stics SSANGYONG KORANDO 1997 Service User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1586 of 2053

SECTION 8B

SUPPLEMENTAL RESTRAINTS SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

other-wise noted.

TABLE OF CONTENTS

Description and Operation...................................8B-3

Supplemental Restraint System (SRS)..................8B-3

Airbag Modules...................................................8B-3

Front Seat Belt Pretensioners...............................8B-4

Sensing and Diagnostic Module (SDM)................8B-4

Airbag Warning Lamp ..........................................8B-5

Clock Spring........................................................8B-5

Wiring Harness Connectors..................................8B-5

Components Locator............................................8B-6

SRS Component and Wiring Location View...........8B-6

Diagnostic Information and Procedures..............8B-7

Diagnostic Trouble Codes (DTC)..........................8B-7

Scan Tool Diagnostics.........................................8B-7

Use of Special Tools............................................8B-7

Diagnostic Trouble Code Table............................8B-7

SRS Diagnostic System Check..........................8B-10

Sensing and Diagnostic Module (SDM)

Integrity Check...............................................8B-12

Airbag Warning Lamp Stays on with Ignition

Switch ON......................................................8B-14

DTCs - Internal Fault..........................................8B-16

DTCs 01 Driver Deployment Loop Shorted to

Voltage...........................................................8B-18

DTC 02 Passenger Deployment Loop Shorted to

Voltage...........................................................8B-20

DTC 03 Driver Seat Belt Pretensioner Shorted to

Voltage...........................................................8B-22

DTC 04 Passenger Seat Belt Pretensioner

Shorted to Voltage..........................................8B-24

DTC 05 Driver Deployment Loop Shorted to

Ground...........................................................8B-26

DTC 06 Passenger Deployment Loop Shorted to

Ground...........................................................8B-28

DTC 07 Driver Seat Belt Pretensioner Shorted to

Ground...........................................................8B-30DTC 08 Passenger Seat Belt Pretensioner

Shorted to Ground ..........................................8B-32

DTC 17 Driver Deployment Loop

Resistance High.............................................8B-34

DTC 18 Passenger Deployment Loop

Resistance High.............................................8B-38

DTC 19 Driver Seat Belt Pretensioner

Deployment Loop resistance High...................8B-40

DTC 20 Passenger Seat Belt Pretensioner

Deployment Loop Resistance High.................8B-42

DTC 21 Driver Airbag Deployment Loop

Resistance Low..............................................8B-44

DTC 22 Passenger Airbag Deployment Loop

Resistance Low..............................................8B-48

DTC 23 Driver Seat Belt Pretensioner

Deployment Loop resistance Low....................8B-50

DTC 24 Passenger Seat Belt Pretensioner

Deployment Loop Resistance Low..................8B-52

DTC 46 Airbag Warning Lamp Circuit Open or

Short to Ground/Battery..................................8B-54

DTC 47 Battery Voltage is Out of

Specification...................................................8B-56

Repair Instruction...............................................8B-58

On-Vehicle Service...............................................8B-58

Service Precaution.............................................8B-58

Disabling the Supplemental Restraint

System (SRS).................................................8B-58

Enabling the Supplemental Restraint

System (SRS).................................................8B-58

Handling, Installation and Diagnosis..................8B-58

Repairs and Inspections Required After an

Accident ........................................................8B-58

Accident with Deployment - Components

Replacement..................................................8B-58

Accident without Deployment - Component

Inspection......................................................8B-59

Page 1592 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-7

SSANGYONG MY2002

Driver Deployment Loop Shorted to Voltage

Passenger Deployment Loop Shorted to Voltage

Driver Seat Belt Pretensioner Shorted to Voltage

Passenger Seat Belt Pretensioner Shorted to Voltage

Driver Deployment Loop Shorted to Ground

Passenger Deployment Loop Shorted to Ground

Driver Seat Belt Pretensioner Shorted to Ground

Passenger Seat Belt Pretensioner Shorted to Ground

Driver Energy Shutdown Switch Error

Passenger Energy Shutdown Switch Error

Driver Seat Belt Pretensioner Energy Shutdown Switch Error

Passenger Seat Belt Pretensioner Energy Shutdown

Switch Error

Driver Ignition Switch Fault Internal

Passenger Ignition Switch Fault Internal

Driver Seat Belt Pretensioner Ignition Switch Fault

Passenger Seat Belt Pretensioner Ignition Switch Fault 01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

