low oil pressure SSANGYONG KORANDO 1997 Service Workshop Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1536 of 2053

MANUAL & SEMIAUTO-HVAC 7C-7

SSANGYONG MY2002

DIAGNOSIS USING THE MANIFOLD GAUGE

On normal operation during the cooling cycle, the

manifold gauge must indicate approximately 1.5 - 2.0

kg/cm

2 at low pressure side and 14.5 - 15 kg/cm2 at

high pressure side, on condition that the temperature

at the cooler inlet, 30 ºC - 35 ºC, 2,000 rpm of the

engine rpm , full cold and maximum blower speed.

Cause Symptom

Action

1. High and low pressure are abnormally low.

2. Air at cooler outlet is not cold.

1. High and low pressure are abnormally high.

1. High and low pressure are abnormally high.

2. Connection at the low pressure is not cold.

There is a gas leak in the

cooling system.

Insufficient cooling and

faulty condenser cooling

by excessive

refrigerant.

Belt is slipped

There is an air in the

cooling system

Check the oil leak,

repair

Add the refrigerant

Keep the specified

amount of the

refrigerant, Clean the

condenser

Repair the belt

Clean and repair the

receiver-drier

Check the oil

contamination etc.

YAD7B070

YAD7B080

YAD7B100 YAD7B090

Page 1537 of 2053

SSANGYONG MY2002

7C-8 MANUAL & SEMIAUTO-HVAC

1. The low-pressure and high-pressure are exces-

sive high.

2. There are a lot of moistures in the connection

of the low-side pressure

Cause SymptomAction

1. The low-pressure side indicates excessive high

and high-pressure indicates excessive low.

2. There is a moisture in the connection of the re-

ceiver-drier and the front/back of the expan-

sion valve.

1. The low-side pressure is high or normal inter-

mittently.

The dust and moisture

etc. are frozen at the

expansion valve

A gas leak in the heat

reducer

The mixed moisture is

frozen at the expansion

valve

The faulty expansion

valve, the improper

installation of the heat

reducer

Fail to control the flow

rate

Repair the receiver-drier

Replace the expansion

valve for the faulty heat

reducer

Repair the receiver-drier

and perform the

bleeding

Repair the receiver-drier

Check the oil

contamination etc.

1. The low-pressure is excessive high and high-

pressure is excessive low.

There is an oil leak in

the compressorReplace the compressor

YAD7B110

YAD7B130 YAD7B120

YAD7B140

Page 1543 of 2053

SSANGYONG MY2002

7C-14 MANUAL & SEMIAUTO-HVAC

REFRIGERANT CHARGING

Installation of Manifold Gauge

1. Close both high/low pressure hand valves of

manifold gauge before installation of gauge to the

charging valve.

2. Both high/low pressure hand valves of manifold

gauge connect the appropriate charging valve.

Tighten the hose nuts by hand.

high pressure hand valve → high pressure

charging valve

low pressure hand valve → low pressure

charging valve

Discharging Refrigerant

1. Connect the manifold gauge to the charging valve.

2. Place the free end of the center hose in a shop

towel.

3. Slowly open the high pressure hand valve and

discharge refrigerant.

Notice: If refrigerant is allowed to escape too fast,

compressor oil will be drawn out of the system.

4. Check whether the shop towel gets wet in oil and

if wet, close the hand valve.

5. After the high pressure gauge reading drops below

3.5 kg/cm

2, slowly open the low pressure valve.

6. When both high and low pressure gauges reading

drops to 0 kg/cm

2, discharging is completed.

Evacuating Refrigeration System

Notice: The unit tank must contain a sufficient amount

of R-134a refrigerant for charging. Check the amount

of refrigerant in the tank. If there is less than 3.6 kg

(8 pounds) of refrigerant, add new refrigerant to the

tank.

1. Verify that the high-side and the low-side hoses

are connected to the A/C system. Open both the

high-side and the low-side valves on the unit’s

control panel.

2. Open both the gas and the liquid valves on the

tank.

YAD7B150

YAD7B160

YAD7B170

MAINTENANCE AND REPAIR

Page 1544 of 2053

MANUAL & SEMIAUTO-HVAC 7C-15

SSANGYONG MY2002

Important: Refer to the manufacturer’s

instructions for the charging station in use. It is

necessary to evacuate the system before

recharging it with new or recycled refrigerant.

