sensor SMART FORTWO 2016 Owner's Manual

[x] Cancel search | Manufacturer: SMART, Model Year: 2016, Model line: FORTWO, Model: SMART FORTWO 2016Pages: 214, PDF Size: 4.93 MB

Page 160 of 214

XFold the windshield wiper arms away from

the windshield.

XCarefully clean the wiper blades with a

damp cloth.

XFold the windshield wiper arms back againbefore switching on the ignition.

!Hold the wiper arm securely when folding

back. The windshield could be damaged if

the wiper arm smacks against it suddenly.

Cleaning the exterior lighting

!Only use cleaning agents or cleaning

cloths which are suitable for plastic light

lenses. Unsuitable cleaning agents or

cleaning cloths could scratch or damage

the plastic light lenses.

XClean the plastic lenses of the exterior

lighting using a wet sponge and a mild

cleaning agent, e.g. smart car shampoo or

cleaning cloths.

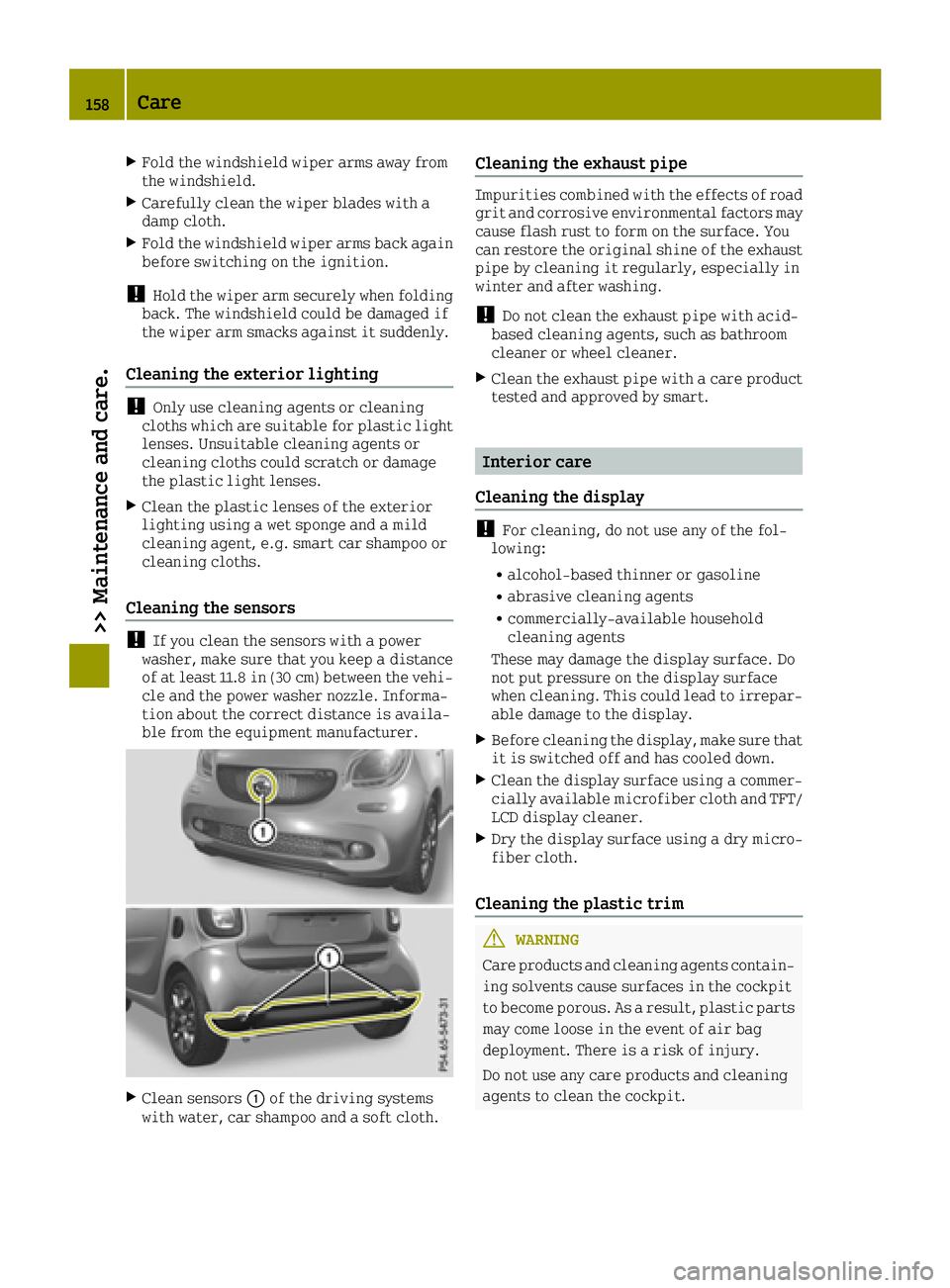

Cleaning the sensors

!If you clean the sensors with a power

washer, make sure that you keep a distance

of at least 11.8 in (30 cm) between the vehi-

cle and the power washer nozzle. Informa-

tion about the correct distance is availa-

ble from the equipment manufacturer.

XClean sensors 0043of the driving systems

with water, car shampoo and a soft cloth.

Cleaning the exhaust pipe

Impurities combined with the effects of road

grit and corrosive environmental factors may

cause flash rust to form on the surface. You

can restore the original shine of the exhaust

pipe by cleaning it regularly, especially in

winter and after washing.

!Do not clean the exhaust pipe with acid-

based cleaning agents, such as bathroom

cleaner or wheel cleaner.

XClean the exhaust pipe with a care product tested and approved by smart.

Interior care

Cleaning the display

!For cleaning, do not use any of the fol-

lowing:

Ralcohol-based thinner or gasoline

Rabrasive cleaning agents

Rcommercially-available household

cleaning agents

These may damage the display surface. Do

not put pressure on the display surface

when cleaning. This could lead to irrepar-

able damage to the display.

XBefore cleaning the display, make sure that

it is switched off and has cooled down.

XClean the display surface using a commer-

cially available microfiber cloth and TFT/

LCD display cleaner.

XDry the display surface using a dry micro-

fiber cloth.

Cleaning the plastic trim

GWARNING

Care products and cleaning agents contain-

ing solvents cause surfaces in the cockpit

to become porous. As a result, plastic parts may come loose in the event of air bag