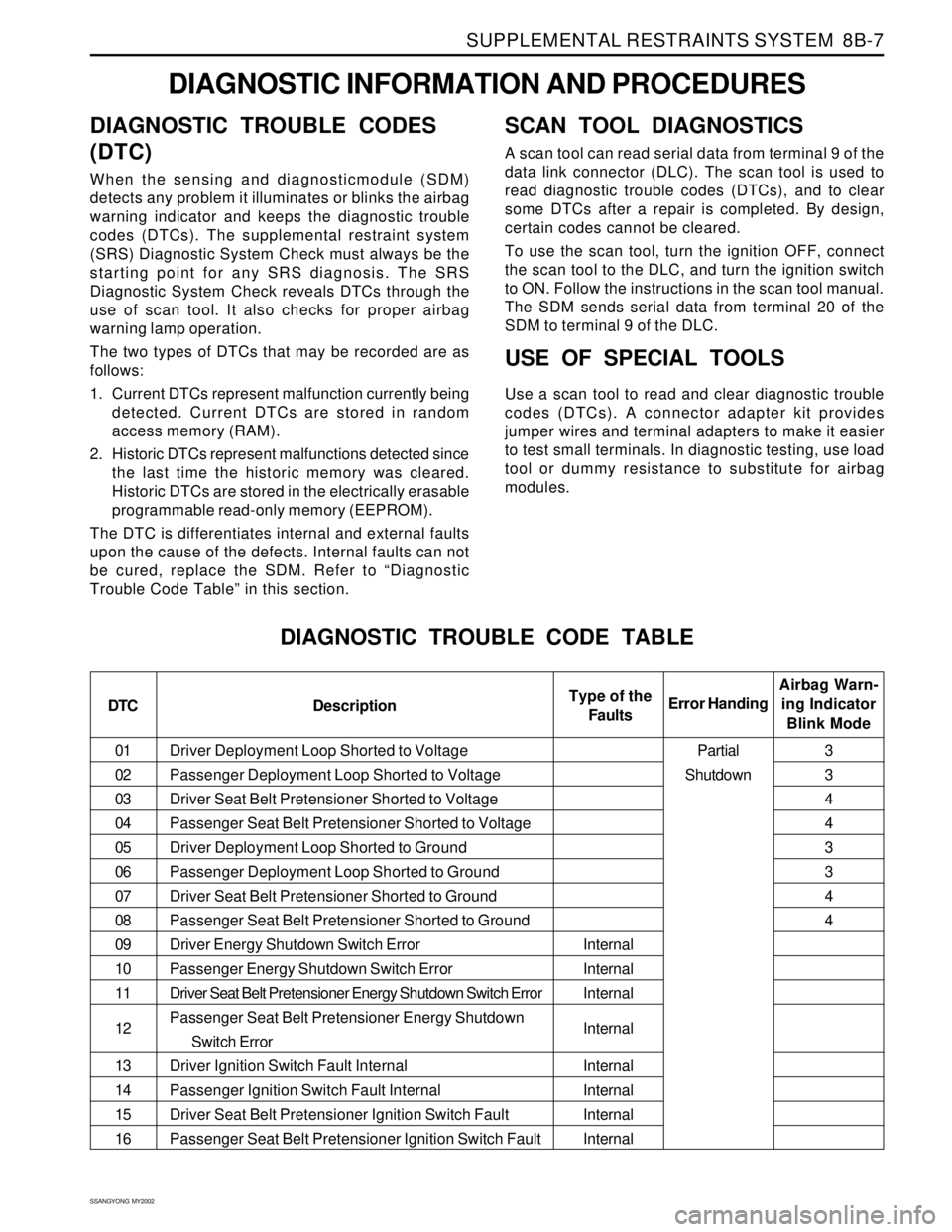

DIAGNOSTIC INFORMATION AND PROCEDURES

DIAGNOSTIC TROUBLE CODES

(DTC)

When the sensing and diagnosticmodule (SDM)

detects any problem it illuminates or blinks the airbag

warning indicator and keeps the diagnostic trouble

codes (DTCs). The supplemental restraint system

(SRS) Diagnostic System Check must always be the

starting point for any SRS diagnosis. The SRS

Diagnostic System Check reveals DTCs through the

use of scan tool. It also checks for proper airbag

warning lamp operation.

The two types of DTCs that may be recorded are as

follows:

1. Current DTCs represent malfunction currently being

detected. Current DTCs are stored in random

access memory (RAM).

2. Historic DTCs represent malfunctions detected since

the last time the historic memory was cleared.

Historic DTCs are stored in the electrically erasable

programmable read-only memory (EEPROM).

The DTC is differentiates internal and external faults

upon the cause of the defects. Internal faults can not

be cured, replace the SDM. Refer to “Diagnostic

Trouble Code Table” in this section.

SCAN TOOL DIAGNOSTICS

A scan tool can read serial data from terminal 9 of the

data link connector (DLC). The scan tool is used to

read diagnostic trouble codes (DTCs), and to clear

some DTCs after a repair is completed. By design,

certain codes cannot be cleared.

To use the scan tool, turn the ignition OFF, connect

the scan tool to the DLC, and turn the ignition switch

to ON. Follow the instructions in the scan tool manual.

The SDM sends serial data from terminal 20 of the

SDM to terminal 9 of the DLC.

USE OF SPECIAL TOOLS

Use a scan tool to read and clear diagnostic trouble

codes (DTCs). A connector adapter kit provides

jumper wires and terminal adapters to make it easier

to test small terminals. In diagnostic testing, use load

tool or dummy resistance to substitute for airbag

modules.