3. Start the vacuum pump and begin the evacuation

process. Non-condensable gases (mostly air) are

vented from the tank automatically during the

recycling process. The pressure being released

may be heard.

4. Check for leaks in the system. Refer to the

manufacturer’s instructions for the charging

station in use.

Important: Change the vacuum pump oil

frequently. Refer to the manufacturer’s

instructions for the charging station in use.

Check for Refrigerant Leaks

1. Connect the center hose of the gauge to the

refrigerant tank.

2. Open the high pressure valve of the gauge to

charge with refrigerant gas.

3. Charge until the low pressure gauge reads 1.0 kg/cm

2

and close the valve.

4. Using a gas leak detector, check the system for

leaks.

5. If any leak is found, replace O-ring or repair the

faulty connection.

How to Use the Tap Valve

1. Rotate the handle counterclockwise fully before

connecting the valve to the refrigerant tank.

2. Rotate the disk counterclockwise fully.

3. Connect the center hose to the valve fitting and

then rotate the disk clockwise fully by hand.

4. Rotate the handle clockwise to drill the sealed

hole.

5. Remove the hose nut securing the center fitting

of the manifold gauge and then tighten the nut

again in a few seconds.

YAD7B180

YAD7B190

YAD7B200

Page 1551 of 2053

SSANGYONG MY2002

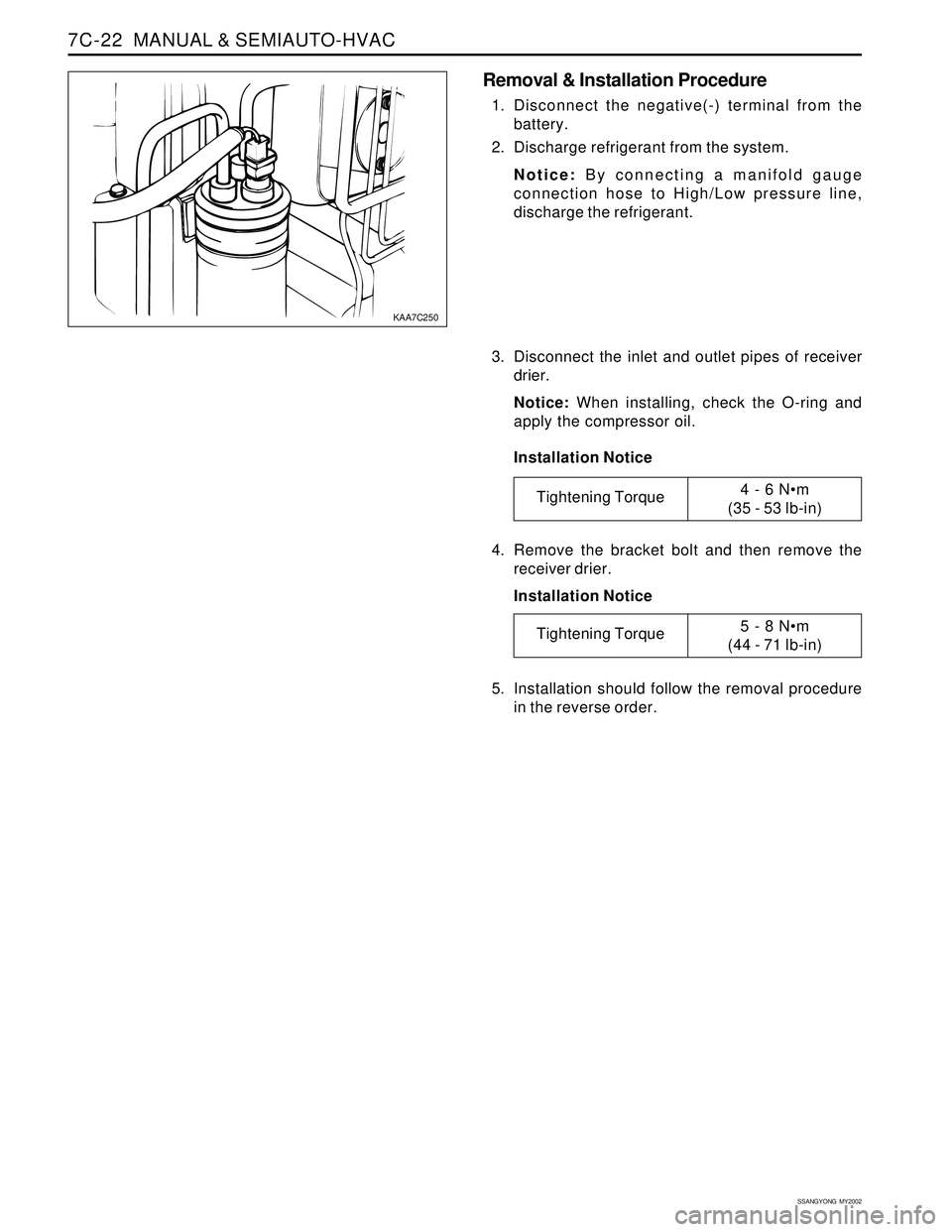

7C-22 MANUAL & SEMIAUTO-HVAC

3. Disconnect the inlet and outlet pipes of receiver

drier.

Notice: When installing, check the O-ring and

apply the compressor oil.

Installation Notice

4. Remove the bracket bolt and then remove the

receiver drier.

Installation Notice

5. Installation should follow the removal procedure

in the reverse order.

KAA7C250

Removal & Installation Procedure

1. Disconnect the negative(-) terminal from the

battery.

2. Discharge refrigerant from the system.

Notice: By connecting a manifold gauge

connection hose to High/Low pressure line,

discharge the refrigerant.

Tightening Torque4 - 6 Nm

(35 - 53 lb-in)

Tightening Torque5 - 8 Nm

(44 - 71 lb-in)

Page 1671 of 2053

SSANGYONG MY2002

9A-20 BODY WIRING SYSTEM

W/H ENGINE CONTROL (GASOLINE)

6 Crankshaft position sensor

7 Oil pressure switch

8 Knock sensor 2

9 Air flow sensor

10 Ignition coil 3

11 Ignition coil 2

12 Ignition coil 1

13 Injector 6

14 Injector 5

15 Injector 416 Injector 3

17 Injector 2

18 Injector 1

19 Camshaft actuator

20 Camshaft position sensor

21 Engine coolant temperature sensor (Gauge)

