SSANGYONG KORANDO 1997 Service Repair Manual

KORANDO 1997

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57502/w960_57502-0.png

SSANGYONG KORANDO 1997 Service Repair Manual

Page 570 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 21

D AEW OO M Y_2000

POLY V-- BELT

1 Nut 23N∙m (17 lb-ft) .......................

2 Tensioning Lever

3Bolt4Spring

5 Tensioning Lever

6PolyV--Belt

Page 571 of 2053

1B3 -- 22 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the nut.

2. Push the tensioning lever in direction of arrow with a

rod (F12’ 180mm) and pull out the bolt to the rear.

3. Push back the tensioning lever (arrow direction) to

release the spring tension and remove the belt.

4. Install the poly V-- belt beginning at the tensioning

pulley (7).

7 Tensioning Pulley

8 Crankshaft

9 Generator

10 Water Pump

11 Guide Pulley

12 Power Steering Pump

13 Aircon. Compressor

Length of Belt

Length (L)With Air Conditioner2,100 mm

Length (L)Without Air Conditioner2,040 mm

Page 572 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 23

D AEW OO M Y_2000

TENSIONING DEVICE

Preceding Work : Removal of cooling fan

1 Bolt 21N∙m (15 lb-ft) ......................

2 Damper

3 Nut 21N∙m (15 lb-ft) .......................

4 Tensioning Lever

5 Guide Rail Pin

6Bolt

7PolyV--Belt

8 Belt Pulley

9 Bolt 10N∙m (89 lb-in) .....................10 Tensioning Pulley

11 Socket Bolt 29N∙m (21 lb-ft) ................

12 Closing Cover

13 Washer

14 Tensioning Lever

15 Fit Bolt 100N∙m (74 lb-ft) ...................

16 Closing Cover

17 Spring

18 Bolt 20N∙m (15 lb-ft) ......................

Page 573 of 2053

1B3 -- 24 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Removal & Installation Procedure

1. Remove the nut.

Installation Notice

Tightening Torque10 N∙m(89lb-in)

2. Push the tensioning lever in direction of arrow with a

rod (F12’ 180mm) and push out the bolt to the rear.

3. Push back the tensioning lever to release the spring

tension and remove the belt.

4. Remove the bolt (9) and then remove the belt pulley

(8).

5. Remove the bolt (1, 18) and take off the damper (2).

Notice

Pay attention to installation position of the damper.

Page 574 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 25

D AEW OO M Y_2000

6. Pull off the tensioning lever (4) from guide rail pin.

7. Remove the spring (17).

Installation Notice

Insert spring (17) with color coding (blue/violet) fac-

ing up.

8. Pry off the closing cover (12) and remove the socket

bolt (11) and then remove the tensioning pulley (10).

Installation Notice

Tightening Torque29 N∙m (21 lb-ft)

9. Pry off the closing cover (16) and remove the fit bolt

(15).

10. Remove the tensioning lever (14) and washer (13).

11. Clean thread in the timing case cover and fit bolt.

Installation Notice

Apply Loctite on thread of fit bolt.

Tightening Torque100 N∙m (74 lb-ft)

12. Installation should follow the removal procedure in

the reverse order.

