remote control SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1317 of 2053

MANUAL TRANSMISSION 5B-9

SSANGYONG MY2002

SEMI-REMOTE KIT DISASSEMBLY AND ASSEMBLY

YAD5B110

1 Remote Shift

2 Shift Lever

3 Shift Inner Boot

4 Lining Shift Socket

5 Control Housing Arm Insulator

6 Control Housing Arm

7 Bushing

8 Shift Rod Link

9 Washer

10 Clip

11 Shift Rod Pin

12 Cover Assembly

13 Shift Tower Cover14 Bolt

15 Breather Hose Bar

16 Control Shift Spring

17 Offset Control Lever

18 Retainer Ring

19 Pin

20 Shift Rail

21 Grove Pin

22 Pin & Clip

23 Joint Assembly

24 Joint Housing

25 Bushing

Page 1320 of 2053

SSANGYONG MY2002

5B-12 MANUAL TRANSMISSION

1 Remote Shift

2 Shift Lever

3 Shift Inner Boot

4 Lining Shift Socket

5 Control Housing Arm Insulator

6 Control Housing Arm

7 Bushing

8 Shift Rod Link

9 Washer

10 Clip

11 Shift Rod Pin

12 Cover Assembly

13 Shift Tower Cover

14 Bolt

15 Bleeder Hose Barb

16 Control Shift Spring

17 Offset Control Lever

18 Retainer Ring

19 Pin

20 Shift Rail

21 Groove Pin

22 Pin and Clip

23 Joint Assembly

24 Joint Housing

25 Bushing

26 Bolt

27 Bolt

28 O-ring

29 Shaft Rail

30 Case Cover

31 Cap Plug

32 Insert

33 Selecter Plate

34 Selecter Arm

35 Inlockter Plate

36 Selecter Arm Pin

37 Selecter Plate

38 Insert

39 Shift Fork

40 Output Shaft

41 Retainer Ring

42 Washer

43 Inner Corn

44 Outer-Race

45 1-2nd Blocking-Ring

46 Output Shaft Assembly

47 Insert

48 Ball

49 Spring

50 Reverse Sliding Gear

51 1-2nd Blocking-Ring

52 Outer Corn Race

53 Inner Corn

54 Sleeve Bearing

55 Sleeve

56 Needle Bearing

57 1st Speed Driven Gear58 Bearing Corn

59 Bearing Cup

60 Thrust Bearing

61 Thrust Race

62 Blocking-Ring

63 Spring

64 Insert

65 Synchronizer Sleeve

66 Spring

67 Blocking-Ring

68 Synchronizer

69 3rd Speed Gear

70 Needle Bearing

71 Spacer

72 Snap Ring

73 Washer

74 2nd Speed Gear

75 Needle Bearing

76 Spacer

77 Synchronizer Sleeve

78 Bearing

79 O-Ring

80 Bearing

81 Corn Bearing

82 Shaft Gear

83 Counter Shaft Gear

84 Corn Bearing

85 Roll Pin

86 Shift 5th Fork

87 Insert

88 Shift Rail

89 Reverse Fork

90 Spring

91 Retainer Ring

92 Shift Lever

93 5th Speed Driven Gear

94 Snap Ring

95 Bearing Cap

96 Shim

97 Rear Retainer

98 Bolt

99 5th Speed Driven Gear

100 Blocking 5th-Ring

101 Hub Bearing

102 Insert

103 Sleeve

104 Spring

105 Spring

106 Synchronizer

107 5th Synchronizer Retainer

108 Snap Ring

109 Oil Ring Funnel

110 Roll Pin

111 Reverse Idler Shaft

112 Reverse Idler Gear

113 O-Ring

114 Cross member Mounting Hole

Page 1322 of 2053

SSANGYONG MY2002

5B-14 MANUAL TRANSMISSION

ON-VEHICLE SERVICE

SEMI-REMOTE KIT

Removal Procedure

1. Remove the control housing arm insulator from the

semi-remote kit.

