reset SSANGYONG KORANDO 1997 Service Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1997, Model line: KORANDO, Model: SSANGYONG KORANDO 1997Pages: 2053, PDF Size: 88.33 MB

Page 1019 of 2053

SSANGYONG MY2002

4F-36 ABS AND TCS

SELF-DIAGNOSTICS

Important: The electronic brake control module (EBCM)

turns the valve relay off when a diagnostic trouble code

(DTC) is set. The scan tool will indicate that the valve

relay is off when it is used to monitor the data list. This

is normal and should not be considered a mal-function.

The EBCM performs system self-diagnostics and can

detect and often isolate system malfunctions. When it

detects a malfunction, the EBCM sets a DTC that repre

sents the malfunction, turns on the ABS and/or the

TCS indicators in most instances, and may disable the

ABS and/or the TCS functions, as necessary, for the

duration of the ignition cycle.

Once each ignition cycle, the EBCM performs an auto-

matic test when the vehicle reaches 2.75 km/h (1.7

mph). In the course of this test, the system cycles

each valve solenoid and the pump motor, along with

the necessary relays, to check component operation.

If the EBCM detects any malfunctions, it will set a

DTC as described above.

DISPLAYING DTCs

Tools Required

Scan Tool

DTCs can be read through the use of the scan tool.

CLEARING DTCs

Tools Required

Scan Tool

The diagnostic trouble codes (DTCs) in the electronic

brake control module (EBCM) memory are erased in

one of two ways:

Use the scan tool “Clear DTCs” selection.

After 249 DTC-free ignition cycles.

These two methods are detailed below. Be sure to verify

the proper system operation and, the absence of DTCs

when the clearing procedure is completed.The EBCM will not permit DTC clearing until all DTCs

have been displayed. Also, DTCs cannot be cleared

by disconnecting the EBCM, disconnecting the battery

cables, or turning the ignition switch to LOCK.

Scan Tool Method

The scan tool can clear ABS/TCS system DTCs using

the mass storage cartridge.

1. Install the scan tool and the mass storage

cartridge.

2. Select “Fault Memory”.

3. Select “Clear Fault Memory”.

Clearing the fault memory cannot reset a valve relay

which was shut down when the fault was recognized.

Changes are possible only after the fault has been elimi-

nated and the next ignition cycle has begun.

Ignition Cycle Default

A DTC is erased from memory after 249 ignition cycles

without any reappearance of that malfunction.

INTERMITTENTS AND POOR

CONNECTIONS

As with most electronic systems, intermittent malfunc

tions may be difficult to diagnose accurately. The follow-

ing is a method to try to isolate an intermittent

malfunction, especially in wheel speed circuitry.

If an ABS malfunction occurs, the ABS indicator will

illuminate during the ignition cycle in which the

malfunction was detected. If it is an intermittent problem

which seems to have corrected itself (ABS indicator

OFF), a history DTC will be stored. Also stored will be

the history data of the DTC at the time the malfunction

occurred. Use the scan tool modular diagnostic system

to read ABS history data.

Most intermittents are caused by faulty electrical con

nections or wiring, although a sticking relay or solenoid

can occasionally be at fault.

Page 1038 of 2053

ABS AND TCS 4F-55

SSANGYONG MY2002

Diagnostic Aids

DTC 11 may be set by running the scan tool auto test

if the throttle angle readings are not updating while in

the data list mode. If this is the case, clear the DTCs,

disconnect the scan tool, and road test the vehicle to

at least 25 km/h (15 mph) to see if the DTC resets.

Check the toothed wheels for any large grooves,

gouges, marks, etc. that might influence the tooth’s

signal at the wheel speed sensor. Also, check for a

buildup of foreign material in the gaps between the teethin the toothed wheel, as this material may cause this

malfunction.

A badly worn hub/bearing assembly may cause this

malfunction. The wheel speed sensor-to-toothed wheel

air gap may change excessively due to bearing play.

