ECU SMART FORTWO 2016 Workshop Manual

[x] Cancel search | Manufacturer: SMART, Model Year: 2016, Model line: FORTWO, Model: SMART FORTWO 2016Pages: 214, PDF Size: 4.93 MB

Page 174 of 214

switched on, use the combination switch as

usual. In this case, only the indicator

lamps for the direction of travel flash.

After resetting the combination switch, the

hazard warning lamp starts flashing again.

Vehicles with automatic transmission: the

automatic transmission automatically shifts

to position Pwhen you open the driver's or

front-passenger door or when you remove the

key from the ignition lock. In order to ensure

that the automatic transmission stays in

position Nwhen towing the vehicle, you must

observe the following points:

XMake sure that the vehicle is stationary.

XTurn the SmartKey to position 2in the igni-

tion lock.

XDepress and hold the brake pedal.

XShift the automatic transmission to posi-

tion N.

Vehicles with manual transmission:

XLeave the SmartKey in position 2in the

ignition lock.

XRelease the brake pedal.

XRelease the parking brake.

XSwitch on the hazard warning lamps

(Ypage 69).

It is important that you observe the safety

instructions when towing away your vehicle

(

Ypage 170).

Transporting the vehicle

!

You may only secure the vehicle by the

wheels, not by parts of the vehicle such as

axle or steering components. Otherwise,

the vehicle could be damaged.

XVehicles with automatic transmission:

turn the SmartKey to position 2in the igni-

tion lock (

Ypage 87).

XVehicles with manual transmission:

depress the clutch pedal fully and select

neutral.

XShift the transmission to position N.

As soon as the vehicle has been loaded:

XPrevent the vehicle from rolling away by

applying the parking brake.

XVehicles with automatic transmission:

shift the transmission to position P.

XVehicles with manual transmission:

depress the clutch pedal fully and engage

first or reverse gear.

XTurn the SmartKey to position0in the igni-

tion lock and remove it.

XSecure the vehicle.

The towing eye can be used to pull the vehicle

onto a trailer or transporter for transporting

purposes.

Tow-starting (emergency engine start-

ing)

!

Vehicles with automatic transmission

must not be started by tow-starting. This

could otherwise damage the transmission.

iYou can find information on "Jump-start-

ing" at (Ypage 168).

Before tow-starting:

Rthe battery must be connected

Rthe engine must be cold

Rthe exhaust system has cooled down.

XSwitch on the hazard warning lamps

(Ypage 69).

XInstall the towing eye (Ypage 171).

XSecure the rigid towing bar or the towing

rope.

XDepress and hold the brake pedal.

XTurn the SmartKey to position 2in the igni-

tion lock.

XDepress the clutch pedal fully, engage sec-

ond gear and keep the clutch pedal fully

depressed.

XRelease the brake pedal.

XTow-start the vehicle.

XRelease the clutch pedal slowly; do not

depress the accelerator pedal while doing

so.

XWhen the engine is started, immediately

depress the clutch pedal fully and select

neutral.

XPull over at a suitable place and stop the

vehicle safely, paying attention to road

and traffic conditions.

XSecure the vehicle against rolling away

with the parking brake.

XRemove the rigid towing bar or towing

rope.

172Towing and tow-starting

>> Breakdown assistance.

Page 175 of 214

XRemove the towing eye (Ypage 171).

XSwitch off the hazard warning lamps.

Fuses

Important safety notes

GWARNING

If you manipulate or bridge a faulty fuse or if you replace it with a fuse with a higher

amperage, the electric cables could be

overloaded. This could result in a fire.

There is a risk of an accident and injury.

Always replace faulty fuses with the speci-

fied new fuses having the correct amper-

age.

!Only use fuses that have been approved for

smart vehicles and which have the correct

fuse rating for the system concerned. Oth-

erwise, components or systems could be

damaged.

The fuses in your vehicle serve to close down

faulty circuits. If a fuse blows, all the com-

ponents on the circuit and their functions

stop operating.

Blown fuses must be replaced with fuses of the

same rating, which you can recognize by the

color and value. The fuse ratings are listed in

the fuse allocation chart (

Ypage 175).