YAD5B120

YAD5B140

YAD5B130

2. Remove two snap rings and two screws using the

snap ring plier.

Notice: Do not reuse the damaged snap ring.

3. Disconnect the shift rod pin using the punch.

MAINTENANCE AND REPAIR

Page 1323 of 2053

MANUAL TRANSMISSION 5B-15

SSANGYONG MY2002

6. Push down the socket lining’s wing from the

control housing arm and disconnect the socket

lining and shift lever from the semi-remote kit.

YAD5B160

YAD5B170

YAD5B180

7. Remove the control housing arm by rotating the

clip pin.

8. Remove the retainer-ring from the U-joint assembly

using the snap ring plier.

YAD5B150

4. Remove the shift rod link from the semi-remote

kit.

5. Remove four metal bushing from the shift rod.

Page 1326 of 2053

SSANGYONG MY2002

5B-18 MANUAL TRANSMISSION

8. Insert the washer and assemble the snap ring.

YAD5B130

YAD5B260

9. Insert the control housing arm insulator to the semi-

remote kit.

YAD5B250

7. Assemble the shift rod, the shift rail and U-joint

using the pin.

Page 1590 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-5

SSANGYONG MY2002

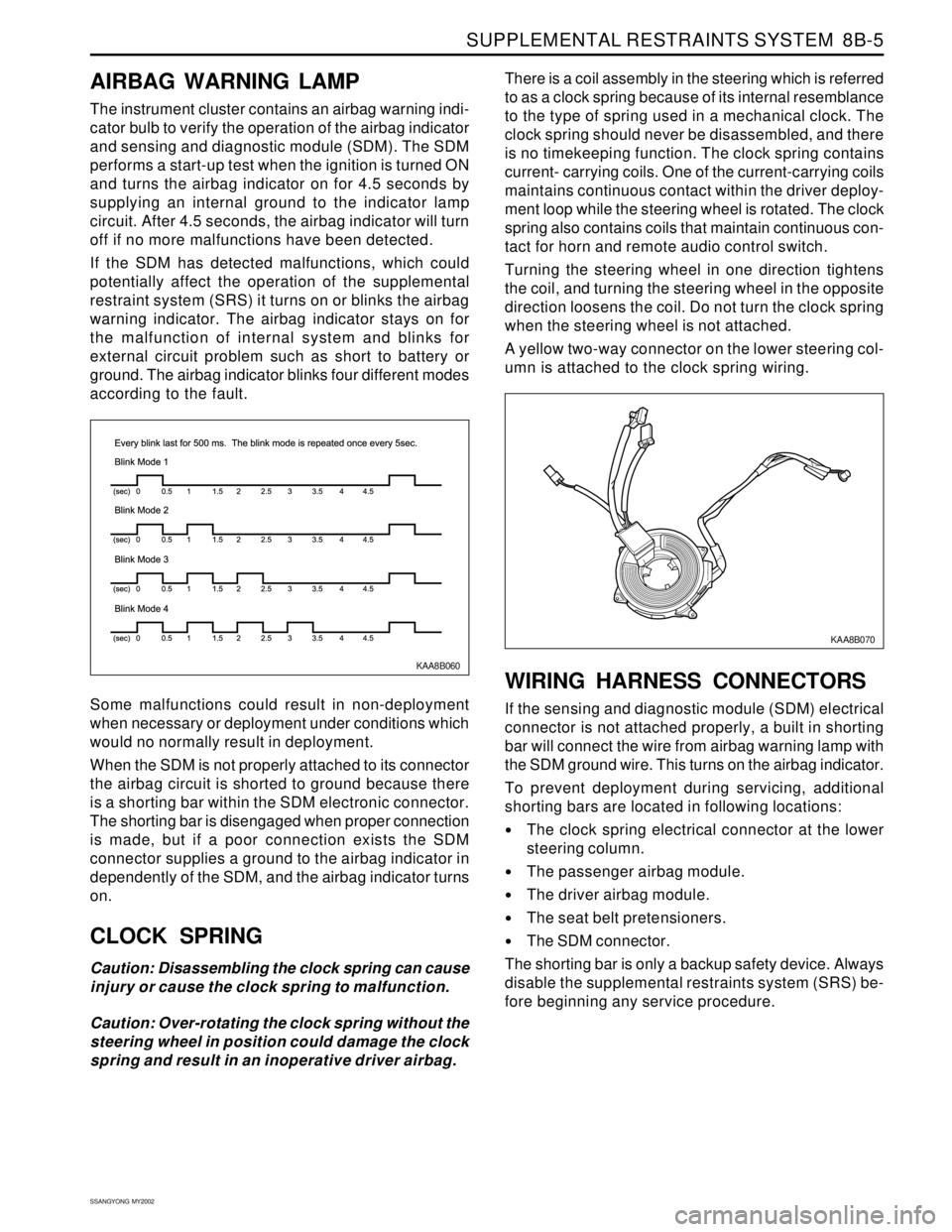

KAA8B060

AIRBAG WARNING LAMP

The instrument cluster contains an airbag warning indi-

cator bulb to verify the operation of the airbag indicator

and sensing and diagnostic module (SDM). The SDM

performs a start-up test when the ignition is turned ON

and turns the airbag indicator on for 4.5 seconds by

supplying an internal ground to the indicator lamp

circuit. After 4.5 seconds, the airbag indicator will turn

off if no more malfunctions have been detected.

If the SDM has detected malfunctions, which could

potentially affect the operation of the supplemental

restraint system (SRS) it turns on or blinks the airbag

warning indicator. The airbag indicator stays on for

the malfunction of internal system and blinks for

external circuit problem such as short to battery or

ground. The airbag indicator blinks four different modes

according to the fault.

Some malfunctions could result in non-deployment

when necessary or deployment under conditions which

would no normally result in deployment.

When the SDM is not properly attached to its connector

the airbag circuit is shorted to ground because there

is a shorting bar within the SDM electronic connector.

The shorting bar is disengaged when proper connection

is made, but if a poor connection exists the SDM

connector supplies a ground to the airbag indicator in

dependently of the SDM, and the airbag indicator turns

on.

