run flat SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 649 of 2053

1B3 -- 100 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

6. Measure axial runout of ring gear (1) on a surface

plate.

LimitMax. 0.4mm

Notice

For correct measurement, put the flywheel on the

flat measuring board.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Page 814 of 2053

SSANGYONG MY2002

2A-2 SUSPENSION DIAGNOSIS

Inspect the tires for improper pressure and uneven wear.

Inspect the joint from the steering column to the steer-

ing gear for loose connections or wear.

Inspect the front and the rear suspension, the steering

gear, and the linkage for loose or damaged parts.

Inspect for out-of-round tires.

Inspect for out-of-balance tires, bent wheels, and worn

or loose wheel bearings.

Check the power steering pump serpentine belt tension.

Inspect the power steering system for leaks. Also, check

the power steering fluid level.Action

Checks

Checks

Inspect for incorrect toe on the front and the rear wheels.

Inspect for a twisted or a bent suspension arm. Inspect for mismatched or uneven tires.

Inspect for a broken or a sagging spring.

Inspect for a radial tire lateral force.

Check the front-wheel alignment.

Inspect for an off-center steering gear.

Inspect for front-brake dragging.

DIAGNOSIS

GENERAL DIAGNOSIS

Problems in the steering, the suspension, the tires,

and the wheels involve several systems. Consider all

systems when diagnosing a complaint. Some problems,

such as abnormal or excessive tire wear and scuffed

tires, may be the result of hard driving. Always roadtest the vehicle first. If possible, do this road test with

the customer.

Proceed with the following preliminary checks. Correct

any substandard conditions.

Preliminary Checks

Replace the tires.

Replace the spring.

Check the wheel alignment. Switch the tire and the

wheel assemblies. Replace the tires, as needed.

Align the front wheels.

Reseat the pinion valve assembly. Replace the pinion

valve assembly, as needed.

Adjust the front brakes.

Car Lead/Pull

Action

Adjust the toe on the front and the rear wheels.

Replace the suspension arm.

Scuffed Tires

Inflate the tires to the proper pressure.

Tighten the intermediate shaft pinch bolts. Replace the

intermediate shaft, as needed.

Tighten the front and the rear suspension. Tighten the

steering gear mounting bracket bolts. Tighten the inter-

mediate shaft pinch bolts. Replace the front and the rear

suspension, as needed. Replace the steering gear, as

needed. Replace the intermediate shaft, as needed.

Perform a free runout test. Match-mount the tires.

Balance the wheels. Replace the wheels. Replace the

wheel bearings.

Tighten the power steering pump serpentine belt.

Repair any leaks. Perform a power steering system test.

Add power steering fluid, as needed.

Action Checks

Page 815 of 2053

SUSPENSION DIAGNOSIS 2A-3

SSANGYONG MY2002

Perform a rack bearing preload adjustment.

Replace the seals and the hoses, as needed.

Lubricate the steering gear. Repair or replace the

steering gear, as needed.

Tighten the steering gear mounting bracket nuts and

the bolts. Check the steering gear preload adjustment.

Check the hydraulic system. Test the power steering

system pressure with a gauge.

Inspect for binding or catching in the steering gear.

Inspect for a loose steering gear mounting.Action ChecksBalance the tire or the wheel.

Measure the hub flange runout. Replace the hub, as

needed.

Adjust the brakes. Replace the brake rotor, as needed.

Replace the outer tie rods.

Balance the wheel.

Replace the lower ball joint.

Measure the wheel runout. Replace the wheel, as

needed.

Match-mount the tire and the wheel assembly. Inspect for an out-of-balance tire or wheel.

Inspect for excessive wheel hub runout.

Inspect for excessive brake rotor imbalance.

Inspect for worn tie rod ends.

Inspect for wheel trim imbalance.

Inspect for a worn lower ball joint.

Inspect for excessive wheel runout.

Inspect for excessive loaded radial runout on the tire

and the wheel assembly.Action ChecksAction

Balance the tire or the wheel. Checks

Inspect for an out-of-balance tire or wheel.Align the front and the rear wheels.

