START CIRCUIT SSANGYONG KORANDO 1997 Service Owner's Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1147 of 2053

5A-52 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The Transmission Control Module (TCM) Diagnistic

System Check is the starting point for any driveability

complaint diagnosis. Before using this procedure,

perform a careful visual/physical check of the

Transmission Control Module (TCM) and the

transmission grounds for cleanliness and tightness.

The TCM Diagnostic System Check is an organized

approach to identifying a problem created by an

electronic transmission control system malfunction.

TCM DIAGNOSTIC SYSTEM CHECK

Diagnostic Aids

An intermittent fault may be caused by a poor connec-

tion, rubbed-through wire insulation or a wire broken

inside the insulation. Check for poor connections or a

damaged harness. Inspect the TCM harness and con-

nections for improper mating, broken locks, improperly

formed or damaged terminals, poor terminal-to-wire

connection, and damaged harness.

TCM Diagnostic System Check

1

StepAction Value(s) Yes No

21 Turn the ignition OFF.

2. Install the scan tool.

3. Turn the ignition ON, with the engine OFF.

4. Attempt to display the Transmission Control

Module (TCM) Data List with the scan tool.

Does the scan tool display the TCM data?

Select the Trouble Code with the scan tool.

Are any Diagnostic Trouble Codes (DTCs) stored?

- Go to Step 2 Go to Step 3

Go to

applicable

DTC table -System OK,

Check

Complete

KAA5A5KA

Page 1161 of 2053

5A-66 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

Circuit Description

The driving mode selector switch is located on the

center console and allows the driver to select the

driving mode.

When NORMAL mode is selected upshifts will occur

to maximize fuel economy. When POWER mode is se-

lected, upshifts will occur to give maximum

performance and the POWER mode indicator light is

switched ON.

When WINTER mode is selected, starting in second

gear is facilitated, the WINTER mode indicator light is

switched ON and the POWER mode indicator light is

switched OFF.

The DTC P0790 sets when an intermittent connection

in the mode selector switch (mode switch) circuit has

been detected. The mode switch input is rapidly

changing states. The switching frequency is greater

than 8.3 Hz.

Conditions for Setting the DTC

The mode switching frequency is greater than 8.3

Hz.

The above condition must be continuously present

for 4 state changes.

Action Taken When the DTC Sets

All shifts will occur as if the mode is set to NORMAL.

The mode indicator will always be OFF indicating

that NORMAL mode is selected.

The mode indicator will not respond to the changes

in switch setting.

DIAGNOSTIC TROUBLE CODE (DTC) P0790

NORMAL/PERFORMANCE SWITCH CIRCUIT MALFUNCTION

Conditions for Clearing the DTC

The DTC will clear after 3 seconds without the fault.

A history DTC will clear after 40 TCM power-up

cycles with a warm transmission (>50 °C) and

without a fault.

History DTCs can be cleared by using a scan tool.

Diagnostic Aids

This fault is caused by too many changes in the

mode input signal over a period of time.

Typical causes would be an intermittent connection

in the switch or wiring or an intermittent short to

ground in the wiring.

Test Description

The number(s) below refer to the step number(s) on

the Diagnostic Table.

3. Check mode switch signal circuit for an

intermittent open / short

5. Check mode switch ground circuit for an

intermittent open / short

8. Check mode switch feed circuit for an intermittent

open / short

KAA5A5NA

Page 1170 of 2053

AUTOMATIC TRANSMISSION 5A-75

SSANGYONG MY2002

DTC P1708 TCM Supply Voltage Low

1Perform a Transmission Control Module (TCM) Diag-

nostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1708?

1. Isolate the driven wheels from the ground and

apply the hand brake.

2. Start the engine and allow it to idle.

3. Move the gear lever to Drive.

4. Select the Ignition Voltage on the scan tool Data

List.

Is the Ignition Voltage less than the specified value?

While running the engine at the specified value, mea-

sure the battery voltage at the battery using a DVM.

Is the battery voltage greater than the specified value?

Check the fuse F23 for a malfunction and replace as

necessary?

Is a repair necessary?

1. Turn the ignition OFF.

2. Disconnect the TCM connector B.

3. Start the engine and raise the engine speed to

specified value.

