low oil pressure SSANGYONG KORANDO 1997 Service Owner's Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1108 of 2053

5A-14 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

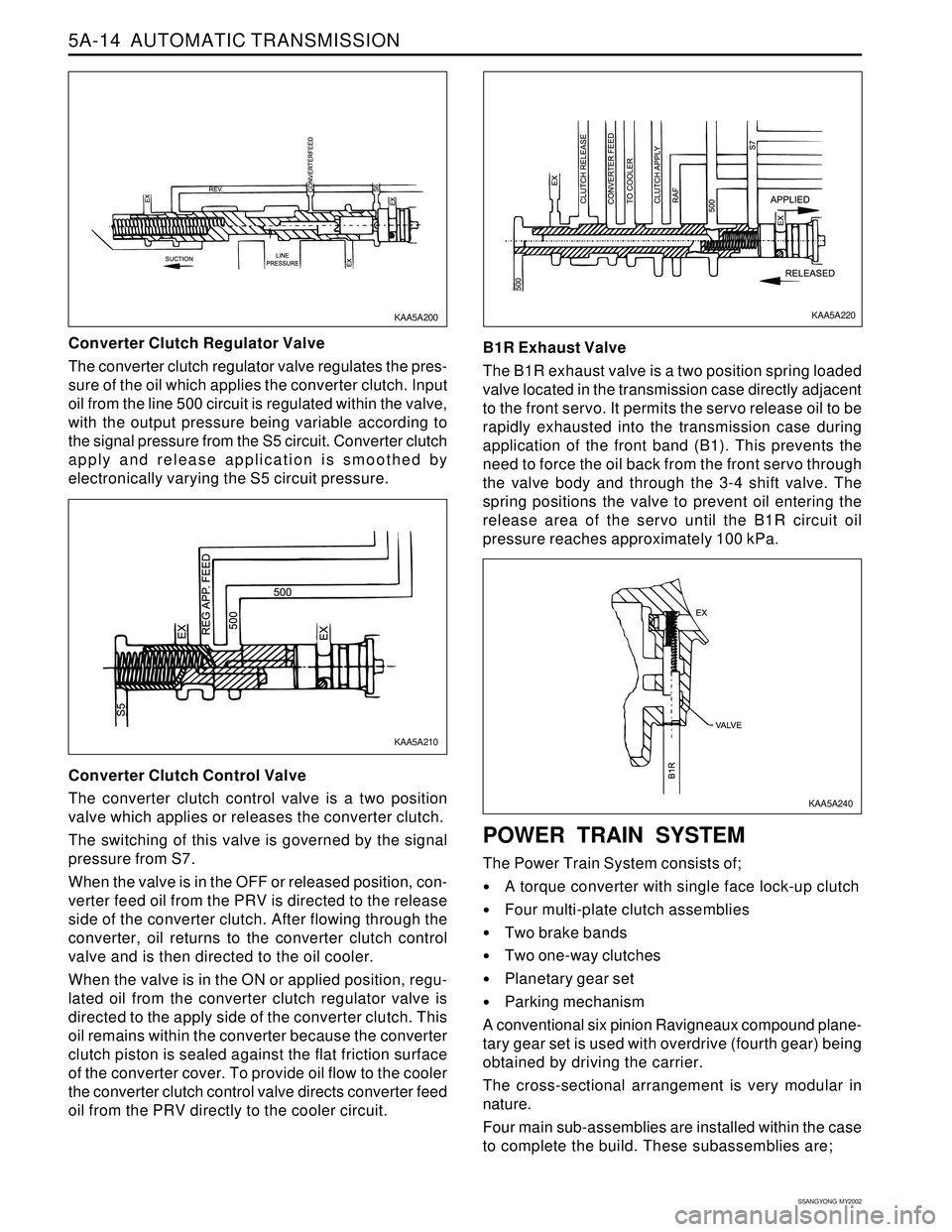

Converter Clutch Regulator Valve

The converter clutch regulator valve regulates the pres-

sure of the oil which applies the converter clutch. Input

oil from the line 500 circuit is regulated within the valve,

with the output pressure being variable according to

the signal pressure from the S5 circuit. Converter clutch

apply and release application is smoothed by

electronically varying the S5 circuit pressure.