DIAGNOSTIC TROUBLE CODE TABLE

DTC DescriptionAirbag Warn-

ing Indicator

Blink Mode Error HandingType of the

Faults

Internal

Internal

Internal

Internal

Internal

Internal

Internal

Internal3

3

4

4

3

3

4

4

Partial

Shutdown

Page 1640 of 2053

SSANGYONG MY2002

8B-58 SUPPLEMENTAL RESTRAINTS SYSTEM

REPAIR INSTRUCTION

ON-VEHICLE SERVICE

SERVICE PRECAUTION

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioner for 0.15 seconds after the ignition

is OFF and the airbag fuse has been removed. If the

airbags or pretensioners are not disconnected, do

not begin service until one minute has passed after

disconnecting power to the SDM. If the airbag are

disconnected, service can begin immediately without

waiting for one-minute time period to expire. Failure

to temporarily disable the SRS during service can

result in unexpected deployment, personal injury,

and otherwise unneeded SRS repairs.

DISABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

1. Turn the steering wheel to the straight-ahead

position.

2. Turn the ignition switch to LOCK and remove the key.

3. Remove the airbag fuse F31 in the I/P fuse block

and wait more than one minute for SRS capacitor to

discharge.

ENABLING THE SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)

Enabling the supplemental restraint system (SRS) is

reverse order of “Disabling the Supplemental Restraint

System (SRS)”.

Caution: Staying well away from the inflator

modules, turn the ignition key switch to ON, and

verify that the airbag indicator illuminates for 4.5

seconds and turns OFF. If it does not operate as

described, perform the “SRS Diagnostic System

Check” referring in this section.

HANDLING, INSTALLATION AND

DIAGNOSIS

Airbag modules should not be subjected to

temperature above 65°C (149°F)

An airbag module or sensing and diagnostic module

(SDM) should not be used if it has been dropped

from height of 0.9 meters (3 feet) or greater.

It is very important for the SDM to be installed flat

on the mounting surface, parallel to the vehicle’s

longitudinal axis.

To avoid setting diagnostic trouble codes (DTCs),

do not apply power to the SRS unless all components

are connected or a diagnostic chart request it.

The SRS Diagnostic System Check must be the

starting point of any SRS diagnostics. The SRS

Diagnostic System Check will verify proper airbag

indicator operation and will lead you to correct chart

to diagnose any SRS malfunctions. Bypassing

these procedures may result in extended diagnostic

time and incorrect parts replacements.

REPAIRS AND INSPECTIONS

REQUIRED AFTER AN ACCIDENT

Caution: any repairs to the vehicle’s structure must

return it to the original production configuration.

Deployment requires replacement of SDM, the

inflator modules, and a dimensional inspection of

the steering column.

If any SRS components are damaged, they must

be replaced. If SRS components mounting points

are damaged, they must be repaired or replaced.

Never use SRS parts from another vehicle. This does

not include remanufactured parts purchased from

an authorized source.

Do not attempt to service the SDM, the clock spring,

or other airbag modules, these items must be

replaced if they are defective.

Verify the part number of replacement airbag

modules. Some inflator modules look identical but

contain different internal components.

ACCIDENT WITH DEPLOYMENT -

COMPONENTS REPLACEMENT

All SRS components must be replaced after frontal crash

involving airbag deployment. After deployment, a

powdery residue may be on the surface of the airbag.

The powder consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-products of the

chemical reaction. Sodium hydroxide dust (similar to

lye soap) is produced as a by-product of the deployment

reaction. The sodium hydroxide then quickly reacts with

atmospheric moisture and is converted to sodium

carbonate and sodium bicarbonate (also known as

baking soda). Therefore, it is unlikely that sodium

hydroxide will be present after deployment. Replace

the following SRS components.

Caution: Wear gloves and safety glasses during the

disposal procedure. Refer to “Deployed Airbag

Module Disposal Procedure” in this section.

The SDM.