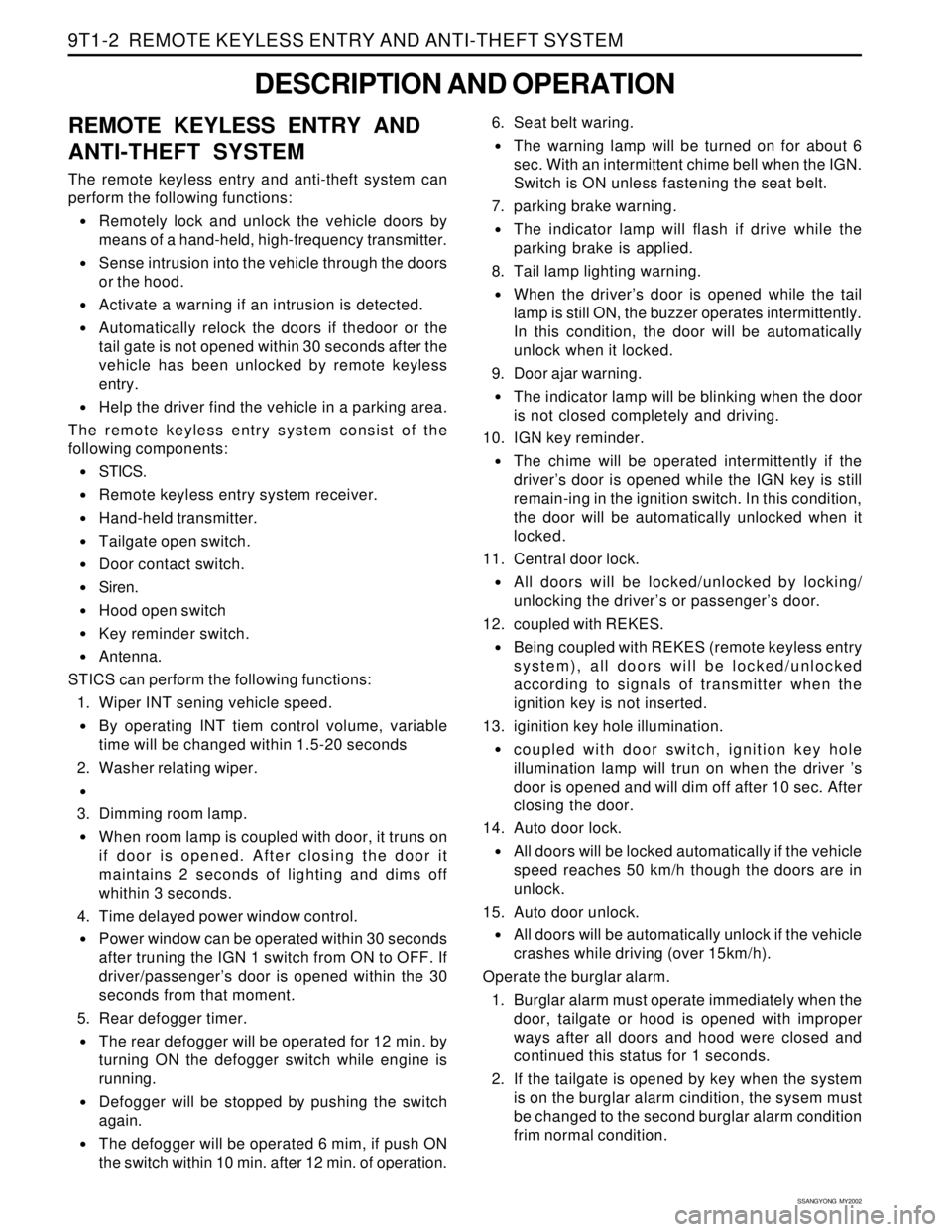

CLOCK SPRING

Caution: Disassembling the clock spring can cause

injury or cause the clock spring to malfunction.

Caution: Over-rotating the clock spring without the

steering wheel in position could damage the clock

spring and result in an inoperative driver airbag.There is a coil assembly in the steering which is referred

to as a clock spring because of its internal resemblance

to the type of spring used in a mechanical clock. The

clock spring should never be disassembled, and there

is no timekeeping function. The clock spring contains

current- carrying coils. One of the current-carrying coils

maintains continuous contact within the driver deploy-

ment loop while the steering wheel is rotated. The clock

spring also contains coils that maintain continuous con-

tact for horn and remote audio control switch.

Turning the steering wheel in one direction tightens

the coil, and turning the steering wheel in the opposite

direction loosens the coil. Do not turn the clock spring

when the steering wheel is not attached.

A yellow two-way connector on the lower steering col-

umn is attached to the clock spring wiring.

WIRING HARNESS CONNECTORS

If the sensing and diagnostic module (SDM) electrical

connector is not attached properly, a built in shorting

bar will connect the wire from airbag warning lamp with

the SDM ground wire. This turns on the airbag indicator.

To prevent deployment during servicing, additional

shorting bars are located in following locations:

The clock spring electrical connector at the lower

steering column.

The passenger airbag module.

The driver airbag module.

The seat belt pretensioners.

The SDM connector.

The shorting bar is only a backup safety device. Always

disable the supplemental restraints system (SRS) be-

fore beginning any service procedure.

KAA8B070

Page 1643 of 2053

SUPPLEMENTAL RESTRAINTS SYSTEM 8B-61

SSANGYONG MY2002

KAA8B050

CLOCK SPRING

Removal and installation Procedure

Caution: The SDM can maintain sufficient voltage

to deploy the airbags for 0.15 seconds after the

Ignition is OFF and the airbag fuse has been

removed. If the airbags are not disconnected, service

cannot begin until one minute has passed after

disconnecting power to the SDM. If the airbags are

disconnected, service can begin immediately

without waiting for one-minute time period to

expire. Failure to temporarily disable the SRS

during service result in unexpected deployment,

personal injury, and otherwise unneeded SRS repair.

