ECO mode SSANGYONG KORANDO 1997 Service User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1098 of 2053

5A-4 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

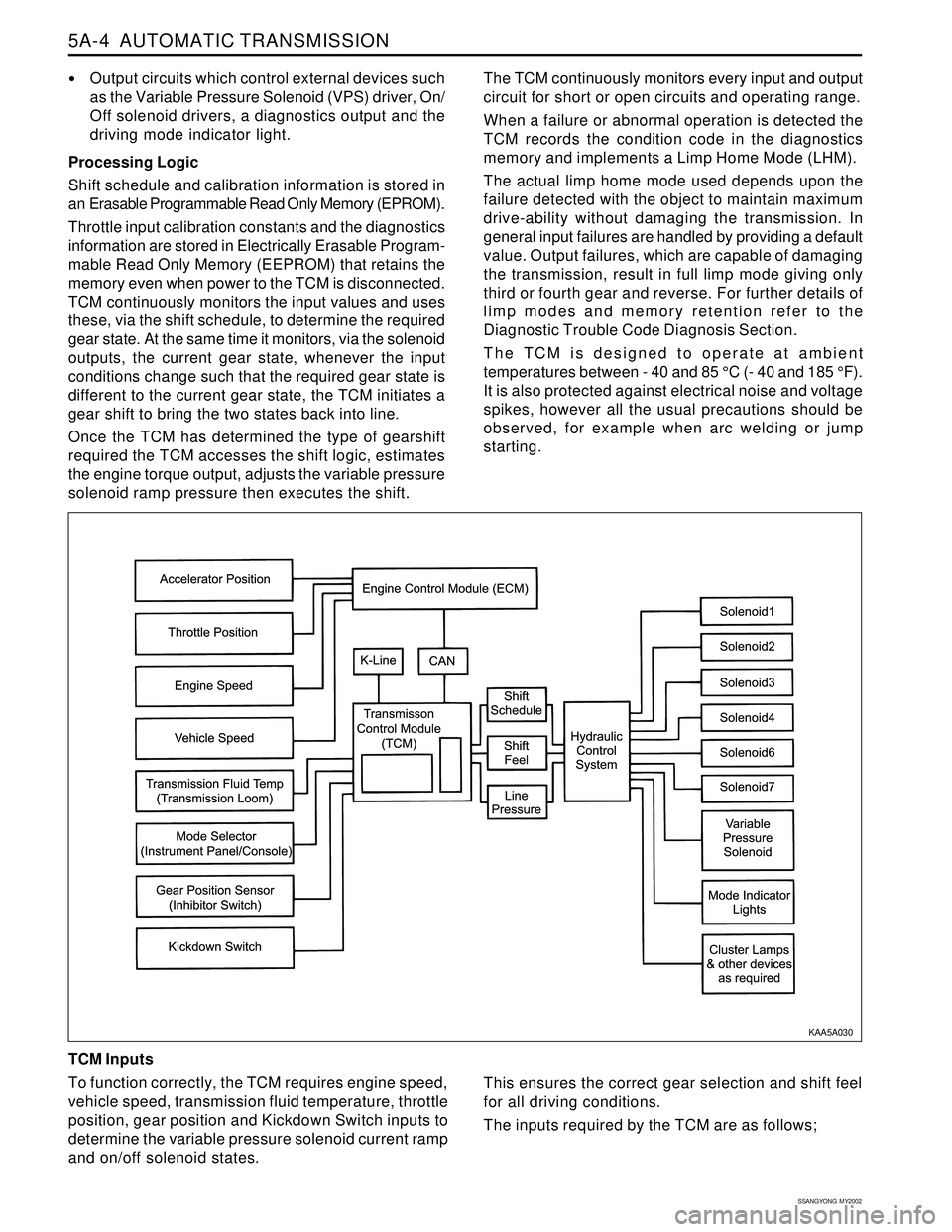

Output circuits which control external devices such

as the Variable Pressure Solenoid (VPS) driver, On/

Off solenoid drivers, a diagnostics output and the

driving mode indicator light.

Processing Logic

Shift schedule and calibration information is stored in

an Erasable Programmable Read Only Memory (EPROM).

Throttle input calibration constants and the diagnostics

information are stored in Electrically Erasable Program-

mable Read Only Memory (EEPROM) that retains the

memory even when power to the TCM is disconnected.