If an improper rear hub assembly or front outer constant

velocity joint is installed, one with a toothed wheel con-

taining the incorrect number of teeth, this DTC can set.

Be sure that all the toothed wheels have 52 teeth.

Step

1

2

3

5

6

7

8

9

DTC 11 - Wheel Speed Sensor Frequency Error

Action

Go to Step 2

System OK

Go to Step 4

System OK

Go to Step 7

System OK

Go to Step 9

System OKGo to Step 3

-

Go to Step 5

-

Go to Step 6

-

Go to Step 9

- -

-

-

-

1280 - 1920 Ω

-

-

-

Visually inspect the wiring for the front wheel speed

sensors.

Is there any damage?

Repair or replace components, as required.

Is the repair complete?

Check that the correct outer constant velocity (CV)

joints are installed on the vehicle. They should have

speed rings with 52 teeth.

Is one of these incorrect?

Replace the incorrect outer CV joint with the proper

unit.

Is the repair complete?

1. Disconnect the wheel speed sensor harnesses

from the wheel speed sensor connectors.

2. Measure the wheel speed sensor resistance at the

wheel speed sensor connector terminals.

Does the resistance fall within the specified values for

both wheel speed sensors?

Replace the faulty wheel speed sensor.

Is the repair complete?

1. Disconnect the ABS control module connector.

2. Check each wheel speed sensor harness for a

short circuit between its wires with a digital ohmme-

ter attached to the two terminals at the harness

side of the wheel speed sensor connector.

3. Also check each wheel speed sensor harness wire

for a short to ground from the connector terminals.

Is there any short circuit in either wheel speed sensor

harness?

Repair the short circuit in the wiring or from a wiring

harness to ground.

Is the repair complete?

Value(s) Yes No

Page 1068 of 2053

ABS AND TCS 4F-85

SSANGYONG MY2002

Step

4

5

6

7

8

9

10

11

12

13

DTC 28 - Low Voltage Fault (Cont’d)

Action

Go to Step 5

System OK

System OK

Go to Step 8

Go to Step 9

System OK

System OK

Go to Step 12

Go to Step 13

System OKGo to Step 6

-

-

Go to Step 11

Go to Step 10

-

-

Go to Step 15

Go to Step 14

- -

-

-

-

-

-

-

-

-

-

1. Replace fuse EF11.

2. Turn the ignition to ON.

Does the fuse blow again?

1. Turn the ignition to OFF.

2. Trace the BLK/WHT wires in the ABS wiring

harness from terminal 8 of C104 at the engine fuse

block to F19 in the I/P fuse block.

3. Repair any short circuit found along this path.

Is the repair complete?

1. Turn the ignition to OFF.

2. Install the scan tool.

3. Clear all DTCs.

4. Road test the vehicle.

Does DTC 28 reset?

Check fuse F19 in the I/P fuse block.

Is the fuse blown?

1. Replace fuse F19.

2. Turn the ignition to ON.

Does the fuse blow again?

1. Turn the ignition to OFF.

2. Trace the WHT/RED wires in the ABS Wiring

harness from fuse F19 to terminal 50 of the EBCM

connector.

3. Repair any short circuit found along this path.

Is the repair complete?

1. Turn the ignition to OFF.

2. Install the scan tool.

3. Clear all DTCs.

4. Rood test the vehicle.

Does DTC 28 reset?

Check fuse F29 in the I/P fuse block.

Is fuse F29 blown?

1. Replace fuse F29.

2. Turn the ignition to ON.

Does fuse F29 blow again?

1. Turn the ignition to OFF.

2. Trace the WHT/RED wire from fuse F19 to terminal

1 of the EBCM connector.

3. Repair any short circuit found along this path.

Is the repair complete?