If a newly inserted fuse also blows, have the

cause traced and rectified at a qualified

specialist workshop, e.g. an authorized

Mercedes-Benz Center.

Before changing a fuse

XSecure the vehicle against rolling away

(Ypage 100).

XSwitch off all electrical consumers.

XTurn the key to position 0in the ignition

lock and remove it (Ypage 87). All indica-

tor lamps in the instrument cluster must be off.

The fuses are located in various fuse boxes:

RFuse box in the front area

RFuse box in the glove compartment

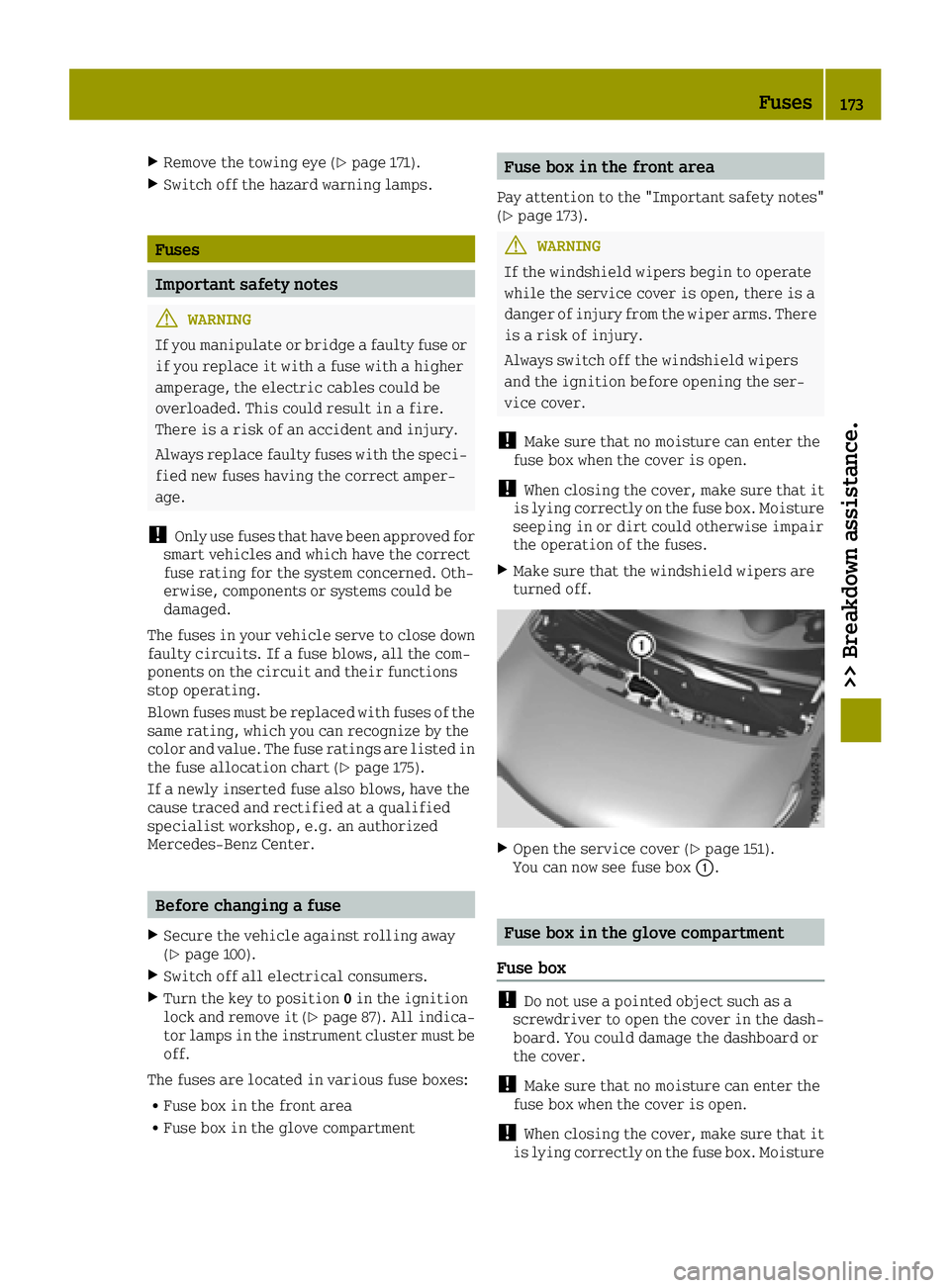

Fuse box in the front area

Pay attention to the "Important safety notes"

(Ypage 173).