Converter Clutch Control Valve

The converter clutch control valve is a two position

valve which applies or releases the converter clutch.

The switching of this valve is governed by the signal

pressure from S7.

When the valve is in the OFF or released position, con-

verter feed oil from the PRV is directed to the release

side of the converter clutch. After flowing through the

converter, oil returns to the converter clutch control

valve and is then directed to the oil cooler.

When the valve is in the ON or applied position, regu-

lated oil from the converter clutch regulator valve is

directed to the apply side of the converter clutch. This

oil remains within the converter because the converter

clutch piston is sealed against the flat friction surface

of the converter cover. To provide oil flow to the cooler

the converter clutch control valve directs converter feed

oil from the PRV directly to the cooler circuit.B1R Exhaust Valve

The B1R exhaust valve is a two position spring loaded

valve located in the transmission case directly adjacent

to the front servo. It permits the servo release oil to be

rapidly exhausted into the transmission case during

application of the front band (B1). This prevents the

need to force the oil back from the front servo through

the valve body and through the 3-4 shift valve. The

spring positions the valve to prevent oil entering the

release area of the servo until the B1R circuit oil

pressure reaches approximately 100 kPa.

POWER TRAIN SYSTEM

The Power Train System consists of;

A torque converter with single face lock-up clutch

Four multi-plate clutch assemblies

Two brake bands

Two one-way clutches

Planetary gear set

Parking mechanism

A conventional six pinion Ravigneaux compound plane-

tary gear set is used with overdrive (fourth gear) being

obtained by driving the carrier.

The cross-sectional arrangement is very modular in

nature.

Four main sub-assemblies are installed within the case

to complete the build. These subassemblies are;

KAA5A220KAA5A200

KAA5A210

KAA5A240

Page 1115 of 2053

AUTOMATIC TRANSMISSION 5A-21

SSANGYONG MY2002

Power Flow - Park and Neutral

In Park and Neutral, there is no drive to the planetary

gear set. The rear band is applied to eliminate ‘clunk’

on engagement of the reverse gear, and to improve

the low range engagement for 4WD applications. No

other clutches or bands are applied.

In Park the transmission is mechanically locked by

engaging a case mounted pawl with teeth on the output

shaft ring gear.

Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows:

Solenoids S1 and S2 are switched OFF.

Line (pump) pressure is applied to the Primary Regu-

lator Valve (PRV) and to the solenoid supply

pressure regulator valve.

The converter, oil cooler, and lubrication circuits are

charged from the primary regulator valve.

The line 500 circuit is charged by the solenoid

supply pressure regulator valve.

The S5 circuit is charged by the variable pressure

solenoid (S5).

Line pressure is prevented from entering the drive

circuit by the manual valve.

The B1 circuit and all clutch circuits are open to ex-

haust.

C1

-C2

-C3

-C4

-B1

-B2

X1-2

OWC

-3-4

OWC

-LU

CLUTCH

- Gear State

Park and Neutral

ELEMENTS ENGAGED

KAA5A320

Page 1117 of 2053

AUTOMATIC TRANSMISSION 5A-23

SSANGYONG MY2002

Power Flow - Reverse

In Reverse, transmission drive is via the input shaft

and the forward clutch cylinder to the hub of the C3

clutch. The elements of the transmission function as

follows;

The C3 clutch is engaged and drives the reverse

sun gear in a clock-wise direction.

The B2 band is engaged and holds the planetary

gear carrier stationary causing the long pinion to

rotate anti-clockwise about its axis on the pinion

shaft.

The long pinion drives the internal ring gear in the

same direction.