1. Disconnect the negative battery cable.

2. Remove the driver airbag module. Refer to “Driver

Airbag Module” in this section.

3. Remove the steering wheel. Refer to Section 6E,

Steering Wheel and Column.

4. Remove the steering column cover. Refer to

Section 6E, Steering Wheel and Column.

5. Carefully full the instrument panel lower cover.

6. Remove driver side knee bolster.

7. Disconnect the clock spring, horn and remote

audio control connectors at the lower steering

column.

8. Remove the screws and the clock spring from the

steering shaft.

Installation Notice

Turning the clock spring more than three turns

clockwise or counterclockwise can damage the

spring.

Align the clock spring before installation. Turn

the lobe of the clock spring clockwise to lock

but do not force. Then turn the lobe of clock

spring count clockwise approximately three

turns to the neutral position, with the front of

the wheels straight ahead. Properly align the

pointed marks on the components of the clock

spring.

9. Installation should follow the removal procedure

in the reverse order.

Caution: If the clock spring is not properly

aligned, the steering wheel may not be able to

rotate completely during a turn. Restricted

turning ability can cause the vehicle to crash.

Improper alignment of the clock spring also may

make the supplemental restraint system (SRS)

inoperative, preventing the airbag from

deploying during crash. Both of the out comes

can result in injury.

Tightening Torque 4 Nm (35 lb-in)

Page 1784 of 2053

SSANGYONG MY2002

9L-2 GLASS AND MIRRORS

DESCRIPTION AND OPERATION

STATIONARY GLASS

Stationary glass consists of all the glass on the vehicle

which is immovable within its frame, such as the wind

shield glass, the back glass, the quarter window, and

the inside rearview mirror.

INSIDE REARVIEW MIRROR

The inside rearview mirror can be manually adjusted

up/down, and left/right.

OUTSIDE REARVIEW MIRRORS

The outside rearview mirrors are equipped with a remote

control mirror. The electric control outside rearviewmirror

can be adjusted by an electric control switch on the

instrument panel

Page 1849 of 2053

SSANGYONG MY2002

9T1-2 REMOTE KEYLESS ENTRY AND ANTI-THEFT SYSTEM

DESCRIPTION AND OPERATION

REMOTE KEYLESS ENTRY AND

ANTI-THEFT SYSTEM

The remote keyless entry and anti-theft system can

perform the following functions:

•Remotely lock and unlock the vehicle doors by

means of a hand-held, high-frequency transmitter.

Sense intrusion into the vehicle through the doors

or the hood.

Activate a warning if an intrusion is detected.

Automatically relock the doors if thedoor or the

tail gate is not opened within 30 seconds after the

vehicle has been unlocked by remote keyless

entry.

Help the driver find the vehicle in a parking area.

The remote keyless entry system consist of the

following components:

STICS.

Remote keyless entry system receiver.

Hand-held transmitter.

Tailgate open switch.

Door contact switch.

Siren.

Hood open switch

Key reminder switch.

Antenna.

STICS can perform the following functions:

1. Wiper INT sening vehicle speed.

By operating INT tiem control volume, variable

time will be changed within 1.5-20 seconds

2. Washer relating wiper.

3. Dimming room lamp.

When room lamp is coupled with door, it truns on

if door is opened. After closing the door it

maintains 2 seconds of lighting and dims off

whithin 3 seconds.

4. Time delayed power window control.

Power window can be operated within 30 seconds

after truning the IGN 1 switch from ON to OFF. If

driver/passenger’s door is opened within the 30

seconds from that moment.

5. Rear defogger timer.

The rear defogger will be operated for 12 min. by

turning ON the defogger switch while engine is

running.

Defogger will be stopped by pushing the switch

again.

The defogger will be operated 6 mim, if push ON

the switch within 10 min. after 12 min. of operation.6. Seat belt waring.