Page 575 of 2053

1B3 -- 26 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

POLY V-- BELT ALIGNMENT & INSPECTION

Without Air Conditioner

With Air Conditioner

Page 576 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 27

D AEW OO M Y_2000

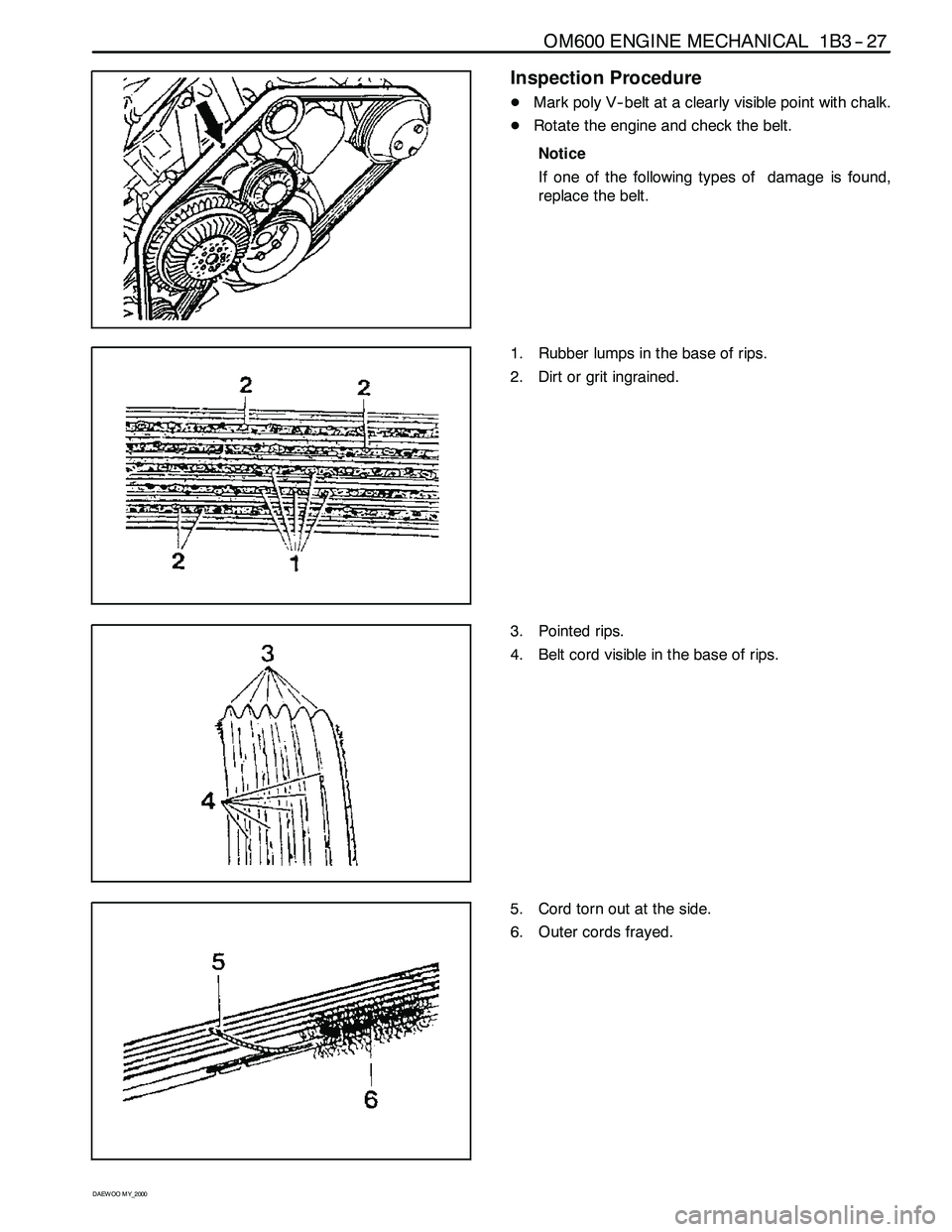

Inspection Procedure

DMark poly V-- belt at a clearly visible point with chalk.

DRotate the engine and check the belt.

Notice

If one of the following types of damage is found,

replace the belt.

