SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Page 120 of 2053

1B1 -- 94 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

OIL PUMP

Preceding Work: Removal of oil pan

1 Bolt (M8 x 20, 1 piece)

29-- 35 NSm (21-- 26 lb-ft) ....................

2 Sprocket (Oil Pump Drive)

3 Bolt (M8 x 35, 3 pieces)

22.5-- 27.5 NSm (16.6-- 20.3 lb-ft) .............4 Spring Pin

5OilPump

Page 121 of 2053

M162 ENGINE MECHANICAL 1B1 -- 95

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the bolt (1) from the oil pump drive sprocket

(2) and separate the gear and the oil pump drive

chain.

Installation Notice

Tightening Torque

29 -- 35 NSm (21 -- 26 lb-ft)

2. Unscrew the oil pump mounting bolts (3).

Installation Notice

Tightening Torque

22.5 -- 27.5 NSm

(16.6 -- 20.3 lb-ft)

Tighten the baffle plate and the oil pump with the two

bolts in right side first, and then tighten the other bolt.

3. Remove the oil pump and oil strainer assembly.

4. Replace the strainer in oil pump if necessary.

5. Installation should follow the removal procedure in

the reverse order.

Page 122 of 2053

1B1 -- 96 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

OIL PRESSURE RELIEF VALVE

Preceding Work: Removal of oil pan

1 Screw Plug 50 NSm (37 lb-ft) ................

2 Compression Spring3 Guide Pin

4Piston

Removal & Installation Procedure

1. Remove the screw plug (1).

Installation Notice

Tightening Torque

50 NSm (37 lb-ft)

2. Remove the spring (2), guide pin (3) and the piston

(4).

3. Installation should follow the removal procedure in

the reverse order.

Notice:Don’t use the seal for the screw plug.

Page 123 of 2053

M162 ENGINE MECHANICAL 1B1 -- 97

D AEW OO M Y_2000

OIL NON-- RETURN VALVE

Preceding Work: Removal of timing gear case cover

1 Oil Non-- return Valve

Functions

The non -- return valve prevents the oil in the chain ten-

sioner from drying up. In other words, it stops oil-- return-

ing in order to prevent the oil in the chain tensioner from

getting dry. As a result, the chain tensioner can be acti-

vated with oil in itself.

