ECO mode SSANGYONG KORANDO 1997 Service Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1376 of 2053

SSANGYONG MY2002

5D1-6 TRANSFER CASE

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4HLeft Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2

Low

Right Stop

Left Stop

Left of High

High

Right to High

Zone 1

Neutral

Zone 2

Low

Right stopNo action required. 4WD LOW indicator off.

Blink 4WD LOW indicator.

After the shift conditions are input, attempt a shift to 4H mode if follow-

ing conditions are maintained for 2 seconds conditions are maintained

for 2 seconds.

Shift lever position is in neutral.

The speed of front and rear propeller shaft is below 87 rpm.

After successfully shifting into 4L mode, stop blinking 4WD LOW indicator.

Blink 4WD LOW indicator.

After the shift conditions are input, attempt a shift to 4L mode if following

conditions are maintained for 2 conditions are maintained for 2 seconds.

Shift lever position is in neutral.

The speed of front and rear propeller shaft is below 87 rpm.

After successfully shifting into 4L mode, stop blinking 4WD LOW indicator.

No action required. 4WD LOW indicator on.

4H/4L Switch

InputAction Motor Position

Page 1562 of 2053

SSANGYONG MY2002

7D-8 FATC-HAVC

FUNCTION DESCRIPTION

1. AUTO switch

By pressing the AUTO switch, set temperature,

AUTO, fan speed, air source, air flow mode will

be appeared on the VFD display.

Following items will be controlled automatically

according to set temperature.

- Mode and intake door

- Temperature door

- Blower fan speed

- Compressor ON/OFF control

When AUTO switch is released, other functions

will be controlled automatically except for manually

selected switches.

2. MODE switch

By pressing the MODE switch while the AUTO

switch is turned ON, AUTO indicator light will go

off and air flow mode will be controlled manually

in the order of VENT → B/L → FLR → MIX → VENT.

3. OFF switch

Press this switch and the airconditioner system

will be turned OFF.

4. Temperature UP/DOWN switch

This switch is a switch increasing or decreasing

set temperature and position of the temperature

door will be automatically controlled according to

set temperature and outlet temperature will be

controlled by adjusting blending ratio of cold and

hot air.

By operating the switch, set temperature will be

increased/decreased by 0.5°C.

Set temperature range is 17 - 32°C.

Max. cold function will be performed at set

temperature of 17°C and max. hot function will be

performed at set temperature of 32°C.

When pressed more than 1 second, it will be

automatically UP/DOWN by interval of 0.28 sec.

after 1 second.

When it changed 17.5°C → 17°C, 31.5°C → 32°C

and DOWN switch is pressed after 17°C or UP

switch is pressed after 32°C, there will be

operating sounds 3 times during 0.1 sec.

5. DEFROST switch

By pressing this switch, DEF will turn on and mode

door will be fixed at DEF.

Recirculation/fresh air switch will be fixed as

FRESH.

When airconditioner is turned ON and ambient

temperature is less than 1.5°C, the airconditioner

will be turned off.

Selection of airconditioner OFF is possible by

manual.

6. A/C switch

The airconditioner system will be turned ON or OFF

by pressing this switch.

7. Recirculationfresh air switch

Air intake will be automatically switched to

recirculation or fresh air (REC → FRE) by pressing

this switch.

8. Blower switch (UP/DOWN)

Blower speed can be controlled by manual and if

fan UP/DOWN switch is pressed when AUTO mode

is selected, fan speed will UP/DOWN based on

current fan level.

When 6 segments are turned on, it is max. HI

operation.

When pressed more than 1 second, it will be

automatically UP/DOWN by interval of 0.28 sec.

after 1 second.

When segment is changed stage 2 → stage 1

(LO), stage 5 → stage 6 (HI) and HI switch is

pressed in HI status or DOWN switch is pressed

in LO status, there will be operating sounds 3

times during 0.1 sec.

When switch is operated in OFF status, it will be

operated as stage 1 (1 segment display).