Airbag modules and pretensioners

SRS wiring

Clock spring

Page 1658 of 2053

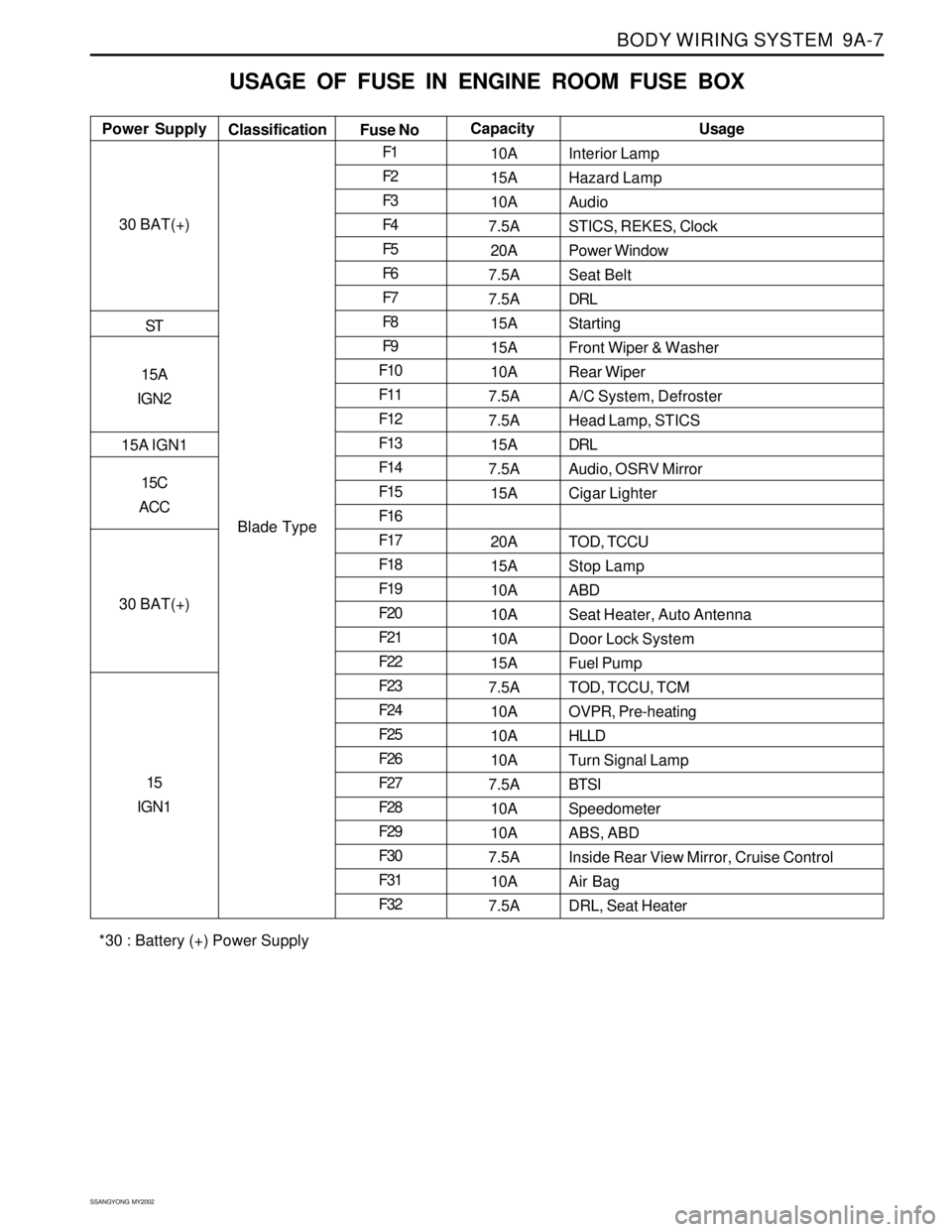

BODY WIRING SYSTEM 9A-7

SSANGYONG MY2002

USAGE OF FUSE IN ENGINE ROOM FUSE BOX

Interior Lamp

Hazard Lamp

Audio

STICS, REKES, Clock

Power Window

Seat Belt

DRL

Starting

Front Wiper & Washer

Rear Wiper

A/C System, Defroster

Head Lamp, STICS

DRL

Audio, OSRV Mirror

Cigar Lighter

TOD, TCCU

Stop Lamp

ABD

Seat Heater, Auto Antenna

Door Lock System

Fuel Pump

TOD, TCCU, TCM

OVPR, Pre-heating

HLLD

Turn Signal Lamp

BTSI

Speedometer

ABS, ABD

Inside Rear View Mirror, Cruise Control

Air Bag

DRL, Seat Heater Power SupplyUsage

Classification

Fuse NoCapacity

30 BAT(+)

ST

15A

IGN2

15A IGN1

15C

ACC

30 BAT(+)

15

IGN1

Blade TypeF1

F2

F3

F4

F5

F6

F7

F8

F9

F10

F11

F12

F13

F14

F15

F16

F17

F18

F19

F20

F21

F22

F23

F24

F25

F26

F27

F28

F29

F30

F31

F3210A

15A

10A

7.5A

20A

7.5A

7.5A

15A

15A

10A

7.5A

7.5A

15A

7.5A

15A

20A

15A

10A

10A

10A

15A

7.5A

10A

10A

10A

7.5A

10A

10A

7.5A

10A

7.5A

*30 : Battery (+) Power Supply

Page 1664 of 2053

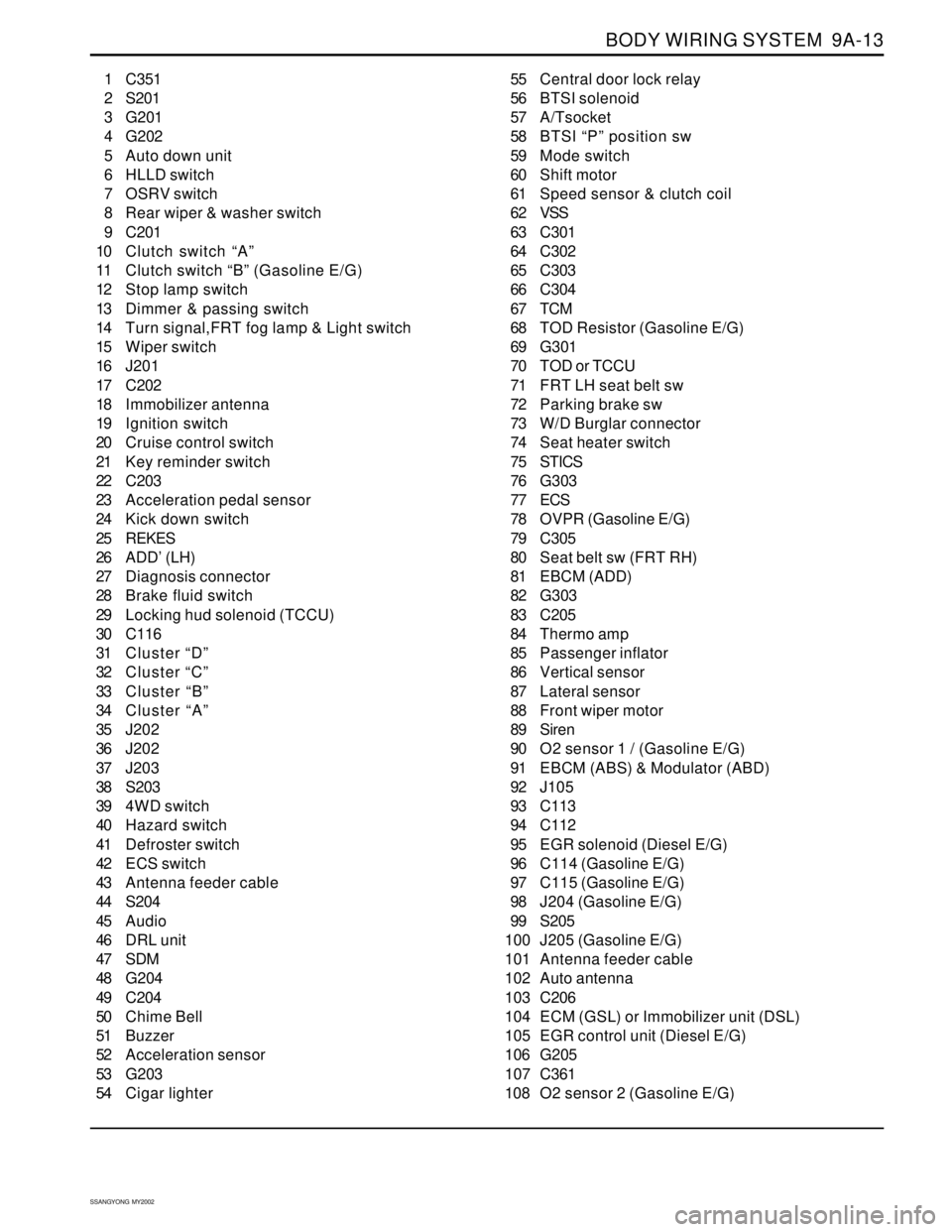

BODY WIRING SYSTEM 9A-13

SSANGYONG MY2002

1 C351

2 S201

3 G201

4 G202

5 Auto down unit

6 HLLD switch

7 OSRV switch

8 Rear wiper & washer switch

9 C201

10 Clutch switch “A”

11 Clutch switch “B” (Gasoline E/G)

12 Stop lamp switch

13 Dimmer & passing switch

14 Turn signal,FRT fog lamp & Light switch

15 Wiper switch

16 J201

17 C202

18 Immobilizer antenna

19 Ignition switch

20 Cruise control switch

21 Key reminder switch

22 C203