TCM continuously monitors the input values and uses

these, via the shift schedule, to determine the required

gear state. At the same time it monitors, via the solenoid

outputs, the current gear state, whenever the input

conditions change such that the required gear state is

different to the current gear state, the TCM initiates a

gear shift to bring the two states back into line.

Once the TCM has determined the type of gearshift

required the TCM accesses the shift logic, estimates

the engine torque output, adjusts the variable pressure

solenoid ramp pressure then executes the shift.The TCM continuously monitors every input and output

circuit for short or open circuits and operating range.

When a failure or abnormal operation is detected the

TCM records the condition code in the diagnostics

memory and implements a Limp Home Mode (LHM).

The actual limp home mode used depends upon the

failure detected with the object to maintain maximum

drive-ability without damaging the transmission. In

general input failures are handled by providing a default

value. Output failures, which are capable of damaging

the transmission, result in full limp mode giving only

third or fourth gear and reverse. For further details of

limp modes and memory retention refer to the

Diagnostic Trouble Code Diagnosis Section.

The TCM is designed to operate at ambient

temperatures between - 40 and 85 °C (- 40 and 185 °F).

It is also protected against electrical noise and voltage

spikes, however all the usual precautions should be

observed, for example when arc welding or jump

starting.

TCM Inputs

To function correctly, the TCM requires engine speed,

vehicle speed, transmission fluid temperature, throttle

position, gear position and Kickdown Switch inputs to

determine the variable pressure solenoid current ramp

and on/off solenoid states.

KAA5A030

This ensures the correct gear selection and shift feel

for all driving conditions.

The inputs required by the TCM are as follows;

Page 1100 of 2053

5A-6 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Solenoids

The TCM controls seven solenoids. Solenoids 1 to 6

(S1 to S6) are mounted in the valve body, while

Solenoid 7 (S7) is mounted in the pump cover.

Solenoid 1 and 2: S1 and S2 are normally open ON/

OFF solenoids that set the selected gear. These

solenoids determine static gear position by

operating the shift valves. Note that S1 and S2

solenoids also send signal pressure to allow or

prohibit rear band engagement.

Solenoid 3 and 4: S3 and S4 are normally open ON/

OFF solenoids that combine to control shift quality

and sequencing. S3 switches the clutch regulator

valve OFF or ON. S4 switches the front band regula-

tor valve OFF or ON. S5 also provides the signal

pressure for the converter clutch regulator valve.

Solenoid 5: S5 is a variable pressure solenoid that

ramps the pressure during gear changes. This sole-

noid provides the signal pressure to the clutch and

band regulator, thereby controlling the shift pres-

sures. S5 also provides the signal pressure for the

converter clutch regulator valve.

Solenoid 6: S6 is a normally open ON/OFF solenoid

that sets the high/low level of line pressure. Solenoid

OFF gives high pressure.

Solenoid 7: S7 is a normally open ON/OFF solenoid

that controls the application of the converter clutch.

Solenoid ON activates the clutch.

Solenoid Logic for Static Gear States

Gear S1 S2

1st ON ON

2nd OFF ON

3 r d OFF OFF

4th ON OFF

Reverse OFF OFF

Neutral OFF OFF

Park OFF OFF

Shift Lever Position Resistance (k

Ω ΩΩ Ω

Ω)

Manual 1 1 ~ 1.4

Manual 221.8 ~ 2.2

Manual 3 3 3 ~ 3.4

Drive4.5 ~ 4.9

Neutral6.8 ~ 7.2

Reverse10.8 ~ 11.2

Park18.6 ~ 19

Kickdown Switch

The Kickdown Switch is used to signal the TCM that

the driver has pressed the acclerator to the floor and

requires a kickdown shift. When this switch is used,

the POWER light comes ON and the POWER shift

pattern is used.

Diagnostic Inputs

The diagnostic control input or K-line is used to initiate

the outputting of diagnostic data from the TCM to a

diagnostic test instrument. This input may also be used

to clear the stored fault history data from the TCM’s

retentive memory. Connection to the diagnostic input

of the TCM is via a connector included in the vehicle’s

wiring harness or computer interface.