4. While running the engine at the specified value,

measure the ignition voltage at the ignition feed

circuit terminal B30 using a DVM.

Is the ignition voltage greater than the specified value?

Check for a malfunctioning connection at the TCM

harness terminals and repair as necessary.

Is a repair necessary?

Repair the poor connection (high resistance) at the

ignition feed circuit.

Is the action complete?

1. Turn the ignition OFF.

2. Replace the TCM.

Is the action complete?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

StepAction Value(s) Yes No

2

3

5

- Go to Step 10 Go to Step 9 6 4

- Go to Step 10 - 7

- Go to Step 10 - 8

- Go to Step 11 Go to Step 2 9

10

- Go to Step 2Go to “TCM

Diagnostic

System Check”

10 V Go to Step 4 Go to Step 10

- Go to Step 3 Go to

“Diagnostic

Aids”

11

-Go to

applicable

DTC tableSystem OK,

Check

Complete

- Go to Step 10 Go to Step 6

Idle in Drive

10 V Go to Step 7 Go to Step 8

Idle in Drive

12 V Go to Step 5 Go to Section

1E, Engine

Electrical

Page 1172 of 2053

AUTOMATIC TRANSMISSION 5A-77

SSANGYONG MY2002

DTC P1709 TCM Supply Voltage High

1Perform a Transmission Control Module (TCM) Diag-

nostic System Check.

Is the check performed?

1. Install the scan tool.

2. Turn the ignition ON, with the engine OFF.

3. Record and then clear DTCs.

4. Operate the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool display P1709?

1. Start the engine and raise the engine speed to the

specified value.

2. Select the Ignition Voltage on the scan tool Data

List.

Is the Ignition Voltage greater than the specified value?

While running the engine at the specified value, mea-

sure the battery voltage at the battery using a DVM.

Is the battery voltage less than the specified value?

1. Turn the ignition OFF.

2. Disconnect the TCM connector B.

3. Start the engine and raise the engine speed to the

specified vale.

4. While running the engine at the specified value,

measure the ignition voltage at the ignition feed

circuit terminal B30 with respect to the ground

terminal B14.

Is the ignition voltage greater than the specified value?

Check the wiring harness from the fuse F23 to TCM

terminal B30 and from the ground G301 to TCM

terminal B14 for damage.

1. Turn the ignition OFF.

2. Replace the TCM.

Is the action complete?

1. Using the scan tool, clear the DTCs.

2. Road test the vehicle within the conditions for

setting this DTC as specified in the text.

Does the scan tool indicate that this diagnostic has

run and passed?

Check if any DTCs are set.

Are there any DTCs displayed or previously recorded

at Step 2 that have not been diagnosed?

StepAction Value(s) Yes No

2

3

5

6 4

- Go to Step 8 -

7

- Go to Step 8 -

8

- Go to Step 9 Go to Step 2

9

- Go to Step 2Go to “TCM

Diagnostic

System Check”

- Go to Step 3 Go to

“Diagnostic

Aids”

1500 rpm

16.5 V

Go to Step 6 Go to Step 7

1500 rpm

16.5 V Go to Step 4 Go to Step 8

2000 rpm

16.5 V Go to Step 5 Go to Section

1E, Engine

Electrical

-Go to

applicable

DTC tableSystem OK,

Check

Complete

Page 1375 of 2053

TRANSFER CASE 5D1-5

SSANGYONG MY2002

The motor reaches its destination.

The motor is on for 5 seconds without reaching its

destination. The shift has failed and the TCCU will

respond as default mode.

A fault occurs with either the motor or position

encoder. Refer to the diagnosis requirement.

When the motor is energized, the Ignition, 4H/4L

switch, propeller shaft speeds, and transmission

neutral inputs are ignored.