Page 1588 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-3

SSANGYONG MY2002

SUPPLEMENTAL RESTRAINT

SYSTEM (SRS)

The supplemental restraint system (SRS) is safety de-

vice used in conjunction with the seat belts.

The air bag does not replace the function of the

seatbelt. The driver and the passengers must always

fasten their seat belts adjust them for a proper fit.

The SRS is designed to protect the driver and the front

seat passenger in the event of a significant frontal im-

pact to the vehicle. The airbags deploy if the force is

applied from a direction within about 30 degrees of

the vehicle’s centerline.

The SRS system consists of the following components:

Driver side airbag module.

Passenger airbag module.

Driver’s and passengers front seat belt pretension-

ers.

Sensing and diagnostic module (SDM).

Clock spring.

Wire harness and connectors.

Airbag warning lamp on the instrument cluster.

There are there are for separate four separate deploy-

ment loops in the SRS system. The term “loop” is

used because current leaves the SDM and returns to

the SDM during deployment or testing. First loop is

the circuit from SDM to the driver airbag and back to

the SDM. Second loop is the circuit from the SDM to

the passenger airbag and back to the SDM. The third

and forth loops are for right and left pretensioners.

DESCRIPTION AND OPERATION

KAA8B010

deployment, the system will enter overall or partial

shutdown status and the airbag will not inflate. The

Diagnostic System Check reveals diagnostic trouble

codes (DTCs) through the use of scan tool. It also

checks for proper airbag warning lamp operation.

Battery Voltage Check

The SDM checks the battery voltage continuously and

if the voltage is out of normal operating range (9-16

volts), all system diagnosis stops and turns on the

warning warning lamp.

Deployment Line Check

The SDM checks not only low or high resistance in the

deployment loop but also short to battery or ground

condition to indicates defects in deployment loop. It

indicates the defects by blinking the airbag warning

warning lamp.

Safety Function Check

The SDM checks the operation of arming sensor. If

the arming sensor is shorted more than 2 seconds,

the SDM will enter overall shutdown mode.

AIRBAG MODULES

Driver Airbag Module

Caution: Tampering with driver side airbag module

creates the risk of an injury from unexpected de-

ployment. Therefore, the passenger airbag module

should never be disassembled.

The passenger airbag module is under the center pad

of the steering wheel. The driver airbag module contains

an igniter charge and a gas generator to inflate the

folded airbag.

The airbag contains a shorting bar, which short-circuit

the driver high circuit to driver low circuit when the

connector is disconnected. The shorting bar prevents

current from traveling through the driver airbag module

during servicing. The shorting bar is disengaged when

the connector is connected.

System Control

The sensing and diagnostic module (SDM) continuously

monitors and controls the supplemental restraint

system (SRS) function during ignition ON or driving.

