ECU SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 967 of 1082

11-150000-00

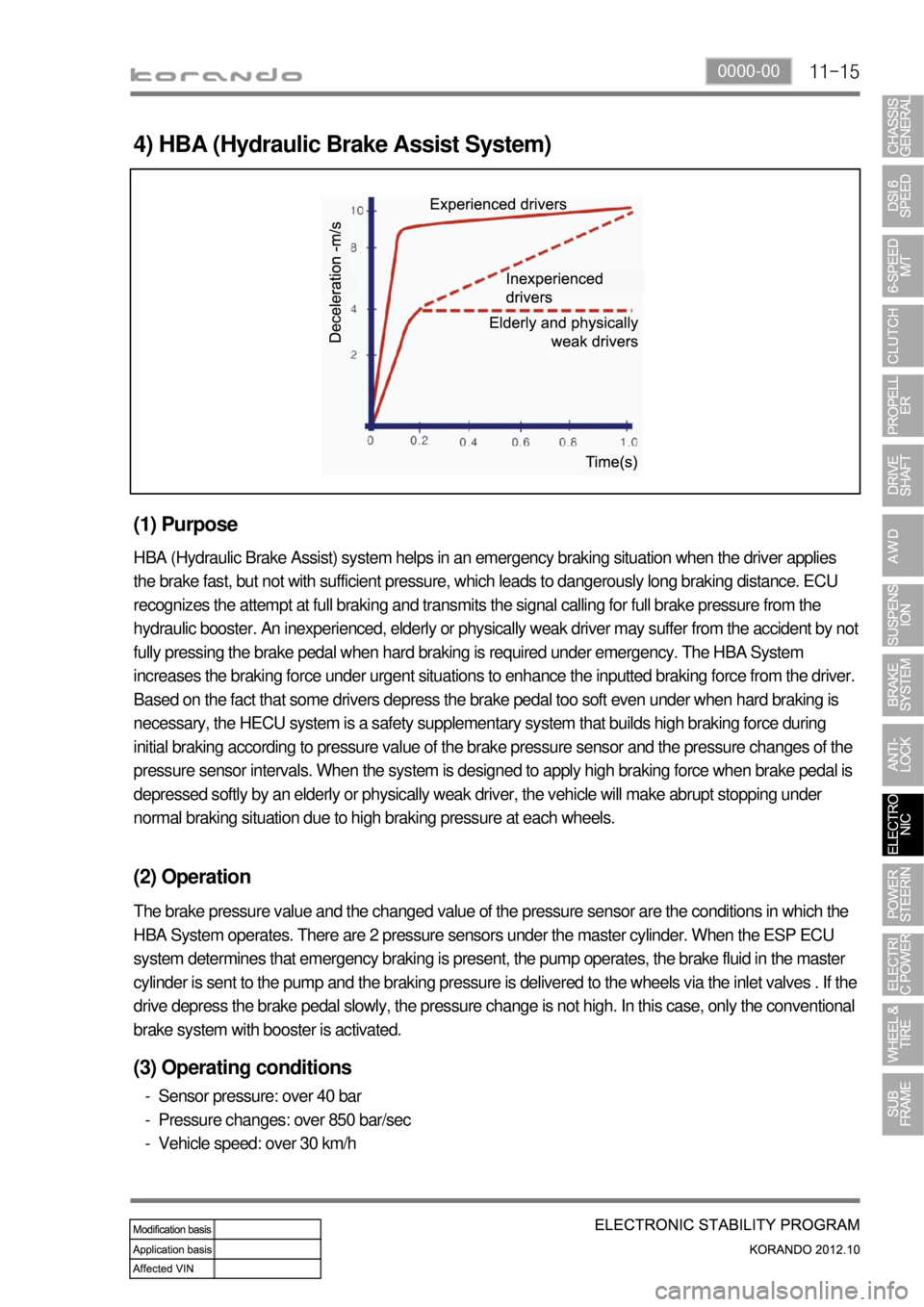

4) HBA (Hydraulic Brake Assist System)

(1) Purpose

HBA (Hydraulic Brake Assist) system helps in an emergency braking situation when the driver applies

the brake fast, but not with sufficient pressure, which leads to dangerously long braking distance. ECU

recognizes the attempt at full braking and transmits the signal calling for full brake pressure from the

hydraulic booster. An inexperienced, elderly or physically weak driver may suffer from the accident by not

fully pressing the brake pedal when hard braking is required under emergency. The HBA System

increases the braking force under urgent situations to enhance the inputted braking force from the driver.