Value(s) Yes No

Page 1069 of 2053

SSANGYONG MY2002

4F-86 ABS AND TCS

Step

14

15

16

17

18

19

20

21

22

23

24

25

26

27

DTC 28 - Low Voltage Fault (Cont’d)

Action

System OK

Go to Step 17

System OK

Go to Step 19

System OK

Go to Step 21

System OK

Go to Step 22

Go to Step 23

System OK

System OK

Go to Step 26

System OK

System OK-

Go to Step 16

-

Go to Step 18

-

Go to Step 18

-

Go to Step 20

-

Go to Step 24

Go to Step 25

-

-

- -

11 - 14v

-

11 - 14v

-

11 - 14v

-

≈ 0 Ω

-

-

-

-

-

-

1. Turn the ignition to OFF.

2. Install the scan tool.

3. Clear all DTCs.

4. Road test the vehicle.

Does DTC 28 reset?

1. Disconnect the EBCM connector from the EBCM.

2. Turn the ignition to ON.

3. Check the voltage between ground and terminal 1,

and between ground and terminal 50.

Is the voltage within the specified value?

1. Turn the ignition to OFF.

2. Trace the WHT/RED wires between terminals 1

and 50 of the EBCM connector to fuse F19 and

F29 in the I/P fuse block.

3. Repair the open in this circuit.

Is the repair complete?

1. Turn the ignition ON.

2. Check the voltage at fuse F19.

Is the voltage within the specified value?

Repair the power supply circuit for fuse F19.

Is the repair complete?

1. Turn the ignition ON.

2. Check the voltage at fuse F29.

Is the voltage within the specified value?

Repair the power supply circuit for Fuse 29.

Is the repair complete?

1. Turn the ignition to OFF.

2. Check the resistance between ground and terminals

28 and 29 of the ABS harness EBCM connector.

Is the resistance equal to the specified value?

Examine terminals 1, 28, 29, and 50 of the EBCM

connector.

Is there a defective terminal?

Repair the defective terminal or replace the connector

or wiring harness, as required.

Is the repair complete?

Repair the defective ground connection.

Is the repair complete?

1. Install the scan tool.

2. Clear all DTCs.

3. Road test the vehicle.

Does DTC 28 set again?

Replace the ABS unit.

Is the repair complete?

1. Examine the wiring harness and connectors for

causes of intermittent problems.

2. Repair any intermittent problem found.

Is the repair complete?

Value(s) Yes No

Page 1381 of 2053

TRANSFER CASE 5D1-11

SSANGYONG MY2002

DIAGNOSIS

While the transfer case control unit (TCCU) is active it

periodically monitors its inputs and outputs. If a fault

is detected the 4WD CHECK lamp is illuminated and a

fault code is stored in the TCCU memory.

When requested, fault codes are downloaded to scan

tool through a diagnostic connector (K-line) serial com

munication.

SELF-DIAGNOSTIC TESTS

TCCU Internal Function

When the ignition is turned on the TCCU tests its read

only memory (ROM) and random access memory

(RAM). If there is a fault, the TCCU immediately resets

itself and re-tests the ROM and RAM. If the fault

persists the TCCU continues to reset and re-test until

the fault is corrected or the ignition is turned off. All

TCCU functions are inhibited until the fault is corrected.

The 4WD CHECK lamp is not illuminated if there is a

ROM or RAM fault.

If the ROM/RAM passes the electronically erasable

programmable read only memory (EEPROM) is tested.

If there is a fault the 4WD CHECK lamp is illuminated

and the TCCU continues to operate using the default

calibration data stored in ROM. Fault codes are not

stored when there is an EEPROM fault.

An EEPROM fault can only be cleared by cycling

ignition OFF-ON.

Shift Motor Assembly Test

If the TCCU detects a shift motor or position encoder

fault continuously for one second the 4WD CHECK

lamp is turned on and the appropriate fault code is

stored in memory.

1. A shift motor fault when the motor is off is defined

as follows:

Motor HI-LO circuits are shorted to ground.