When SDM detects any problem it turns on or blink

the airbag warning lamp and keeps the diagnostic

trouble codes (DTCs). If there is a danger of improper

KAA8B020

Page 1590 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-5

SSANGYONG MY2002

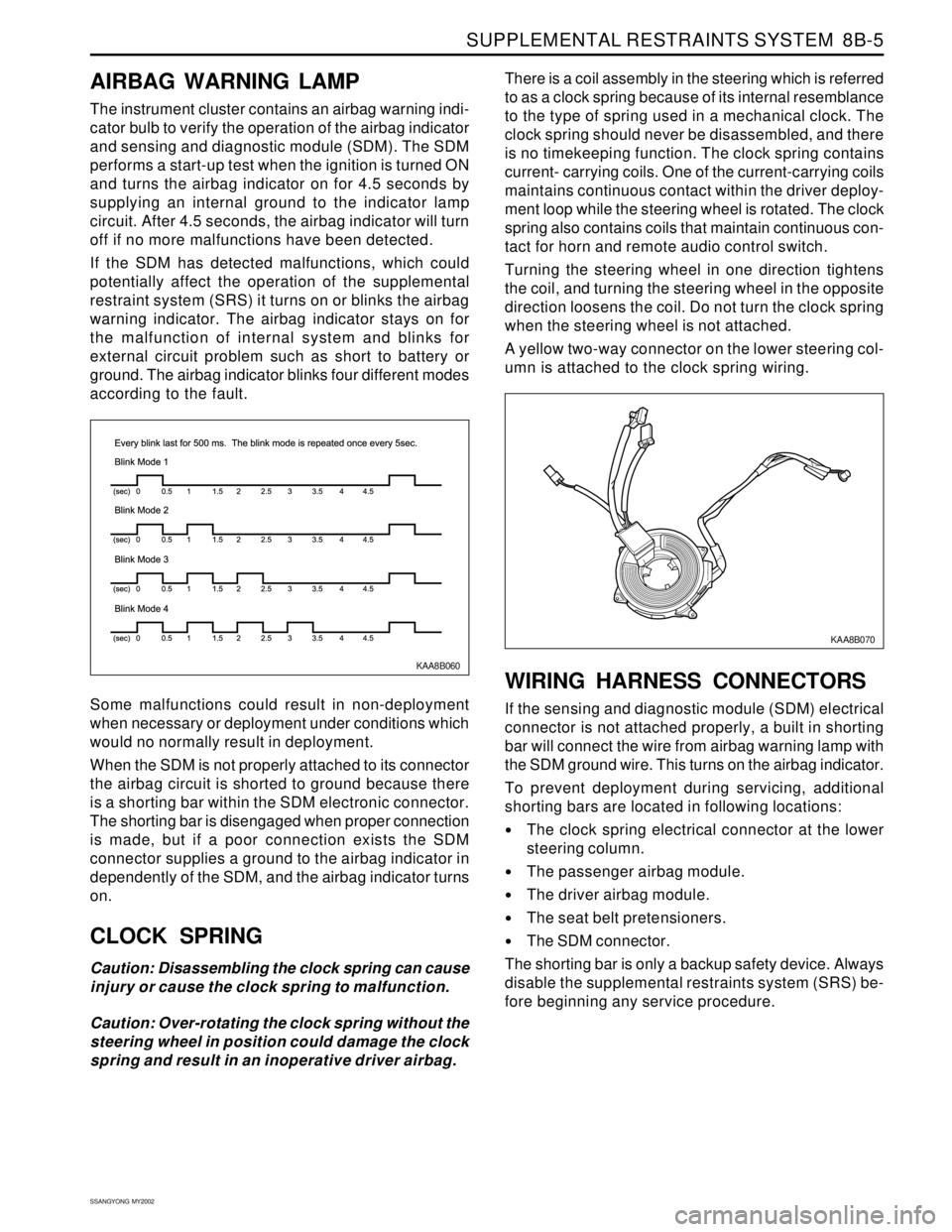

KAA8B060

AIRBAG WARNING LAMP

The instrument cluster contains an airbag warning indi-

cator bulb to verify the operation of the airbag indicator

and sensing and diagnostic module (SDM). The SDM

performs a start-up test when the ignition is turned ON

and turns the airbag indicator on for 4.5 seconds by

supplying an internal ground to the indicator lamp

circuit. After 4.5 seconds, the airbag indicator will turn

off if no more malfunctions have been detected.

If the SDM has detected malfunctions, which could

potentially affect the operation of the supplemental

restraint system (SRS) it turns on or blinks the airbag

warning indicator. The airbag indicator stays on for

the malfunction of internal system and blinks for

external circuit problem such as short to battery or

ground. The airbag indicator blinks four different modes

according to the fault.

Some malfunctions could result in non-deployment

when necessary or deployment under conditions which

would no normally result in deployment.

When the SDM is not properly attached to its connector

the airbag circuit is shorted to ground because there

is a shorting bar within the SDM electronic connector.

The shorting bar is disengaged when proper connection

is made, but if a poor connection exists the SDM

connector supplies a ground to the airbag indicator in

dependently of the SDM, and the airbag indicator turns

on.

CLOCK SPRING

Caution: Disassembling the clock spring can cause

injury or cause the clock spring to malfunction.