Based on the fact that some drivers depress the brake pedal too soft even under when hard braking is

necessary, the HECU system is a safety supplementary system that builds high braking force during

initial braking according to pressure value of the brake pressure sensor and the pressure changes of the

pressure sensor intervals. When the system is designed to apply high braking force when brake pedal is

depressed softly by an elderly or physically weak driver, the vehicle will make abrupt stopping under

normal braking situation due to high braking pressure at each wheels.

(2) Operation

The brake pressure value and the changed value of the pressure sensor are the conditions in which the

HBA System operates. There are 2 pressure sensors under the master cylinder. When the ESP ECU

system determines that emergency braking is present, the pump operates, the brake fluid in the master

cylinder is sent to the pump and the braking pressure is delivered to the wheels via the inlet valves . If the

drive depress the brake pedal slowly, the pressure change is not high. In this case, only the conventional

brake system with booster is activated.

(3) Operating conditions

Sensor pressure: over 40 bar

Pressure changes: over 850 bar/sec

Vehicle speed: over 30 km/h -

-

-

Page 969 of 1082

11-170000-00

6) HSA (Hill Start Assist)

The HSA (Hill Start Assist) prevents the vehicle from rolling backward by supplying the hydraulic

pressure to the wheels by the HECU after the brake pedal is released when starting off on uphill.

Page 975 of 1082

11-230000-00

2) DUMP (ESP is working) Mode

The pressure decreases just before the wheel speed drops and the wheels are locked.

The inlet valve closes and the outlet valve opens as in the ABS HECU and the oil is gathered at the low

pressure chamber while no additional oil is being supplied. Then the pump operates to allow fast oil

drainage. The shuttle valve and the separation valve do not operate while decompression.