Motor LO-HI circuits are shorted to ground.

Motor circuits are open.

2. A shift motor fault when the motor is energized is

defined as follows:

Motor HI-LO circuits are shorted to ground.

Motor LO-HI circuits are shorted to ground.

Motor HI-LO circuits are shorted to motor LO

HI circuits.

Motor circuits are open.

3. A position encoder fault is defined as follows:

Any position code which does not correspond

to the valid 9 codes.

A short to ground on any of the encoder lines.

4. If no shifts are in progress when a failure occurs

the TCCU will not respond to any shift commands.5. If a shift command has been received but not

acted upon when a failure occurred the TCCU

would cancel the command and not respond to

any subsequent shift commands.

6. If a shift command is in progress when an invalid

position code is confirmed it will be halted and

the TCCU will turn the motor toward the high

position. Afterwards the TCCU will not respond to

any shift commands.

7. If the shift motor or position encoder assembly

failures, other than a motor failure which occurs

when the motor is energized, recovers continuously

for one second the TCCU will function normally.

The 4WD CHECK lamp is turned off but the fault

code will remain in memory.

8. A motor failure (i.e. open or short circuit) which

occurs when the motor is energized can only be

cleared by cycling the ignition OFF-ON.

Front Speed Sensor Test

If a front speed sensor fault is detected continuously

for 0.5 second the 4WD CHECK lamp is illuminated.

The TCCU then responds as follows:

1. If the system is in high range the TCCU uses the

rear speed sensor to determine the EMC touch off

level and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum, independent of vehicle speed,

until the system is shifted out of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

If the front speed sensor recovers continuously for O.5

second the TCCU will function normally. The 4WD

CHECK lamp is turned off but the fault code will remain

in memory.

Rear Speed Sensor Test

If a rear speed sensor fault is detected continuously

for 0.5 second the 4WD CHECK lamp is illuminated.

The TCCU then responds as follows:

1. If the system is in high range the TCCU uses the

front speed sensor to determine the EMC touch

off level and wheel slip control is suspended.

2. If the system is in low range, the EMC duty cycle

is set to maximum independent of vehicle speed

until the system is shifted out of low range.

3. All electric shift activity is halted until the Ignition

is cycled. If a shift is in progress it will be

completed.

4. If the rear speed sensor recovers continuously for

0.5 second the TCCU will function normally. The

4WD CHECK lamp is turned off but the fault code

will remain in memory.