Caution: Over-rotating the clock spring without the

steering wheel in position could damage the clock

spring and result in an inoperative driver airbag.There is a coil assembly in the steering which is referred

to as a clock spring because of its internal resemblance

to the type of spring used in a mechanical clock. The

clock spring should never be disassembled, and there

is no timekeeping function. The clock spring contains

current- carrying coils. One of the current-carrying coils

maintains continuous contact within the driver deploy-

ment loop while the steering wheel is rotated. The clock

spring also contains coils that maintain continuous con-

tact for horn and remote audio control switch.

Turning the steering wheel in one direction tightens

the coil, and turning the steering wheel in the opposite

direction loosens the coil. Do not turn the clock spring

when the steering wheel is not attached.

A yellow two-way connector on the lower steering col-

umn is attached to the clock spring wiring.

WIRING HARNESS CONNECTORS

If the sensing and diagnostic module (SDM) electrical

connector is not attached properly, a built in shorting

bar will connect the wire from airbag warning lamp with

the SDM ground wire. This turns on the airbag indicator.

To prevent deployment during servicing, additional

shorting bars are located in following locations:

The clock spring electrical connector at the lower

steering column.

The passenger airbag module.

The driver airbag module.

The seat belt pretensioners.

The SDM connector.

The shorting bar is only a backup safety device. Always

disable the supplemental restraints system (SRS) be-

fore beginning any service procedure.

KAA8B070

Page 1592 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-7

SSANGYONG MY2002

Driver Deployment Loop Shorted to Voltage

Passenger Deployment Loop Shorted to Voltage

Driver Seat Belt Pretensioner Shorted to Voltage

Passenger Seat Belt Pretensioner Shorted to Voltage

Driver Deployment Loop Shorted to Ground

Passenger Deployment Loop Shorted to Ground

Driver Seat Belt Pretensioner Shorted to Ground

Passenger Seat Belt Pretensioner Shorted to Ground

Driver Energy Shutdown Switch Error

Passenger Energy Shutdown Switch Error

Driver Seat Belt Pretensioner Energy Shutdown Switch Error

Passenger Seat Belt Pretensioner Energy Shutdown

Switch Error

Driver Ignition Switch Fault Internal

Passenger Ignition Switch Fault Internal

Driver Seat Belt Pretensioner Ignition Switch Fault

Passenger Seat Belt Pretensioner Ignition Switch Fault 01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