Battery Voltage Monitoring Input

The battery voltage monitoring input is connected to

the positive side of the battery. This signal is taken

from the main supply to the TCM.

If the battery voltage at the TCM falls below 11.3 V,

the transmission will adopt a low voltage mode of

operating in which shifts into first gear are inhibited.

All other shifts are allowed but may not occur because

of the reduced voltage. This condition normally occurs

only when the battery is in poor condition.

If the battery voltage is greater than 16.5 V, the trans-

mission will adopt limp home mode and all solenoids

are turned OFF.

When system voltage recovers, the TCM will resume

normal operation after a 30 seconds delay period.

TCM Outputs

The outputs from the TCM are supplied to the compo-

nents described below;

Solenoids

Mode Indicator Light Readings for Resistance / Shift Lever Positions

Page 1132 of 2053

5A-38 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DIAGNOSIS

BASIC KNOWLEDGE REQUIRED

You must be familliar with some basic electronics to

use this section of the Service Manual. They will help

you to follow diagnostic procedures.

Notice: Lack of the basic knowledge of this transmis-

sion when performing diagnostic procedures could re-

sult in incorrect diagnostic performance or damage to

transmission components. Do not, under any circum-

stances, attempt to diagnose a transmission problem

without this basic knowledge.

Notice: If a wire is probed with a sharp instrument

and not properly sealed afterward, the wire will corrode

and an open circuit will result.

Diagnostic test probes are now available that allow

you to probe individual wires without leaving the wire

open to the environment. These probe devices are

inexpensive and easy to install, and they permanently

seal the wire from corrosion.

Special Tools

You should be able to use a Digital Volt Meter (DVM),

a circuit tester, jumper wires or leads and a line

pressure gauge set. The functional check procedure

is designed to verify the correct operation of electronic

components in the transmission. This will eliminate the

unnecessary removal of transmission components.

FUNCTIONAL CHECK

PROCEDURE

Begin with the Functional Check Procedure which pro-

vides a general outline of how to diagnose automatic

transmission. The following functional check procedure

will indicate the proper path of diagnosing the transmis-

sion by describing the basic checks and then referenc-

ing the locations of the specific checks.

Check the fluid level according to the Fluid Level

Service Procedure.

Check the transmission fluid leak.

Check if the transmission fluid is not burnt by smell.

Notice: The specific fluid used in this transmission

turns brown during normal operation. Brown fluid

does not indicate a transmission fault.

Ensure that the transmission is not in Limp Home

Mode (LHM).

Check the battery terminals and the earth connec-

tions for corrosion or looseness.

Check that the cooler flow is not restricted.

Check all electrical plug connections for tightness.

Use on-board diagnostic tool or a scan tool to see

if any transmission trouble codes have been set.

DIAGNOSTIC INFORMATION AND PROCEDURES

Refer to the appropriate “Diagnostic Trouble Code

(DTC)” information and repair the vehicle as

directed. After repairing the vehicle, perform the

road test and verify that the code has not set again.

Perform the Electrical/Garage Shift Tests.

Perform the Road Test Procedure in this section.

Inspect the oil and check for metal or other contami-

nants in the oil pan.

TRANSMISSION FLUID LEVEL

SERVICE PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will

result in slipping and loss of drive/ reverse or delay on

engagement of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transmission diagnostic

messages on the scan tool. If the oil level is low, it is

possible to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is

an abnormal delay when selecting drive or reverse, or

loss of drive. One symptom of low fluid level is a

momentary loss of drive when driving the vehicle around

a corner. Also when the transmission fluid level is low,

a loss of drive may occur when the transmission fluid

temperature is low.

If there is no loss of drive when the vehicle is driven

warm and a vehicle speed signal fault is registered,

then fluid should be added to the transmission.

When adding or changing transmission fluid use only

Castrol TQ 95 automatic transmission fluid. The use of

incorrect fluid will cause the performance and durability

of the transmission to be severely degraded.

Fluid Level Diagnosis procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes or, if possible, drive the

vehicle for a few kilometers. This will allow the

transmission to be within the correct temperature

range. Transmission fluid level should be checked

at temperature 50 - 60 °C (82 - 140 °F).

Caution: Removal of the fluid filler plug when

the transmission fluid is hot may cause injury if

fluid drains from the filler hole.