22 Engine temperature sensor

23 Throttle motor & sensor

24 Knock sensor 1

25 Intake manifold resonance flap

KAA9A150

Page 1876 of 2053

2-12 2-12 2-12 2-12

2-12

ELECTRICAL WIRING DIAGRAMS ELECTRICAL WIRING DIAGRAMSELECTRICAL WIRING DIAGRAMS ELECTRICAL WIRING DIAGRAMS

ELECTRICAL WIRING DIAGRAMS8) 8)8) 8)

8)

W/H ENGINE CONTROL (GASOLINE) W/H ENGINE CONTROL (GASOLINE)W/H ENGINE CONTROL (GASOLINE) W/H ENGINE CONTROL (GASOLINE)

W/H ENGINE CONTROL (GASOLINE)

1. C114

2. C115

3. J106

4. J107

5. J108

6. Crankshaft position sensor

7. Oil pressure switch

8. Knock sensor 2

9. Air flow sensor

10. Ignition coil 3

11. Ignition coil 2

12. Ignition coil 1

13. Injector 6

14. Injector 5

15. Injector 4

16. Injector 3

17. Injector 2

18. Injector 1

19. Camshaft actuator

20. Camshaft position sensor

21. Engine coolant temperature sensor (Gauge)

22. Engine temperature sensor

23. Throttle motor & sensor

24. Knock sensor 1

25. Intake manifold resonance flap

Page 1898 of 2053

1) VSS(VEHICLE SPEED SENSOR), METER(SPEEDO, TACHO) & GAUGE(FUEL, TEMPERATURE)

- GASOLINE ........................................................................................................................................................... 5-96

(1) W/O EURO III .................................................................................................................................................................................... 5-96

(2) W/ EURO III ....................................................................................................................................................................................... 5-98

2) WARNING LAMP(ENGINE CHECK, AIR BAG, EBD, ABS), TCS INDICATOR............................................. 5-100

3) INDICATOR(DEFROSTER, WINTER MODE, POWR MODE, 4WD LOW, 4WD HIGH, 4WD CHECK)..... 5-102

4) WARNING LAMP (SEAT BELT, DOOR OPEN, PARKING BRAKE), INDICATOR (BATTERY CHARGING,

GLOW).................................................................................................................................................................. 5-104

5) FRONT FOG LAMP, TURN SIGNAL, HAZARD, HIGH BEAM ......................................................................... 5-106

6) DIGITAL CLOCK,WARNING (OIL PRESSURE, LOW FUEL LEVEL) CLUSTER ILLUMINATION............... 5-108

7) SELECTOR LEVER POSITION LAMP (P,R,N,D,3,2,1).................................................................................... 5-110

19. 19.19. 19.