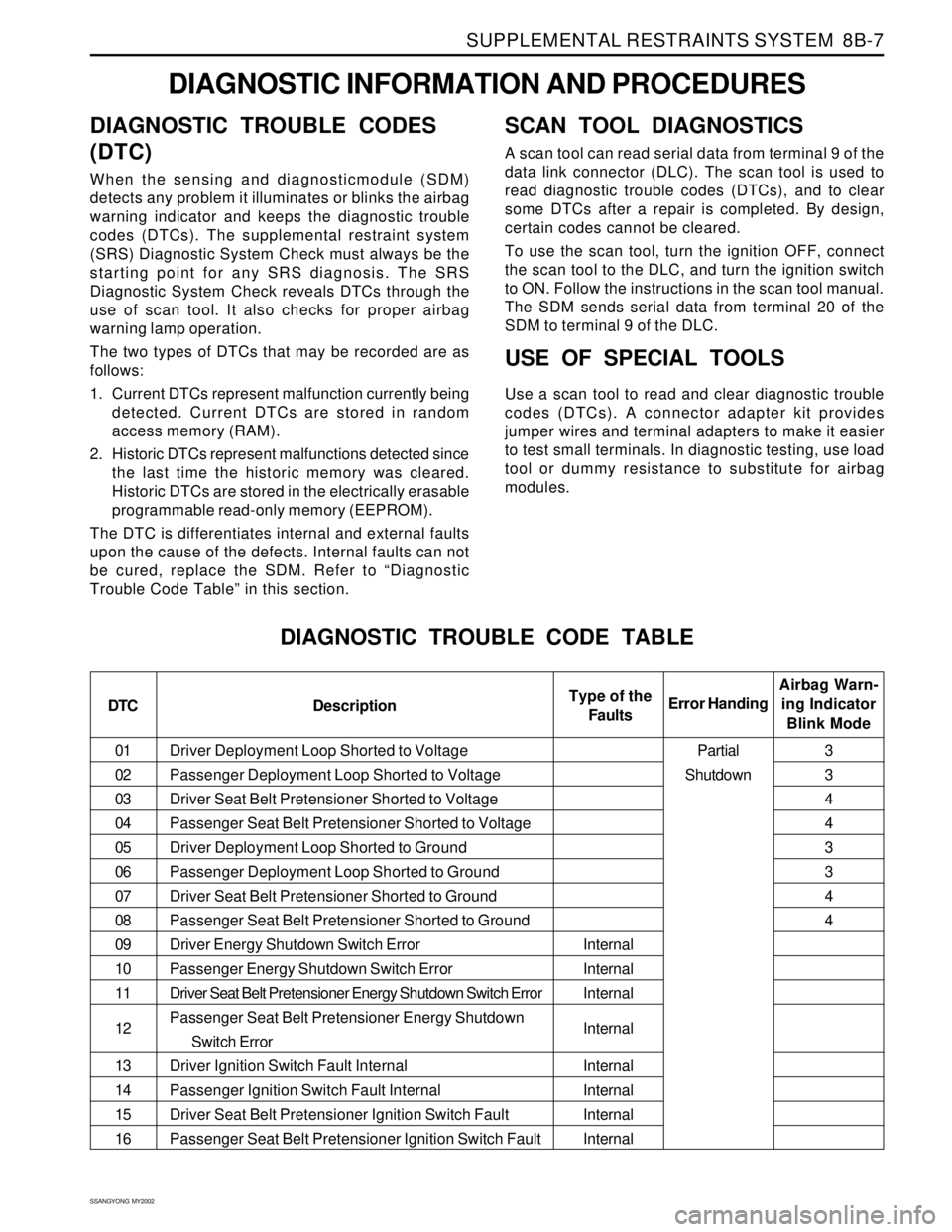

DIAGNOSTIC INFORMATION AND PROCEDURES

DIAGNOSTIC TROUBLE CODES

(DTC)

When the sensing and diagnosticmodule (SDM)

detects any problem it illuminates or blinks the airbag

warning indicator and keeps the diagnostic trouble

codes (DTCs). The supplemental restraint system

(SRS) Diagnostic System Check must always be the

starting point for any SRS diagnosis. The SRS

Diagnostic System Check reveals DTCs through the

use of scan tool. It also checks for proper airbag

warning lamp operation.

The two types of DTCs that may be recorded are as

follows:

1. Current DTCs represent malfunction currently being

detected. Current DTCs are stored in random

access memory (RAM).

2. Historic DTCs represent malfunctions detected since

the last time the historic memory was cleared.

Historic DTCs are stored in the electrically erasable

programmable read-only memory (EEPROM).

The DTC is differentiates internal and external faults

upon the cause of the defects. Internal faults can not

be cured, replace the SDM. Refer to “Diagnostic

Trouble Code Table” in this section.

SCAN TOOL DIAGNOSTICS

A scan tool can read serial data from terminal 9 of the

data link connector (DLC). The scan tool is used to

read diagnostic trouble codes (DTCs), and to clear

some DTCs after a repair is completed. By design,

certain codes cannot be cleared.

To use the scan tool, turn the ignition OFF, connect

the scan tool to the DLC, and turn the ignition switch

to ON. Follow the instructions in the scan tool manual.

The SDM sends serial data from terminal 20 of the

SDM to terminal 9 of the DLC.

USE OF SPECIAL TOOLS

Use a scan tool to read and clear diagnostic trouble

codes (DTCs). A connector adapter kit provides

jumper wires and terminal adapters to make it easier

to test small terminals. In diagnostic testing, use load

tool or dummy resistance to substitute for airbag

modules.