deployment. There is a risk of injury.

Do not use any care products and cleaning

agents to clean the cockpit.

158Care

>> Maintenance and care.

Page 185 of 214

iThe actual values for tires are vehicle-

specific and may deviate from the values in

the illustration.

Checking the tire pressures

Important safety notes

Observe the notes on tire pressure

(Ypage 180).

Information on air pressure for the tires on

your vehicle can be found:

Ron the vehicle's Tire and Loading Informa- tion placard on the B-pillar

Rin the tire pressure table in the fuel filler

flap (Ypage 98)

Rin the "Tire pressure" section

Checking tire pressures manually

To determine and set the correct tire pres-

sure, proceed as follows:

XRemove the valve cap of the tire that is to bechecked.

XPress the tire pressure gauge securely onto

the valve.

XRead the tire pressure and compare it with

the recommended value on the Tire and

Loading Information placard (

Ypage 180).

XIf the tire pressure is too low increase the

tire pressure to the recommended value.

XIf the tire pressure is too high, release

air. To do this, press down the metal pin in

the valve using the tip of a pen, for exam-

ple. Then check the tire pressure again

using the tire pressure checker.

XScrew the valve cap onto the valve.

XRepeat these steps for the other tires.

Tire pressure monitor

General notes

iThis function is only available in the

USA.

If a tire pressure monitor is installed, the

vehicle's wheels have sensors that monitor

the tire pressures in all four tires. The tire

pressure monitor warns you if the pressure

drops in one or more of the tires. The tire pressure monitor only functions if the cor-

responding sensors are fitted to all wheels.

Important safety notes

GWARNING

Each tire, including the spare (if provi-

ded), should be checked at least once every

two weeks when cold and inflated to the

pressure recommended by the vehicle man- ufacturer on the Tire and Loading Informa-

tion placard on the driver's door B-pillar

or the tire pressure label on the inside of

the fuel filler flap. If your vehicle has

tires of a different size than the size indi-

cated on the Tire and Loading Information

placard or, if available, the tire pressure

label, you should determine the proper tire

pressure for those tires.

As an added safety feature, your vehicle has been equipped with a tire pressure moni-

toring system (TPMS) that illuminates a low

tire pressure telltale when one or more of

your tires are significantly underinflated.