23 Acceleration pedal sensor

24 Kick down switch

25 REKES

26 ADD’ (LH)

27 Diagnosis connector

28 Brake fluid switch

29 Locking hud solenoid (TCCU)

30 C116

31 Cluster “D”

32 Cluster “C”

33 Cluster “B”

34 Cluster “A”

35 J202

36 J202

37 J203

38 S203

39 4WD switch

40 Hazard switch

41 Defroster switch

42 ECS switch

43 Antenna feeder cable

44 S204

45 Audio

46 DRL unit

47 SDM

48 G204

49 C204

50 Chime Bell

51 Buzzer

52 Acceleration sensor

53 G203

54 Cigar lighter55 Central door lock relay

56 BTSI solenoid

57 A/Tsocket

58 BTSI “P” position sw

59 Mode switch

60 Shift motor

61 Speed sensor & clutch coil

62 VSS

63 C301

64 C302

65 C303

66 C304

67 TCM

68 TOD Resistor (Gasoline E/G)

69 G301

70 TOD or TCCU

71 FRT LH seat belt sw

72 Parking brake sw

73 W/D Burglar connector

74 Seat heater switch

75 STICS

76 G303

77 ECS

78 OVPR (Gasoline E/G)

79 C305

80 Seat belt sw (FRT RH)

81 EBCM (ADD)

82 G303

83 C205

84 Thermo amp

85 Passenger inflator

86 Vertical sensor

87 Lateral sensor

88 Front wiper motor

89 Siren

90 O2 sensor 1 / (Gasoline E/G)

91 EBCM (ABS) & Modulator (ABD)

92 J105

93 C113

94 C112

95 EGR solenoid (Diesel E/G)

96 C114 (Gasoline E/G)

97 C115 (Gasoline E/G)

98 J204 (Gasoline E/G)

99 S205

100 J205 (Gasoline E/G)

101 Antenna feeder cable

102 Auto antenna

103 C206

104 ECM (GSL) or Immobilizer unit (DSL)

105 EGR control unit (Diesel E/G)

106 G205

107 C361

108 O2 sensor 2 (Gasoline E/G)

Page 1848 of 2053

SECTION 9T1

REMOTE KEYLESS ENTRY AND ANTI-THEFT

SYSTEM

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless

otherwise noted.