Page 1446 of 2053

SSANGYONG MY2002

6A-4 POWER STEERING SYSTEM

KAA6A020

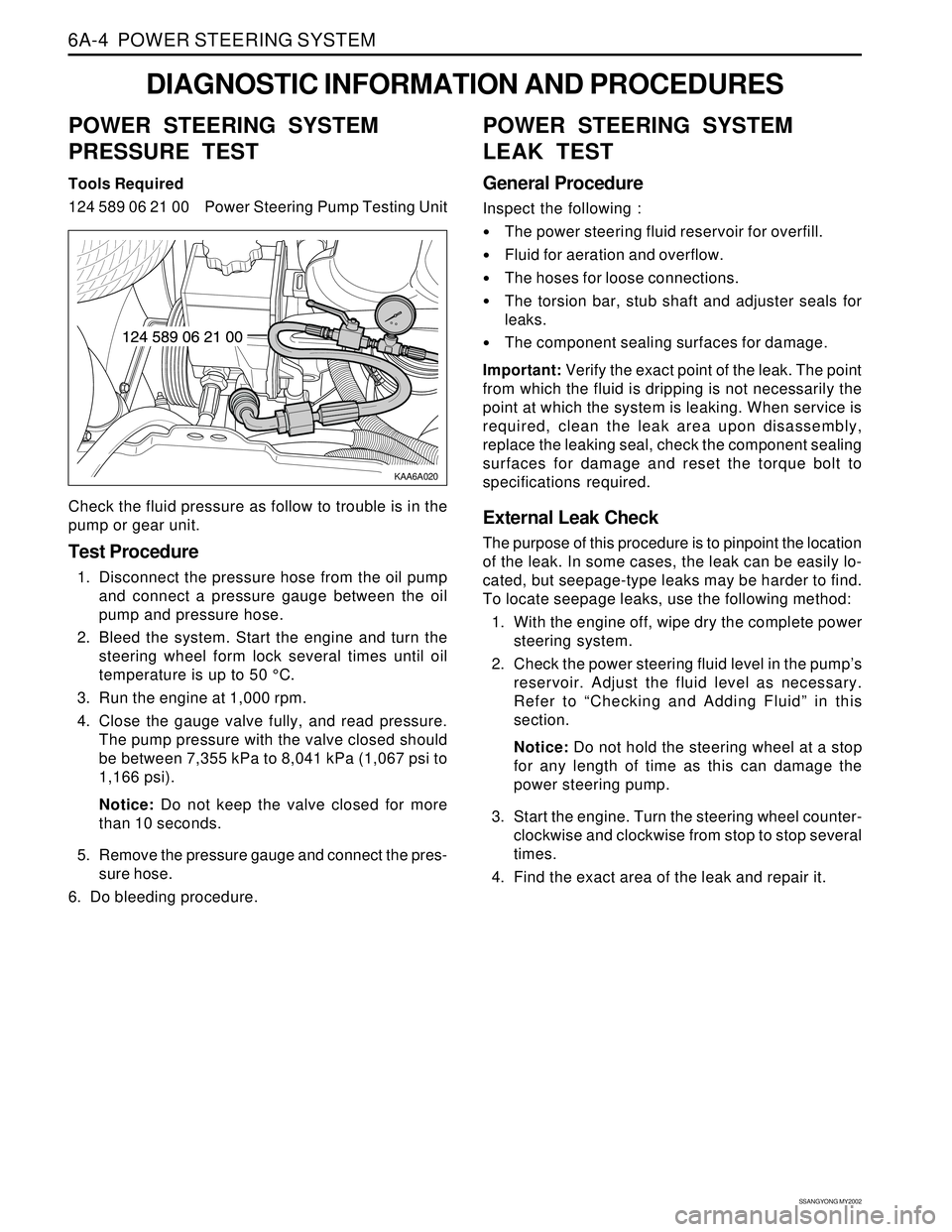

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

124 589 06 21 00 Power Steering Pump Testing Unit

Check the fluid pressure as follow to trouble is in the

pump or gear unit.

Test Procedure

1. Disconnect the pressure hose from the oil pump

and connect a pressure gauge between the oil

pump and pressure hose.

2. Bleed the system. Start the engine and turn the

steering wheel form lock several times until oil

temperature is up to 50 °C.

3. Run the engine at 1,000 rpm.

4. Close the gauge valve fully, and read pressure.

The pump pressure with the valve closed should

be between 7,355 kPa to 8,041 kPa (1,067 psi to

1,166 psi).

Notice: Do not keep the valve closed for more

than 10 seconds.

5. Remove the pressure gauge and connect the pres-

sure hose.

6. Do bleeding procedure.

POWER STEERING SYSTEM

LEAK TEST

General Procedure

Inspect the following :

The power steering fluid reservoir for overfill.

Fluid for aeration and overflow.

The hoses for loose connections.

The torsion bar, stub shaft and adjuster seals for

leaks.

The component sealing surfaces for damage.

Important: Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the

point at which the system is leaking. When service is

required, clean the leak area upon disassembly,

replace the leaking seal, check the component sealing

surfaces for damage and reset the torque bolt to

specifications required.

External Leak Check

The purpose of this procedure is to pinpoint the location

of the leak. In some cases, the leak can be easily lo-

cated, but seepage-type leaks may be harder to find.

To locate seepage leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary.