The internal ring being splined to the output shaft

drives it in an anti-clockwise or reverse direction.Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows;

Solenoids S1 and S2 are switched OFF.

Line pressure is directed through the reverse lockout

valve to both the inner and outer apply areas of the

rear servo piston for B2 band application.

Line pressure feeds the reverse oil circuit via the

manual valve.

Reverse oil is routed from the manual valve to the

C3 clutch.

Reverse oil is also applied to the spring end of the

primary regulator valve to assist the spring and to

boost the line pressure value.

All other clutch and band apply circuits are open to

exhaust.

C3

X

Gear State

ReverseC1

-C2

-C4

-B1

-B2

X1-2

OWC

-3-4

OWC

-LU

CLUTCH

- ELEMENTS ENGAGED

KAA5A340

Page 1119 of 2053

AUTOMATIC TRANSMISSION 5A-25

SSANGYONG MY2002

Power Flow - Manual 1

In Manual 1, transmission drive is via the input shaft

to the forward clutch cylinder. The elements of the

trans-mission function as follows;

The C2 clutch is engaged to drive the forward sun

gear, via the 3-4 OWC.

The B2 band is engaged to hold the planetary gear

carrier stationary.

The forward sun gear drives the short pinion anti-

clockwise.

The short pinion drives the long pinion clockwise.

The long pinion rotating about its axis drives the

inter-nal ring gear and the output shaft in a clockwise

or forward direction.

The C4 clutch provides engine braking through the

3-4 OWC on overrun.Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows;

Solenoids S1 and S2 are switched ON.

The 1-2, 2-3, and 3-4 shift valves are held in their

first gear positions by line 500 pressure.

Drive (line pressure) oil from the manual valve en-

gages the C2 clutch.

Lo-1st (line pressure) oil is routed through the 1-2

shift valve to the C4 clutch, and to the inner apply

area of the rear servo piston for B2 band application.

ELEMENTS ENGAGED

Gear State

Manual 1C1

-C2

XC3

-C4

XB1

-B2

X1-2

OWC

-3-4

OWC

XLU

CLUTCH

-

KAA5A360

Page 1121 of 2053

AUTOMATIC TRANSMISSION 5A-27

SSANGYONG MY2002

Power Flow - Drive 1

In Drive 1, transmission drive is via the input shaft to

the forward clutch cylinder. The elements of the

transmission function as follows :

The C2 clutch is engaged to drive the forward sun

gear via the 3-4 OWC.

The forward sun gear drives the short pinion anti-

clockwise.

The short pinion drives the long pinion clockwise.

The 1-2 OWC prevents the planetary gear carrier

from rotating under reaction force and the long pinion

rotates on its axis driving the internal ring gear and

output shaft in a clockwise or forward direction.

There is no engine braking on overrun.Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows:

Solenoids S1 and S2 are switched ON.

The 1-2, 2-3, and 3-4 shift valves are held in their

first gear positions by line 500 pressure.

Drive (line pressure) oil from the manual valve en-

gages the C2 clutch.

Gear State

Drive 1C1

-

C2

XC3

-C4

-B1

-B2

-1-2

OWC

X3-4

OWC

XLU

CLUTCH

- ELEMENTS ENGAGED

KAA5A380

Page 1123 of 2053

AUTOMATIC TRANSMISSION 5A-29

SSANGYONG MY2002

Power Flow - Drive 2 and Manual 2

In Drive 2 and Manual 2, transmission drive is via the

input shaft and forward clutch cylinder. The elements

of the transmission function as follows;

The C2 clutch is applied to drive the forward sun

gear.

The forward sun gear drives the short pinion anti-

clockwise.

The short pinion drives the long pinion clockwise.

The B1 band is applied holding the reverse sun

gear stationary therefore the long pinion walks

around the reverse sun gear taking the internal ring

gear and output shaft with it in a clockwise or

forward direction.

The C4 clutch is applied to bypass the 3-4 OWC

and provide engine braking on overrun.

Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows;

Solenoid S1 is switched OFF. S2 is switched ON.

Drive (line pressure) oil from the manual valve en-

gages the C2 clutch.

When S1 switches OFF, S1 oil pressure, which is

derived from line 500 pressure, moves the 3-4 shift

valve to the left. At the same time S1 oil is directed

to the 1-2 shift valve which moves the valve to the

second gear position.

2nd oil (line pressure) from the 1-2 shift valve is di-

rected to the band apply regulator valve, and to

the 2-3 shift valve.

The band apply feed regulator valve supplies 2nd

oil (regulated to line pressure multiplied by the valve

ratio) to the Band Apply Feed (BAF) circuit.

Band apply feed oil is directed to;

- The outer apply area of the front servo

- The 1-2 shift valve to provide an exhaust port

when the transmission is shifted to first gear

- The 3-4 shift valve for use when the transmission

is shifted into fourth gear

Drive (line pressure) is routed through the 3-4 shift

valve to apply the C4 clutch.

Gear State

Drive 2 and Manual 2ELEMENTS ENGAGEDC1

-C2

XC3

-C4

XB1

XB2

-1-2

OWC

-3-4

OWC

XLU

CLUTCH

-

KAA5A400

Page 1125 of 2053

AUTOMATIC TRANSMISSION 5A-31

SSANGYONG MY2002

Power Flow - Drive 3 and Manual 3

In Drive 2 and Manual 2, transmission drive is via the

input shaft and forward clutch cylinder. The elements

of the transmission function as follows;

The C2 clutch is engaged to drive the forward sun

gear.

The C1 clutch is engaged to drive the planet carrier.

The short pinion drives the long pinion clockwise.

The forward sun gear and the planet carrier are driv-

en clockwise at the same speed therefore there is

no relative motion between the sun gear and the

pinions.

The ring gear and output shaft are driven in a clock-

wise or forward direction at input shaft speed.

The C4 clutch is applied to bypass the 3-4 OWC

and provide engine braking on overrun.

Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows:

Solenoid S1 is switched OFF. S2 is switched OFF.

With S1 and S2 switched OFF, the 2-3 and 3-4 shift

valves are held in the third gear position by line

500 pressure.

The 1-2 shift valve is held in the third gear position

by S1-S2 oil pressure.

2nd oil (line pressure) from the 1-2 shift valve is di-

rected to the band apply feed regulator valve and

to the 2-3 shift valve.

The band apply feed regulator valve supplies 2nd

oil (regulated to line pressure multiplied by the valve

ra-tio) to the Band Apply Feed (BAF) circuit.

Band apply feed oil is directed to;

- The outer apply area of the front servo

- The 1-2 shift valve to provide an exhaust port

when the transmission is shifted to first gear

- The 3-4 shift valve for use when the transmission

is shifted into fourth gear

2nd oil at the 2-3 shift valve is directed to the 3rd

oil circuit.

3rd oil from the 2-3 shift valve is directed to the

clutch apply regulator valve, and to the 4-3

sequence valve.

The clutch apply regulator valve supplies oil (regu-

lated to line 500 pressure multiplied by the valve

ratio) to the Clutch Apply Feed (CAF) circuit.

The CAF oil is directed to;

- The C1clutch

- The 4-3 sequence valve

At the 4-3 sequence valve the CAF oil becomes

Band 1 Release Feed (B1R-F) oil, and is directed

through the 3-4 shift valve to the spring end of the

4-3 sequence valve, and to the release side of the

front servo piston to hold band 1 OFF.

Drive (line pressure) is routed through the 3-4 shift

valve to apply the C4 clutch.

3-4

OWC

XLU

CLUTCH

- ELEMENTS ENGAGED

Gear State

Drive 3 and Manual 3C1

XC2

XC3

-C4

XB1

-B2

-1-2

OWC

-

KAA5A420

Page 1129 of 2053

AUTOMATIC TRANSMISSION 5A-35

SSANGYONG MY2002

Power Flow - Drive 4 (Overdrive)

In Drive 4 (Overdrive), transmission drive is via the

input shaft to the forward clutch cylinder.