GWARNING

If the windshield wipers begin to operate

while the service cover is open, there is a

danger of injury from the wiper arms. There

is a risk of injury.

Always switch off the windshield wipers

and the ignition before opening the ser-

vice cover.

!Make sure that no moisture can enter the

fuse box when the cover is open.

!When closing the cover, make sure that it

is lying correctly on the fuse box. Moisture

seeping in or dirt could otherwise impair

the operation of the fuses.

XMake sure that the windshield wipers are

turned off.

XOpen the service cover (Ypage 151).

You can now see fuse box 0043.

Fuse box in the glove compartment

Fuse box

!Do not use a pointed object such as a

screwdriver to open the cover in the dash-

board. You could damage the dashboard or

the cover.

!Make sure that no moisture can enter the

fuse box when the cover is open.

!When closing the cover, make sure that it

is lying correctly on the fuse box. Moisture

Fuses173

>> Breakdown assistance.

Z

Page 185 of 214

iThe actual values for tires are vehicle-

specific and may deviate from the values in

the illustration.

Checking the tire pressures

Important safety notes

Observe the notes on tire pressure

(Ypage 180).

Information on air pressure for the tires on

your vehicle can be found:

Ron the vehicle's Tire and Loading Informa- tion placard on the B-pillar

Rin the tire pressure table in the fuel filler

flap (Ypage 98)

Rin the "Tire pressure" section

Checking tire pressures manually

To determine and set the correct tire pres-

sure, proceed as follows:

XRemove the valve cap of the tire that is to bechecked.

XPress the tire pressure gauge securely onto

the valve.

XRead the tire pressure and compare it with

the recommended value on the Tire and

Loading Information placard (

Ypage 180).

XIf the tire pressure is too low increase the

tire pressure to the recommended value.

XIf the tire pressure is too high, release

air. To do this, press down the metal pin in

the valve using the tip of a pen, for exam-

ple. Then check the tire pressure again

using the tire pressure checker.

XScrew the valve cap onto the valve.

XRepeat these steps for the other tires.

Tire pressure monitor

General notes

iThis function is only available in the

USA.

If a tire pressure monitor is installed, the

vehicle's wheels have sensors that monitor

the tire pressures in all four tires. The tire

pressure monitor warns you if the pressure

drops in one or more of the tires. The tire pressure monitor only functions if the cor-

responding sensors are fitted to all wheels.

Important safety notes

GWARNING

Each tire, including the spare (if provi-

ded), should be checked at least once every

two weeks when cold and inflated to the

pressure recommended by the vehicle man- ufacturer on the Tire and Loading Informa-

tion placard on the driver's door B-pillar

or the tire pressure label on the inside of

the fuel filler flap. If your vehicle has

tires of a different size than the size indi-

cated on the Tire and Loading Information

placard or, if available, the tire pressure

label, you should determine the proper tire

pressure for those tires.

As an added safety feature, your vehicle has been equipped with a tire pressure moni-

toring system (TPMS) that illuminates a low

tire pressure telltale when one or more of

your tires are significantly underinflated.

Accordingly, when the low tire pressure

telltale lights up, you should stop and

check your tires as soon as possible, and

inflate them to the proper pressure. Driv-

ing on a significantly underinflated tire

causes the tire to overheat and can lead to

tire failure.

Underinflation also reduces fuel effi-

ciency and tire tread life, and may affect

the vehicle's handling and stopping abil-

ity. Please note that the TPMS is not a sub-

stitute for proper tire maintenance, and it

is the driver's responsibility to maintain

correct tire pressure, even if underinfla-

tion has not reached the level to trigger

illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with a

TPMS malfunction indicator to indicate

when the system is not operating properly.