The warning lamp will be turned on for about 6

sec. With an intermittent chime bell when the IGN.

Switch is ON unless fastening the seat belt.

7. parking brake warning.

The indicator lamp will flash if drive while the

parking brake is applied.

8. Tail lamp lighting warning.

When the driver’s door is opened while the tail

lamp is still ON, the buzzer operates intermittently.

In this condition, the door will be automatically

unlock when it locked.

9. Door ajar warning.

The indicator lamp will be blinking when the door

is not closed completely and driving.

10. IGN key reminder.

The chime will be operated intermittently if the

driver’s door is opened while the IGN key is still

remain-ing in the ignition switch. In this condition,

the door will be automatically unlocked when it

locked.

11. Central door lock.

All doors will be locked/unlocked by locking/

unlocking the driver’s or passenger’s door.

12. coupled with REKES.

Being coupled with REKES (remote keyless entry

system), all doors will be locked/unlocked

according to signals of transmitter when the

ignition key is not inserted.

13. iginition key hole illumination.

coupled with door switch, ignition key hole

illumination lamp will trun on when the driver ’s

door is opened and will dim off after 10 sec. After

closing the door.

14. Auto door lock.

All doors will be locked automatically if the vehicle

speed reaches 50 km/h though the doors are in

unlock.

15. Auto door unlock.

All doors will be automatically unlock if the vehicle

crashes while driving (over 15km/h).

Operate the burglar alarm.

1. Burglar alarm must operate immediately when the

door, tailgate or hood is opened with improper

ways after all doors and hood were closed and

continued this status for 1 seconds.

2. If the tailgate is opened by key when the system

is on the burglar alarm cindition, the sysem must

be changed to the second burglar alarm condition

frim normal condition.

Page 1858 of 2053

SSANGYONG MY2002

9T2-2 IMMOBILIZER SYSTEM

DESCRIPTION AND OPERATION

Immobilizer is a device disabling vehicle ignition unless

a speific key is used and designed to help prevent

vehicle theft.

Immobilizer is comprised of two devices, a key with

encoded transponder and engine control unit (ECU)

with the same encoding of the transponder. When a

key is inserted into the key hole to start vehicle and

turned to ‘ON’, the ECU reads and decodes the

transponder code and, if the same, starts the engine,

it is called immobilizer. It means immobilizer system

disables starting by stopping fuel supply if the code

in the transponder does not match the code stored in

ECU each other.

Notice:

If vehicle is equipped with immobilizer system and

the engine cranks normally but not start, check

immobilizer system first rather than ignition and

other electrical systems because it can be

disabled fuel supply of injectors by ECU due to

defective immobilizer system.

Programming of the immobilizer system will be

performed by authorized personnel only. If

following defective codes for immobilizer system

appear during diagnosis of vehicle with SCANNER,

ask immobilizer programming to authorized

personnel and actual programming should be

performed by authorized per-sonnel only.

Display of defectives relevant to immobilizer

system : SCANNER

1. No communication with transponder

2. No immobilizer programming

The transponder in the key can be damaged by

shocks of dropping or hitting other objectives, so

handle it with care.

Each supplied key has programming of code on

its own. Accordingly if ECU needs to be replaced,

replace the transponder in the key.

The vehicle equipped with immobilizer system will

never be started with remote ignition device, so

do not attempt to install it.

The immobilizer system will never be removed from

the vehicle. So never attempt to remove it to install

a remote ignition device or others.

If engine does not start during service, use every

key to start the engine and then check immobilizer

sys-tem finally.

Cases that requires immobilizer

programming

1. Replacement ECU

In this case, replace the every transponder of the

key at once.

2. Replacement of the transponder

3. Additional key for lost 1 or 2 keys

1) Clear all codes for current keys from the ECU

2) When using current key : clear code of the trans-

ponder and re-program it

3) Additional (purchased) key : perform programming

4. When lost all keys

1) Clear all memorized key codes from the ECU

2) Replace the key and key set

3) Immobilizer programming