Adjust the toe on the front and the rear wheels.

Replace the spring.

Balance the tires.

Rotate the tires. Replace the tires, as needed.

Maintain the proper load weight.

Inflate the tires to the proper pressure. Check the front-wheel and the rear-wheel alignment.

Inspect for excessive toe on the front and the rear wheels.

Inspect for a broken or a sagging spring.

Inspect for out-of-balance tires.

Check for a failure to rotate tires.

Check for an overloaded vehicle.

Inspect for low tire inflation.

Abnormal or Excessive Tire Wear

Shimmy, Shake, or Vibration

Hard Steering

Wheel Tramp

Action Checks

Page 822 of 2053

WHEEL ALIGNMENT 2B-3

SSANGYONG MY2002

DIAGNOSTIC INFORMATION AND PROCEDURES

TIRE DIAGNOSIS

Irregular and Premature Wear

Irregular and premature tire wear has many causes.

Some of them are incorrect inflation pressures, lack of

regular rotation, poor driving habits, or improper wheel

alignment.

Rotate the tires if :

•The front tire wear is different from the rear.

The left and right front tire wear is unequal.

The left and right rear tire wear is unequal.

Check wheel alignment if :

The left and right front tire wear is unequal.

The wear is uneven across the tread of either front

tire.

The front tire treads are scuffed with “feather” edges

on the side of the tread ribs or blocks.

Tread Wear Indicators

The original equipment tires have built-in tread wear in

dicators to show when the tires need replacement.

These indicators appear as bands when the tire tread

depth becomes shallow. Tire replacement is recom

mended when the indicators appear in three or more

grooves at six locations.

KAA2B010

Radial Tire Waddle

Waddle is side-to-side movement at the front or rear of

the vehicle. It is caused by the steel belt not being

straight within the tire, or by excessive lateral runout

of the tire or wheel.

The vehicle must be road tested to determine which

end of the vehicle has the faulty tire. The rear end of

the vehicle will shake from side to side or “waddle” if

the waddle tire is on the rear of the vehicle. From the

driver’s seat, it feels as though someone is pushing

on the side of the vehicle.

If the faulty tire is on the front of the vehicle, the waddle

is more visual. The front sheet meld appears to be mov-

ing back and forth, and the drivers seat feels like the

pivot point in the vehicle.

Waddle can be diagnosed using the method of substitut-

ing known good tire and wheel assemblies on the prob-

lem vehicle.

1. Road test the vehicle to determine if the waddle is

coming from the front or the rear of the vehicle.

2. Install good tires and wheels from a similar vehicle

in place of those on the offending end of the problem

vehicle. If the source of the waddle is not obvious,

change the rear tires.

3. Road test the vehicle. If there is improvement,

install the original tires to find the offending tire. If

there is no a straight improvement, install good tires

in place of all four offending tires.

KAA2B020

Page 825 of 2053

SSANGYONG MY2002

2B-6 WHEEL ALIGNMENT

VIBRATION DIAGNOSIS

Wheel imbalance causes most highway speed vibration

problems. A vibration can remain after dynamic balanc-

ing because:

A tire is out of round

A rim is out of round

A tire stiffness variation exists

Measuring tire and wheel free runout will uncover only

part of the problem. All three causes, known as loaded

radial runout, must be checked using method of substi-

tuting known good tire and wheel assemblies on the

problem vehicle.

Tire Balancing

Balance is the easiest procedure to perform and should

be done first if the vibration occurs at high speeds. Do

an off-vehicle, two-plane dynamic balance first to

correct any imbalance in the tire and wheel assembly.

An on-vehicle finish balance will correct any brake drum,

rotor, or wheel cover imbalance, If balancing does not

correct the high-speed vibration, or if the vibration oc-

curs at low speeds, runout is the probable cause.

Preliminary Checks

Prior to performing any work, always road test the car

and perform a careful visual inspection for:

Obvious tire and wheel runout.