Page 978 of 1082

11-26

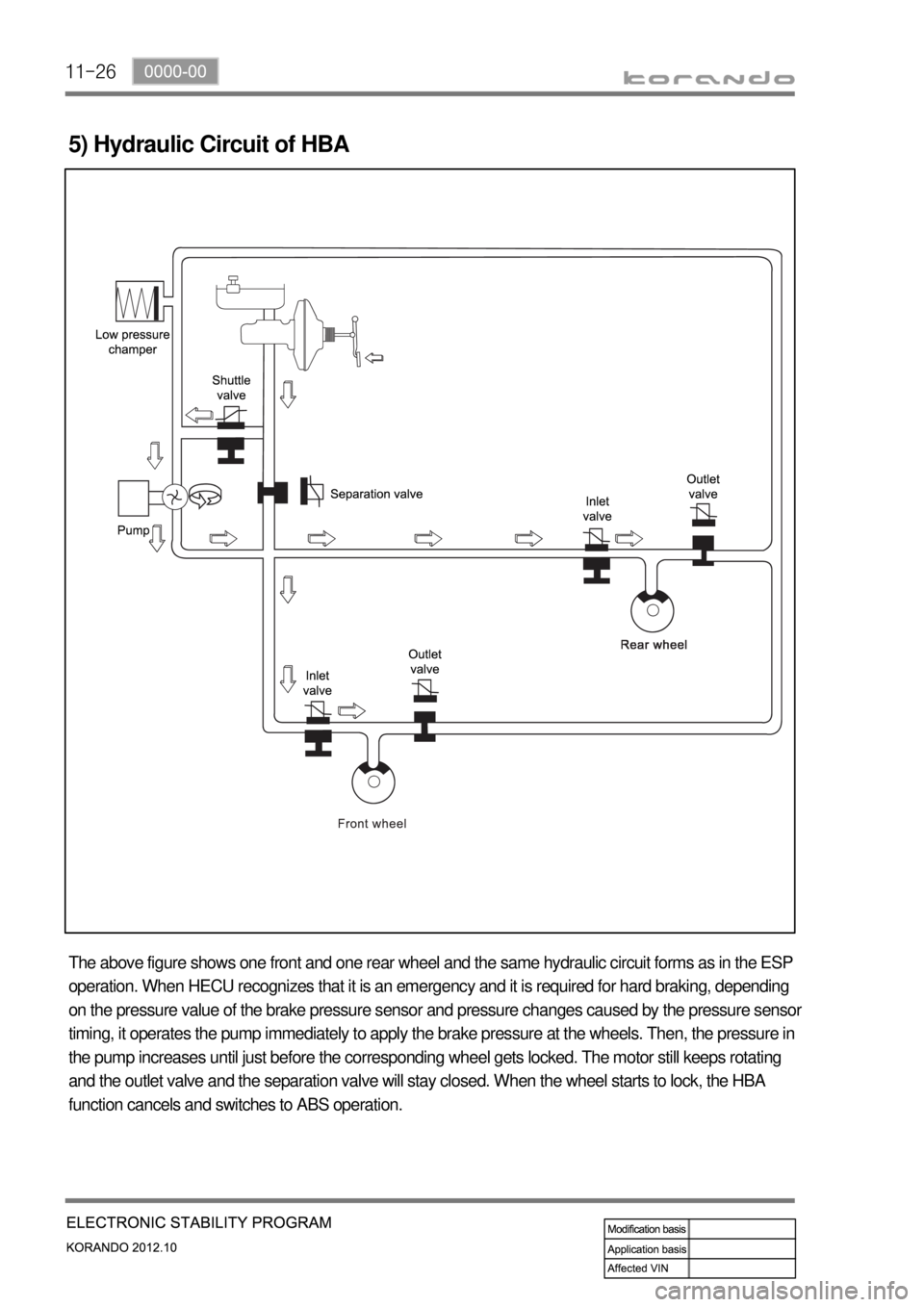

5) Hydraulic Circuit of HBA

The above figure shows one front and one rear wheel and the same hydraulic circuit forms as in the ESP

operation. When HECU recognizes that it is an emergency and it is required for hard braking, depending

on the pressure value of the brake pressure sensor and pressure changes caused by the pressure sensor

timing, it operates the pump immediately to apply the brake pressure at the wheels. Then, the pressure in

the pump increases until just before the corresponding wheel gets locked. The motor still keeps rotating

and the outlet valve and the separation valve will stay closed. When the wheel starts to lock, the HBA

function cancels and switches to ABS operation.

Page 986 of 1082

13-34610-00

1. SPECIFICATION

Unit Description Specification

System operationOperating type Motor driven power steering system

Operating temperature- 40°C to 80°C

Rated voltage 12 V

Rated current 85 A

Operating voltageNetwork 8 to 16 V

C-EPS ECU 8 to 16 V

Full Performance 10 to 16 V

MotorType 3-Phase BLAC (Brushless AC)

Rated current/voltage 85 A / 12 V (at idle 0.5 A)