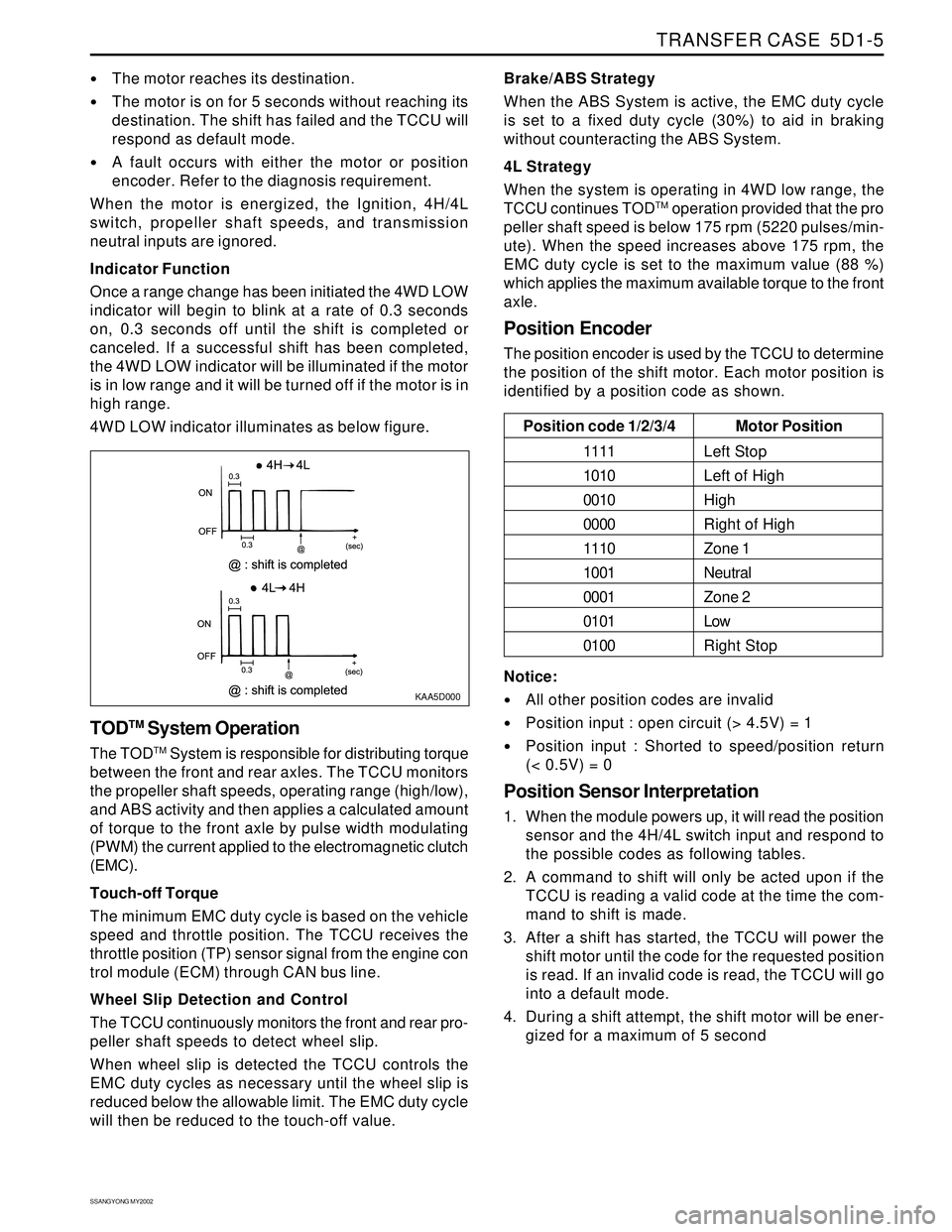

Indicator Function

Once a range change has been initiated the 4WD LOW

indicator will begin to blink at a rate of 0.3 seconds

on, 0.3 seconds off until the shift is completed or

canceled. If a successful shift has been completed,

the 4WD LOW indicator will be illuminated if the motor

is in low range and it will be turned off if the motor is in

high range.

4WD LOW indicator illuminates as below figure.

KAA5D000

TODTM System Operation

The TODTM System is responsible for distributing torque

between the front and rear axles. The TCCU monitors

the propeller shaft speeds, operating range (high/low),

and ABS activity and then applies a calculated amount

of torque to the front axle by pulse width modulating

(PWM) the current applied to the electromagnetic clutch

(EMC).

Touch-off Torque

The minimum EMC duty cycle is based on the vehicle

speed and throttle position. The TCCU receives the

throttle position (TP) sensor signal from the engine con

trol module (ECM) through CAN bus line.

