and the risk of vehicle dam-

age.

Towing the vehicle

Information about the towing process

Fig. 179

Braided tow rope / Spiral tow rope

To tow with a tow rope, only use a braided synthetic fibre rope » Fig. 179 -

»

.

Attach the tow rope or the tow bar to the towing eyes at the front

» page 163 , towing eyes at the rear » page 163 or to the towing device of

the trailer device » page 124 .

Conditions for towing. Cars with automatic gearboxes must not be towed with the rear wheels

raised - there is a risk of gearbox damage!

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

The maximum towing speed is 50 km/h.

The vehicle must be transported on a special breakdown vehicle or trailer

if it is not possible to tow in the vehicle in the way described or if the tow-

ing distance is greater than 50 km.

Driver of the tow vehicle›

On vehicles with manual transmission , engage gear slowly when starting.

›

On vehicles with automatic transmission , accelerate with particular care.

›

Only then approach correctly when the rope is taut.

Driver of the towed vehicle

›

If possible, the vehicle should be towed with the engine running. The brake

booster and power steering only operate if the engine is running, otherwise

much greater force has to be applied to the brake pedal and more power has

to be expended for steering.

›

If it is not possible to start the engine, switch on the ignition so that the

steering wheel does not lock and so that the turn signal lights, windscreen

wipers and windscreen washer system can be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

›

Keep the tow rope taut at all times during the towing procedure.

WARNING■ Spiral tow ropes must not be used for towing » Fig. 179- , the towing

eye may unscrew out of the vehicle - There is a risk of an accident.■

Ensure tow rope is not twisted - risk of accident.

CAUTION

■ Do not tow-start the engine – There is a risk of damaging the engine. The

battery from another vehicle can be used as a jump-start aid » page 161, Jump-

starting .■

For off-road towing manoeuvres, there is a risk to both vehicles that the fas-

teners may become overloaded and damaged.

Note

We recommend that you use a tow rope from ŠKODA Original Accessories.162Do-it-yourself

Page 166 of 200

Remote control and removable light - replacing thebattery/batteries

Introduction

This chapter contains information on the following subjects:

Key with fold-out key bit

164

Remote control of the auxiliary heating

164

Removable light

164

CAUTION

■ The replacement battery/batteries must comply with the original specifica-

tion.■

Pay attention to the correct polarity when changing the rechargeable batter-

ies.

Note

■ We recommend having the faulty battery/batteries replaced by a specialist

garage.■

If a key has an affixed decorative cover, this will be destroyed when the bat-

tery is replaced. A replacement cover can be purchased from a ŠKODA Partner.

Key with fold-out key bit

Fig. 182

Remove cover/take out battery

Read and observe

on page 164 first.

›

Pop out the key bit.

›

Press off the battery cover

A

» Fig. 182 with your thumb or by using a

screwdriver in the area of arrow

1

.

› Remove the discharged battery in the direction of arrow 2 and install a new

battery.›

Insert the battery cover

A

and press it down until it clicks audibly into place.

Remote control of the auxiliary heating

Fig. 183

Radio remote control: Battery

cover

Read and observe on page 164 first.

›

Insert a flat, blunt object, such as a coin, into the gap of the battery cov-

er » Fig. 183 .

›

Turn the cover away from the marked arrow direction up to the mark

A

to

open the cover.

›

Replace the battery and reinstall the battery cover.

›

Rotate the cover in the direction of the arrow marked up to the mark

B

to

close the cover.

Removable light

Fig. 184

Locking clip on the battery cover

Read and observe on page 164 first.

›

Take out the light in the direction of arrow » Fig. 184.

164Do-it-yourself

Page 167 of 200

›Lever off the cover for the rechargeable batteries with a narrow and pointed

object from the area of the lock clips A.›

Replace the batteries.

›

Insert the cover for the rechargeable batteries and press it down until it

clicks into place.

CAUTION

If an incorrect battery type is used or a non-rechargeable battery, there is a

risk of damaging the light and the vehicle's electrical system.

Emergency unlocking / unlocking of doors

Introduction

This chapter contains information on the following subjects:

Unlocking/locking the driver's door

165

Locking the door without locking cylinders

165

Unlock the boot lid

165

Selector lever-emergency unlocking

166

Unlocking/locking the driver's door

Fig. 185

Handle on the driver's door: open

lock cover

The driver's door can be emergency unlocked / emergency locked using the key via the lock cylinder.

›

Pull on the door handle and hold.

›

Insert the key into the recess on the lower side of the cover and fold up

» Fig. 185 in the direction of arrow.

›

Release the door handle.

›

Insert the vehicle key bit into the lock cylinder and unlock or lock the vehicle.

›

Pull on the door handle and hold.

›

Replace the cover.

CAUTIONMake sure you do not damage the paint when performing an emergency lock-

ing/unlocking.

Locking the door without locking cylinders

Fig. 186

Emergency locking: Left/right rear door

›

Open the corresponding back door remove the trim

A

» Fig. 186 .

›

Insert the key into the slot and turn in the direction of the arrow (spring-loa-

ded position).

›

Replace the cover

A

.

After closing, the door is locked.

Unlock the boot lid

Fig. 187

Unlocking the door

The boot lid can be unlocked manually from inside the vehicle.

›

Insert a screwdriver or similar tool into the opening in the trim » Fig. 187 as

far as the latch.