2. With the brake pedal pressed, move the gear shift

control lever through the gear ranges, pausing a

few seconds in each range. Return the gear shift

control lever to P (Park). Turn the engine OFF.

3. Park the vehicle on a hoist, inspection pit or similar

raised level surface. The vehicle must be control

level to obtain a correct fluid level measurement.

Page 1134 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.

Page 1135 of 2053

5A-40 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Dye and Black Light Method

1. Add dye to the transmission through the transmission

fluid filler plug. Follow the manufacturer’s recommen-

dation for the amount of dye to be used.

2. Use the black light to find the fluid leak.

3. Make the necessary repairs.

Repairing the Fluid Leak

Once the leak point is found the source of the leak

must be determined. The following list describes the

potential causes for the leak:

Fasteners are not torqued to specification.

Fastener threads and fastener holes are dirty or

corroded.

Gaskets, seals or sleeves are misaligned, damaged

or worn.

Damaged, warped or scratched seal bore or gasket

surface.

Loose or worn bearing causing excess seal or sleeve

wear.

Case or component porosity.

Fluid level is too high.

Plugged vent or damaged vent tube.

Water or coolant in fluid.

Fluid drain back holes plugged.

ELECTRICAL / GARAGE SHIFT

TEST

This preliminary test should be performed before a hoist

or road test to make sure electronic control inputs are

connected and operating. If the inputs are not checked

before operating the transmission, a simple electrical

condition could be misdiagnosed as a major

transmission condition.

A scan tool provides valuable information and must

be used on the automatic transmission for accurate

diagnosis.

1. Move gear shift control lever to P (Park) and set

the parking brake.

2. Connect scan tool to Data Link Connector (DLC)

terminal.

3. Start engine.

4. Turn the scan tool ON.

5. Verify that the appropriate signals are present.

These signals may include:

ENGINE SPEED

VEHICLE SPEED

THROTTLE POSITION

ACCEL. PEDAL POSITION

TRANSMISSION GEAR STATE

GEAR SHIFT LEVER POSITION

TRANSMISSION FLUID TEMPERATURE

CLOSED THROTTLE POSITION LEARN

OPEN THROTTLE POSITION LEARNT

CLOSED ACCEL. PEDAL POSITION LEARNT

OPEN ACCEL. PEDAL POSITION LEARNT

A/C COMPRESSOR STATUS

KICKDOWN SWITCH STATUS

4WD STATUS

MODE SWITCH

THROTTLE POSITION VOLTAGE

GEAR SHIFT LEVER POSITION VOLTAGE

TRANS. FLUID TEMPERATURE VOLTAGE

A/C SWITCH

KICKDOWN SWITCH VOLTAGE

4WD LAMP LOW VOLTAGE

4WD LAMP HIGH VOLTAGE

MODE SWITCH VOLTAGE

BATTERY VOLTAGE

6. Monitor the A/C COMPRESSOR STATUS signal

while pushing the A/C switch.

The A/C COMPRESSOR STATUS should come

ON when the A/C switch is pressed, and turn

OFF when the A/C switch is repushed.

7. Monitor the GEAR SHIFT LEVER POSITION signal

and move the gear shift control lever through all

the ranges.

Verify that the GEAR SHIFT LEVER POSITION

value matches the gear range indicated on the

instrument panel or console.

Gear selections should be immediate and not

harsh.

8. Move gear shift control lever to neutral and monitor

the THROTTLE POSITION signal while increasing

and decreasing engine speed with the accelerator

pedal.

THROTTLE POSITION should increase with en-

gine speed.

ROAD TEST PROCEDURE

Perform the road test using a scan tool.

This test should be performed when traffic and road

conditions permit.

Observe all traffic regulations.

ELECTRONIC ADJUSTMENTS

Idle Speed Adjustments

Carry out the adjustments to the idle speed as detailed

in the workshop manual.

Vehicle Coding

The vehicle coding is integrated as part of the

diagnostic software. A scan tool has the function to

code the ve-hicle through the K-line.

Page 1157 of 2053

5A-62 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Transmission Fluid Temperature (TFT) sensor is a

thermistor located in the solenoid wiring loom within

the valve body of the transmission. This sensor is a

typical Negative Temperature Coefficient (NTC) resistor

with low temperatures producing a high resistance and

high temperatures producing a low resistance.