The elements of the transmission function as follows;

The C1 clutch is applied to drive the planet carrier

clockwise.

The B1 band is applied to hold the reverse sun gear

stationary.

As the planet carrier tuns, the long pinion walks

around the stationary reverse sun gear and rotates

around its axis driving the internal ring gear and

output shaft in a clockwise or forward direction at a

speed faster than the input shaft i.e. in overdrive

ratio.

The forward sun gear is also driven faster than the

input shaft and overruns the 3-4 OWC.

The C2 clutch is engaged to reduce the speed differ-

ential across the 3-4 OWC.

Control

To maintain this arrangement in the steady state sole-

noids and valves are activated as follows;

Solenoid S1 is switched ON. S2 is switched OFF.

With S1 switched ON, the 3-4 shift valve is held in

the fourth gear position by line 500 pressure on the

small end of the valve.

With S2 switched OFF, the 2-3 shift valve is held in

the fourth gear position by line 500 pressure on the

large end of the valve.

The 1-2 shift valve is held in the fourth gear position

by S2 oil pressure.

2nd oil (line pressure) from the 1-2 shift valve is di-

rected to the band apply feed regulator valve, and

to the 2-3 shift valve.

The band apply feed regulator valve supplies 2nd

oil (regulated to line pressure multiplied by the valve

ra-tio) to the Band Apply Feed (BAF) circuit.

Band apply feed oil is directed to;

- the outer apply area of the front servo

- the inner apply area of the front servo piston via

the 3-4 shift valve

- the 1-2 shift valve to provide an exhaust port

when the transmission is shifted to first gear

2nd oil at the 2-3 shift valve is directed to the 3rd

oil circuit.

3rd oil from the 2-3 shift valve is directed to the

clutch apply regulator valve, and to the 4-3

sequence valve.

The clutch apply regulator valve supplies oil (regu-

lated to line 500 pressure multiplied by the valve

ratio) to the Clutch Apply Feed (CAF) circuit.

The CAF oil is directed to;

- the C1 clutch

- the 4-3 sequence valve

Drive oil (line pressure) from the manual valve en-

gages the C2 clutch.