Wheel Slip Detection and Control

The TCCU continuously monitors the front and rear pro-

peller shaft speeds to detect wheel slip.

When wheel slip is detected the TCCU controls the

EMC duty cycles as necessary until the wheel slip is

reduced below the allowable limit. The EMC duty cycle

will then be reduced to the touch-off value.Brake/ABS Strategy

When the ABS System is active, the EMC duty cycle

is set to a fixed duty cycle (30%) to aid in braking

without counteracting the ABS System.

4L Strategy

When the system is operating in 4WD low range, the

TCCU continues TOD

TM operation provided that the pro

peller shaft speed is below 175 rpm (5220 pulses/min-

ute). When the speed increases above 175 rpm, the

EMC duty cycle is set to the maximum value (88 %)

which applies the maximum available torque to the front

axle.

Position Encoder

The position encoder is used by the TCCU to determine

the position of the shift motor. Each motor position is

identified by a position code as shown.

Motor Position

Left Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2

Low

Right Stop Position code 1/2/3/4

1111

1010

0010

0000

1110

1001

0001

0101

0100

Notice:

All other position codes are invalid

Position input : open circuit (> 4.5V) = 1

Position input : Shorted to speed/position return

(< 0.5V) = 0

Position Sensor Interpretation

1. When the module powers up, it will read the position

sensor and the 4H/4L switch input and respond to

the possible codes as following tables.

2. A command to shift will only be acted upon if the

TCCU is reading a valid code at the time the com-

mand to shift is made.

3. After a shift has started, the TCCU will power the

shift motor until the code for the requested position

is read. If an invalid code is read, the TCCU will go

into a default mode.

4. During a shift attempt, the shift motor will be ener-

gized for a maximum of 5 second

Page 1384 of 2053

SSANGYONG MY2002

5D1-14 TRANSFER CASE

4WD CHECK INDICATOR STAYS ON WITH IGNITION SWITCH ON

KAA5D040

Circuit Description

When the ignition switch turns to ON the transfer case

control unit (TCCU) illuminates 4WD CHECK and 4WD

LOWindicator to check bulb operation and turns off

after 0.6 seconds. Then TCCU starts self-diagnosis

and illuminate 4WD CHECK indicator when TCCU

detects any fault.

Diagnostic Aids

If the 4WD CHECK indicator illuminates steadily the

TCCU may detect some fault. TCCU should be

checked by scan tool to solve the problem.

The 4WD CHECK indicator also illuminates steadily

if the terminal B2 of TCCU connector is shorted to

ground. The shorted wire or terminals should be re-

paired.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. This step, along with step 4, checks the short to

ground condition of the wire or terminals

Step

1

ABS INDICATOR LAMP ILLUMINATED CONTINUOUSLY, NO DTCs STORED

Action Yes

Go to the

specific DTC

diagnostic tableNo

Go to Step 2 Value(s)

1. Turn the ignition switch to OFF.

2. Connect the scan tool to the data link connector

(DLC).

3. Turn the ignition switch to ON and request the DTC.

Does the scan tool display any DTC?

Page 1386 of 2053

SSANGYONG MY2002

5D1-16 TRANSFER CASE

KAA5D040

NO 4WD LOW INDICATOR STAYS ON WITH IGNITION SWITCH ON

Circuit Description

When the ignition switch turns to ON the transfer case

control unit (TCCU) illuminates 4WD CHECK and 4WD

LOWindicator to check bulb operation and turns off

after 0.6 seconds. Then TCCU starts self-diagnosis

and illuminate 4WD CHECK indicator when TCCU

detects any fault.

Diagnostic Aids

If the 4WD LOW indicator illuminates steadily the

transfer case in 4 wheel drive low range and 4H/4L

switch set to 4L. It is normal condition.

The 4WD LOW indicator also illuminates steadily if

the terminal B9 of TCCU connector is shorted to

ground. The shorted wire or terminals should be re-

paired.

Test Description

The number(s) below refer to step(s) on the diagnostic

table.

2. This step checks for the normal bulb operation.

Step

1

2

Action Yes

Go to Step 2

System OKNo

Go to Step 3

- Value(s)

Check the position of 4H/4L switch.

Does the 4H/4L switch set on 4L.