If the transmission fluid temperature exceeds 135 °C

(275 °F), the TCM will impose converter lock-up at lower

vehicle speeds. Favour a lower gear to increase engine

speed, and in some vehicles flashes the mode indicator

lamp. This results in maximum oil flow through the exter-

nal oil cooler and eliminates slippage in the torque

converter. Both these actions combine to reduce the

oil temperature in the transmission.

The DTC P0710 sets when the TFT sensor signal is not

feasible.

Conditions for Setting the DTC

Transmission fluid temperature sensor signal is

greater than 4.88 volts (immediate detection).

Transmission fluid temperature sensor signal is less

than 0.21 volts (immediate detection).

Transmission temperature has not changed by 2 °C

in 15 minutes since ignition on and temperature is

less than 20 °C or greater than 125 °C.

Action Taken When the DTC Sets

Transmission fluid temperature is assumed to be

120 °C (248 °F).

All shifts will be firm until the transmission has

warmed up because a high transmission fluid

temperature is assumed.

DIAGNOSTIC TROUBLE CODE (DTC) P0710

TRANSMISSION FLUID TEMPERATURE SENSOR CIRCUIT

MALFUNCTION

Conditions for Clearing the DTC

The DTC will clear when the malfunction has not oc

curred for 3 seconds.

A history DTC will clear after 40 TCM power-up cycles

with a warm transmission (>50 °C) and without a

fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

The voltage measured by the TCM across the trans-

mission fluid temperature input terminals has been

outside acceptable levels.

If the DTC sets when an accessory is operated,

check for a poor connection or excessive current

draw.

Inspect the wiring for poor electrical connections

at the TCM and at the 10-way transmission

connector. Look for possible bent, backed out,

deformed or damaged terminals. Check for weak

terminal tension as well. Also, check for chafed wires

that could short to bare metal or other wiring. Inspect

for broken wires inside the insulation.

In searching for a possible intermittent short or open

condition, move or massage the wiring harness

while observing test equipment for a change.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

5. This step simulates a DTC P0710 condition. If the

scan tool displays the specified value, the TFT

sensor signal circuit and the TCM are OK.

KAA5A5M0

Page 1161 of 2053

5A-66 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The driving mode selector switch is located on the

center console and allows the driver to select the

driving mode.

When NORMAL mode is selected upshifts will occur

to maximize fuel economy. When POWER mode is se-

lected, upshifts will occur to give maximum

performance and the POWER mode indicator light is

switched ON.

When WINTER mode is selected, starting in second

gear is facilitated, the WINTER mode indicator light is

switched ON and the POWER mode indicator light is

switched OFF.

The DTC P0790 sets when an intermittent connection

in the mode selector switch (mode switch) circuit has

been detected. The mode switch input is rapidly

changing states. The switching frequency is greater

than 8.3 Hz.

Conditions for Setting the DTC

The mode switching frequency is greater than 8.3

Hz.

The above condition must be continuously present

for 4 state changes.

Action Taken When the DTC Sets

All shifts will occur as if the mode is set to NORMAL.

The mode indicator will always be OFF indicating

that NORMAL mode is selected.

The mode indicator will not respond to the changes

in switch setting.

DIAGNOSTIC TROUBLE CODE (DTC) P0790

NORMAL/PERFORMANCE SWITCH CIRCUIT MALFUNCTION

Conditions for Clearing the DTC

The DTC will clear after 3 seconds without the fault.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

This fault is caused by too many changes in the

mode input signal over a period of time.

Typical causes would be an intermittent connection

in the switch or wiring or an intermittent short to

ground in the wiring.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Check mode switch signal circuit for an

intermittent open / short

5. Check mode switch ground circuit for an

intermittent open / short

8. Check mode switch feed circuit for an intermittent

open / short

KAA5A5NA

Page 1162 of 2053

AUTOMATIC TRANSMISSION 5A-67

SSANGYONG MY2002

DTC P0790 Normal/Performance Switch Circuit Malfunction

1Perform a Transmission Control Module (TCM) Diag-

nostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P0790?

1. Turn the ignition OFF.

2. Disconnect the mode switch connector. Refer to

Shift Control Lever in this section.

3. Turn the ignition ON.

4. Select Mode Switch on scan tool Data List.

Is the Mode Switch value frequently changing?