1. Rubber lumps in the base of rips.

2. Dirt or grit ingrained.

3. Pointed rips.

4. Belt cord visible in the base of rips.

5. Cord torn out at the side.

6. Outer cords frayed.

Page 577 of 2053

1B3 -- 28 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

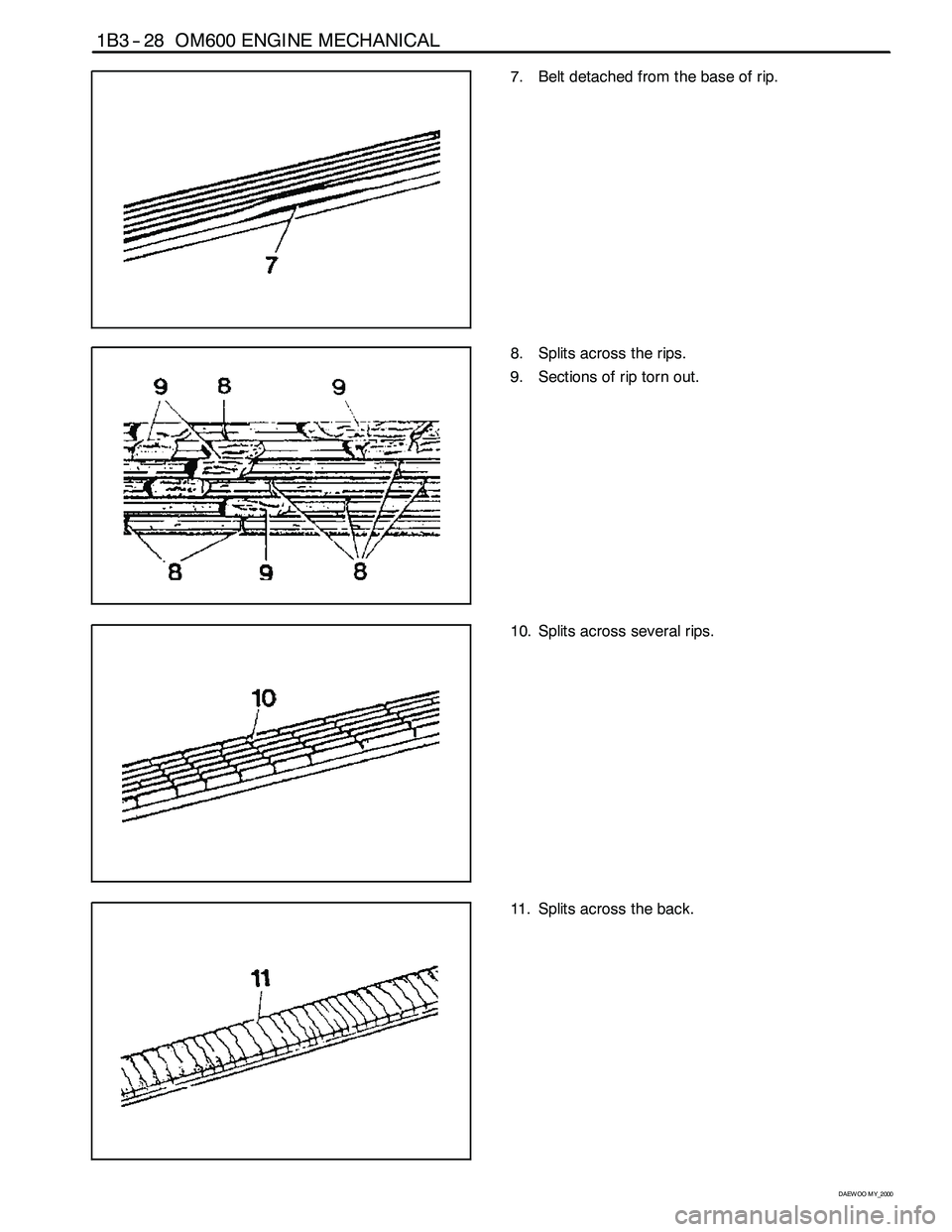

7. Belt detached from the base of rip.

8. Splits across the rips.

9. Sections of rip torn out.

10. Splits across several rips.

11. Splits across the back.

Page 578 of 2053

OM600 ENGINE MECHANICAL 1B3 -- 29

D AEW OO M Y_2000

PRECHAMBER

Preceding Work : Removal of glow plug

Removal of fuel injection nozzle

1 Threaded Ring 130 N∙m (96 lb-ft) ...........

2 Prechamber3 Cylinder Head

Page 579 of 2053

1B3 -- 30 OM600 ENGINE MECHANICAL

D AEW OO M Y_2000

Tools Required

603 589 00 09 00 Serration Wrench

667589036300 SlidingHammer

Removal & Installation Procedure

1. Using the serration wrench (4), remove the threaded

ring (1).

Serration Wrench 603 589 00 09 00

2. Install the sliding hammer into the prechamber.

Sliding Hammer 667 589 03 63 00

3. Remove the perchamber (2).

Notice

After removing the prechamber, cover over the

bores with clean rag.

4. Inspect the prechamber.

Notice

If the prechamber seats in the cylinder head are

leaking or if the prechambers are replaced, the seal-

ing surfaces in the cylinder head must be rema-

chined.