1. Turn the ignition switch to ON.

2. Set the shift lever to N (neutral).

3. Turn the 4H/4L switch to 4H.

Does the 4WD LOWindicator go off?

Page 1590 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-5

SSANGYONG MY2002

KAA8B060

AIRBAG WARNING LAMP

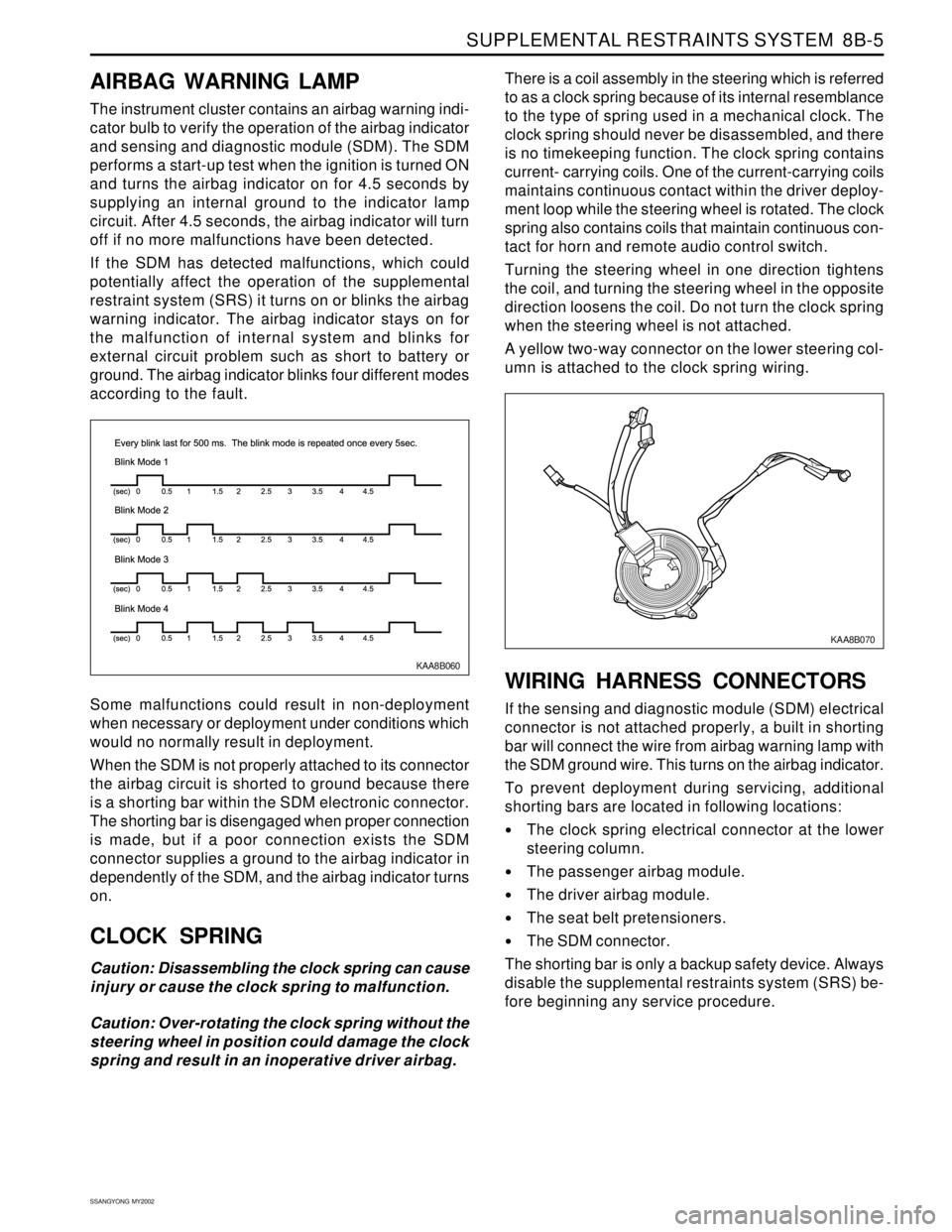

The instrument cluster contains an airbag warning indi-

cator bulb to verify the operation of the airbag indicator

and sensing and diagnostic module (SDM). The SDM

performs a start-up test when the ignition is turned ON

and turns the airbag indicator on for 4.5 seconds by

supplying an internal ground to the indicator lamp

circuit. After 4.5 seconds, the airbag indicator will turn

off if no more malfunctions have been detected.