Gear State

Drive 4 Overdrive

C1

XC2

XC3

-C4

-B1

XB2

-1-2

OWC

-3-4

OWC

-LU

CLUTCH

- ELEMENTS ENGAGED

KAA5A460

Page 1132 of 2053

5A-38 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

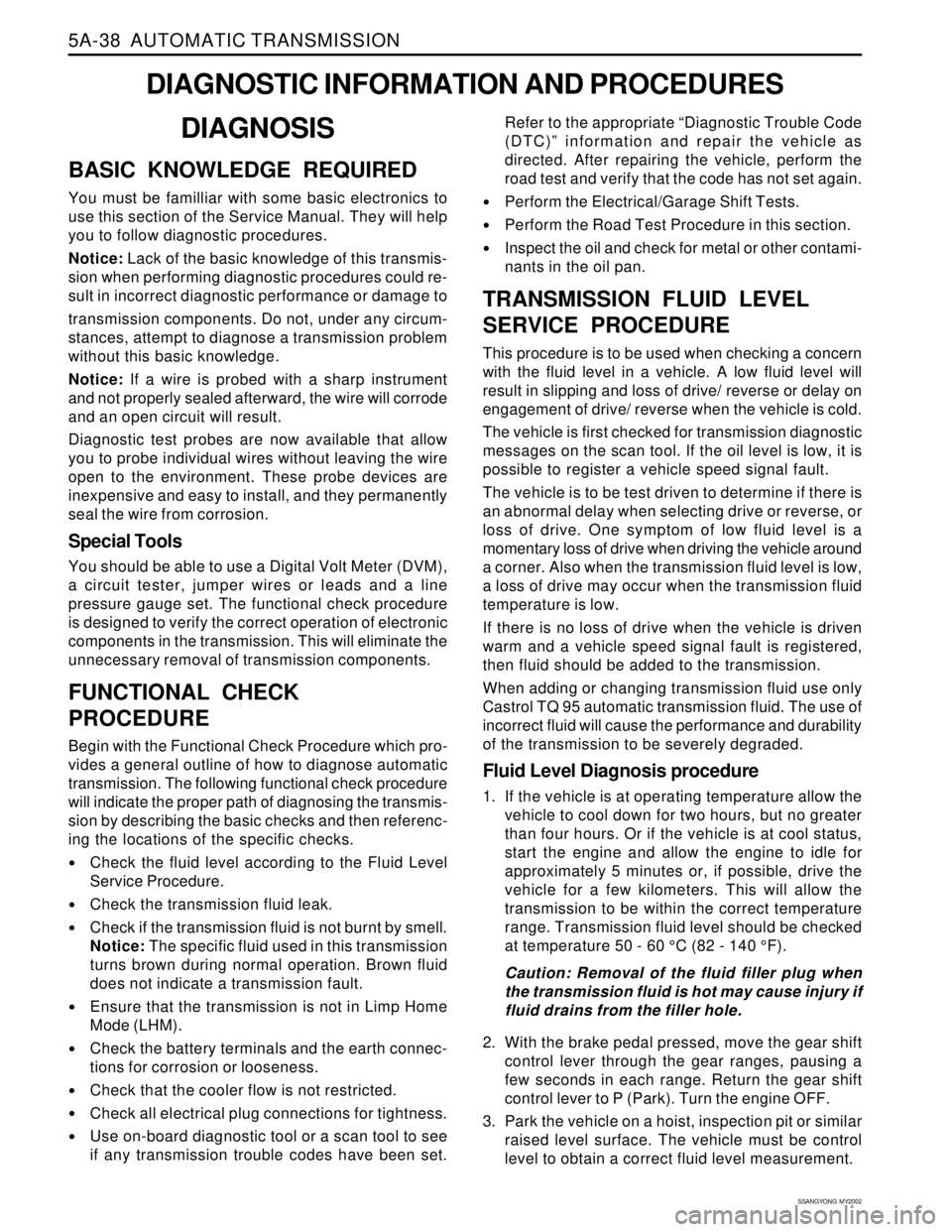

DIAGNOSIS

BASIC KNOWLEDGE REQUIRED

You must be familliar with some basic electronics to

use this section of the Service Manual. They will help

you to follow diagnostic procedures.

Notice: Lack of the basic knowledge of this transmis-

sion when performing diagnostic procedures could re-

sult in incorrect diagnostic performance or damage to

transmission components. Do not, under any circum-

stances, attempt to diagnose a transmission problem

without this basic knowledge.

Notice: If a wire is probed with a sharp instrument

and not properly sealed afterward, the wire will corrode

and an open circuit will result.

Diagnostic test probes are now available that allow

you to probe individual wires without leaving the wire

open to the environment. These probe devices are

inexpensive and easy to install, and they permanently

seal the wire from corrosion.

Special Tools

You should be able to use a Digital Volt Meter (DVM),

a circuit tester, jumper wires or leads and a line

pressure gauge set. The functional check procedure

is designed to verify the correct operation of electronic

components in the transmission. This will eliminate the

unnecessary removal of transmission components.

FUNCTIONAL CHECK

PROCEDURE

Begin with the Functional Check Procedure which pro-

vides a general outline of how to diagnose automatic

transmission. The following functional check procedure

will indicate the proper path of diagnosing the transmis-

sion by describing the basic checks and then referenc-

ing the locations of the specific checks.

Check the fluid level according to the Fluid Level

Service Procedure.

Check the transmission fluid leak.

Check if the transmission fluid is not burnt by smell.