The TPMS malfunction indicator is com-

bined with the low tire pressure telltale.

When the system detects a malfunction, the

Tire pressure183

>> Wheels and tires.

Z

Page 198 of 214

Tread

The part of the tire that comes into contact

with the road.

Bead

The tire bead ensures that the tire sits

securely on the wheel. There are several steel

wires in the bead to prevent the tire from

coming loose from the wheel rim.

Sidewall

The part of the tire between the tread and the

bead.

Weight of optional extras

The combined weight of those optional extras

that weigh more than the replaced standard

parts and more than 5 lbs (2.3 kilograms).

These optional extras, such as high-perform-

ance brakes, level control, a roof rack or a

high-performance battery, are not included

in the curb weight and the weight of the

accessories.

TIN (Tire Identification Number)

This is a unique identifier which can be used

by a tire manufacturer to identify tires, for

example for a product recall, and thus iden-

tify the purchasers. The TIN is made up of the manufacturer's identity code, tire size, tire

type code and the manufacturing date.

Load bearing index

The load bearing index (also load index) is a

code that contains the maximum load bearing

capacity of a tire.

Traction

Traction is the result of friction between the

tires and the road surface.

Treadwear indicators

Narrow bars (tread wear bars) that are dis-

tributed over the tire tread. If the tire tread

is level with the bars, the wear limit of 00CDin

(1.6 mm) has been reached.

Occupant distribution

The distribution of occupants in a vehicle at

their designated seating positions.

Total load limit

Nominal load and luggage load plus 68 kg

(150 lbs) multiplied by the number of seats in

the vehicle.

Changing a wheel

Flat tire

You can find information on what to do in the

event of a flat tire in the "Flat tire" section

(

Ypage 161).

Rotating the wheels

GWARNING

Never interchange the front and rear wheels

as they have different dimensions, e.g.

size, wheel offset etc. Otherwise, there

could be a negative effect on the road hold- ing and you could endanger yourself or oth-

ers.

!On vehicles equipped with a tire pressure

monitor, electronic components are loca-

ted in the wheel.

Tire-mounting tools should not be used

near the valve. This could damage the elec-

tronic components.

Only have tires changed at a qualified spe-

cialist workshop.

Various types of steel wheel can be fitted on

your vehicle. Some steel wheels have a red

mark in the hub cap area. The hub cap has to be

removed to see the red mark, see "Raising the

vehicle" in the "Wheel change" section

(

Ypage 197). When changing the wheels,

always fit wheels of the same type on all axles.

Always pay attention to the instructions and

safety notes when changing a wheel

(

Ypage 196).

The wear patterns on the front and rear tires

differ, depending on the operating condi-

tions. Front tires typically wear more on the

shoulders and the rear tires in the center.

Clean the contact surfaces of the wheel and

the brake disc thoroughly every time a wheel

is rotated. Check the tire pressure and reac-

tivate the tire pressure monitor if necessary.

196Changing a wheel

>> Wheels and tires.

Page 199 of 214

Direction of rotation

Tires with a specified direction of rotation

have additional benefits, e.g. if there is a

risk of hydroplaning. These advantages can

only be gained if the tires are fitted corre-

sponding to the direction of rotation.

An arrow on the sidewall of the tire indicates

its correct direction of rotation.

Storing wheels

Store wheels that are not being used in a cool,

dry and preferably dark place. Protect the

tires from oil, grease, gasoline and diesel.

Mounting a wheel

Preparing the vehicle

XMake sure that you have the appropriate

tire-changing tools. For further informa-

tion inquire at any smart center.

XStop the vehicle on solid, non-slippery and

level ground.

XApply the parking brake (Ypage 101).

XBring the front wheels into the straight-

ahead position.

XVehicles with automatic transmission:

shift the transmission to position P.

XVehicles with manual transmission:

depress the clutch pedal fully and engage

first or reverse gear.

XSwitch off the engine.

XRemove the SmartKey from the ignition

lock.