Obvious drive axle runout.

Improper tire inflation.

Incorrect trim height.

Bent or damaged wheels.

Debris build-up on the tire or the wheel.

Irregular or excessive tire wear.

Improper tire bead seating on the rim,

Imperfections in the tires, including: tread deforma-

tions, separations, or bulges from impact damage.

Slight sidewall indentations are normal and will not

affect ride quality.

KAA2B040

Page 855 of 2053

SECTION 2E

TIRES AND WHEELS

TABLE OF CONTENTS

Description and Operation....................................2E-2

Tire and Wheel Balancing....................................2E-2

Tire Chain Usage.................................................2E-3

Replacement Tires...............................................2E-3

All Season Tires...................................................2E-3

Passenger Metric Sized Tires...............................2E-3

Tire Label............................................................2E-4

Spare Tire............................................................2E-4

Wheels................................................................2E-4

Inflation of Tires...................................................2E-4

Diagnostic Information and Procedures..............2E-5

Wheel Runout......................................................2E-5

Maintenance and Repair.....................................2E-6

On-Vehicle Service.................................................2E-6Wheel..................................................................2E-6

On-Vehicle Balancing ...........................................2E-7

Unit Repair............................................................2E-8

Alloy Wheel Porosity............................................2E-8

Alloy Wheel Refinishing .......................................2E-8

Off-Vehicle Balancing ..........................................2E-9

Correcting Non-Uniform Tires...............................2E-9

Tire and Wheel Match-Mounting...........................2E-9

Tire Mounting and Dismounting............................2E-9

Specifications.....................................................2E-10

Tire Size and Pressure Specifications.................2E-10

Inflation Pressure Conversion Specifications.......2E-10

Fastener Tightening Specifications.....................2E-10

Page 858 of 2053

SSANGYONG MY2002

2E-4 TIRE AND WHEELS

TIRE LABEL

The tire label is permanently located on the rear face

of the driver’s door and should be referred to for tire

information. It lists the maximum vehicle load, the tire

size (including the spare tire), and the cold inflation

pressure (including the spare tire).

S PARE TIRE

This vehicle comes equipped with a full-sized spare

tire and wheel.

The temporary spare tire is designed for emergency

use only. The original tire should be repaired or replaced

at the first opportunity and reinstall.

WHEELS

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, leak air through

welds, have elongated bolt holes, or if the wheel bolts

won’t stay tight or are heavily rusted. Wheels with

excessive runout may cause vehicle vibration.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim width,

offset, and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer/odometer calibration, vehicle

ground clearance, and tire clearance to the body and

the chassis. The wheel offset is 49 ± 1 (1.93 ± 0.04

inches). Steel wheels may be identified by a two- or

three-letter code stamped into the rim near the valve

stem. Alloy wheels should have the code, the part

number, and the manufacturer ID cast into the back

side.

INFLATION OF TIRES

The pressure recommended for any vehicle line is care-

fully calculated to give a satisfactory ride, handling,

tread life, and load-carrying capacity.

Tire pressure should be checked monthly or before any

extended trip. Check the tires when they are cold, after

the vehicle has sat for 3 hours or more or has been

driven less than 1 mile. Set the tire pressure to the

specifications on the tire label located on the rear face

of the drive r ’s door. Tire inflation pressure is also given

under “Tire Size and Pressure Specifications” in

this section.

Valve caps or extensions should be on the valves to

keep dust and water out.

For sustained driving at speeds up to 140 km/h (85 mph),

inflate the tires to the pressure recommended on the

tire. Sustained driving at speeds faster than 140 km/h

(85 mph), even if permitted by law, is not advised unless

the vehicle has special high-speed tires available from

many tire dealers. Tire pressures may increase as much

as 41 kPa (6 psi) when the tires are hot.

Higher than recommended tire pressure can cause

Hard ride.

Tire bruising or damage.

Rapid tread wear at the center of the tire.

Lower than recommended pressure can cause

Tire squeal on turns.

Hard steering.