19.

STICS(SUPER STICS(SUPER STICS(SUPER STICS(SUPER

STICS(SUPER

TIME & ALARM INTEGRA TIME & ALARM INTEGRATIME & ALARM INTEGRA TIME & ALARM INTEGRA

TIME & ALARM INTEGRA

TED CONTR TED CONTRTED CONTR TED CONTR

TED CONTR

OL SYSTEM) OL SYSTEM)OL SYSTEM) OL SYSTEM)

OL SYSTEM)

................................ ................................................................ ................................

................................

5-112 5-112 5-112 5-112

5-112

1) STICS UNIT .......................................................................................................................................................... 5-112

2) FRONT WIPER CIRCUIT.................................................................................................................................... 5-114

3) CENTRAL DOOR LOCK SYSTEM ..................................................................................................................... 5-116

4) KEYLESS, KEY REMINDER SWITCH, SIREN, CHIME BELL BUZZER ........................................................ 5-118

5) DEFROSTER........................................................................................................................................................ 5-120

6) LAMP(ROOM, DOOR COURTESY LH/RH, LUGGAGE), DOOR CONTACT SWITCH .................................. 5-122

20. 20.20. 20.

20.

SEA SEASEA SEA

SEA

T HEA T HEAT HEA T HEA

T HEA

TER TERTER TER

TER

.......................................................................................................................... .................................................................................................................................................................................................................................................... ..........................................................................................................................

..........................................................................................................................

5-124 5-124 5-124 5-124

5-124

21. 21.21. 21.

21.

ST STST ST

ST

OP LAMP OP LAMPOP LAMP OP LAMP

OP LAMP

, ,, ,

,

BTSI (BRAKE BTSI (BRAKE BTSI (BRAKE BTSI (BRAKE

BTSI (BRAKE

TRANSMISSION SHIFT INTERLOCK) TRANSMISSION SHIFT INTERLOCK)TRANSMISSION SHIFT INTERLOCK) TRANSMISSION SHIFT INTERLOCK)

TRANSMISSION SHIFT INTERLOCK)

................................... ...................................................................... ...................................

...................................

5-126 5-126 5-126 5-126

5-126

1) METAL TOP .......................................................................................................................................................... 5-126

2) SOFT TOP............................................................................................................................................................ 5-128

22. 22.22. 22.

22.

POWER WINDOW POWER WINDOWPOWER WINDOW POWER WINDOW

POWER WINDOW

..................................................................................................................... .......................................................................................................................................................................................................................................... .....................................................................................................................

.....................................................................................................................

5-130 5-130 5-130 5-130

5-130

23. 23.23. 23.

23.

ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRRORELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR

ELECTRIC OSRV (OUTSIDE REAR VIEW) MIRROR

........................................................... ...................................................................................................................... ...........................................................

...........................................................

5-132 5-132 5-132 5-132

5-132

24. 24.24. 24.

24.

REAR REAR REAR REAR

REAR

WIPER & WIPER & WIPER & WIPER &

WIPER &

W WW W

W

ASHER ASHERASHER ASHER

ASHER

...................................................................................................... ............................................................................................................................................................................................................ ......................................................................................................

......................................................................................................

5-134 5-134 5-134 5-134

5-134

25. 25.25. 25.

25.

CIGARETTE LIGHTER, HORN CIGARETTE LIGHTER, HORNCIGARETTE LIGHTER, HORN CIGARETTE LIGHTER, HORN

CIGARETTE LIGHTER, HORN

................................................................................................ ................................................................................................................................................................................................ ................................................................................................

................................................................................................

5-136 5-136 5-136 5-136

5-136

26.HEAD LAMP 26.HEAD LAMP26.HEAD LAMP 26.HEAD LAMP

26.HEAD LAMP

.............................................................................................................................. ............................................................................................................................................................................................................................................................ ..............................................................................................................................