DIAGNOSTIC TROUBLE CODE TABLE

DTC DescriptionAirbag Warn-

ing Indicator

Blink Mode Error HandingType of the

Faults

Internal

Internal

Internal

Internal

Internal

Internal

Internal

Internal3

3

4

4

3

3

4

4

Partial

Shutdown

Page 1602 of 2053

SSANGYONG MY2002

8B-18 SUPPLEMENTAL RESTRAINTS SYSTEM

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to diag-

nose critical malfunctions within SDM itself. Upon pass-

ing these tests ignition and deployment loop voltages

are measured to ensure that they are within their re-

spective normal voltage ranges. The SDM monitors the

voltages at the driver low (terminal 14), passenger low

(terminal 11), driver seat belt pretensioner low (terminal

7) and passenger seat belt pretensioner low (terminal

4) to detect short to voltage in the deployment loops.

DTC 01 Will Set When

DTC 01 will set when the driver low is above 5 volts for

250 milliseconds while the other deployment loop low

is below 5 volts and ignition voltage is within the normal

operating voltage range.

DIAGNOSTIC TROUBLE CODE (DTC) 01

DRIVER DEPLOYMENT LOOP SHORTED TO VOLTAGE

This test is run during start-up test and every 250

milliseconds during continuous monitoring.

Action Taken

The SDM will turn on the airbag indicator (blink mode

3) and set DTC 01. The SDM will shutdown deployment

loop of driver airbag module.

DTC 01 Will Clear When

The scan tool CLEAR CODES command is received.

Diagnostic Aids

Carefully inspect the wires in driver airbag deployment

loop for cutting or chafing.

KAA8B100

DTC 01 - Driver Deployment Loop Shorted to Voltage

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the air-

bags and pretensioners for 0.15 seconds after the

ignition is OFF and the fuse has been removed. If

the airbags or pretensioners are not disconnected,

do not begin service until one minute has passed

after disconnecting power to the SDM. Otherwise,

injury could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

StepAction Value(s) Yes No

1-

Go to Step 2 -

Page 1604 of 2053

SSANGYONG MY2002

8B-20 SUPPLEMENTAL RESTRAINTS SYSTEM

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to

diagnose critical malfunctions within SDM itself. Upon

passing these tests ignition and deployment loop

voltages are measured to ensure that they are within

their respective normal voltage ranges. The SDM

monitors the voltages at the driver low (terminal 14),

passenger low (terminal 11), driver seat belt

pretensioner low (terminal 7) and passenger seat belt

pretensioner low (terminal 4) to detect short to voltage

in the deployment loops.

DTC 02 Will Set When

DTC 02 will set when the driver low is above 5 volts for

250 milliseconds while the other deployment loop low

DIAGNOSTIC TROUBLE CODE (DTC) 02

PASSENGER DEPLOYMENT LOOP SHORTED TO VOLTAGE

is below 5 volts and ignition voltage is within the normal

operating voltage range. This test is run during start-

up test and every 250 milliseconds during continuous

monitoring.

Action Taken

The SDM will turn on the airbag indicator (blink mode

3) and set DTC 02. The SDM will shutdown the

passenger airbag deployment loop.

DTC 02 Will Clear When

The scan tool CLEAR CODES command is received.

Diagnostic Aids

Carefully inspect the wires in passenger airbag

deployment loop for cutting or chafing.

KAA8B100

DTC 02 - Passenger Deployment Loop Shorted to Voltage

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

StepAction Value(s) Yes No

1- Go to Step 2 -

Page 1606 of 2053

SSANGYONG MY2002

8B-22 SUPPLEMENTAL RESTRAINTS SYSTEM

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to

diagnose critical malfunctions within SDM itself. Upon

passing these tests ignition and deployment loop

voltages are measured to ensure that they are within

their respective normal voltage ranges. The SDM

monitors the voltages at the driver low (terminal 14),

passenger low (terminal 11), driver seat belt

pretensioner low (terminal 7) and passenger seat belt

pretensioner low (terminal 4) to detect short to voltage

in the deployment loops.