Notice: The specific fluid used in this transmission

turns brown during normal operation. Brown fluid

does not indicate a transmission fault.

Ensure that the transmission is not in Limp Home

Mode (LHM).

Check the battery terminals and the earth connec-

tions for corrosion or looseness.

Check that the cooler flow is not restricted.

Check all electrical plug connections for tightness.

Use on-board diagnostic tool or a scan tool to see

if any transmission trouble codes have been set.

DIAGNOSTIC INFORMATION AND PROCEDURES

Refer to the appropriate “Diagnostic Trouble Code

(DTC)” information and repair the vehicle as

directed. After repairing the vehicle, perform the

road test and verify that the code has not set again.

Perform the Electrical/Garage Shift Tests.

Perform the Road Test Procedure in this section.

Inspect the oil and check for metal or other contami-

nants in the oil pan.

TRANSMISSION FLUID LEVEL

SERVICE PROCEDURE

This procedure is to be used when checking a concern

with the fluid level in a vehicle. A low fluid level will

result in slipping and loss of drive/ reverse or delay on

engagement of drive/ reverse when the vehicle is cold.

The vehicle is first checked for transmission diagnostic

messages on the scan tool. If the oil level is low, it is

possible to register a vehicle speed signal fault.

The vehicle is to be test driven to determine if there is

an abnormal delay when selecting drive or reverse, or

loss of drive. One symptom of low fluid level is a

momentary loss of drive when driving the vehicle around

a corner. Also when the transmission fluid level is low,

a loss of drive may occur when the transmission fluid

temperature is low.

If there is no loss of drive when the vehicle is driven

warm and a vehicle speed signal fault is registered,

then fluid should be added to the transmission.

When adding or changing transmission fluid use only

Castrol TQ 95 automatic transmission fluid. The use of

incorrect fluid will cause the performance and durability

of the transmission to be severely degraded.

Fluid Level Diagnosis procedure

1. If the vehicle is at operating temperature allow the

vehicle to cool down for two hours, but no greater

than four hours. Or if the vehicle is at cool status,

start the engine and allow the engine to idle for

approximately 5 minutes or, if possible, drive the

vehicle for a few kilometers. This will allow the

transmission to be within the correct temperature

range. Transmission fluid level should be checked

at temperature 50 - 60 °C (82 - 140 °F).

Caution: Removal of the fluid filler plug when

the transmission fluid is hot may cause injury if

fluid drains from the filler hole.

2. With the brake pedal pressed, move the gear shift

control lever through the gear ranges, pausing a

few seconds in each range. Return the gear shift

control lever to P (Park). Turn the engine OFF.

3. Park the vehicle on a hoist, inspection pit or similar

raised level surface. The vehicle must be control

level to obtain a correct fluid level measurement.