Refer to “Checking and Adding Fluid” in this

section.

Notice: Do not hold the steering wheel at a stop

for any length of time as this can damage the

power steering pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1455 of 2053

SSANGYONG MY2002

6A-4 POWER STEERING SYSTEM

KAA6A020

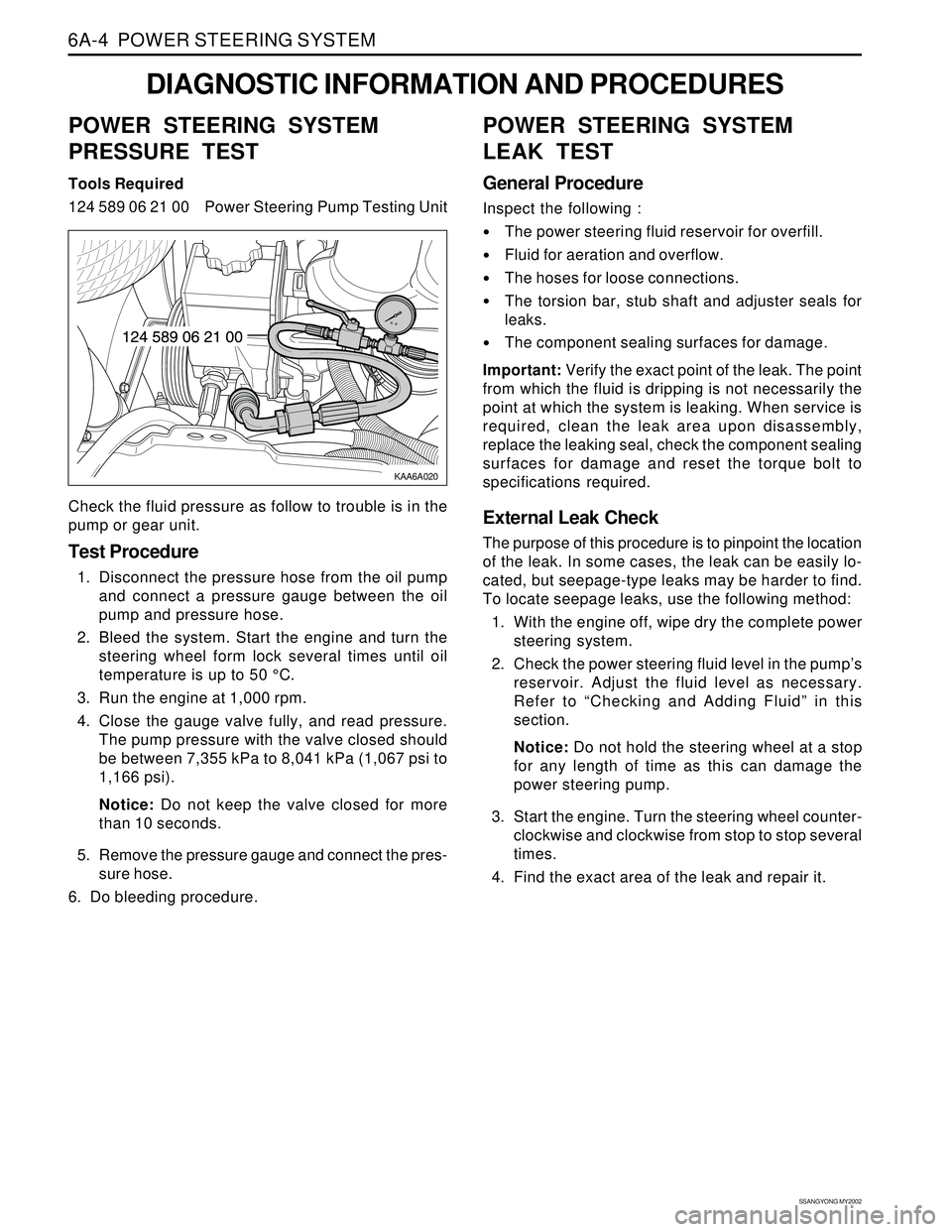

DIAGNOSTIC INFORMATION AND PROCEDURES

POWER STEERING SYSTEM

PRESSURE TEST

Tools Required

124 589 06 21 00 Power Steering Pump Testing Unit

Check the fluid pressure as follow to trouble is in the

pump or gear unit.