..............................................................................................................................

5-138 5-138 5-138 5-138

5-138

27. 27.27. 27.

27.

HEAD LAMP LEVELING DEVICE (HLLD) HEAD LAMP LEVELING DEVICE (HLLD)HEAD LAMP LEVELING DEVICE (HLLD) HEAD LAMP LEVELING DEVICE (HLLD)

HEAD LAMP LEVELING DEVICE (HLLD)

.............................................................................. ............................................................................................................................................................ ..............................................................................

..............................................................................

5-140 5-140 5-140 5-140

5-140

Page 2002 of 2053

5-108 5-108 5-108 5-108

5-108

ELECTRICAL WIRING DIAGRAMS ELECTRICAL WIRING DIAGRAMSELECTRICAL WIRING DIAGRAMS ELECTRICAL WIRING DIAGRAMS

ELECTRICAL WIRING DIAGRAMS6) 6)6) 6)

6)

DIGITAL CLOCK, WARNING (OIL PRESSURE, LOW FUEL LEVEL) DIGITAL CLOCK, WARNING (OIL PRESSURE, LOW FUEL LEVEL)DIGITAL CLOCK, WARNING (OIL PRESSURE, LOW FUEL LEVEL) DIGITAL CLOCK, WARNING (OIL PRESSURE, LOW FUEL LEVEL)

DIGITAL CLOCK, WARNING (OIL PRESSURE, LOW FUEL LEVEL)

CLUSTER ILLUMINATION CLUSTER ILLUMINATIONCLUSTER ILLUMINATION CLUSTER ILLUMINATION

CLUSTER ILLUMINATION

a. a.a. a.

a.

CONNECTOR INFORMATION CONNECTOR INFORMATIONCONNECTOR INFORMATION CONNECTOR INFORMATION

CONNECTOR INFORMATIONb. b.b. b.

b.

CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITIONCONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

CONNECTOR IDENTIFICATION SYMBOL & PIN NUMBER POSITION

CLUSTER "B"

CLUSTER "A"

CLUSTER "C" CLUSTER "D"

C115 (BLACK)

C206 (BLACK)C302 (BLACK)C303 (DSL)

(BLACK)C303 (GSL)

(BLACK)C303 (GSL:EURO III)

(BLACK)

S202 (BLACK)

S203 (COLORLESS) S204 (COLORLESS)

C101 (19Pin, White)

C104 (8Pin, Colorless)

C115 (40Pin, Black)

C206 (6Pin, Black)

C302 (10Pin, Black)

C303 (3Pin, Black)

C303 (4Pin, Black)

C303 (6Pin, Black)

S201 (8Pin, Colorless)

S202 (20Pin, Black)

S203 (14Pin, Colorless)

S204 (14Pin, Colorless)

J202

G201

G302CONNECTOR(NUMBER) CONNECTOR(NUMBER)CONNECTOR(NUMBER) CONNECTOR(NUMBER)

CONNECTOR(NUMBER)

CONNECTING. WIRING HARNESS CONNECTING. WIRING HARNESSCONNECTING. WIRING HARNESS CONNECTING. WIRING HARNESS

CONNECTING. WIRING HARNESS

CONNECTOR POSITION CONNECTOR POSITIONCONNECTOR POSITION CONNECTOR POSITION

CONNECTOR POSITION

Engine Room Fuse Box - W/H Main

Engine Room Fuse Box - W/H Main

W/H Engine Control - W/H ECM Main

W/H Engine Control - W/H ECM Main

W/H Main - W/H Transmission

W/H Main - W/H Fuel Pump

W/H Main - W/H Fuel Pump

W/H Main - W/H Fuel Pump

W/H Main

W/H Main

W/H Main

W/H Main

W/H Main

W/H Main

W/H MainEngine Room Fuse Box

Engine Room Fuse Box

Behind Hydraulic Unit

Lower "A" Piller (Upper ECM)

Below Center Console

Below Center Console

Below Center Console

Below Center Console

Upper Fuse Box (Passenger Room)

Behind Cluster

Behind 4WD Switch

Behind Audio

Behind Cluster

Upper Front Left Leg Room

Below Center Console

S201 (COLORLESS)