Rapid and uneven wear on the edges of the tread.

Tire rim bruises and rupture.

Tire cord breakage.

High tire temperatures.

Unequal tire pressures on same axle can cause

Uneven braking.

Steering lead.

Reduced handling.

Swerve on acceleration.

Torque steer.

Page 923 of 2053

HYDRAULIC BRAKES 4A-3

SSANGYONG MY2002

DIAGNOSTIC INFORMATION AND PROCEDURES

BRAKE SYSTEM TESTING

Brakes should be tested on a dry, clean, reasonably

smooth and level roadway. A true test of brake perfor-

mance cannot be made if the roadway is wet, greasy,

or covered with loose dirt which can cause tires not to

grip the road unequally. Testing also will be inaccurate

on a crowned roadway because the wheels tend to

bounce.

Test the brakes at different vehicle speeds with both

light-and heavy-pedal pressure; however, avoid locking

the brakes and sliding the tires. Locked brakes and

slid-ing tires do not indicate brake efficiency since

heavily braked but turning wheels will stop the vehicle

in less distance than locked brakes. More tire-to-road

friction is present with a heavily braked, turning tire

than with a sliding tire.

Because of the high deceleration capability, a firmer

pedal may be felt at higher deceleration levels.

There are three major external conditions that affect

brake performance:

•Tires having unequal contact and grip of the road

will cause unequal braking. Tires must be equally

inflated, and the tread pattern of the right and the

left tires must be approximately equal.

Unequal loading of the vehicle can affect the brake

performance since the most heavily loaded wheels

require more braking power, and thus more braking

effort, than the others.

Misalignment of the wheels, particularly conditions

of excessive camber and caster, will cause the

brakes to pull to one side.

To check for brake fluid leaks, hold constant foot pres-

sure on the pedal with the engine running at idle and

the shift lever in NEUTRAL. If the pedal gradually falls

away with the constant pressure, the hydraulic system

may be leaking. Perform a visual check to confirm any

suspected leaks.

Check the master cylinder fluid level. While a slight

drop in the reservoir level results from normal lining

wear, an abnormally low level indicates a leak in the

system. The hydraulic system may be leaking either

internally or externally. Refer to the procedure below

to check the master cylinder. The system may appear

to pass this test while still having a slight leak. If the

fluid level is normal, check the vacuum booster pushrod

length. If an incorrect pushrod length is found, adjust

or replace the rod.Check the master cylinder using the following proce

dure:

Check for a cracked master cylinder casting or a

brake fluid leak around the master cylinder. Leaks

are indicated only if there is at least one drop of

fluid. A damp condition is not abnormal.

Check for a binding pedal linkage and for an

incorrect pushrod length. If both of these parts are

in satisfactory condition, disassemble the master

cylinder and check for an elongated or swollen

primary cylinder or piston seals. If swollen seals

are found, substandard or contaminated brake fluid

should be suspected. If contaminated brake fluid

is found, all the components should be

disassembled and cleaned, and all the rubber

components should be replaced. All of the pipes

must also be flushed.

Improper brake fluid, or mineral oil or water in the fluid,

may cause the brake fluid to boil or cause deterioration

of the rubber components. If the primary piston cups in

the master cylinder are swollen, the rubber parts have

deteriorated.

If deterioration of the rubber is evident, disassemble

all the hydraulic parts and wash the parts with alcohol.

Dry these parts with compressed air before reassembly

to keep the alcohol out of the system. Replace all the

rubber parts in the system, including the hoses. When

working on the brake mechanisms, check for fluid on

the linings. If excessive fluid is found, replace the

linings.

If the master cylinder piston seals are in satisfactory

condition, check for leaks or excessive heat conditions.

If these conditions are not found, drain the fluid, flush

the master cylinder with brake fluid, refill the master

cylinder, and bleed the system.

BRAKE HOSE INSPECTION

The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be

checked for road hazard damage, cracks, chafing of

the outer cover, and for leaks or blisters. Inspect the

hoses for proper routing and mounting. A brake hose

that rubs on a suspension component will wear and

eventually fail. A light and a mirror may be needed for

an adequate inspection. If any of the above conditions

are observed on the brake hose, adjust or replace the

hose as necessary.

