engine SSANGYONG KORANDO 1997 Service Owners Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 100 of 2053

M162 ENGINE MECHANICAL 1B1 -- 73

D AEW OO M Y_2000

12. Place the outer plate (7, thickness 1.2mm) inside

the thrust piece (b).

13. Install the chain assembly 000 589 58 43 00 above

the link and tighten the spindle (c) until a block is felt.

14. Place the chain assembly 000 589 58 43 00.

15. Replace the thrust piece (b) as shown in the figure.

16. Install the chain assembly 000 589 58 43 00 to the

link pin and tighten the spindle (c).

Installation Notice

Tightening Torque

30 NSm (22 lb-ft)

Page 101 of 2053

1B1 -- 74 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

17. Rivet the link pin.

Check the condition and it again if necessary.

18. Install the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

19. Check the camshaft timing position.

Page 102 of 2053

M162 ENGINE MECHANICAL 1B1 -- 75

D AEW OO M Y_2000

TENSIONING RAIL

Preceding Work: Removal of timing gear case cover

1 Tensioning Rail

2 Plastic Guide3 Tensioning Rail Pin

4 Guide Rail

Removal & Installation Procedure

1. Put the assembly mark at the camshaft sprocket and

the timing chain with the paint (arrow).

2. Remove the exhaust camshaft sprocket.

3. Remove the tensioning rail (1) from the tensioning rail

pin (3).

Notice:

DReplace the plastic guide (2) if it is damaged.

DFor installation, exactly align the plastic guide (2) with

the tensioning rail (1).

4. Installation should follow the removal procedure in

the reverse order.

5. Check the camshaft timing position.

Page 103 of 2053

1B1 -- 76 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

CYLINDER HEAD GUIDE RAIL

Preceding Work: Removal of cylinder head front cover

1 Chain Tensioner

2 Upper Guide Rail3 Upper Guide Rail Pin

4 Wrench

Removal & Installation Procedure

1. Remove the chain tensioner (1).

2. Turn the exhaust camshaft to the camshaft rotating

direction using the wrench (4) and loosen the timing

chain at upper guide rail (2).

3. Pull out the upper guide rail pin from the guide rail (2).

4. Turn the exhaust camshaft to the opposite direction

of rotation using the wrench.

5. Check for damages at the upper sliding rail and re-

place it if necessary. Install the upper guide rail pin.

6. Install the chain tensioner.

Installation Notice

Ti

ghteningScrew Plug40 NSm

(30 lb-ft)

Tightening

TorqueTensioner

Assembly72 -- 88 NSm

(53 -- 65 lb-ft)

Page 104 of 2053

M162 ENGINE MECHANICAL 1B1 -- 77

D AEW OO M Y_2000

CRANKCASE GUIDE RAIL

Preceding Work: Removal of timing gear case cover

1 Guide Rail

2 Plastic Guide3 Guide Rail Pin

4 Tensioning Rail

Removal & Installation Procedure

1. Put the assembly mark at the camshaft sprocket and

the timing chain with the paint (arrow).

2. Remove the exhaust camshaft sprocket.

3. Remove the guide rail (1) from the guide rail pin (3).

Notice:

DReplace the plastic guide (2) if damaged.

DConnect the plastic guide (2) and the guide rail (1) by

aligning them accurately when installing.

4. Installation should follow the removal procedure in

the reverse order.

5. Check the camshaft timing position.

Page 105 of 2053

1B1 -- 78 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

CRANKSHAFT SPROCKET

Preceding Work: Removal of oil pan

Removal of tensioning rail

Removal of crank case guide rail

1 Oil Pump Chain Tensioner

2 Oil Pump Chain Bushing

3 Oil Pump Chain Spring

4 Crankshaft Sprocket

5Key6 Bolt (M8 x 20, 1 piece) / Washer

29-- 35 NSm (21-- 26 lb-ft) ....................

7 Oil Pump Sprocket

8OilPump

9 Oil Pump Roller Chain

10 Timing Chain

Page 106 of 2053

1B1 -- 80 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

PISTON

Preceding Work: Removal of engine

Removal of cylinder head

Removal of oil pan

Removal of oil pump

Removal of baffle plate

1 Connecting Rod Bearing Cap

2 Connecting Rod

3 Connecting Rod Bearing Cap Bolt

(M9 x 52, 12 pieces)

1ststep40NSm (30 lb-ft) ..................

2nd step 90°4Piston

5 Snap Ring

6 Piston Pin

Page 107 of 2053

M162 ENGINE MECHANICAL 1B1 -- 81

D AEW OO M Y_2000

Removal Procedure

1. Unscrew the connecting rod bearing cap bolt (3) and

remove the cap.

2. Remove the connecting rod and the piston upward.

Notice:Make sure that the bearing cap and shell are not

changed each other.

3. Removethesnapring(5) andpulloutthepistonpin

(6).

Notice:Remove the snap ring using a clean cloth as

shown in the right picture so that the piston, piston ring,

and the snap ring don’t get damaged.

Page 108 of 2053

1B1 -- 82 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Installation Procedure

1. Check the piston ring gap and apply the engine oil to

the piston pin and the connecting rod bushing.

2. Connect the piston and the connecting rod by press-

ing in the piston pin (6) and install the snap ring to the

groove.

3. Clean the cylinder bore, connecting rod bearing jour-

nal, connecting rod bearing shell and the piston and

coat them with engine oil.

4. Install the piston ring.

5. Install the piston so that the arrow on the piston head

faces to the forward of the vehicle.

6. After aligning the connecting rod and the bearing cap

mark (// or a number), tighten the bolts.