Accordingly, when the low tire pressure

telltale lights up, you should stop and

check your tires as soon as possible, and

inflate them to the proper pressure. Driv-

ing on a significantly underinflated tire

causes the tire to overheat and can lead to

tire failure.

Underinflation also reduces fuel effi-

ciency and tire tread life, and may affect

the vehicle's handling and stopping abil-

ity. Please note that the TPMS is not a sub-

stitute for proper tire maintenance, and it

is the driver's responsibility to maintain

correct tire pressure, even if underinfla-

tion has not reached the level to trigger

illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is com-

bined with the low tire pressure telltale.

When the system detects a malfunction, the

Tire pressure183

>> Wheels and tires.

Z

Page 202 of 214

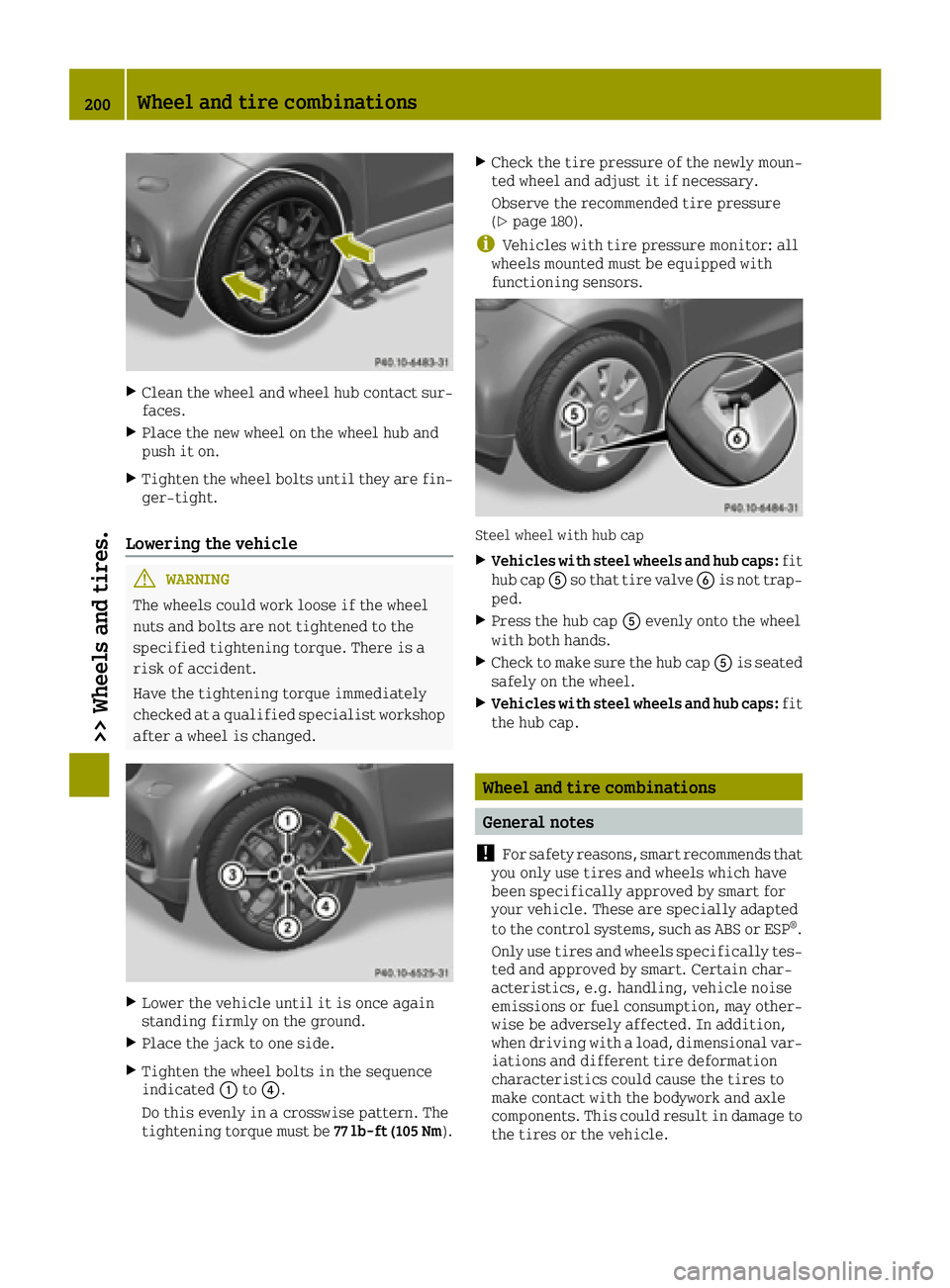

XClean the wheel and wheel hub contact sur-faces.