DTC 03 Will Set When

DTC 03 will set when the driver seat belt pretensioner

low is above 5 volts for 250 milliseconds while the other

DIAGNOSTIC TROUBLE CODE (DTC) 03

DRIVER SEAT BELT PRETENSIONER SHORTED TO VOLTAGE

deployment loop low is below 5 volts and ignition

voltage is within the normal operating voltage range.

This test is run during start-up test and every 250

milliseconds during continuous monitoring.

Action Taken

The SDM will turn on the airbag indicator (blink mode

4) and set DTC 03. The SDM will shutdown the driver

seat belt pretensioner deployment loop.

DTC 03 Will Clear When

The scan tool CLEAR CODES command is received.

Diagnostic Aids

Carefully inspect the wires in passenger airbag

deployment loop for cutting or chafing.

KAA8B120

DTC 03 - Driver Seat Belt Pretensioner Shorted to Voltage

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

StepAction Value(s) Yes No

1- Go to Step 2 -

Page 1608 of 2053

SSANGYONG MY2002

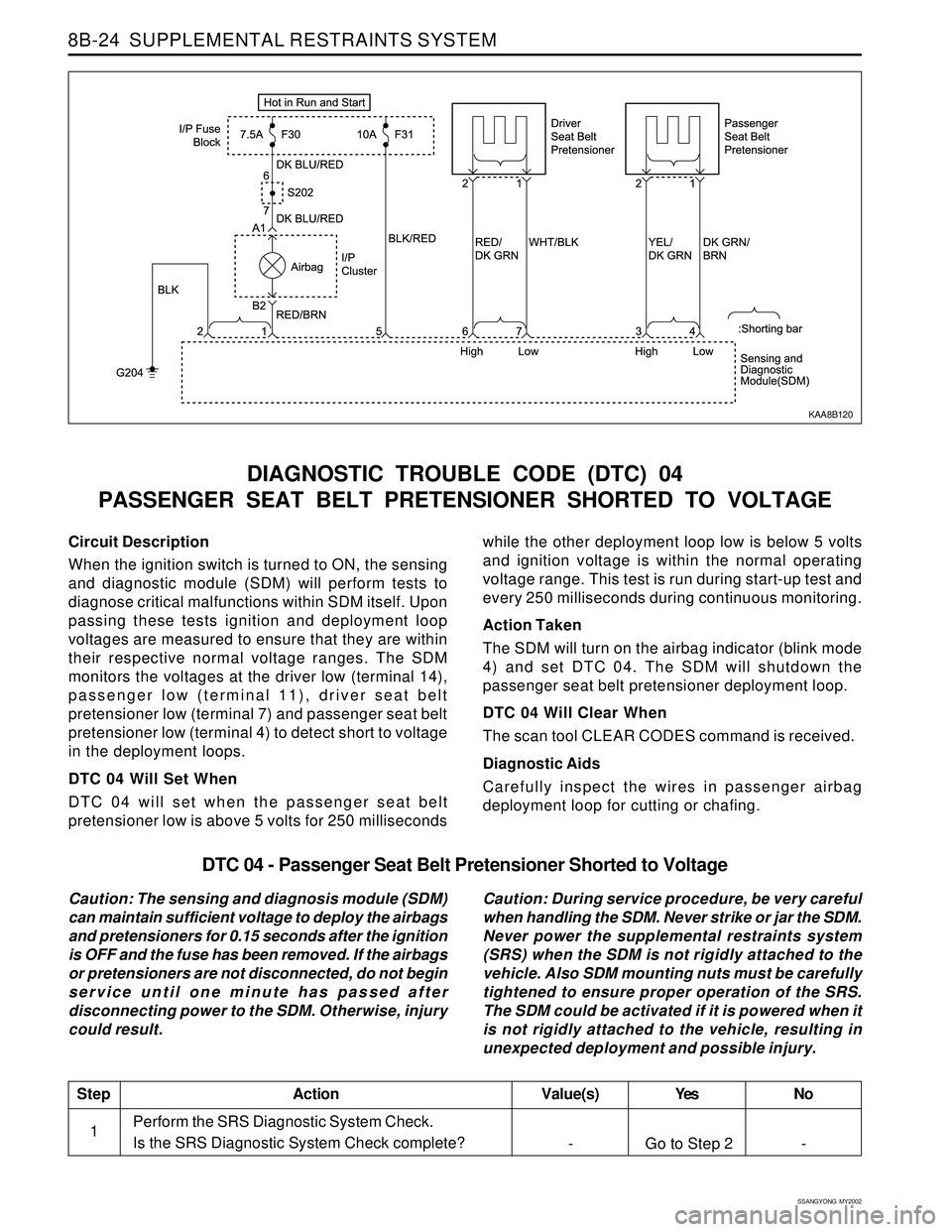

8B-24 SUPPLEMENTAL RESTRAINTS SYSTEM

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to

diagnose critical malfunctions within SDM itself. Upon

passing these tests ignition and deployment loop

voltages are measured to ensure that they are within

their respective normal voltage ranges. The SDM

monitors the voltages at the driver low (terminal 14),

passenger low (terminal 11), driver seat belt

pretensioner low (terminal 7) and passenger seat belt

pretensioner low (terminal 4) to detect short to voltage

in the deployment loops.

DTC 04 Will Set When

DTC 04 will set when the passenger seat belt

pretensioner low is above 5 volts for 250 milliseconds

DIAGNOSTIC TROUBLE CODE (DTC) 04

PASSENGER SEAT BELT PRETENSIONER SHORTED TO VOLTAGE

while the other deployment loop low is below 5 volts

and ignition voltage is within the normal operating

voltage range. This test is run during start-up test and

every 250 milliseconds during continuous monitoring.

Action Taken

The SDM will turn on the airbag indicator (blink mode

4) and set DTC 04. The SDM will shutdown the