TABLE OF CONTENTS

Description and Operation.................................9T1-2

Remote Keyless Entry and Anti-Theft System.....9T1-2

Components Locator..........................................9T1-3

REKES & STICS................................................9T1-3

Diagnostic Information and Procedure.............9T1-4

Input Memory....................................................9T1-5

Repair Instructions..............................................9T1-6

On-Vehicle Service Unit Repair..............................9T1-6Receiver............................................................9T1-6

Antenna.............................................................9T1-6

Stics..................................................................9T1-6

Schematic and Routing Diagrams.....................9T1-7

STICS - Stics Unit..............................................9T1-7

STICS - Door Contact Switch..............................9T1-8

STICS - Keyless, Key Reminder Switch, Siren,

Chime Bell Buzzer ..........................................9T1-9

Page 1849 of 2053

SSANGYONG MY2002

9T1-2 REMOTE KEYLESS ENTRY AND ANTI-THEFT SYSTEM

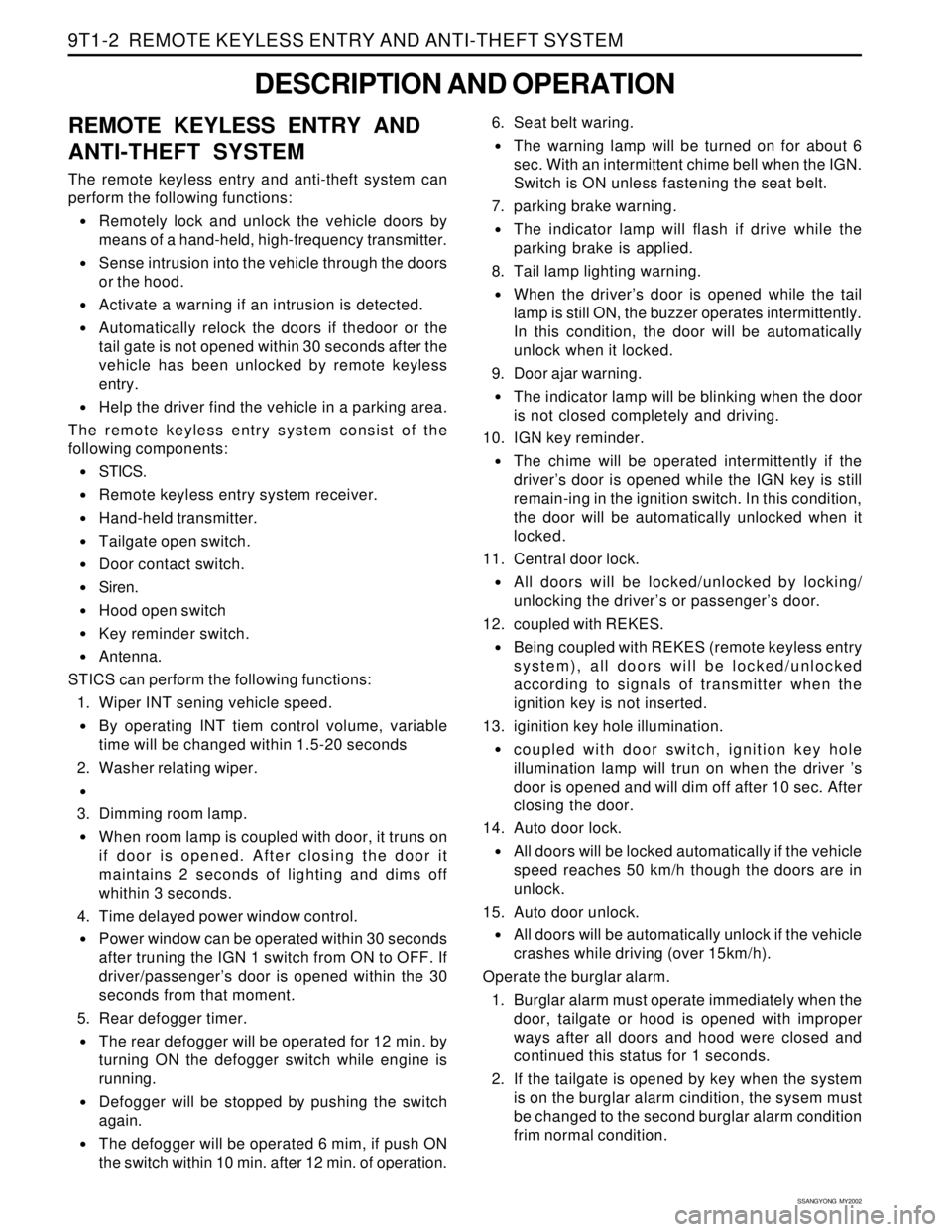

DESCRIPTION AND OPERATION

REMOTE KEYLESS ENTRY AND

ANTI-THEFT SYSTEM

The remote keyless entry and anti-theft system can

perform the following functions:

•Remotely lock and unlock the vehicle doors by

means of a hand-held, high-frequency transmitter.

Sense intrusion into the vehicle through the doors

or the hood.

Activate a warning if an intrusion is detected.