Position sensor type Hall sensor type

Torque & angle sensorType Non-contact type

Steering columnOperating type Manual tilting & telescoping

Lower shaftType Sliding (Ball slip) type

Steering gearGear ratio 46.94 mm/rev

Rack stroke 146 mm

Maximum steering angleInner wheel39°

Outer wheel31.24°

Page 1008 of 1082

01-76810-00

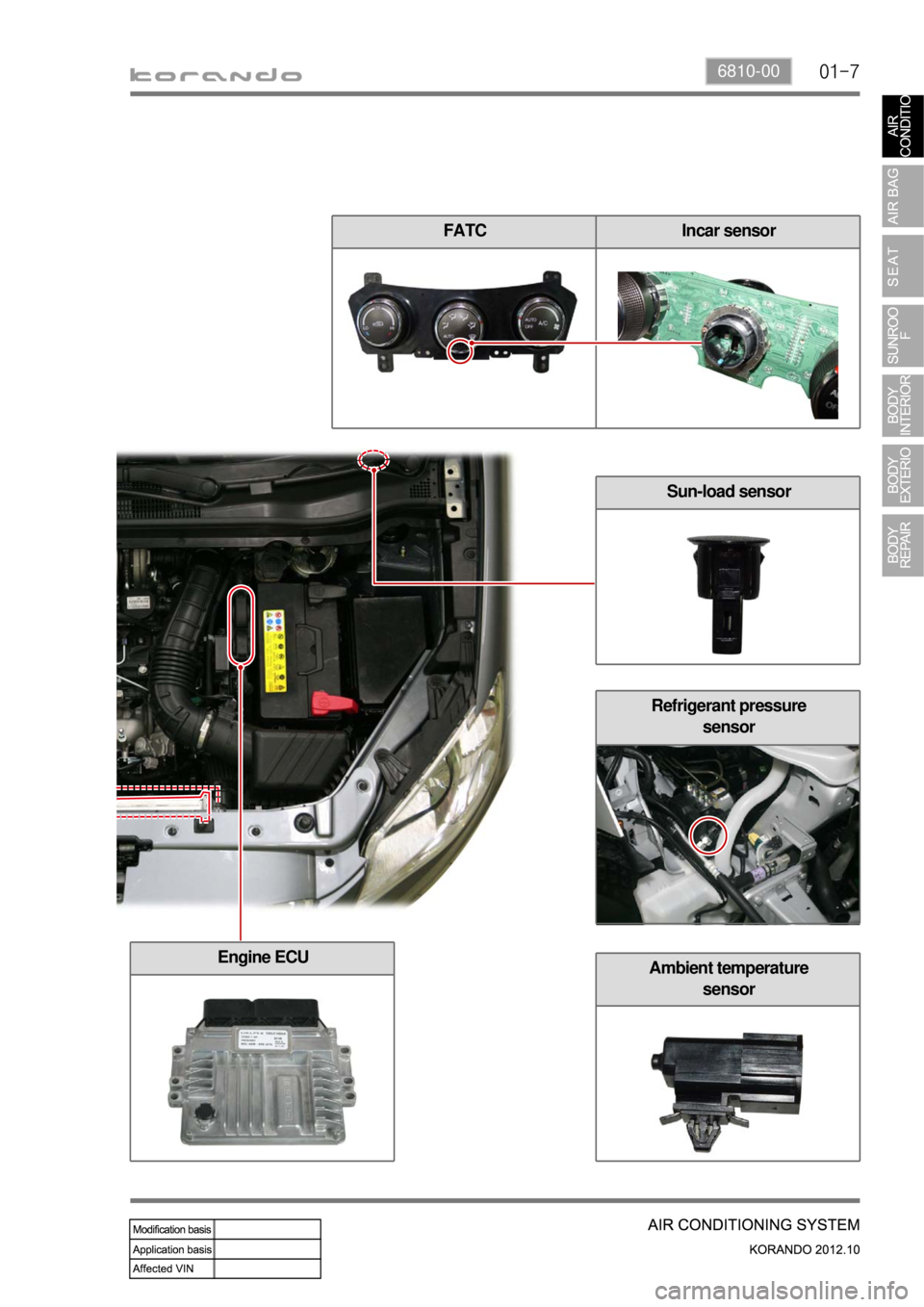

FATC Incar sensor

Refrigerant pressure

sensor

Ambient temperature

sensor

Sun-load sensor

Engine ECU

Page 1037 of 1082

03-4

2. WARNINGS FOR POWER SEAT

Adjust the driver's seat before driving.

Make sure that the seat is firmly secured after adjusting.

Never drive the vehicle with the head restraint removed or lowered excessively. Otherwise, you

r

neck, spine or other parts of the body can be severely injured in the event of an accident.

If you recline the seatback excessively, you could slide under the seat belt and be injured severely

in a collision.

Do not put any object that could damage the seat on the seat.

The front and rear seats are equipped with the heated wire (seat warmer) system. Using the seat

warmer system excessively may cause minor burns. The following occupants should exercise

special care when using the heated wire seat. ▷

▷

▷

▷

▷

▷

Infant, child, old or handicapped person

Person with sensitive skin

Exhausted person

Persons who is drunk or took medicine which causes drowsiness such as sleeping pills, cold

tablets, etc. -

-

-

-

Do not place anything on the seat that insulates against the heat, such as a blanket or cushion.

Make sure that the head restraints are in place and secured properly. Never drive the vehicle with

the head restraint removed.

To minimize the injuries in a collision or an abrupt stop, make sure the seatback is in the upright

position before driving. If the seatback is reclined too much, the occupant could slide under the seat

belt in a collision or an abrupt stop and cannot be protected properly by the airbag system. ▷

▷

▷

3. CAUTIONS FOR POWER SEAT

You can operate the power seat with the ignition switch OFF. However, frequent operation of the

seat switch with the engine stopped can result in battery becoming discharged.

Operating more than one seat adjustment switch at the same time can cause damage to the seat

motor. Therefore, operate the seat switch only one at a time.

Do not use organic solvents such as benzene, thinner, alcohol or gasoline to prevent the seat cove

r

from being damaged while cleaning.

Do not operate the seat position adjustment switch forcefully when the seat does not move or it

contacts an object.

If the power seat is not operated, check and correct the problem before driving off. ▷

▷

▷

▷

▷