Page 1292 of 2053

AUTOMATIC TRANSMISSION 5A-197

SSANGYONG MY2002

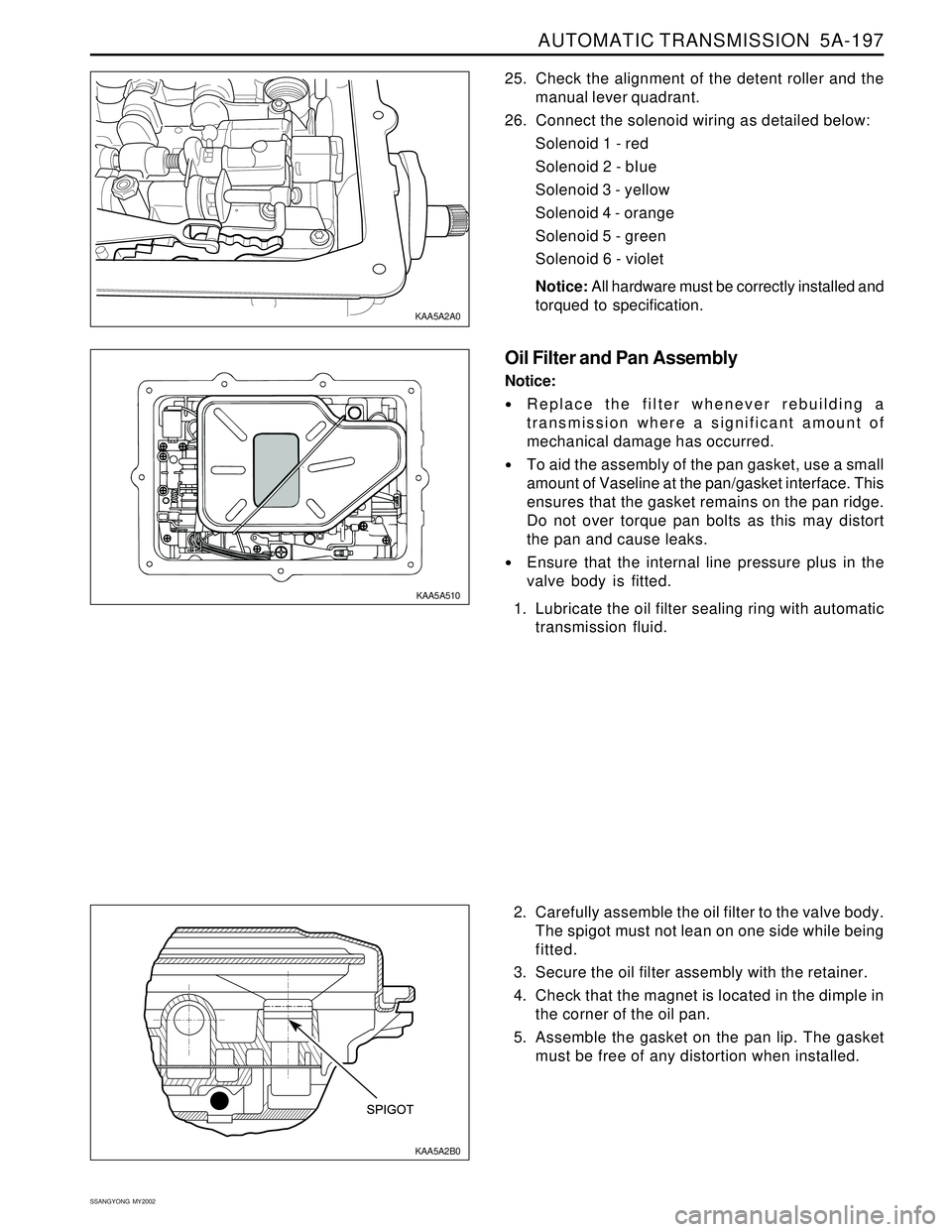

2. Carefully assemble the oil filter to the valve body.

The spigot must not lean on one side while being

fitted.

3. Secure the oil filter assembly with the retainer.

4. Check that the magnet is located in the dimple in

the corner of the oil pan.

5. Assemble the gasket on the pan lip. The gasket

must be free of any distortion when installed. 25. Check the alignment of the detent roller and the

manual lever quadrant.

26. Connect the solenoid wiring as detailed below:

Solenoid 1 - red

Solenoid 2 - bIue

Solenoid 3 - yellow

Solenoid 4 - orange

Solenoid 5 - green

Solenoid 6 - violet

Notice: All hardware must be correctly installed and

torqued to specification.

Oil Filter and Pan Assembly

Notice:

Replace the filter whenever rebuilding a

transmission where a significant amount of

mechanical damage has occurred.

To aid the assembly of the pan gasket, use a small

amount of Vaseline at the pan/gasket interface. This

ensures that the gasket remains on the pan ridge.

Do not over torque pan bolts as this may distort

the pan and cause leaks.

Ensure that the internal line pressure plus in the

valve body is fitted.

1. Lubricate the oil filter sealing ring with automatic

transmission fluid.

KAA5A2B0 KAA5A2A0

KAA5A510