If the SDM has detected malfunctions, which could

potentially affect the operation of the supplemental

restraint system (SRS) it turns on or blinks the airbag

warning indicator. The airbag indicator stays on for

the malfunction of internal system and blinks for

external circuit problem such as short to battery or

ground. The airbag indicator blinks four different modes

according to the fault.

Some malfunctions could result in non-deployment

when necessary or deployment under conditions which

would no normally result in deployment.

When the SDM is not properly attached to its connector

the airbag circuit is shorted to ground because there

is a shorting bar within the SDM electronic connector.

The shorting bar is disengaged when proper connection

is made, but if a poor connection exists the SDM

connector supplies a ground to the airbag indicator in

dependently of the SDM, and the airbag indicator turns

on.

CLOCK SPRING

Caution: Disassembling the clock spring can cause

injury or cause the clock spring to malfunction.

Caution: Over-rotating the clock spring without the

steering wheel in position could damage the clock

spring and result in an inoperative driver airbag.There is a coil assembly in the steering which is referred

to as a clock spring because of its internal resemblance

to the type of spring used in a mechanical clock. The

clock spring should never be disassembled, and there

is no timekeeping function. The clock spring contains

current- carrying coils. One of the current-carrying coils

maintains continuous contact within the driver deploy-

ment loop while the steering wheel is rotated. The clock

spring also contains coils that maintain continuous con-

tact for horn and remote audio control switch.

Turning the steering wheel in one direction tightens

the coil, and turning the steering wheel in the opposite

direction loosens the coil. Do not turn the clock spring

when the steering wheel is not attached.

A yellow two-way connector on the lower steering col-

umn is attached to the clock spring wiring.

WIRING HARNESS CONNECTORS

If the sensing and diagnostic module (SDM) electrical

connector is not attached properly, a built in shorting

bar will connect the wire from airbag warning lamp with

the SDM ground wire. This turns on the airbag indicator.

To prevent deployment during servicing, additional

shorting bars are located in following locations:

The clock spring electrical connector at the lower

steering column.

The passenger airbag module.

The driver airbag module.

The seat belt pretensioners.

The SDM connector.

The shorting bar is only a backup safety device. Always

disable the supplemental restraints system (SRS) be-

fore beginning any service procedure.

KAA8B070

Page 1595 of 2053

SSANGYONG MY2002

8B-10 SUPPLEMENTAL RESTRAINTS SYSTEM

SRS DIAGNOSTIC SYSTEM CHECK

Notice: If the vehicle interior has been exposed to

extensive water intrusion such as water leaks, driving

through high water, flooding, or other caucuses, the

sensing and diagnostic module (SDM) and SDM

connector may be need to be replaced. With ignition

OFF, inspect the area around the SDM, including the

carpet. If any significant soaking or evidence of previous

soaking is detected, the water must be removed, water

damage repaired, and the SDM and SDM connector must

be replaced. Before attempting any of these repairs, the

supplemental restraint system (SRS) must be disabled.

Refer to “Disabling the SRS” and “Sensing and

Diagnostic Module (SDM)” in this section.

The SRS Diagnostic System Check must always be

the starting point for any SRS system diagnosis. The

SRS Diagnostic System Check reveals diagnostic

trouble codes (DTCs) through the use of scan tool.

The diagnostic procedures used in this section are

designed to find and repair SRS conditions. To get

the best results, it is important to use the diagnostic

charts and follow the sequence listed below.

1. Perform the SRS Diagnostic System Check, which

reveals diagnostic trouble codes (DTCs) through

the use of scan tool. It also checks for proper airbag

indicator operation.

2. Refer to the proper diagnostic chart as directed by

SRS Diagnostic System Check. Bypassing these

procedures may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts

replacement.3. Repeat the SRS Diagnostic System Check after any

repair or diagnostic procedures have been

performed to ensure that the repair has beenmade

correctly and that no other malfunction exists.