Automatically relock the doors if thedoor or the

tail gate is not opened within 30 seconds after the

vehicle has been unlocked by remote keyless

entry.

Help the driver find the vehicle in a parking area.

The remote keyless entry system consist of the

following components:

STICS.

Remote keyless entry system receiver.

Hand-held transmitter.

Tailgate open switch.

Door contact switch.

Siren.

Hood open switch

Key reminder switch.

Antenna.

STICS can perform the following functions:

1. Wiper INT sening vehicle speed.

By operating INT tiem control volume, variable

time will be changed within 1.5-20 seconds

2. Washer relating wiper.

3. Dimming room lamp.

When room lamp is coupled with door, it truns on

if door is opened. After closing the door it

maintains 2 seconds of lighting and dims off

whithin 3 seconds.

4. Time delayed power window control.

Power window can be operated within 30 seconds

after truning the IGN 1 switch from ON to OFF. If

driver/passenger’s door is opened within the 30

seconds from that moment.

5. Rear defogger timer.

The rear defogger will be operated for 12 min. by

turning ON the defogger switch while engine is

running.

Defogger will be stopped by pushing the switch

again.

The defogger will be operated 6 mim, if push ON

the switch within 10 min. after 12 min. of operation.6. Seat belt waring.

The warning lamp will be turned on for about 6

sec. With an intermittent chime bell when the IGN.

Switch is ON unless fastening the seat belt.

7. parking brake warning.

The indicator lamp will flash if drive while the

parking brake is applied.

8. Tail lamp lighting warning.

When the driver’s door is opened while the tail

lamp is still ON, the buzzer operates intermittently.

In this condition, the door will be automatically

unlock when it locked.

9. Door ajar warning.

The indicator lamp will be blinking when the door

is not closed completely and driving.

10. IGN key reminder.

The chime will be operated intermittently if the

driver’s door is opened while the IGN key is still

remain-ing in the ignition switch. In this condition,

the door will be automatically unlocked when it

locked.

11. Central door lock.

All doors will be locked/unlocked by locking/

unlocking the driver’s or passenger’s door.

12. coupled with REKES.

Being coupled with REKES (remote keyless entry

system), all doors will be locked/unlocked

according to signals of transmitter when the

ignition key is not inserted.

13. iginition key hole illumination.

coupled with door switch, ignition key hole

illumination lamp will trun on when the driver ’s

door is opened and will dim off after 10 sec. After

closing the door.

14. Auto door lock.

All doors will be locked automatically if the vehicle

speed reaches 50 km/h though the doors are in

unlock.

15. Auto door unlock.

All doors will be automatically unlock if the vehicle

crashes while driving (over 15km/h).

Operate the burglar alarm.

1. Burglar alarm must operate immediately when the

door, tailgate or hood is opened with improper

ways after all doors and hood were closed and

continued this status for 1 seconds.

2. If the tailgate is opened by key when the system

is on the burglar alarm cindition, the sysem must

be changed to the second burglar alarm condition

frim normal condition.