1. Turn the ignition OFF.

2. Disconnect the TCM connector B.

3. Check the mode switch signal circuit for an

intermittent open or short and repair as necessary.

Is a repair necessary?

Jumper the mode switch ground terminal 1 to the

signal terminal 2.

Is the Mode Switch value frequently changing?

1. Turn the ignition OFF.

2. Disconnect the TCM connector B.

3. Check the mode switch ground circuit for an

intermittent open and repair as necessary.

Is a repair complete?

Check the fuse F27 for a malfunctioning and replace

as necessary?

Is a repair necessary?

Jumper the mode switch feed terminal 3 to the signal

terminal 2.

Is the Mode Switch value frequently changed?

1. Turn the ignition OFF.

2. Disconnect the TCM connector B.

3. Check the mode switch feed circuit for an

intermittent open and repair as necessary.

Is a repair complete?

Check for a poor connection at the mode switch and

TCM connector and repair the malfunctioning terminals

as necessary.

Is a repair necessary?

StepAction Value(s) Yes No

2

3

- Go to Step 6 Go to Step 7 5

- Go to Step 13 - 6

- Go to Step 13 Go to Step 10 4

- Go to Step 13 Go to Step 8 7

- Go to Step 9 Go to Step 11 8

- Go to Step 13 - 9

10

- Go to Step 2Go to “TCM

Diagnostic

System Check”

-

Go to Step 4 Go to Step 5

- Go to Step 3 Go to

“Diagnostic

Aids”

- Go to Step 13 Go to Step 12

Page 1163 of 2053

5A-68 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

DTC P0790 Normal/Performance Switch Circuit Malfunction (Cont'd)

Replace the mode switch. Refer to Shift Control Lever

in this section.

Is the action complete?

1. Turn the ignition OFF.

2. Replace the TCM.

Is the action complete?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

StepAction Value(s) Yes No

11

12

- Go to Step 14 Go to Step 2

14

- Go to Step 13 -

13

- Go to Step 13 -

-Go to

applicable

DTC tableSystem OK,

Check

Complete

Page 1165 of 2053

5A-70 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Controller Area Network (CAN) connects various

control modules by using a twisted pair of wires, to

share common information. This results in a reduction

of sensors and wiring. TCM obtains the actual engine

speed and throttle position, vehicle speed and

accelerator position etc. from ECM via CAN without

any additional sensors.

The DTC P1703 sets when the engine speed signal via

CAN is out of range or not feasible: The engine speed

signal is greater than 7000 rpm or less than 0 rpm, or

the indicated engine speed is low while other signals

indicate the car is moving (i.e. the vehicle speed has

increased more than 125 rpm).

Conditions for Setting the DTC

Immediately upon the test indicating malfunction

as follows.

The engine speed signal is greater than 7000 rpm

or less than 0 rpm under the precondition that DTC

P1719 is not set.

The indicated engine speed is low while other signals

indicate the car is moving, i.e. the vehicle speed

has increased more than 125 rpm under the following

precondition;

- Driving gear is selected.

- The applied throttle is greater than 5 %.

- The engine speed is less than 550 rpm.

- DTCs P0706, P0707, P0708, P1704, P1719 and

1721 are not set.

Action Taken When the DTC Sets

Fault detection of some other signals will not pos-

sible.

DIAGNOSTIC TROUBLE CODE (DTC) P1703

ENGINE SPEED SIGNAL ERROR

Conditions for Clearing the DTC

The DTC will clear after 30 seconds without the fault.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool

Diagnostic Aids

Inspect the wiring for poor electrical connections

at the TCM and ECM connectors. Look for possible

bent, backed out, deformed or damaged terminals.

Check for weak terminal tension as well. Also check

for chafed wires that could short to bare metal or

other wiring. Inspect for broken wire inside the

insulation.

If diagnosing for a possible intermittent short or

open condition, move or massage the wiring

harness while observing test equipment for a

change.

When ECM finds a fault on the engine speed

signals, ECM will adopt a default mode and send

the default value and trouble message to TCM via

CAN.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Check if there are any DTCs related to the engine

speed sensor on the ECM side.

4. Check for a poor connection at the ECM and TCM

connectors.

KAA5A5KA