Test Procedure

1. Disconnect the pressure hose from the oil pump

and connect a pressure gauge between the oil

pump and pressure hose.

2. Bleed the system. Start the engine and turn the

steering wheel form lock several times until oil

temperature is up to 50 °C.

3. Run the engine at 1,000 rpm.

4. Close the gauge valve fully, and read pressure.

The pump pressure with the valve closed should

be between 7,355 kPa to 8,041 kPa (1,067 psi to

1,166 psi).

Notice: Do not keep the valve closed for more

than 10 seconds.

5. Remove the pressure gauge and connect the pres-

sure hose.

6. Do bleeding procedure.

POWER STEERING SYSTEM

LEAK TEST

General Procedure

Inspect the following :

The power steering fluid reservoir for overfill.

Fluid for aeration and overflow.

The hoses for loose connections.

The torsion bar, stub shaft and adjuster seals for

leaks.

The component sealing surfaces for damage.

Important: Verify the exact point of the leak. The point

from which the fluid is dripping is not necessarily the

point at which the system is leaking. When service is

required, clean the leak area upon disassembly,

replace the leaking seal, check the component sealing

surfaces for damage and reset the torque bolt to

specifications required.

External Leak Check

The purpose of this procedure is to pinpoint the location

of the leak. In some cases, the leak can be easily lo-

cated, but seepage-type leaks may be harder to find.

To locate seepage leaks, use the following method:

1. With the engine off, wipe dry the complete power

steering system.

2. Check the power steering fluid level in the pump’s

reservoir. Adjust the fluid level as necessary.

Refer to “Checking and Adding Fluid” in this

section.

Notice: Do not hold the steering wheel at a stop

for any length of time as this can damage the

power steering pump.

3. Start the engine. Turn the steering wheel counter-

clockwise and clockwise from stop to stop several

times.

4. Find the exact area of the leak and repair it.

Page 1491 of 2053

POWER STEERING AND COLUMN 6E-5

SSANGYONG MY2002

Check the lock cylinder for damage.

Check the ignition switch for lack of free movement.

Check the steering column housing for binding or

damage.ChecksActionReplace the lock cylinder.

Lubricate the ignition switch.

Remove the steering shaft and clear the steering

column housing. Replace the steering column housing

as needed.

Lock System Will Not Lock

High Lock Effort

Check the lock cylinder for damage.

Check the ignition switch for lack of free movement.

Check for extreme misalignment of the housing to the

cover.

Check for a bent ignition switch mounting bracket.ChecksActionReplace the lock cylinder.

Lubricate the ignition switch.

Realign the cover on the housing. Replace the cover

as needed.

Replace the ignition switch mounting bracket.

STEERING COLUMN DIAGNOSIS

Lock System

Lock System Will Not Unlock

Check the lock cylinder for damage.

Check the ignition switch for lack of free movement.

Check the steering column housing for binding or

damage.ChecksActionReplace the lock cylinder.

Lubricate the ignition switch.

Remove the steering shaft and clear the steering

column housing. Replace the steering column housing

as needed.

High Lock Effort

Check to see that the ignition switch is set correctly.

Check the lock cylinder for damage.ChecksActionReset the ignition switch.

Replace the lock cylinder. Reset the ignition switch.

Check the steering gear-to-column joints for improper

installation.

Check the steering shaft bearing for wear or damage.

Check the spherical joint for lack of lubrication.

Check the steering shaft for lack of lubrication.

Check the shaft lock snap ring for improper seating.ChecksActionTighten the steering shaft universal joint pinch bolts.