Circuit Description

When the ignitions witch is first turned to ON, ignition

voltage is supplied from airbag fuse to the SDM at

input terminal 5. The SDM responds by turning on the

airbag indicator for 4.5 seconds and then turning it off

while the SDM performs tests on the SRS system.

Diagnostic Aids

The order in which DTCs are diagnosed is very

important. Failure to diagnose the DTCs in the order

specified may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts replacement.

Test Description

The numbers below refer to steps on the diagnostic

table.

2. This test differentiates between an indicator that

will not come on and an indicator that stays on when

it should be off.

3. Refer to the first caution below

5. This test, along with step 6, differentiates internal

or external faults of SDM.

9. Refer to the cautions below.

Page 1597 of 2053

SSANGYONG MY2002

8B-12 SUPPLEMENTAL RESTRAINTS SYSTEM

Sensing and Diagnostic Module (SDM) Integrity Check

Caution: The sensing and diagnosis module (SDM)

can maintain sufficient voltage to deploy the airbags

and pretensioners for 0.15 seconds after the ignition

is OFF and the fuse has been removed. If the airbags

or pretensioners are not disconnected, do not begin

service until one minute has passed after

disconnecting power to the SDM. Otherwise, injury

could result.Caution: During service procedure, be very careful

when handling the SDM. Never strike or jar the SDM.

Never power the supplemental restraints system

(SRS) when the SDM is not rigidly attached to the

vehicle. Also SDM mounting nuts must be carefully

tightened to ensure proper operation of the SRS

operation. The SDM could be activated if it is

powered when it is not rigidly attached to the

vehicle, resulting in unexpected deployment and

possible injury.

Yes

Chear the SRS

DTCs and go

to “Diagnostic

system Check”

Go to Step 3No

Go to Step 2

Go to table for

the DTC

indicated Value

-

-

Step

1

2Action

1. Turn the ignition to LOCK and remove the key.

2. Connect all SRS components, and ensure that all

components are properly mounted.

3. Ensure that the ignition switch has been off for at least

30 seconds.

4. Observe the airbag indicator as the ignition is turned

ON.

Does the indicator lamp turn on for 4.5 seconds and then

turn off?

1. Turn the ignition to LOCK and remove the key.

2. Connect the scan tool to DLC. Follow the directions

given in the scan tool manual.

3. Turn the ignition to ON.

4. Request SRS DTC display with the scan tool.

Is the same DTC displayed that was previously occurring

when the SRS Diagnostic System Check was previously

performed?

SENSING AND DIAGNOSTIC MODULE (SDM) INTEGRITY CHECK

The following diagnostic chart must be used when all

circuitry outside the sensing and diagnostic module

(SDM) has been found to operate properly, as indicated

by following the appropriate diagnostic trouble code

(DTC) chart. The chart verifies the need for SDM

replacement.

Circuit Description

When the SDM recognizes ignition voltage greater then

9 volts at terminal 5 of the SDM, the airbag indicator is

turns on for 4.5 seconds to verify operation. At this

time the SDM performs start-up tests followed by

resistance measurement tests and continues

monitoring tests. When malfunction is detected, the

SDM sets a current DTC and illuminates or blinks the

airbag indicator. When the malfunction is no longer

detected and/or the ignition switch is cycled, the SDM

will clear current DTCs and move them to a history file,

except for the DTCs 18, 24, 51, 53 and sometimes 71.

DTCs 18, 24, 51 and 53 will not clear using a scan tool

because these codes require replacement of SDM. The

SDM must be replaced only after the malfunction that

set the DTC has been repaired.Diagnostic Aids

The order in which DTCs are diagnosed is very

important. Failure to diagnose the DTCs in the order

specified may result in extended diagnostic time,

incorrect diagnosis, and incorrect parts replacement.

Test Description

The numbers below refer to steps on the diagnostic

table.

1. This test confirms a current malfunction. If no current

malefaction is occurring, refer to “Diagnostic Aids”

for the appropriate DTC. The SDM should not be

replaced for a historic DTC except when directed.

2. This test checks for a malfunction introduced into

the supplemental restraints system (SRS) during

the diagnostic procedure. It is extremely unlikely

that a malfunctioning SDM would cause a new

malfunction to occur during the diagnostic process.

4. See the caution below.