Installation Notice

TighteningTorque1st step: 40 NSm (30 lb-ft)TighteningTorque2nd step: 90°

Apply the engine oil to the bearing cap upper and low-

er bearing shells.

7. Check if the crankshaft rotates without any trouble by

rotating it.

Page 109 of 2053

M162 ENGINE MECHANICAL 1B1 -- 83

D AEW OO M Y_2000

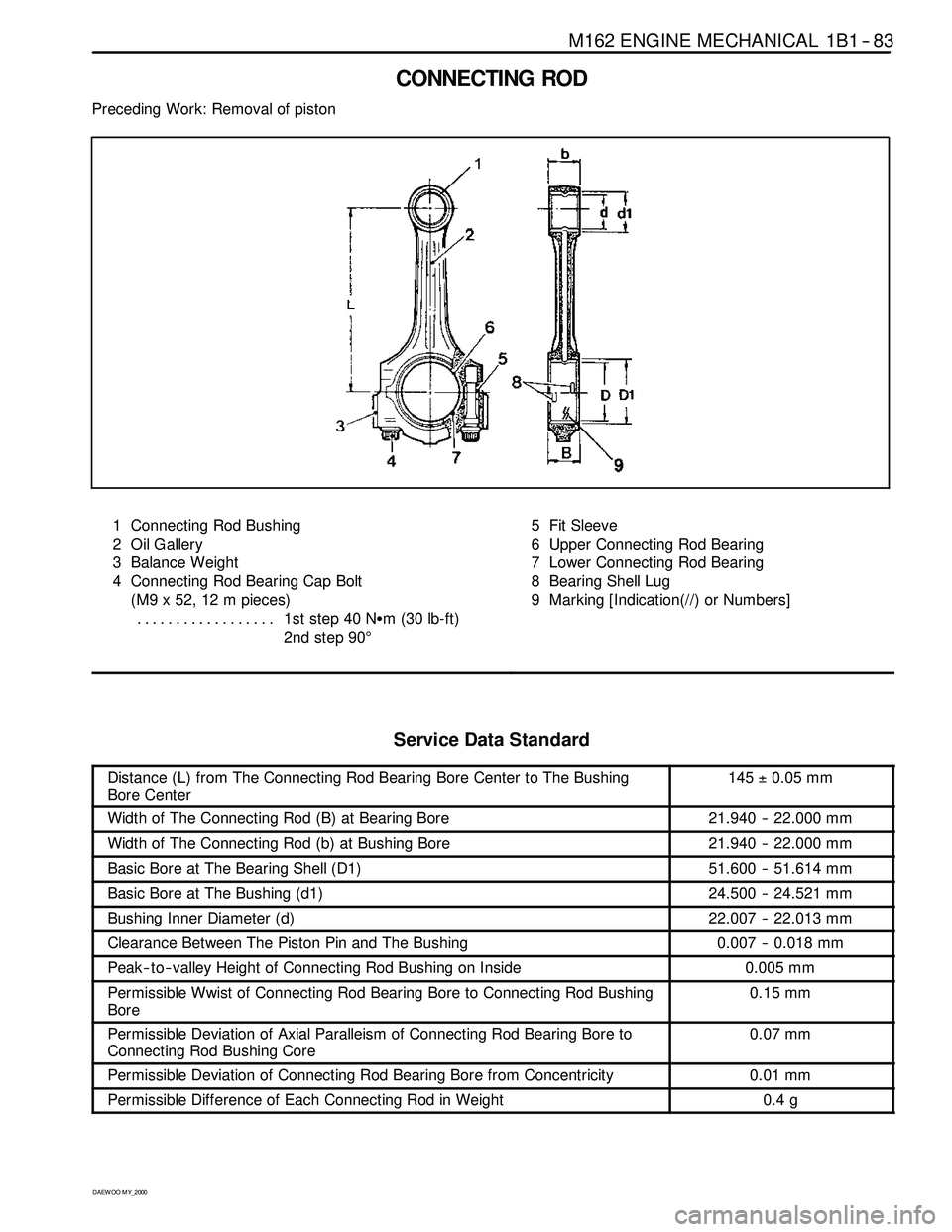

CONNECTING ROD

Preceding Work: Removal of piston

1 Connecting Rod Bushing

2 Oil Gallery

3 Balance Weight

4 Connecting Rod Bearing Cap Bolt

(M9 x 52, 12 m pieces)

1ststep40NSm (30 lb-ft) ..................

2nd step 90°5 Fit Sleeve

6 Upper Connecting Rod Bearing

7 Lower Connecting Rod Bearing

8 Bearing Shell Lug

9 Marking [Indication(//) or Numbers]

ServiceDataStandard

Distance (L) from The Connecting Rod Bearing Bore Center to The Bushing

Bore Center145±0.05 mm

Width of The Connecting Rod (B) at Bearing Bore21.940 -- 22.000 mm

Width of The Connecting Rod (b) at Bushing Bore21.940 -- 22.000 mm

Basic Bore at The Bearing Shell (D1)51.600 -- 51.614 mm

Basic Bore at The Bushing (d1)24.500 -- 24.521 mm

Bushing Inner Diameter (d)22.007 -- 22.013 mm

Clearance Between The Piston Pin and The Bushing0.007 -- 0.018 mm

Peak -- to-- valley Height of Connecting Rod Bushing on Inside0.005 mm

Permissible Wwist of Connecting Rod Bearing Bore to Connecting Rod Bushing

Bore0.15 mm

Permissible Deviation of Axial Paralleism of Connecting Rod Bearing Bore to

Connecting Rod Bushing Core0.07 mm

Permissible Deviation of Connecting Rod Bearing Bore from Concentricity0.01 mm

Permissible Difference of Each Connecting Rod in Weight0.4 g