Replacement Procedure

1. Remove the non--return valve using a pliers.

2. Insert new non-- return valve with hand.

Page 124 of 2053

1B1 -- 98 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

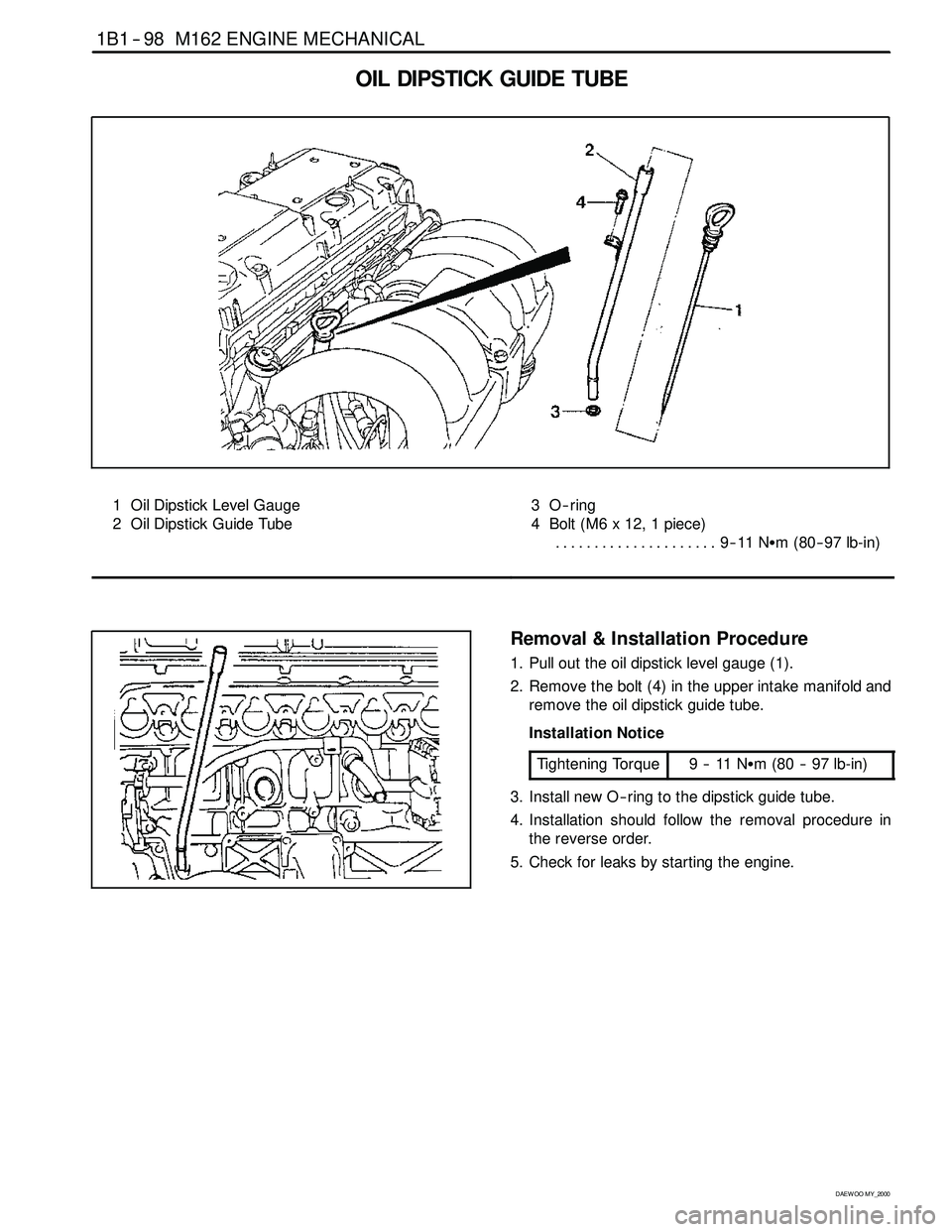

OIL DIPSTICK GUIDE TUBE

1 Oil Dipstick Level Gauge

2 Oil Dipstick Guide Tube3O--ring

4 Bolt (M6 x 12, 1 piece)

9--11 NSm (80-- 97 lb-in) .....................

Removal & Installation Procedure

1. Pull out the oil dipstick level gauge (1).

2. Remove the bolt (4) in the upper intake manifold and

remove the oil dipstick guide tube.

Installation Notice

Tightening Torque

9--11NSm (80 -- 97 lb-in)

3. Install new O -- ring to the dipstick guide tube.

4. Installation should follow the removal procedure in

the reverse order.

5. Check for leaks by starting the engine.

Page 125 of 2053

M162 ENGINE MECHANICAL 1B1 -- 99

D AEW OO M Y_2000

UNIT REPAIR

OIL GALLERY IN CRANKCASE

Preceding Work: Removal of crankshaft, removal of oil spray nozzle

1Plug

2 Steel Ball3 Round Barφ11 x 750 mm ...................

Cleaning Procedure

1. Remove the plug (1) with a screwdriver.

2. Using a round bar (3) and hammer, remove the steel

ball (2).

3. Using the compressed air, blow into the oil galleries

and clean it off.

Page 126 of 2053

1B1 -- 100 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

1 Plug Replace..............................

2 Main Oil Gallery3 Screw Plug

Tools Required

102589121500 Drift

Sealing Procedure

1. Enlarge the end of main oil gallery (4) to be diameter

of 16mm, depth of 15mm.

2. Using an M16 x 1.5 thread (tap), make the thread at

the end of main oil gallery (4).

3. Throughly clean the oil gallery with compressed air

and tighten the screw plug (M16 x 1.5) after applying

sealingbondonit.

4. Apply Loctite 270 on new plug and tighten to the hole

until the drift is stopped after inserting new plug into

the drift.

Page 127 of 2053

M162 ENGINE MECHANICAL 1B1 -- 101

D AEW OO M Y_2000

OIL GALLERY IN CYLINDER HEAD

Preceding Work: Removal of cylinder head

Removal of camshaft

Removal of tappet

1 Screw Plug 15 NSm (11 lb-ft) ................

2 Seal3SteelBall(φ8mm)

Page 128 of 2053

1B1 -- 102 M162 ENGINE MECHANICAL

D AEW OO M Y_2000

Cleaning Procedure

1. Remove the screw plug (1) and the seal (2).

Installation Notice

Tightening Torque

15 NSm (11 lb-ft)

Replace the seal with new one.

2. Clean the oil gallery using the compressed air.

Sealing Procedure

1. Remove the screw plug (1) and the seal.

Installation Notice

Tightening Torque

15 NSm (11 lb-ft)

2. Remove the steel ball from the oil gallery (4), (5), (6)

and (7) using the round bar (12,φ6 x 700 mm).

3. Remove the plug (8) using the screw driver.

Page 129 of 2053

M162 ENGINE MECHANICAL 1B1 -- 103

D AEW OO M Y_2000

4. Enlarge the oil gallery at the rear of the cylinder

head to be diameter 9mm, depth 8mm.

5. Tap in the steel ball (3) from the side to the oil gallery

using the punch (13).

6. Pull out the steel ball (3) using the round bar (12).

7. Enlarge the oil gallery to be diameter 9mm, depth

8mm.

8. Make a screw hole at the oil gallery using M10 x 1

thread.

9. All the oil gallery should be cleaned with the com-

pressed air.

10. Apply the Loctite 270 to new plug and press in using

a suitable drift (arrow).

11. Tighten the screw plug with the seal (arrow).