XAlso secure the vehicle against rolling

away.

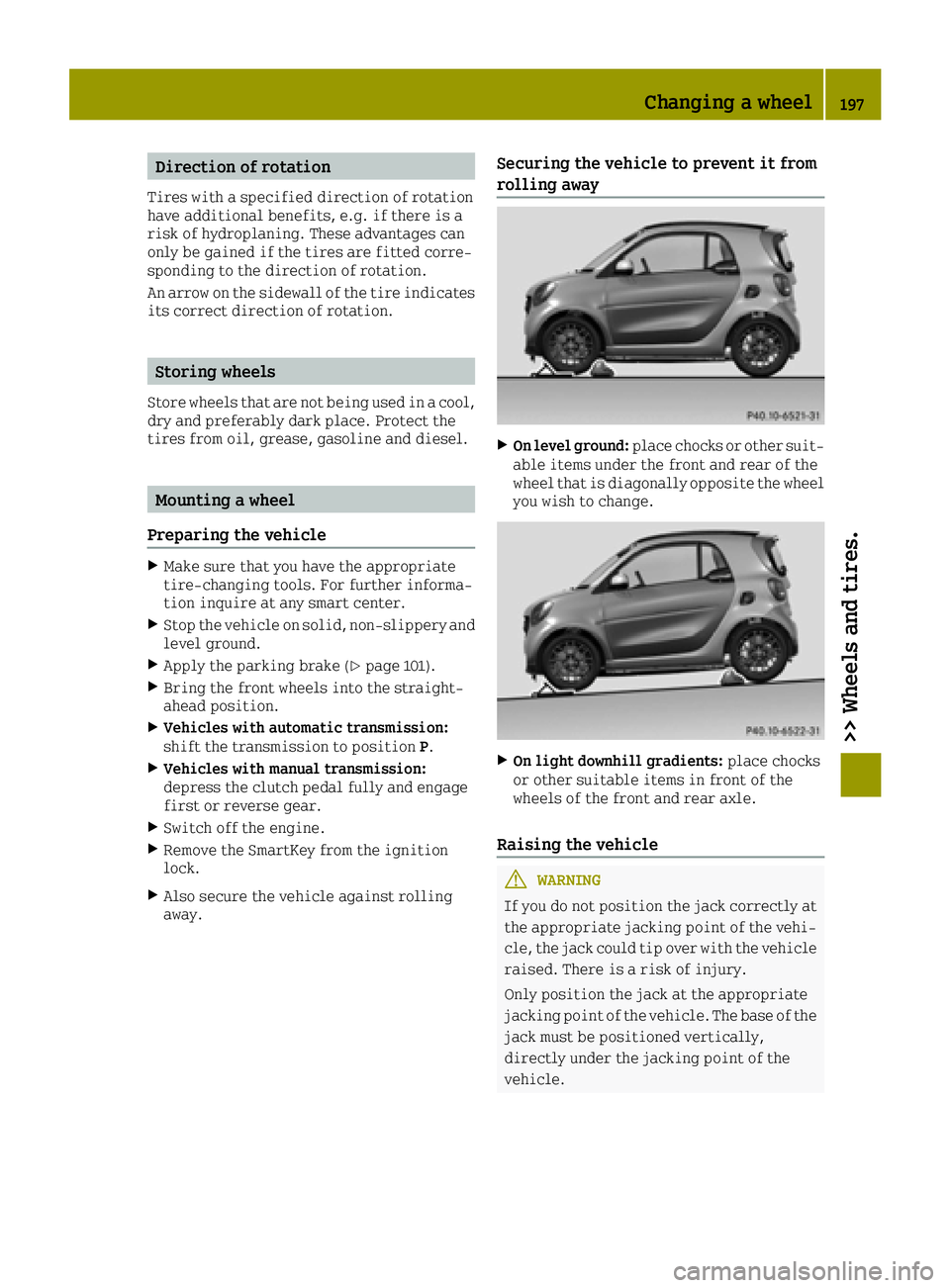

Securing the vehicle to prevent it from

rolling away

XOn level ground:place chocks or other suit-

able items under the front and rear of the

wheel that is diagonally opposite the wheel

you wish to change.