Page 955 of 2053

FRONT BRAKES 4D-5

SSANGYONG MY2002

���� ����

����

����

����

����

yyyy yyyy

yyyy

yyyy

yyyy

yyyy

����� �����

�����

�����

�����

�����

�����

yyyyy yyyyy

yyyyy

yyyyy

yyyyy

yyyyy

yyyyy

DIAGNOSTIC INFORMATION AND PROCEDURES

KAA4D020

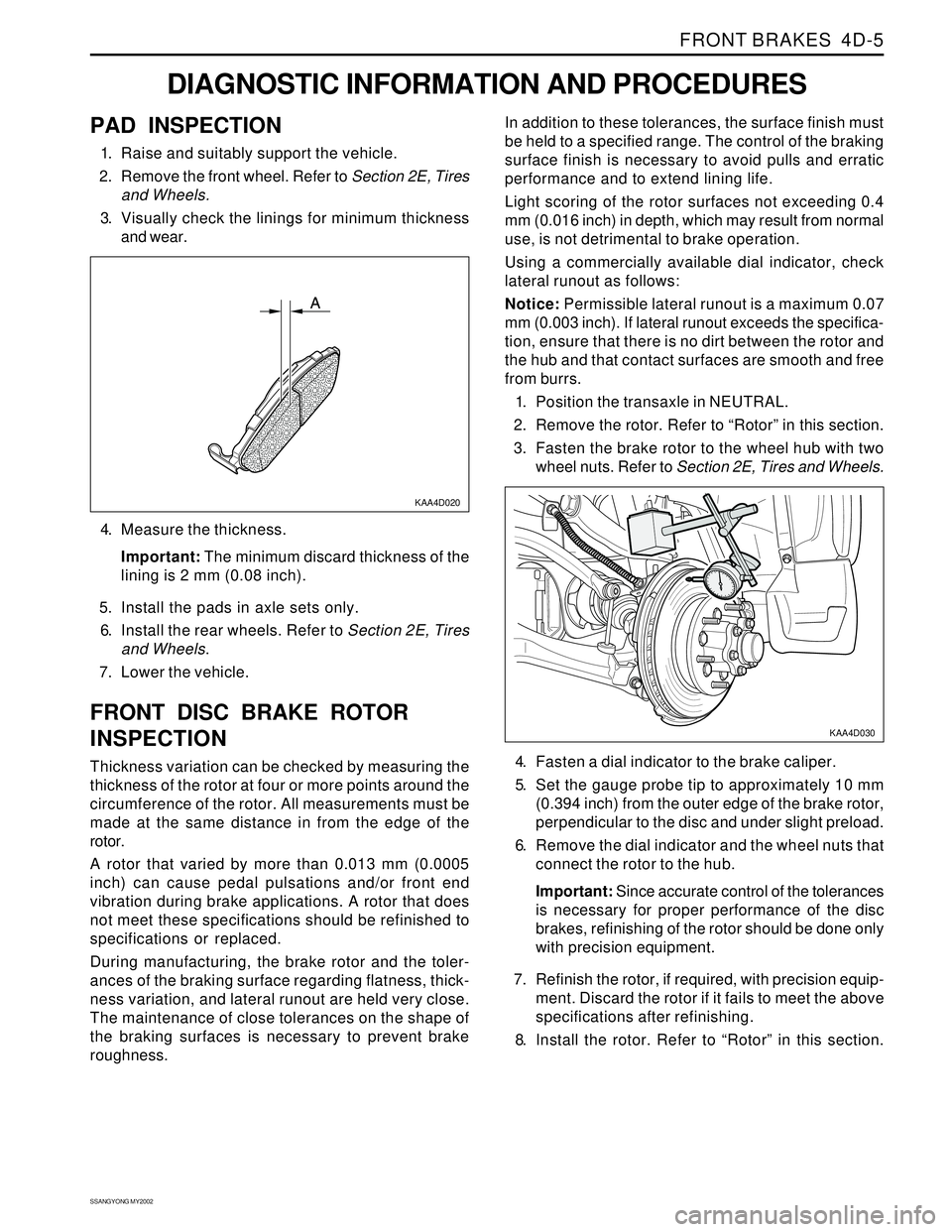

PAD INSPECTION

1. Raise and suitably support the vehicle.

2. Remove the front wheel. Refer to Section 2E, Tires

and Wheels.