passenger seat belt pretensioner deployment loop.

DTC 04 Will Clear When

The scan tool CLEAR CODES command is received.

Diagnostic Aids

Carefully inspect the wires in passenger airbag

deployment loop for cutting or chafing.

KAA8B120

DTC 04 - Passenger Seat Belt Pretensioner Shorted to Voltage

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

StepAction Value(s) Yes No

1- Go to Step 2 -

Page 1610 of 2053

SSANGYONG MY2002

8B-26 SUPPLEMENTAL RESTRAINTS SYSTEM

Circuit Description

When the ignition switch is turned to ON, the sensing

and diagnostic module (SDM) will perform tests to

diagnose critical malfunctions within SDM itself. Upon

passing these tests ignition and deployment loop

voltages are measured to ensure that they are within

their respective normal voltage ranges. The SDM

monitors the voltages at the driver low (terminal 14),

passenger low (terminal 11), driver seat belt

pretensioner low (terminal 7) and passenger seat belt

pretensioner low (terminal 4) to detect short to ground

in the deployment loops.

DTC 05 Will Set When

DTC 05 will set when the voltage at driver airbag low

falls below a specified value, and ignition voltage is

within the normal operating voltage range.

DIAGNOSTIC TROUBLE CODE (DTC) 05

DRIVER DEPLOYMENT LOOP SHORTED TO GROUND

This test is run during start-up test and every 250

milliseconds during continuous monitoring.

Action Taken

The SDM will turn on the airbag indicator (blink mode

3) and set DTC 05. The SDM will shutdown the driver

airbag module deployment loop.

DTC 05 Will Clear When

The scan tool CLEAR CODES command is received.

Diagnostic Aids

Carefully inspect the wires in driver airbag deployment

loop for cutting or chafing.

KAA8B100

DTC 05 - Driver Deployment Loop Shorted to Ground

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS.

The SDM could be activated if it is powered when it

is not rigidly attached to the vehicle, resulting in

unexpected deployment and possible injury.

Perform the SRS Diagnostic System Check.

Is the SRS Diagnostic System Check complete?

StepAction Value(s) Yes No

1-

Go to Step 2 -