XOn light downhill gradients: place chocks

or other suitable items in front of the

wheels of the front and rear axle.

Raising the vehicle

GWARNING

If you do not position the jack correctly at

the appropriate jacking point of the vehi- cle, the jack could tip over with the vehicle

raised. There is a risk of injury.

Only position the jack at the appropriate

jacking point of the vehicle. The base of the jack must be positioned vertically,

directly under the jacking point of the

vehicle.

Changing a wheel197

>> Wheels and tires.

Z

Page 200 of 214

Observe the following when raising the vehi-

cle:

Rmake sure you have a suitable jack and

wheel wrench. If used incorrectly, the jack

could tip over with the vehicle raised.

For further information inquire at any

smart center.

Rthe jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for per-

forming maintenance work under the vehi-

cle.

Ravoid changing the wheel on uphill and

downhill slopes.

Rbefore raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

Rthe jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, flat load-bearing underlay must be

used. On a slippery surface, a non-slip

underlay must be used, e.g. rubber mats.

Rdo not use wooden blocks or similar objects

as a jack underlay. Otherwise, the jack will

not be able to achieve its load-bearing

capacity due to the restricted height.

Rmake sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

Rnever place your hands and feet under the

raised vehicle.

Rdo not lie under the vehicle.

Rdo not start the engine when the vehicle is

raised.

Rdo not open or close a door or the tailgate

while the vehicle is raised.

Rmake sure that no persons are present in the

vehicle when the vehicle is raised.

!The jack is designed exclusively for

jacking up the vehicle at the jacking

points. Otherwise, your vehicle could be

damaged.

Steel wheel with hub cap

XVehicles with steel wheels and hub caps:

carefully reach into two of the hub cap

openings and remove the hub cap.

Steel wheel with hub cap

XVehicles with steel wheels and hub caps:

remove the hub cap.

XUsing wheel wrench 0043, loosen the bolts on

the wheel you wish to change by about one

full turn. Do not unscrew the bolts com-

pletely.

198Changing a wheel

>> Wheels and tires.

Page 201 of 214

The vehicle may only be raised at the desig-

nated jacking points on the sill.

The jacking points are located just behind

the wheel housings of the front wheels and

just in front of the wheel housings of the rear

wheels (arrows). You can identify the jacking

points by the triangular indentations on the

sill.

To avoid damage, position the jack centrally

under the triangular indentations.

XPosition jack 0044centrally under the tri-

angular indentations at the jacking points on the sill 0043.

Example

XMake sure the foot of the jack is directly

beneath the jacking point.

XRaise the vehicle with jack 0044until the

tire is a maximum of 1.2 in (3 centimeters)

off the ground.

Removing a wheel

!Do not place wheel bolts in sand or on a

dirty surface. The bolt and wheel hub

threads could otherwise be damaged when

you screw them in.

XUnscrew the wheel bolts.

XRemove the wheel.

Mounting a new wheel

GWARNING

Oiled or greased wheel bolts or damaged

wheel bolts/hub threads can cause the wheel

bolts to come loose. As a result, you could

lose a wheel while driving. There is a risk of accident.

Never oil or grease wheel bolts. In the event

of damage to the threads, contact a quali-

fied specialist workshop immediately.

Have the damaged wheel bolts or hub threads

replaced/renewed. Do not continue driv-

ing.

GWARNING

If you tighten the wheel bolts or wheel nuts when the vehicle is raised, the jack could

tip over. There is a risk of injury.

Only tighten the wheel bolts or wheel nuts

when the vehicle is on the ground.

Always pay attention to the instructions and

safety notes in the "Changing a wheel" sec-

tion (

Ypage 196).

Only use wheel bolts that are designed for the

wheel and the vehicle. For safety reasons,

smart recommends that you only use wheel

bolts which have been approved for smart

vehicles and the respective wheel.

!To prevent damage to the paintwork, hold

the wheel securely against the wheel hub

while screwing in the first wheel bolt.

Changing a wheel199

>> Wheels and tires.

Z