Page 1850 of 2053

REMOTE KEYLESS ENTRY AND ANTI-THEFT SYSTEM 9T1-3

SSANGYONG MY2002

COMPONENTS LOCATOR

REKES & STICS

KAA9T010

1. Remote Keyless Entry System Receiver

2. Antenna3. STICS

Page 1851 of 2053

SSANGYONG MY2002

9T1-4 REMOTE KEYLESS ENTRY AND ANTI-THEFT SYSTEM

DIAGNOSTIC INFORMATION AND PROCEDURE

DIAGNOSIS TEST

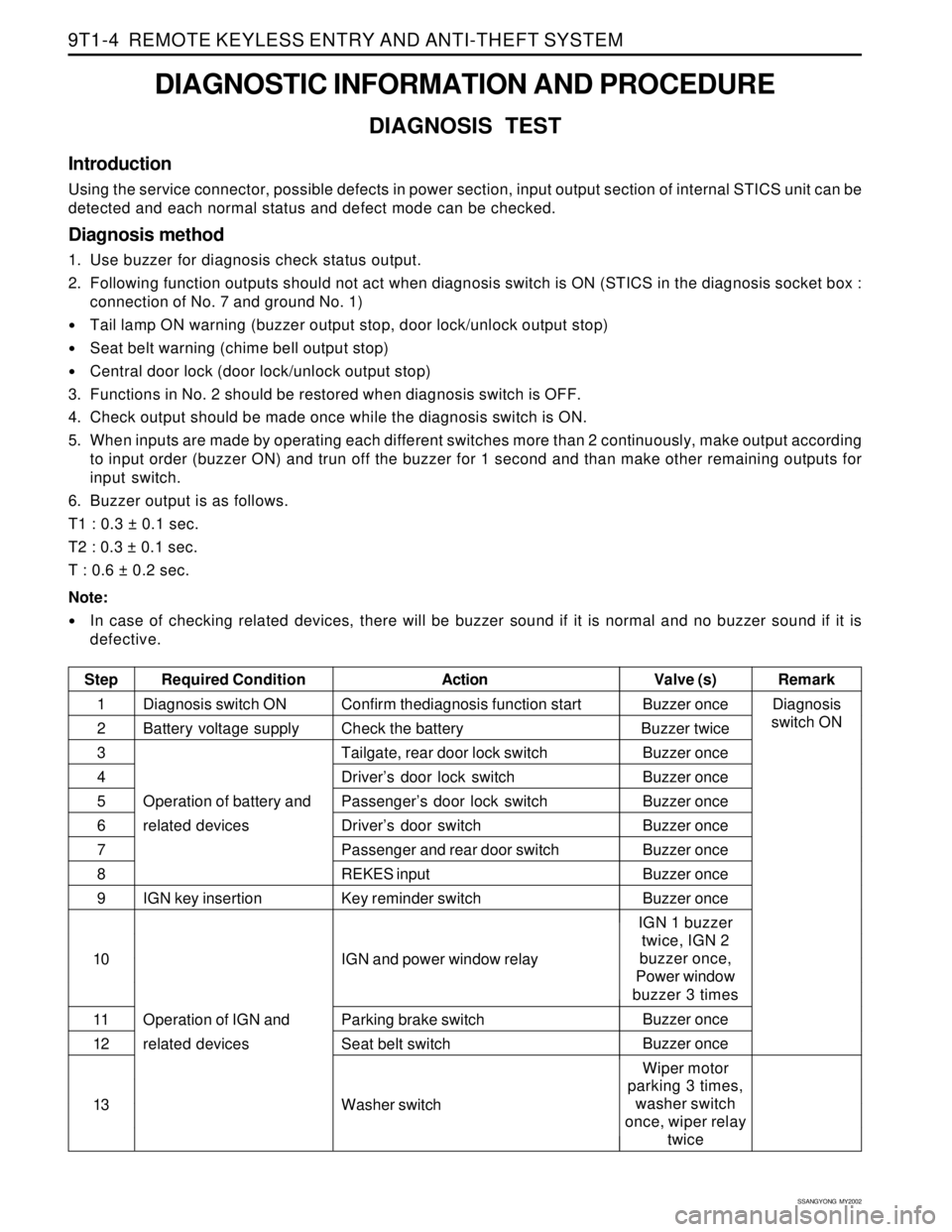

Introduction

Using the service connector, possible defects in power section, input output section of internal STICS unit can be

detected and each normal status and defect mode can be checked.

Diagnosis method

1. Use buzzer for diagnosis check status output.

2. Following function outputs should not act when diagnosis switch is ON (STICS in the diagnosis socket box :

connection of No. 7 and ground No. 1)

Tail lamp ON warning (buzzer output stop, door lock/unlock output stop)

Seat belt warning (chime bell output stop)

Central door lock (door lock/unlock output stop)

3. Functions in No. 2 should be restored when diagnosis switch is OFF.

4. Check output should be made once while the diagnosis switch is ON.

5. When inputs are made by operating each different switches more than 2 continuously, make output according

to input order (buzzer ON) and trun off the buzzer for 1 second and than make other remaining outputs for

input switch.

6. Buzzer output is as follows.

T1 : 0.3 ± 0.1 sec.

T2 : 0.3 ± 0.1 sec.

T : 0.6 ± 0.2 sec.

Note:

In case of checking related devices, there will be buzzer sound if it is normal and no buzzer sound if it is

defective.

Step Required ConditionActionRemark Valve (s)

Diagnosis switch ON

Battery voltage supply

Operation of battery and

related devices

IGN key insertion

Operation of IGN and

related devicesBuzzer once

Buzzer twice

Buzzer once

Buzzer once

Buzzer once

Buzzer once

Buzzer once

Buzzer once

Buzzer once

IGN 1 buzzer

twice, IGN 2

buzzer once,

Power window

buzzer 3 times

Buzzer once

Buzzer once

Wiper motor

parking 3 times,

washer switch

once, wiper relay

twice Confirm thediagnosis function start

Check the battery

Tailgate, rear door lock switch

Driver’s door lock switch

Passenger’s door lock switch

Driver’s door switch

Passenger and rear door switch

REKES input

Key reminder switch

IGN and power window relay

Parking brake switch

Seat belt switch

Washer switch1

2

3

4

5

6

7

8

9

10

11

12

13Diagnosis

switch ON

Page 1853 of 2053

SSANGYONG MY2002

9T1-6 REMOTE KEYLESS ENTRY AND ANTI-THEFT SYSTEM

KAA9T040

ON-VEHICLE SERVICE

UNIT REPAIR

RECEIVER

Removal and Installation Procedure

1. Remove the bolts with the receiver.

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

2. Installation should follow the removal procedure

in the reverse order.

ANTENNA

Removal and Installation Procedure

1. Disconnect the antenna cable from the receiver.

2. Remove the REKES antenna.

3. Installation should follow the removal procedure

in the reverse order.

REPAIR INSTRUCTIONS

1 Receiver

2 Antenna

STICS

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the floor console. Refer to Section 9G,

Interior Trim.

3. Disconnect the electrical connector.

4. Remove the bolts with the STICS.

Dissimilar metals in direct contact with each

other may corrode rapidly. Make sure to use

the correct fasteners to prevent premature

corrosion.

5. Installation should follow the removal procedure

in the reverse order.

KAA9T060