3. Visually check the linings for minimum thickness

and wear.

4. Measure the thickness.

Important: The minimum discard thickness of the

lining is 2 mm (0.08 inch).

5. Install the pads in axle sets only.

6. Install the rear wheels. Refer to Section 2E, Tires

and Wheels.

7. Lower the vehicle.

FRONT DISC BRAKE ROTOR

INSPECTION

Thickness variation can be checked by measuring the

thickness of the rotor at four or more points around the

circumference of the rotor. All measurements must be

made at the same distance in from the edge of the

rotor.

A rotor that varied by more than 0.013 mm (0.0005

inch) can cause pedal pulsations and/or front end

vibration during brake applications. A rotor that does

not meet these specifications should be refinished to

specifications or replaced.

During manufacturing, the brake rotor and the toler-

ances of the braking surface regarding flatness, thick-

ness variation, and lateral runout are held very close.

The maintenance of close tolerances on the shape of

the braking surfaces is necessary to prevent brake

roughness.In addition to these tolerances, the surface finish must

be held to a specified range. The control of the braking

surface finish is necessary to avoid pulls and erratic

performance and to extend lining life.

Light scoring of the rotor surfaces not exceeding 0.4

mm (0.016 inch) in depth, which may result from normal

use, is not detrimental to brake operation.

Using a commercially available dial indicator, check

lateral runout as follows:

Notice: Permissible lateral runout is a maximum 0.07

mm (0.003 inch). If lateral runout exceeds the specifica-

tion, ensure that there is no dirt between the rotor and

the hub and that contact surfaces are smooth and free

from burrs.

1. Position the transaxle in NEUTRAL.

2. Remove the rotor. Refer to “Rotor” in this section.

3. Fasten the brake rotor to the wheel hub with two

wheel nuts. Refer to Section 2E, Tires and Wheels.

KAA4D030

4. Fasten a dial indicator to the brake caliper.

5. Set the gauge probe tip to approximately 10 mm

(0.394 inch) from the outer edge of the brake rotor,

perpendicular to the disc and under slight preload.

6. Remove the dial indicator and the wheel nuts that

connect the rotor to the hub.

Important: Since accurate control of the tolerances

is necessary for proper performance of the disc

brakes, refinishing of the rotor should be done only

with precision equipment.

7. Refinish the rotor, if required, with precision equip-

ment. Discard the rotor if it fails to meet the above

specifications after refinishing.

8. Install the rotor. Refer to “Rotor” in this section.

Page 1490 of 2053

SSANGYONG MY2002

6E-4 POWER STEERING AND COLUMN

DIAGNOSTIC INFORMATION AND PROCEDURES

STEERING WHEEL FREEPLAY

INSPECTION

KAA6E020

Inspection Procedure

1. Start the engine and set the wheels in straight

ahead position.

2. Slightly move the steering wheel to the left and

right and measure steering wheel free play when

the front wheel is start to move.

Notice: If exceeds specification, the steering

column shaft connections and steering linkage

clearance. Replace or repair if necessary.

StandardMax. 30 mm

STEERING EFFORT INSPECTION

KAA6E030

Inspection Procedure

1. Place a vehicle on the paved flat ground with front

wheels in a straight ahead position.

2. Start the engine and run it at 1,000 rpm.

3. Using a scale, measure the steering effort in both

directions.

Notice : The difference in steering effort of left

and right should be within 0.6 kg.

StandardMax. 3.0 kg