›

Unlock the lid by moving it in the direction of the arrow.

165Emergency equipment and self-help

Page 168 of 200

Selector lever-emergency unlockingFig. 188

Remove / release the selector lever

›

Firmly apply the handbrake.

›

Insert a slot screwdriver or similar tool into the gap in the arrow area

1

» Fig. 188 and lift the cover in arrow direction

2

.

›

Press on the yellow plastic part in the direction of arrow

3

, simultaneously

press the lock button in the selector lever handle and put the lever in posi-

tion N.

If the selector lever is moved again to position P, it is once again blocked.

CAUTION

Make sure when lifting not to damage cover parts by the screwdriver in the

shift lever environment.

Replacing windscreen wiper blades

Introduction

This chapter contains information on the following subjects:

Replacing the windscreen wiper blades

166

Replacing the rear window wiper blade

167WARNINGReplace the windscreen wiper blades once or twice a year for safety rea-

sons.Replacing the windscreen wiper bladesFig. 189

Setting the service position for

the wiper arms

Fig. 190

Changing the windscreen wiper blade

Read and observe

on page 166 first.

Before replacing the windscreen wiper blades, close the bonnet and put the

windscreen wiper arms into the service position.

Setting the service position

›

Switch the ignition on and off again.

›

Push the lever in the direction of arrow » Fig. 189 within 10 seconds and hold

for approximately 2 seconds.

Removing the wiper blade

›

Lift the wiper arm from the windscreen in the direction of

1

» Fig. 190 .

›

Tilt the wiper blade to the stop in the same direction.

›

Grip the wiper arm and press securing latch

A

down in the direction of arrow

2

.

›

Remove the wiper blade in the direction of the arrow

3

.

166Do-it-yourself

Page 170 of 200

Fuses in the dashboardFig. 193

Distribution board cover.

Read and observe and on page 167 first.

The fuses are located on the left side of the dash panel behind a cover.

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Insert a screwdriver into the opening in the cover in the direction of the ar-

row » Fig. 193 .

›

Remove the cover of the fuse box and remove.

›

Remove the plastic clip from the holder in the fuse box cover in the dash

panel.

›

Use the clip to pull the fuse out, then insert a new fuse.

›

Re-insert the cover of the fuse box .

›

Replace the bracket at the original position.

Fuse arrangement in the dashboard

Fig. 194

Fuses

Read and observe and on page 167 first.No.Consumer1Heating of the gearbox vent (diesel engine)

Automatic gearbox2Towing hitch - left light3Trailer device - electrical outlet4Instrument cluster control lever under the steering wheel, camera5Air blower for heating, radiator fan, air conditioning system, Clima-

tronic6Rear window wiper7emergency call8Towing hitch - right light9Interior lighting, rear fog light10Rain sensor, light switch, diagnostic socket11Left side front headlight12Right side front headlight13Radio14Central control system, engine management system15Light switch16All-wheel drive17KESSY, steering lock18Diagnostic connector, engine control system, brake sensor, four-

wheel drive, START-STOP19ABS, ESP, switch for tyre air pressure control, parking aid, switch for

OFF ROAD mode, START STOP button20Airbag21Variable Service Interval - WIV, reversing lamps, dimmable mirrors,

pressure sensor, telephone preparation, air mass meter, headlamp

levelling and swivelling headlights22Instrument cluster, electromechanical power steering, databus23Central locking, boot lid24Electric windows - Rear25Rear window heater, auxiliary heating and ventilation26Power socket in the boot 168Do-it-yourself

Page 174 of 200

Protective grille for removing fog lights- plug for Park AssistsensorFig. 200

Guard: Version 1/version 2

Fig. 201

Remove the plug

Read and observe

and on page 170 first.

›

Remove the plastic cover for the guard in the arrow direction » Fig. 200 using

the bow to pull the full wheel covers.

›

Remove the remaining part of the grille.

›

Pull the latch out of the connector in the direction of arrow

1

» Fig. 201 .

›

Undo the latch on the connector in the direction of arrow

2

.

›

Remove the key in the direction of the arrow

3

.

Insertion of the ashtray takes place in reverse order.

Changing light bulbs for fog lightsFig. 202

Remove the number plate light / replace the bulb

Read and observe

and on page 170 first.

First remove the grille for the fog lights and before changing bulbs » Fig. 199

on page 171 and / or » Fig. 200 on page 172 .

Removing the headlight

›

Unscrew the screws

A

» Fig. 202 with the screwdriver from the tool kit.

›

Remove the headlight in the direction of arrow

1

.

›

Remove the headlight in the direction of arrow

2

.

Replacing the light bulb

›

Pull the plug on the lamp base.

›

Turn the socket with the bulb to the stop in the direction of the arrow

3

» Fig. 202 .

›

Insert the new bulb into the headlight and turn counter to the direction of

arrow

3

as far as the stop.

›

Attach the connector on the lamp base.

Refit the headlight and grille

›

Replace the fog light by inserting it in the opposite direction of the arrow

2

» Fig. 202 and tighten.

›

Attach the connector on guard carefully » Fig. 201 on page 172 1)

.

›

Insert the protective grille and press it in.

›

Replace the plastic cover and press into the guard » Fig. 200 on page 172 1 )

.

The protective grille must engage firmly.

1)

Applies to vehicles with parking assistance system.

172Do-it-yourself