XPlace the new wheel on the wheel hub and

push it on.

XTighten the wheel bolts until they are fin-

ger-tight.

Lowering the vehicle

GWARNING

The wheels could work loose if the wheel

nuts and bolts are not tightened to the

specified tightening torque. There is a

risk of accident.

Have the tightening torque immediately

checked at a qualified specialist workshop

after a wheel is changed.

XLower the vehicle until it is once again

standing firmly on the ground.

XPlace the jack to one side.

XTighten the wheel bolts in the sequence

indicated 0043to0085.

Do this evenly in a crosswise pattern. The

tightening torque must be 77 lb-ft (105 Nm).

XCheck the tire pressure of the newly moun-

ted wheel and adjust it if necessary.

Observe the recommended tire pressure

(

Ypage 180).

iVehicles with tire pressure monitor: all

wheels mounted must be equipped with

functioning sensors.

Steel wheel with hub cap

XVehicles with steel wheels and hub caps: fit

hub cap 0083so that tire valve 0084is not trap-

ped.

XPress the hub cap 0083evenly onto the wheel

with both hands.

XCheck to make sure the hub cap 0083is seated

safely on the wheel.

XVehicles with steel wheels and hub caps: fit

the hub cap.

Wheel and tire combinations

General notes

!

For safety reasons, smart recommends that

you only use tires and wheels which have

been specifically approved by smart for

your vehicle. These are specially adapted

to the control systems, such as ABS or ESP

®.

Only use tires and wheels specifically tes-

ted and approved by smart. Certain char-

acteristics, e.g. handling, vehicle noise

emissions or fuel consumption, may other-

wise be adversely affected. In addition,

when driving with a load, dimensional var-

iations and different tire deformation

characteristics could cause the tires to

make contact with the bodywork and axle

components. This could result in damage to

the tires or the vehicle.

200Wheel and tire combinations

>> Wheels and tires.

Page 213 of 214

Operating Fluids 310.1 and 325.6 can be mixed

together. An orange discoloration depending

on the mixing ratio does not affect the func-

tion.

iWhen the vehicle is first delivered, it is

filled with a coolant mixture that ensures

adequate antifreeze and corrosion protec-

tion.

iThe coolant is checked with every main-

tenance interval at a qualified specialist

workshop.

Windshield washer system

General notes

!Do not add distilled or de-ionized water

to the washer fluid container. Otherwise,

the level sensor may be damaged.

!Only MB SummerFit and MB WinterFit

washer fluid should be mixed together. The spray nozzles may otherwise become

blocked.

When handling washer fluid, observe the

important safety notes on service products

(

Ypage 207).

At temperatures above freezing:

XFill the washer fluid reservoir with a mix- ture of water and windshield washer fluid,

e.g. MB SummerFit.

Add 1 part MB SummerFit to 100 parts water.

At temperatures below freezing:

XFill the washer fluid reservoir with a mix-

ture of water and washer fluid, e.g. MB Win-

terFit.

The correct mixing ratio can be taken from

the information on the antifreeze protec-

tion container.

iAdd windshield washer fluid, e.g. MB

SummerFit or MB WinterFit, to the washer

fluid all year round.

Climate control system refrigerant

Important safety notes

The climate control system of your vehicle is

filled with refrigerant R‑134a.

The instruction label regarding the refrig-

erant type used can be found on the left, on the

underside of the hood.

!Only the refrigerant R‑134a and the PAG

oil approved by Mercedes-Benz may be

used. The approved PAG oil may not be

mixed with any other PAG oil that is not

approved for R-134a refrigerant. Other-

wise, the climate control system may be

damaged.

Service work, such as topping up refrigerant

or replacing components, may only be carried

out by a qualified specialist workshop. All

applicable regulations must be adhered to,

SAE standard J639 included.

Always have work on the climate control sys-

tem carried out at a qualified specialist

workshop.

Refrigerant instruction label

The refrigerant instruction label:

Ris located at the front on the right on the

body frame.

Rinforms that service work is to be carried

out at a qualified specialist workshop.

Service products and filling capacities211

>> Technical data.

Z