Replace the steering shaft joints as needed.

Replace the steering shaft bearing.

Lubricate the spherical joint.

Lubricate the steering shaft bearing.

Adjust the shaft lock snap ring.

Replace the shaft lock snap ring as needed.

Column

Noise in the Column

Page 1719 of 2053

SSANGYONG MY2002

9E-2 INSTRUMENTATION, DRIVER INFORMATION

DESCRIPTION AND OPERATION

CIGAR LIGHTER

The cigar lighter is located in the front portion of the

floor console. To use the lighter, push it in completely.

When the lighter is hot, it will release itsef from contact

with the heating element. The lighter and the heating

element can be damaged if the lighter does not fully

release itsef from the heating element.

ASHTRAY

The ashtray is located in the console. To access the

ashtray, pullit out of the ashtray housing. The ashtray

lamp will go on when the parking lamps or headlamps

are turned on.

INSTRUMENT PANEL VENTS

The center and the side vents in the instrument panel

can be adjusted up and down and from side to side.

The side vents can also be aimed toward the side

windows to defog them.

GLOVE BOX

The glove box can be opened by pulling upon the latch

handle.

DIGITAL CLOCK

The digital clock is located in the instrument cluster.

INSTRUMENT CLUSTER

The instrument cluster is located above the steering

column and in the instrument cluster trim panel. The

instrument cluster contains the instruments that

provide the driver with vehicle performance information.

The instrument cluster contains a speedometer, a

tachometer, an odometer, a trip odometer, a

temperature gauge, a fuel gauge, and several indicator

lamps. For replacement of the indicator lamp bulbs

contained in the instrument cluster, refer to “Instrument

Cluster Indicator Lamps Specifications” in the section.

SPEEDOMETER AND

TACHOMETER

The speedometer measures the speed of the vehicle

in km/h (with mph) or mph (with km/h). It consists of

an instrument cluster gauge connected to the vehicle

speed sensor on the transaxle output shaft. The

tachometer measures the engine’s speed in terms of

thousands of revolutions per minute. It consists of an

instrument cluster gauge connected to a sending unit

in the engine con-trol module. Do not operate the

engine in the red zone. Engine damage may occur.

TRIP ODOMETER

The trip odometer measures the distance the vehicle

has traveled since it was last reset. It consists of an

instrument cluster gauge connected to the sending unit

on the tasnsaxle output shaft. The trip oddometer can

be record the distance traveled from any starting point.

FUEL GAUGE

The fuel gauge consists of an instrument cluster gauge

connected to a sending unit in the fuel tank. The fuel

gauge indicates the quantity of fuel in the tank only

when the ignition is turned to ON or ACC. When the

ignition is turned to LOCK or START, the pointer may

come to rest at any position.

TEMPERATURE GAUGE

The temperature gauge consists of an instrument

cluster gauge connected to a temperature sensor that

is in con-tact with the circulating engine coolant. The

temperature gauge indicates the temperature of the

coolant. Prolonged driving or idling in very hot weather

may cause the pointer to move beyond the center of

the gauge. The engine is overheating if the pointer

moves into the red zone at the upper limit of the gauge.

INSTRUMENT CLUSTER

INDICATOR LAMPS

The instrument cluster contains indicator lamps that

indicatethe functioning of certain systems or the

existenceof potential problems with the operation of

the vehicle. The indicator lamps are replaceable. For

replacement of the indicator lamps contained in the

instrument cluster, refer to “instrument cluster indicator

lamps specifications” in this section.

CHIME MODULE

The chime module will sound to bring attention to one

or more of the following conditions:

The lights are on and the ignition not in ACC, ON,

or START.

The ignition key is in the ignition switch when the

driver’s side door is open.

The seat belt is unbuckled when the ignition is in

ACC, ON, or START.

Voltage is supplied at all times through the fuse block

to power the chime module.